['Air Programs']

['Air Quality', 'Stationary Emission Sources']

05/13/2025

...

Authority: 42 U.S.C. 7401 et seq.

Subpart A - General Provisions

§60.1 Applicability.

(a) Except as provided in subparts B, Ba, and C of this part, the provisions of this part apply to the owner or operator of any stationary source which contains an affected facility, the construction or modification of which is commenced after the date of publication in this part of any standard (or, if earlier, the date of publication of any proposed standard) applicable to that facility.

(b) Any new or revised standard of performance promulgated pursuant to section 111(b) of the Act shall apply to the owner or operator of any stationary source which contains an affected facility, the construction or modification of which is commenced after the date of publication in this part of such new or revised standard (or, if earlier, the date of publication of any proposed standard) applicable to that facility.

(c) In addition to complying with the provisions of this part, the owner or operator of an affected facility may be required to obtain an operating permit issued to stationary sources by an authorized State air pollution control agency or by the Administrator of the U.S. Environmental Protection Agency (EPA) pursuant to Title V of the Clean Air Act (Act) as amended November 15, 1990 (42 U.S.C. 7661). For more information about obtaining an operating permit see part 70 of this chapter.

(d) Site-specific standard for Merck & Co., Inc.'s Stonewall Plant in Elkton, Virginia. (1) This paragraph applies only to the pharmaceutical manufacturing facility, commonly referred to as the Stonewall Plant, located at Route 340 South, in Elkton, Virginia (“site”).

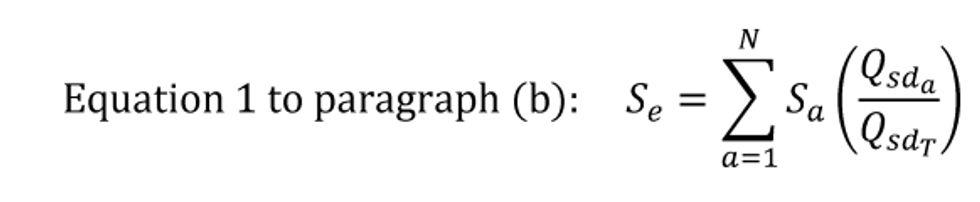

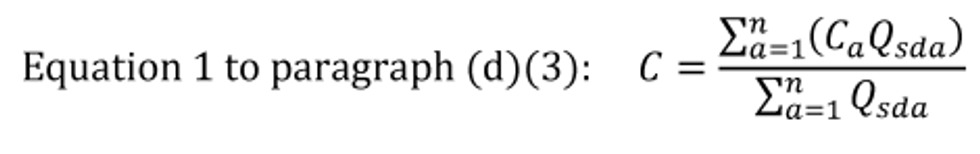

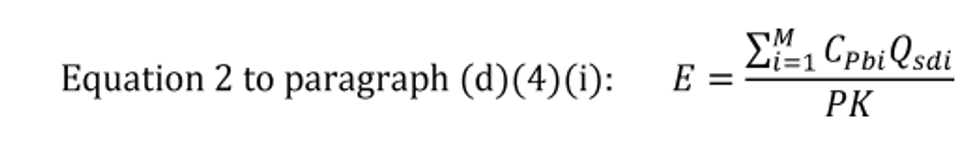

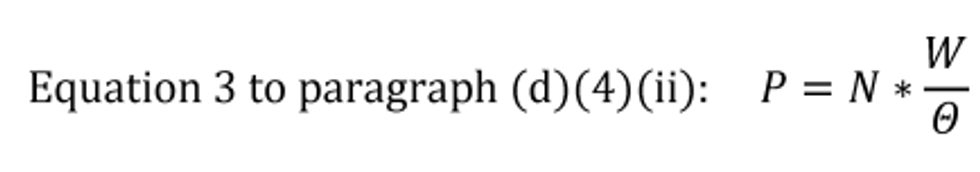

(2) Except for compliance with 40 CFR 60.49b(u), the site shall have the option of either complying directly with the requirements of this part, or reducing the site-wide emissions caps in accordance with the procedures set forth in a permit issued pursuant to 40 CFR 52.2454. If the site chooses the option of reducing the site-wide emissions caps in accordance with the procedures set forth in such permit, the requirements of such permit shall apply in lieu of the otherwise applicable requirements of this part.

(3) Notwithstanding the provisions of paragraph (d)(2) of this section, for any provisions of this part except for Subpart Kb, the owner/operator of the site shall comply with the applicable provisions of this part if the Administrator determines that compliance with the provisions of this part is necessary for achieving the objectives of the regulation and the Administrator notifies the site in accordance with the provisions of the permit issued pursuant to 40 CFR 52.2454.

[40 FR 53346, Nov. 17, 1975, as amended at 55 FR 51382, Dec. 13, 1990; 59 FR 12427, Mar. 16, 1994; 62 FR 52641, Oct. 8, 1997; 88 FR 80542, Nov. 17, 2023]

§60.2 Definitions.

The terms used in this part are defined in the Act or in this section as follows:

Act means the Clean Air Act (42 U.S.C. 7401 et seq.)

Administrator means the Administrator of the Environmental Protection Agency or his authorized representative.

Affected facility means, with reference to a stationary source, any apparatus to which a standard is applicable.

