The Warehouse Whisperer: Unstacking your Top 7 material handling questions

Curious what others are asking about material handling regulations? Look no further! We’ll unload the answers to the Top 7 questions asked of our J.J. Keller & Associates, Inc. environmental, health and safety (EHS) experts.

Question #7 — How tall and wide must shelf openings be for forklift and pedestrian traffic to pass underneath?

OSHA doesn’t have any specific design or placement requirements for racks. However, 1910.176(a) requires “sufficient clearance when there is use of mechanical equipment.” So, width and height clearances will depend on the size of equipment used in the facility.

Safe clearances must also provide allowances for aisles, at loading docks, through doorways and wherever turns or passage must be made. Aisles and passageways be kept clear and in good repair, with no obstruction across or in aisles that could create a hazard and they must be appropriately marked.

One area of caution with over-aisle storage is that pedestrians must not be permitted to stand or pass under the elevated portion of any truck, whether loaded or empty, per the powered industrial truck standard, 1910.178(m)(2).

Question #6 — Is there a limit to the weight or length of an object that one worker is permitted to handle by themselves?

OSHA doesn’t set limits for objects workers can handle by themselves. However, the National Institute for Occupational Safety and Health (NIOSH) provides a lifting equation, which establishes a maximum lifting weight of 51 pounds for an individual. The equation then accounts for variables in the lift including the frequency of lifts, twisting motions, vertical and horizontal distances, the distance of the load from the body, and how easy it is to hold the load.

In many cases, the longer an object is, the more awkward it could be to lift and move. This can cause imbalance when loads shift and potentially cause other collateral damage (e.g., strikes to lighting, windows, other equipment, or worse - people). These types of situations could be considered "recognized hazards" by OSHA and be cited under the General Duty Clause (Section 5(a)(1)).

