Your top 3 storage rack myths shelved!

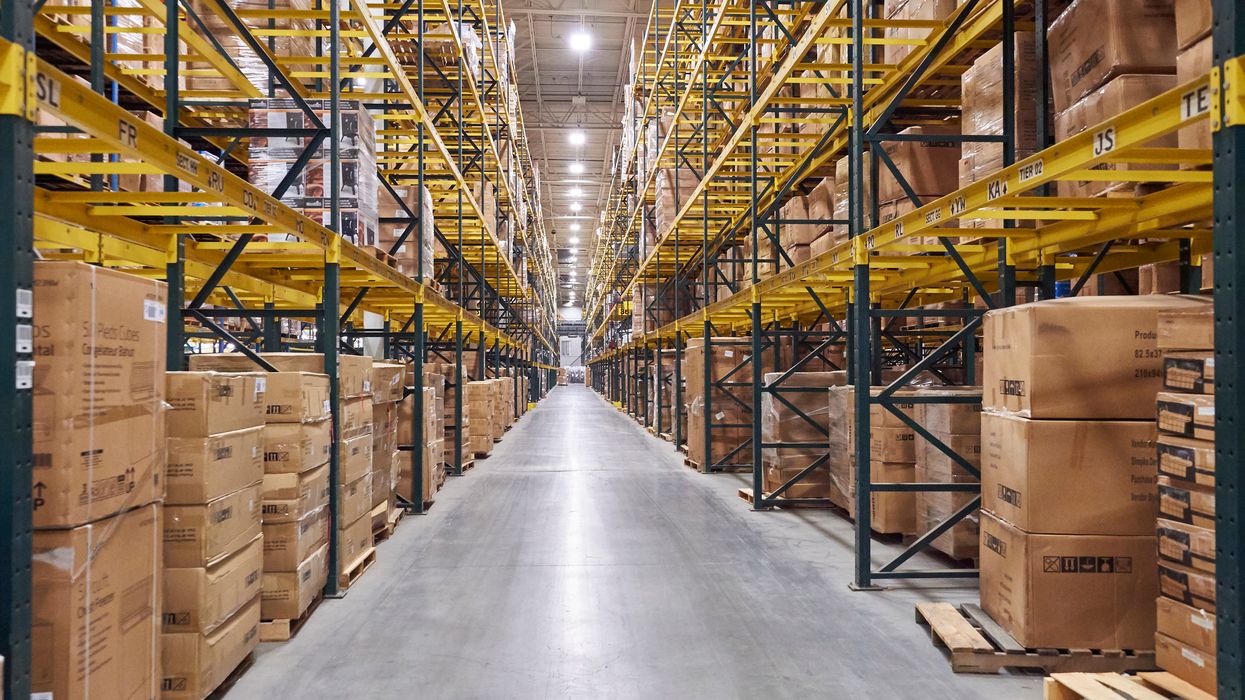

Warehouse injuries occur at higher rates than the national average for other industries, which is why OSHA may eagle-eye your storage shelving. Want to avoid injuries and costly citations but don’t know where to start? Keep reading to see how we’ve myth-busted our clients’ top 3 storage rack curiosities!

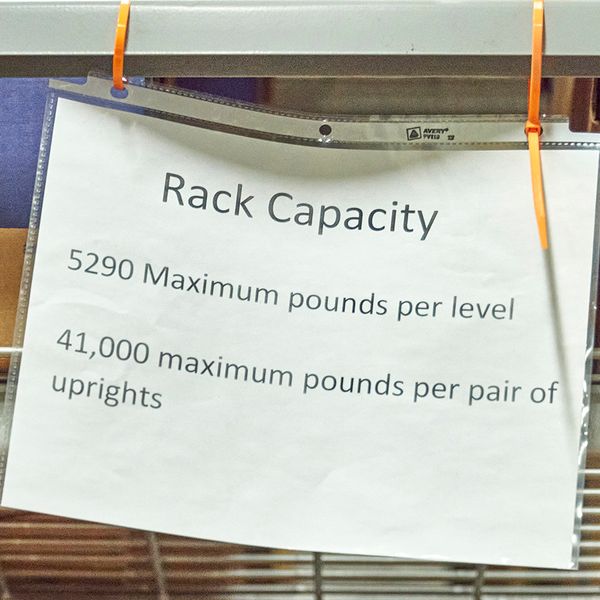

Myth #1: Storage shelves must be labeled with maximum weight capacity.

Busted! OSHA regulations don’t specifically address storage racks capacity marking, anchoring, or stacking height. However, the agency does use the General Duty Clause to cite hazards involving shelving, particularly for shelving or rack collapse from overloading. To justify a General Duty Clause citation, OSHA may refer to the rack manufacturer’s recommendations or to ANSI/MH 16.1.

As an example, OSHA issued a General Duty Clause citation to one employer in November 2006 citing, “... the employer did not furnish employment and a place of employment which were free from recognized hazards that were causing or likely to cause death or serious physical harm to employees in that employees were exposed to...crushing hazards from not anchoring the storage rack systems. The storage racks are used to store various gauge metal sheets, parts, and products. The storage rack systems range in height from 4 to 6 tiers.”

As a best practice, many employers will place small placards or tags on shelves, while others who have larger installations may place larger signs/boards at the end of the shelving along or above aisles.

Myth #2: Storage racks don’t have to be secured to walls or flooring.

Busted! OSHA requires industrial steel racks to have anchoring as referenced in ANSI MH16.1-2023: Design, Testing, And Utilization of Industrial Steel Storage Racks. The standard at 1910.176(b) requires that stored items be, "stacked, blocked, interlocked and limited in height so that they are stable and secure against sliding or collapse" which can indicate shelves may need to be secured. For non-industrial shelving, employers should also refer to the manufacturer instructions for load limits and securement.

From the same citation as in Myth #2, OSHA cited, “In addition, load capacity rating plaques were not in place to state the storage capacity of the systems. Among other methods, one feasible and acceptable abatement method to correct this hazard is to anchor the storage racks systems and install load capacity plaques...”

Myth #3: Materials on the top shelf of storage racks don’t have to be wrapped, banded, or otherwise secured.

Busted! OSHA requires in 1910.176 that "Storage of material shall not create a hazard. Bags, containers, bundles, etc., stored in tiers shall be stacked, blocked, interlocked and limited in height so that they are stable and secure against sliding or collapse." Additionally, 1910.159 and NFPA 13 require an 18-inch clearance for sprinklers and racking systems.

Maximum shelf height should be based on the manufacturer's specifications, what the building design can support, load requirements, and fire/building safety. Although requirements don’t specifically state material on the top shelf must be secured with bands, plastic, etc., pallets with loose or unevenly stacked components, especially at heights, pose a potential hazard of falling if shelving is moved or bumped.

Key to remember: Despite some myths, and some OSHA grey areas, employers must ensure storage shelving is not overloaded, and that racks and materials are secured from tipping or collapse.