Alternative method means any method of sampling and analyzing for an air pollutant which is not a reference or equivalent method but which has been demonstrated to the Administrator's satisfaction to, in specific cases, produce results adequate for his determination of compliance.

Approved permit program means a State permit program approved by the Administrator as meeting the requirements of part 70 of this chapter or a Federal permit program established in this chapter pursuant to Title V of the Act (42 U.S.C. 7661).

Capital expenditure means an expenditure for a physical or operational change to an existing facility which exceeds the product of the applicable “annual asset guideline repair allowance percentage” specified in the latest edition of Internal Revenue Service (IRS) Publication 534 and the existing facility's basis, as defined by section 1012 of the Internal Revenue Code. However, the total expenditure for a physical or operational change to an existing facility must not be reduced by any “excluded additions” as defined in IRS Publication 534, as would be done for tax purposes.

Clean coal technology demonstration project means a project using funds appropriated under the heading ‘Department of Energy-Clean Coal Technology’, up to a total amount of $2,500,000,000 for commercial demonstrations of clean coal technology, or similar projects funded through appropriations for the Environmental Protection Agency.

Commenced means, with respect to the definition of new source in section 111(a)(2) of the Act, that an owner or operator has undertaken a continuous program of construction or modification or that an owner or operator has entered into a contractual obligation to undertake and complete, within a reasonable time, a continuous program of construction or modification.

Construction means fabrication, erection, or installation of an affected facility.

Continuous monitoring system means the total equipment, required under the emission monitoring sections in applicable subparts, used to sample and condition (if applicable), to analyze, and to provide a permanent record of emissions or process parameters.

Electric utility steam generating unit means any steam electric generating unit that is constructed for the purpose of supplying more than one-third of its potential electric output capacity and more than 25 MW electrical output to any utility power distribution system for sale. Any steam supplied to a steam distribution system for the purpose of providing steam to a steam-electric generator that would produce electrical energy for sale is also considered in determining the electrical energy output capacity of the affected facility.

Equivalent method means any method of sampling and analyzing for an air pollutant which has been demonstrated to the Administrator's satisfaction to have a consistent and quantitatively known relationship to the reference method, under specified conditions.

Excess Emissions and Monitoring Systems Performance Report is a report that must be submitted periodically by a source in order to provide data on its compliance with stated emission limits and operating parameters, and on the performance of its monitoring systems.

Existing facility means, with reference to a stationary source, any apparatus of the type for which a standard is promulgated in this part, and the construction or modification of which was commenced before the date of proposal of that standard; or any apparatus which could be altered in such a way as to be of that type.

Force majeure means, for purposes of §60.8, an event that will be or has been caused by circumstances beyond the control of the affected facility, its contractors, or any entity controlled by the affected facility that prevents the owner or operator from complying with the regulatory requirement to conduct performance tests within the specified timeframe despite the affected facility's best efforts to fulfill the obligation. Examples of such events are acts of nature, acts of war or terrorism, or equipment failure or safety hazard beyond the control of the affected facility.

Isokinetic sampling means sampling in which the linear velocity of the gas entering the sampling nozzle is equal to that of the undisturbed gas stream at the sample point.

Issuance of a part 70 permit will occur, if the State is the permitting authority, in accordance with the requirements of part 70 of this chapter and the applicable, approved State permit program. When the EPA is the permitting authority, issuance of a Title V permit occurs immediately after the EPA takes final action on the final permit.

Malfunction means any sudden, infrequent, and not reasonably preventable failure of air pollution control equipment, process equipment, or a process to operate in a normal or usual manner. Failures that are caused in part by poor maintenance or careless operation are not malfunctions.

Modification means any physical change in, or change in the method of operation of, an existing facility which increases the amount of any air pollutant (to which a standard applies) emitted into the atmosphere by that facility or which results in the emission of any air pollutant (to which a standard applies) into the atmosphere not previously emitted.

Monitoring device means the total equipment, required under the monitoring of operations sections in applicable subparts, used to measure and record (if applicable) process parameters.

Nitrogen oxides means all oxides of nitrogen except nitrous oxide, as measured by test methods set forth in this part.

One-hour period means any 60-minute period commencing on the hour.

Opacity means the degree to which emissions reduce the transmission of light and obscure the view of an object in the background.

Owner or operator means any person who owns, leases, operates, controls, or supervises an affected facility or a stationary source of which an affected facility is a part.

Part 70 permit means any permit issued, renewed, or revised pursuant to part 70 of this chapter.

Particulate matter means any finely divided solid or liquid material, other than uncombined water, as measured by the reference methods specified under each applicable subpart, or an equivalent or alternative method.

Permit program means a comprehensive State operating permit system established pursuant to title V of the Act (42 U.S.C. 7661) and regulations codified in part 70 of this chapter and applicable State regulations, or a comprehensive Federal operating permit system established pursuant to title V of the Act and regulations codified in this chapter.

Permitting authority means:

(1) The State air pollution control agency, local agency, other State agency, or other agency authorized by the Administrator to carry out a permit program under part 70 of this chapter; or

(2) The Administrator, in the case of EPA-implemented permit programs under title V of the Act (42 U.S.C. 7661).

Proportional sampling means sampling at a rate that produces a constant ratio of sampling rate to stack gas flow rate.