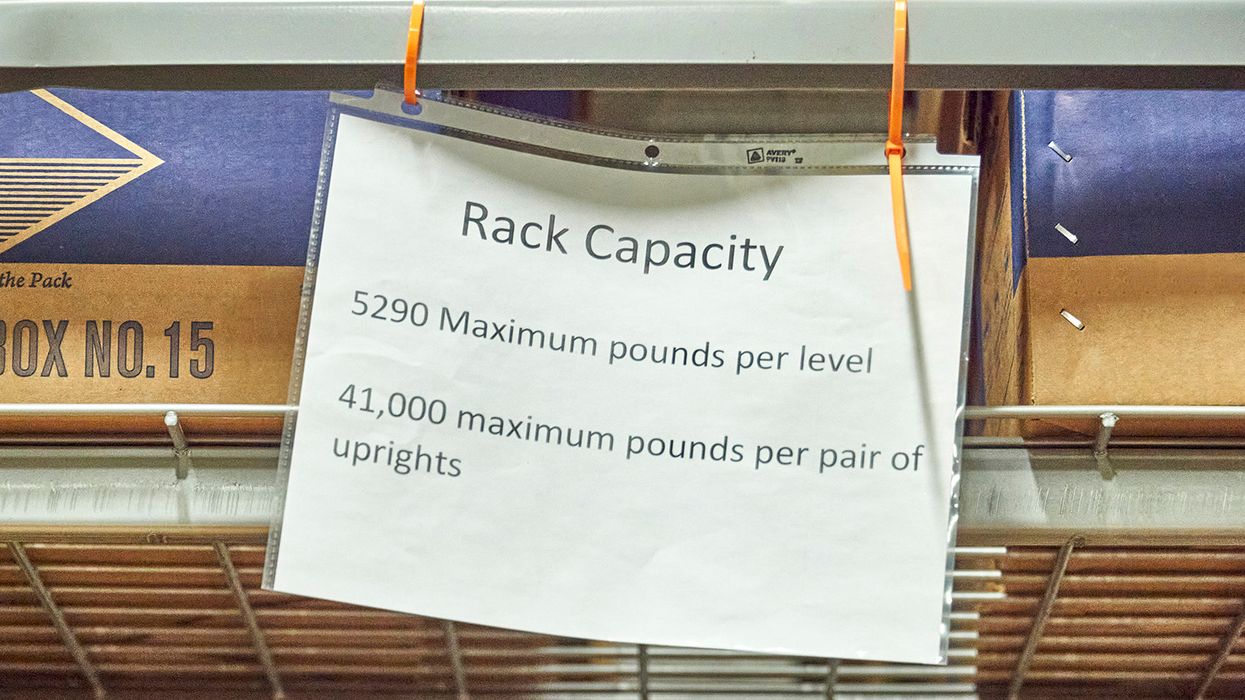

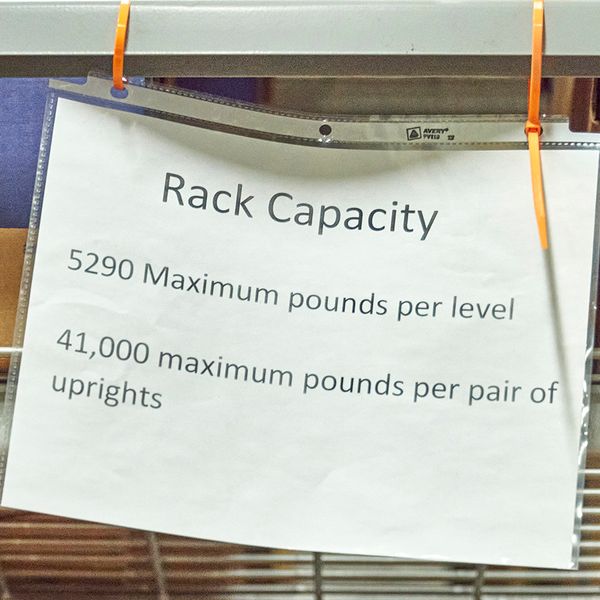

Question #5 — Are storage racks required to be posted or labeled with load limits?

OSHA does not have specific requirements for labeling of racking, however the General Duty Clause (Section 5(a)(1)) does ensure employers protect workers from recognized hazards. Without knowing the load limits, workers can overload the racking, creating a dangerous situation. Posting or labeling load limits is a best practice to minimize the hazards of overloading a rack.

The general duty clause may be cited when a particular hazard is not addressed by any standard or when the OSHA standard is known to be insufficiently protective. This is where ANSI, ISEA, NIOSH, or other professional recommendations come into play. For storage racks, they may very well cite ANSI MH16-1 -2021 if they deem the hazards were concerning.

Question #4 — Are there any regulations requiring rack guards or similar protection for shelving, especially in high traffic areas?

The short answer is, "not really." OSHA states in 1910.176(b) that “storage of material shall not create a hazard”, but this is really a performance-based requirement where “hazard” depends on the situation, materials, and other factors. If hazards have been identified in high traffic areas, rack guards may be the best way to mitigate those hazards. Other solutions may include restricting access, rerouting traffic in susceptible storage areas, painting the racking a distinguishable color, training employees, etc.

The General Duty Clause (Section 5(a)(1)) could also be cited by OSHA due to this “recognized hazard” since employers are required to “furnish to each employee employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees."

Question #3 — What is the proper spacing for storage racks?

OSHA references safe aisle clearances in 1910.176 where equipment like forklifts are used. Specifically, 1910.176(a) states, “Where mechanical handling equipment is used, sufficient safe clearances shall be allowed for aisles, at loading docks, through doorways and wherever turns or passage must be made.”

OSHA issued a 1972 letter of interpretation (LOI) stating “at least 3 feet wider than the equipment” as a safe clearance distance. Although that LOI was withdrawn, this is still considered a best practice.

Question #2 — How high can materials be stacked?

OSHA requires in 1910.176(b) that, “Storage of material shall not create a hazard. Bags, containers, bundles, etc., stored in tiers shall be stacked, blocked, interlocked, and limited in height so that they are stable and secure against sliding or collapse.”

The agency doesn’t mandate a maximum height, although being a performance-based standard, the employer must determine what a “safe” height would be based on type of material, packaging, area traffic, and other circumstances. It may be that some materials can’t be safely stacked more than 5 or 6 feet, while others could be safely stacked to several times that height . Also, 1910.159 includes an 18” clearance requirement for sprinklers and racking systems.

Question #1 — Are shelving units required to be bolted down?

OSHA requires in 1910.176(b) that “storage of material shall not create a hazard… and storage must be stable and secure against sliding and storage.” The most commonly used method is bolting or otherwise securing shelving to prevent tipping.

The agency also references ANSI MH16.1: Specification for the Design, Testing, and Utilization of Industrial Steel Storage Racks that requires all columns be anchored to the floor with anchor bolts or based on the manufacturer's requirements. OSHA has cited organizations referencing this standard under the General Duty Clause (Section 5(a)(1)).

Keys to remember: When seeking clarification for material handling questions, contact our experts or reference 1910.176. Employers must also remember that any “recognized hazard” associated with material handling can be cited under the General Duty Clause.