Reactivation of a very clean coal-fired electric utility steam generating unit means any physical change or change in the method of operation associated with the commencement of commercial operations by a coal-fired utility unit after a period of discontinued operation where the unit:

(1) Has not been in operation for the two-year period prior to the enactment of the Clean Air Act Amendments of 1990, and the emissions from such unit continue to be carried in the permitting authority's emissions inventory at the time of enactment;

(2) Was equipped prior to shut-down with a continuous system of emissions control that achieves a removal efficiency for sulfur dioxide of no less than 85 percent and a removal efficiency for particulates of no less than 98 percent;

(3) Is equipped with low-NOX burners prior to the time of commencement of operations following reactivation; and

(4) Is otherwise in compliance with the requirements of the Clean Air Act.

Reference method means any method of sampling and analyzing for an air pollutant as specified in the applicable subpart.

Repowering means replacement of an existing coal-fired boiler with one of the following clean coal technologies: atmospheric or pressurized fluidized bed combustion, integrated gasification combined cycle, magnetohydrodynamics, direct and indirect coal-fired turbines, integrated gasification fuel cells, or as determined by the Administrator, in consultation with the Secretary of Energy, a derivative of one or more of these technologies, and any other technology capable of controlling multiple combustion emissions simultaneously with improved boiler or generation efficiency and with significantly greater waste reduction relative to the performance of technology in widespread commercial use as of November 15, 1990. Repowering shall also include any oil and/or gas-fired unit which has been awarded clean coal technology demonstration funding as of January 1, 1991, by the Department of Energy.

Run means the net period of time during which an emission sample is collected. Unless otherwise specified, a run may be either intermittent or continuous within the limits of good engineering practice.

Shutdown means the cessation of operation of an affected facility for any purpose.

Six-minute period means any one of the 10 equal parts of a one-hour period.

Standard means a standard of performance proposed or promulgated under this part.

Standard conditions means a temperature of 293 K (68F) and a pressure of 101.3 kilopascals (29.92 in Hg).

Startup means the setting in operation of an affected facility for any purpose.

State means all non-Federal authorities, including local agencies, interstate associations, and State-wide programs, that have delegated authority to implement: (1) The provisions of this part; and/or (2) the permit program established under part 70 of this chapter. The term State shall have its conventional meaning where clear from the context.

Stationary source means any building, structure, facility, or installation which emits or may emit any air pollutant.

Title V permit means any permit issued, renewed, or revised pursuant to Federal or State regulations established to implement title V of the Act (42 U.S.C. 7661). A title V permit issued by a State permitting authority is called a part 70 permit in this part.

Volatile Organic Compound means any organic compound which participates in atmospheric photochemical reactions; or which is measured by a reference method, an equivalent method, an alternative method, or which is determined by procedures specified under any subpart.

[44 FR 55173, Sept. 25, 1979, as amended at 45 FR 5617, Jan. 23, 1980; 45 FR 85415, Dec. 24, 1980; 54 FR 6662, Feb. 14, 1989; 55 FR 51382, Dec. 13, 1990; 57 FR 32338, July 21, 1992; 59 FR 12427, Mar. 16, 1994; 72 FR 27442, May 16, 2007]

§60.3 Units and abbreviations.

Used in this part are abbreviations and symbols of units of measure. These are defined as follows:

(a) System International (SI) units of measure:

A - ampere

g - gram

Hz - hertz

J - joule

K - degree Kelvin

kg - kilogram

m - meter

m 3 - cubic meter

mg - milligram - 10 −3 gram

mm - millimeter - 10 −3 meter

Mg - megagram - 10 6 gram

mol - mole

N - newton

ng - nanogram - 10 −9 gram

nm - nanometer - 10 −9 meter

Pa - pascal

s - second

V - volt

W - watt

Ω - ohm

µg - microgram - 10 −6 gram

(b) Other units of measure:

Btu - British thermal unit

°C - degree Celsius (centigrade)

cal - calorie

cfm - cubic feet per minute

cu ft - cubic feet

dcf - dry cubic feet

dcm - dry cubic meter

dscf - dry cubic feet at standard conditions

dscm - dry cubic meter at standard conditions

eq - equivalent

°F - degree Fahrenheit

ft - feet

gal - gallon

gr - grain

g-eq - gram equivalent

hr - hour

in - inch

k - 1,000

l - liter

lpm - liter per minute

lb - pound

meq - milliequivalent

min - minute

ml - milliliter

mol. wt. - molecular weight

ppb - parts per billion

ppm - parts per million

psia - pounds per square inch absolute

psig - pounds per square inch gage

°R - degree Rankine

scf - cubic feet at standard conditions

scfh - cubic feet per hour at standard conditions

scm - cubic meter at standard conditions

sec - second

sq ft - square feet

std - at standard conditions

(c) Chemical nomenclature:

CdS - cadmium sulfide

CO - carbon monoxide

CO2 - carbon dioxide

HCl - hydrochloric acid

Hg - mercury

H2O - water

H2S - hydrogen sulfide

H2SO4 - sulfuric acid

N2 - nitrogen

NO - nitric oxide

NO2 - nitrogen dioxide

NOX - nitrogen oxides

O2 - oxygen

SO2 - sulfur dioxide

SO3 - sulfur trioxide

SOX - sulfur oxides

(d) Miscellaneous:

A.S.T.M. - American Society for Testing and Materials

[42 FR 37000, July 19, 1977; 42 FR 38178, July 27, 1977]

§60.4 Address.

(a) All requests, reports, applications, submittals, and other communications to the Administrator pursuant to this part shall be submitted in duplicate to the appropriate Regional Office of the U.S. Environmental Protection Agency to the attention of the Director of the Division indicated in the following list of EPA Regional Offices.

Region I (Connecticut, Maine, Massachusetts, New Hampshire, Rhode Island, Vermont) Director, Enforcement and Compliance Assurance Division, U.S. EPA Region I, 5 Post Office Square—Suite 100 (04-2), Boston, MA 02109-3912, Attn: Air Compliance Clerk.

Region II (New Jersey, New York, Puerto Rico, Virgin Islands), Director, Air and Waste Management Division, U.S. Environmental Protection Agency, Federal Office Building, 26 Federal Plaza (Foley Square), New York, NY 10278.

Region III (Delaware, District of Columbia, Maryland, Pennsylvania, Virginia, West Virginia), Director, Air Protection Division, Mail Code 3AP00, 1650 Arch Street, Philadelphia, PA 19103-2029.

Region IV (Alabama, Florida, Georgia, Kentucky, Mississippi, North Carolina, South Carolina, Tennessee), Director, Air, Pesticides and Toxics Management Division, U.S. Environmental Protection Agency, 61 Forsyth St. SW., Suite 9T43, Atlanta, Georgia 30303-8960.

Region V (Illinois, Indiana, Michigan, Minnesota, Ohio, Wisconsin), Director, Air and Radiation Division, U.S. Environmental Protection Agency, 77 West Jackson Boulevard, Chicago, IL 60604-3590.

Region VI (Arkansas, Louisiana, New Mexico, Oklahoma, Texas); Director; Enforcement and Compliance Assurance Division; U.S. Environmental Protection Agency, 1201 Elm Street, Suite 500, Mail Code 6ECD, Dallas, Texas 75270-2102.

Region VII (Iowa, Kansas, Missouri, Nebraska), Director, Air and Waste Management Division, 11201 Renner Boulevard, Lenexa, Kansas 66219.

Region VIII (Colorado, Montana, North Dakota, South Dakota, Utah, Wyoming) Director, Air and Toxics Technical Enforcement Program, Office of Enforcement, Compliance and Environmental Justice, Mail Code 8ENF-AT, 1595 Wynkoop Street, Denver, CO 80202-1129.

Region IX (Arizona, California, Hawaii and Nevada; the territories of American Samoa and Guam; the Commonwealth of the Northern Mariana Islands; the territories of Baker Island, Howland Island, Jarvis Island, Johnston Atoll, Kingman Reef, Midway Atoll, Palmyra Atoll, and Wake Islands; and certain U.S. Government activities in the freely associated states of the Republic of the Marshall Islands, the Federated States of Micronesia, and the Republic of Palau): Director, Enforcement and Compliance Assurance Division (ENF 2–1), U.S. Environmental Protection Agency Region IX, 75 Hawthorne Street, San Francisco, CA 94105.

Region X (Alaska, Oregon, Idaho, Washington), Director, Air and Waste Management Division, U.S. Environmental Protection Agency, 1200 Sixth Avenue, Seattle, WA 98101.

(b) Section 111(c) directs the Administrator to delegate to each State, when appropriate, the authority to implement and enforce standards of performance for new stationary sources located in such State. All information required to be submitted to EPA under paragraph (a) of this section, must also be submitted to the appropriate State Agency of any State to which this authority has been delegated (provided, that each specific delegation may except sources from a certain Federal or State reporting requirement). The appropriate mailing address for those States whose delegation request has been approved is as follows:

(1) [Reserved]

(2) State of Alabama: Alabama Department of Environmental Management, P.O. Box 301463, Montgomery, Alabama 36130-1463.

(3) State of Alaska, Department of Environmental Conservation, Pouch O, Juneau, AK 99811.

(4) Arizona:

Arizona Department of Environmental Quality, Suite #160, 1110 West Washington Street, Phoenix, AZ 85007.

Maricopa County Air Quality Department, 301 West Jefferson Street, Phoenix, AZ 85003.

Pima County Department of Environmental Quality, 33 North Stone Avenue, Suite 700, Tucson, AZ 85701.

Pinal County Air Quality Department, 31 North Pinal Street, Building F, Florence, AZ 85132.

Note 1 to paragraph (b)(4):

For tables listing the delegation status of agencies in Region IX, see paragraph (c)(9) of this section.

(5) State of Arkansas: Chief, Division of Air Pollution Control, Arkansas Department of Pollution Control and Ecology, 8001 National Drive, P.O. Box 9583, Little Rock, AR 72209.

(6) California:

Amador Air District, 810 Court Street, Jackson, CA 95642.

Antelope Valley Air Quality Management District, 2551 W Avenue H, Lancaster, CA 93536.

Bay Area Air Quality Management District, 375 Beale Street, Suite 600, San Francisco, CA 94105.

Butte County Air Quality Management District, 629 Entler Avenue, Suite 15, Chico, CA 95928.

Calaveras County Air Pollution Control District, 891 Mountain Ranch Road, Building E, San Andreas, CA 95249.

Colusa County Air Pollution Control District, 100 Sunrise Blvd., Suite A, Colusa, CA 95932–3246.

El Dorado County Air Quality Management District, 330 Fair Lane, Placerville, CA 95667–4100.

Eastern Kern Air Pollution Control District, 2700 “M” Street, Suite 302, Bakersfield, CA 93301–2370.

Feather River Air Quality Management District, 541 Washington Avenue, Yuba City, CA 95991.

Glenn County Air Pollution Control District, 720 N Colusa Street, P.O. Box 351, Willows, CA 95988–0351.

Great Basin Unified Air Pollution Control District, 157 Short Street, Bishop, CA 93514–3537.

Imperial County Air Pollution Control District, 150 South Ninth Street, El Centro, CA 92243–2839.

Lake County Air Quality Management District, 2617 S Main St., Lakeport, CA 95453–5405.

Lassen County Air Pollution Control District, 720 South St., Susanville, CA 96130.

Mariposa County Air Pollution Control District, P.O. Box 5, Mariposa, CA 95338.

Mendocino County Air Quality Management District, 306 E Gobbi Street, Ukiah, CA 95482–5511.

Modoc County Air Pollution Control District, 202 W 4th Street, Alturas, CA 96101.

Mojave Desert Air Quality Management District, 14306 Park Avenue, Victorville, CA 92392–2310.

Monterey Bay Air Resources District, 24580 Silver Cloud Court, Monterey, CA 93940.

North Coast Unified Air Quality Management District, 707 L Street, Eureka, CA 95501–3327.

Northern Sierra Air Quality Management District, 200 Litton Drive, Suite 320, Grass Valley, CA 95945–2509.

Northern Sonoma County Air Pollution Control District, 150 Matheson Street, Healdsburg, CA 95448–4908.

Placer County Air Pollution Control District, 110 Maple Street, Auburn, CA 95603.

Sacramento Metropolitan Air Quality Management District, 777 12th Street, Suite 300, Sacramento, CA 95814–1908.

San Diego County Air Pollution Control District, 10124 Old Grove Road, San Diego, CA 92131–1649.

San Joaquin Valley Air Pollution Control District, 1990 E Gettysburg, Fresno, CA 93726.

San Luis Obispo County Air Pollution Control District, 3433 Roberto Court, San Luis Obispo, CA 93401–7126.

Santa Barbara County Air Pollution Control District, 260 North San Antonio Road, Suite A, Santa Barbara, CA 93110–1315.

Shasta County Air Quality Management District, 1855 Placer Street, Suite 101, Redding, CA 96001–1759.

Siskiyou County Air Pollution Control District, 525 So. Foothill Drive, Yreka, CA 96097–3036.

South Coast Air Quality Management District, 21865 Copley Drive, Diamond Bar, CA 91765–4182.

Tehama County Air Pollution Control District, P.O. Box 1169 (1834 Walnut Street), Red Bluff, CA 96080–0038.

Tuolumne County Air Pollution Control District, 2 South Green St., Sonora, CA 95370–4618.

Ventura County Air Pollution Control District, 4567 Telephone Road, 2nd Floor, Ventura, CA 93003–5417.

Yolo-Solano Air Quality Management District, 1947 Galileo Court, Suite 103, Davis, CA 95618.

Note 2 to paragraph (b)(6):

For tables listing the delegation status of agencies in Region IX, see paragraph (d) of this section.

(7) State of Colorado, Department of Public Health and Environment, 4300 Cherry Creek Drive South, Denver, CO 80222-1530.

Note:

For a table listing Region VIII's NSPS delegation status, see paragraph (c) of this section.

(8) State of Connecticut, Compliance Analysis and Coordination Unit, Bureau of Air Management, Department of Energy and Environmental Protection, 79 Elm Street, 5th Floor, Hartford, CT 06106-5127.

(9) State of Delaware, Department of Natural Resources & Environmental Control, 89 Kings Highway, P.O. Box 1401, Dover, Delaware 19903.

(10) District of Columbia, Department of Public Health, Air Quality Division, 51 N Street, NE., Washington, DC 20002.

(11) State of Florida: Florida Department of Environmental Protection, Division of Air Resources Management, 2600 Blair Stone Road, MS 5500, Tallahassee, Florida 32399-2400.

(12) State of Georgia: Georgia Department of Natural Resources, Environmental Protection Division, Air Protection Branch, 4244 International Parkway, Suite 120, Atlanta, Georgia 30354.

(13) Hawaii:

Clean Air Branch, Hawaii Department of Health, 2827 Waimano Home Road, #130 Pearl City, HI 96782.

Note 4 to paragraph (b)(13):

For tables listing the delegation status of agencies in Region IX, see paragraph (d) of this section.

(14) State of Idaho, Department of Health and Welfare, Statehouse, Boise, ID 83701.

(15) State of Illinois: Illinois Environmental Protection Agency, 1021 North Grand Avenue East, Springfield, Illinois 62794.

(16) State of Indiana: Indiana Department of Environmental Management, Office of Air Quality, 100 North Senate Avenue, Indianapolis, Indiana 46204.

(17) State of Iowa: Iowa Department of Natural Resources, Environmental Protection Division, Air Quality Bureau, 7900 Hickman Road, Suite 1, Urbandale, IA 50322.

(18) State of Kansas: Kansas Department of Health and Environment, Bureau of Air and Radiation, 1000 S.W. Jackson, Suite 310, Topeka, KS 66612-1366.

(19) Commonwealth of Kentucky: Kentucky Department for Environmental Protection, Division for Air Quality, 300 Sower Boulevard, 2nd Floor, Frankfort, Kentucky 40601 or local agency, Louisville Metro Air Pollution Control District, 701 W. Ormsby Ave., Suite 303, Louisville, Kentucky 40203.

(20) State of Louisiana: Louisiana Department of Environmental Quality, P.O. Box 4301, Baton Rouge, Louisiana 70821-4301.

Note:

For a list of delegated standards for Louisiana (excluding Indian country), see paragraph (e)(2) of this section.

(21) State of Maine, Maine Department of Environmental Protection, Bureau of Air Quality, 17 State House Station, Augusta, ME 04333-0017.

(22) State of Maryland, Department of the Environment, 1800 Washington Boulevard, Suite 705, Baltimore, Maryland 21230.

(23) Commonwealth of Massachusetts, Massachusetts Department of Environmental Protection, Division of Air and Climate Programs, One Winter Street, Boston, MA 02108.

(24) State of Michigan: Michigan Department of Natural Resources and Environment, Air Quality Division, P.O. Box 30028, Lansing, Michigan 48909.

(25) State of Minnesota: Minnesota Pollution Control Agency, Division of Air Quality, 520 Lafayette Road North, St. Paul, Minnesota 55155.

(26) State of Mississippi: Hand Deliver or Courier: Mississippi Department of Environmental Quality, Office of Pollution Control, Air Division, 515 East Amite Street, Jackson, Mississippi 39201, Mailing Address: Mississippi Department of Environmental Quality, Office of Pollution Control, Air Division, P.O. Box 2261, Jackson, Mississippi 39225.

(27) State of Missouri: Missouri Department of Natural Resources, Division of Environmental Quality, P.O. Box 176, Jefferson City, MO 65102.

(28) State of Montana, Department of Environmental Quality, 1520 E. 6th Ave., PO Box 200901, Helena, MT 59620-0901.

Note:

For a table listing Region VIII's NSPS delegation status, see paragraph (c) of this section.

(29) State of Nebraska, Nebraska Department of Environmental Control, P.O. Box 94877, State House Station, Lincoln, NE 68509.

Lincoln-Lancaster County Health Department, Division of Environmental Health, 2200 St. Marys Avenue, Lincoln, NE 68502

(30) Nevada:

Nevada Division of Environmental Protection, 901 South Stewart Street, Suite 4001, Carson City, NV 89701–5249.

Clark County Division of Air Quality, 500 S Grand Central Parkway, 1st Floor, P.O. Box 555210, Las Vegas, NV 89155–5210.

Northern Nevada Public Health, Air Quality Management Division, 1001 E 9th Street, Building B, Reno, NV 89512.

Note 7 to paragraph (b)(30):

For tables listing the delegation status of agencies in Region IX, see paragraph (d) of this section.

(31) State of New Hampshire, New Hampshire Department of Environmental Services, Air Resources Division, 29 Hazen Drive, P.O. Box 95, Concord, NH 03302-0095.

(32) State of New Jersey: New Jersey Department of Environmental Protection, Division of Environmental Quality, Enforcement Element, John Fitch Plaza, CN-027, Trenton, NJ 08625.

(1) The following table lists the specific source and pollutant categories that have been delegated to the states in Region II. The (X) symbol is used to indicate each category that has been delegated.

| Subpart | State | ||||

|---|---|---|---|---|---|

| New Jersey | New York | Puerto Rico | Virgin Islands | ||

| D | Fossil-Fuel Fired Steam Generators for Which Construction Commenced After August 17, 1971 (Steam Generators and Lignite Fired Steam Generators) | X | X | X | X |

| Da | Electric Utility Steam Generating Units for Which Construction Commenced After September 18, 1978 | X | X | ||

| Db | Industrial-Commercial-Institutional Steam Generating Units | X | X | X | X |

| E | Incinerators | X | X | X | X |

| F | Portland Cement Plants | X | X | X | X |

| G | Nitric Acid Plants | X | X | X | X |

| H | Sulfuric Acid Plants | X | X | X | X |

| I | Asphalt Concrete Plants | X | X | X | X |

| J | Petroleum Refineries - (All Categories) | X | X | X | X |

| K | Storage Vessels for Petroleum Liquids Constructed After June 11, 1973, and prior to May 19, 1978 | X | X | X | X |

| Ka | Storage Vessels for Petroleum Liquids Constructed After May 18, 1978 | X | X | X | |

| L | Secondary Lead Smelters | X | X | X | X |

| M | Secondary Brass and Bronze Ingot Production Plants | X | X | X | X |

| N | Iron and Steel Plants | X | X | X | X |

| O | Sewage Treatment Plants | X | X | X | X |

| P | Primary Copper Smelters | X | X | X | X |

| Q | Primary Zinc Smelters | X | X | X | X |

| R | Primary Lead Smelters | X | X | X | X |

| S | Primary Aluminum Reduction Plants | X | X | X | X |

| T | Phosphate Fertilizer Industry: Wet Process Phosphoric Acid Plants | X | X | X | X |

| U | Phosphate Fertilizer Industry: Superphosphoric Acid Plants | X | X | X | X |

| V | Phosphate Fertilizer Industry: Diammonium Phosphate Plants | X | X | X | X |

| W | Phosphate Fertilizer Industry: Triple Superphosphate Plants | X | X | X | X |

| X | Phosphate Fertilizer Industry: Granular Triple Superphosphate | X | X | X | X |

| Y | Coal Preparation Plants | X | X | X | X |

| Z | Ferroally Production Facilities | X | X | X | X |

| AA | Steel Plants: Electric Arc Furnaces | X | X | X | X |

| AAa | Electric Arc Furnaces and Argon-Oxygen Decarburization Vessels in Steel Plants | X | X | X | |

| BB | Kraft Pulp Mills | X | X | X | |

| CC | Glass Manufacturing Plants | X | X | X | |

| DD | Grain Elevators | X | X | X | |

| EE | Surface Coating of Metal Furniture | X | X | X | |

| GG | Stationary Gas Turbines | X | X | X | |

| HH | Lime Plants | X | X | X | |

| KK | Lead Acid Battery Manufacturing Plants | X | X | ||

| LL | Metallic Mineral Processing Plants | X | X | X | |

| MM | Automobile and Light-Duty Truck Surface Coating Operations | X | X | ||

| NN | Phosphate Rock Plants | X | X | ||

| PP | Ammonium Sulfate Manufacturing Plants | X | X | ||

| Graphic Art Industry Publication Rotogravure Printing | X | X | X | X | |

| RR | Pressure Sensitive Tape and Label Surface Coating Operations | X | X | X | |

| SS | Industrial Surface Coating: Large Appliances | X | X | X | |

| TT | Metal Coil Surface Coating | X | X | X | |

| UU | Asphalt Processing and Asphalt Roofing Manufacture | X | X | X | |

| VV | Equipment Leaks of Volatile Organic Compounds in Synthetic Organic Chemical Manufacturing Industry | X | X | ||

| WW | Beverage Can Surface Coating Industry | X | X | X | |

| XX | Bulk Gasoline Terminals | X | X | X | |

| FFF | Flexible Vinyl and Urethane Coating and Printing | X | X | X | |

| GGG | Equipment Leaks of VOC in Petroleum Refineries | X | X | ||

| HHH | Synthetic Fiber Production Facilities | X | X | ||

| JJJ | Petroleum Dry Clearners | X | X | X | |

| KKK | Equipment Leaks of VOC from Onshore Natural Gas Processing Plants | ||||

| LLL | Onshore Natural Gas Processing Plants; SO2 Emissions | X | |||

| OOO | Nonmetallic Mineral Processing Plants | X | X | ||

| PPP | Wool Fiberglass Insulation Manufacturing Plants | X | X | ||

(33) State of New Mexico: New Mexico Environment Department, P.O. Box 5469, Santa Fe, New Mexico 87502-5469. Note: For a list of delegated standards for New Mexico (excluding Bernalillo County and Indian country), see paragraph (e)(1) of this section.

(34) New York: New York State Department of Environmental Conservation, 50 Wolf Road Albany, New York 12233, attention: Division of Air Resources.

(35) State of North Carolina: North Carolina Department of Environmental Quality, Division of Air Quality, 1641 Mail Service Center, Raleigh, North Carolina 27699-1641 or local agencies, Forsyth County Office of Environmental Assistance and Protection, 201 North Chestnut Street, Winston-Salem, North Carolina 27101-4120; Mecklenburg County Land Use and Environmental Services Agency, Air Quality, 2145 Suttle Avenue, Charlotte, North Carolina 28208; Western North Carolina Regional Air Quality Agency, 125 S. Lexington Ave., Suite 101, Asheville, North Carolina 28801-3661.

(36) State of North Dakota, North Dakota Department of Environmental Quality, 918 East Divide Avenue, Bismarck, ND 58501-1947.

Note:

For a table listing Region VIII's NSPS delegation status, see paragraph (c) of this section.

(37) State of Ohio:

(i) Medina, Summit and Portage Counties; Director, Akron Regional Air Quality Management District, 146 South High Street, Room 904, Akron, OH 44308.

(ii) Stark County; Director, Canton City Health Department, Air Pollution Control Division, 420 Market Avenue North, Canton, Ohio 44702-1544.

(iii) Butler, Clermont, Hamilton, and Warren Counties; Director, Hamilton County Department of Environmental Services, 250 William Howard Taft Road, Cincinnati, Ohio 45219-2660.

(iv) Cuyahoga County; Commissioner, Cleveland Department of Public Health, Division of Air Quality, 75 Erieview Plaza 2nd Floor, Cleveland, Ohio 44114.

(v) Clark, Darke, Greene, Miami, Montgomery, and Preble Counties; Director, Regional Air Pollution Control Agency, 117 South Main Street, Dayton, Ohio 45422-1280.

(vi) Lucas County and the City of Rossford (in Wood County); Director, City of Toledo, Division of Environmental Services, 348 South Erie Street, Toledo, OH 43604.

(vii) Adams, Brown, Lawrence, and Scioto Counties; Portsmouth Local Air Agency, 605 Washington Street, Third Floor, Portsmouth, OH 45662.

(viii) Allen, Ashland, Auglaize, Crawford, Defiance, Erie, Fulton, Hancock, Hardin, Henry, Huron, Marion, Mercer, Ottawa, Paulding, Putnam, Richland, Sandusky, Seneca, Van Wert Williams, Wood (Except City of Rossford), and Wyandot Counties; Ohio Environmental Protection Agency, Northwest District Office, Air Pollution Control, 347 North Dunbridge Road, Bowling Green, Ohio 43402.

(ix) Ashtabula, Caroll, Colombiana, Holmes, Lorain, and Wayne Counties; Ohio Environmental Protection Agency, Northeast District Office, Air Pollution Unit, 2110 East Aurora Road, Twinsburg, OH 44087.

(x) Athens, Belmont, Coshocton, Gallia, Guemsey, Harrison, Hocking, Jackson, Jefferson, Meigs, Monroe, Morgan, Muskingum, Noble, Perry, Pike, Ross, Tuscarawas, Vinton, and Washington Counties; Ohio Environmental Protection Agency, Southeast District Office, Air Pollution Unit, 2195 Front Street, Logan, OH 43138.

(xi) Champaign, Clinton, Highland, Logan, and Shelby Counties; Ohio Environmental Protection Agency, Southwest District Office, Air Pollution Unit, 401 East Fifth Street, Dayton, Ohio 45402-2911.

(xii) Delaware, Fairfield, Fayette, Franklin, Knox, Licking, Madison, Morrow, Pickaway, and Union Counties; Ohio Environmental Protection Agency, Central District Office, Air Pollution control, 50 West Town Street, Suite 700, Columbus, Ohio 43215.

(xiii) Geauga and Lake Counties; Lake County General Health District, Air Pollution Control, 33 Mill Street, Painesville, OH 44077.

(xiv) Mahoning and Trumbull Counties; Mahoning-Trumbull Air Pollution Control Agency, 345 Oak Hill Avenue, Suite 200, Youngstown, OH 44502.

(38) State of Oklahoma, Oklahoma State Department of Health, Air Quality Service, P.O. Box 53551, Oklahoma City, OK 73152.

(i) Oklahoma City and County: Director, Oklahoma City-County Health Department, 921 Northeast 23rd Street, Oklahoma City, OK 73105.

(ii) Tulsa County: Tulsa City-County Health Department, 4616 East Fifteenth Street, Tulsa, OK 74112.

(39) State of Oregon. (i) Oregon Department of Environmental Quality (ODEQ), 811 SW Sixth Avenue, Portland, OR 97204-1390, http://www.deq.state.or.us.

(ii) Lane Regional Air Pollution Authority (LRAPA), 1010 Main Street, Springfield, Oregon 97477, http://www.lrapa.org.

(40)(i) City of Philadelphia, Department of Public Health, Air Management Services, 321 University Avenue, Philadelphia, Pennsylvania 19104.

(ii) Commonwealth of Pennsylvania, Department of Environmental Protection, Bureau of Air Quality Control, P.O. Box 8468, 400 Market Street, Harrisburg, Pennsylvania 17105.

(iii) Allegheny County Health Department, Bureau of Environmental Quality, Division of Air Quality, 301 39th Street, Pittsburgh, Pennsylvania 15201.

(41) State of Rhode Island, Rhode Island Department of Environmental Management, Office of Air Resources, 235 Promenade Street, Providence, RI 02908.

(42) State of South Carolina: South Carolina Department of Health and Environmental Control, 2600 Bull Street, Columbia, South Carolina 29201.

(b)(43) State of South Dakota, Air Quality Program, Department of Agriculture and Natural Resources, Joe Foss Building, 523 East Capitol, Pierre, SD 57501-3181.

Note:

For a table listing Region VIII's NSPS delegation status, see paragragh (c) of this section.

(44) State of Tennessee: Tennessee Department of Environment and Conservation, Division of Air Pollution Control, William R. Snodgrass Tennessee Tower, 312 Rosa L. Parks Avenue, 15th Floor, Nashville, Tennessee 37243, or local agencies, Knox County Air Quality Management - Department of Public Health, 140 Dameron Avenue, Knoxville, Tennessee 37917; Metro Public Health Department, Pollution Control Division, 2500 Charlotte Ave., Nashville, Tennessee 37209; Chattanooga-Hamilton County Air Pollution Control Bureau, 6125 Preservation Drive, Chattanooga, Tennessee 37416; Shelby County Health Department, Pollution Control Section, 814 Jefferson Avenue, Memphis, Tennessee 38105.

(45) State of Texas, Texas Air Control Board, 6330 Highway 290 East, Austin, TX 78723.

(46) State of Utah, Division of Air Quality, Department of Environmental Quality, P.O. Box 144820, Salt Lake City, UT 84114-4820.

Note:

For a table listing Region VIII's NSPS delegation status, see paragraph (c) of this section.

(47) State of Vermont, Agency of Natural Resources, Department of Environmental Conservation, Air Quality and Climate Division, Davis 2, One National Life Drive, Montpelier, VT 05620-3802.

(48) Commonwealth of Virginia, Department of Environmental Quality, 629 East Main Street, Richmond, Virginia 23219.

(49) State of Washington. (i) Washington State Department of Ecology (Ecology), P.O. Box 47600, Olympia, WA 98504-7600, http://www.ecy.wa.gov/

(ii) Benton Clean Air Authority (BCAA), 650 George Washington Way, Richland, WA 99352-4289, http://www.bcaa.net/

(iii) Northwest Air Pollution Control Authority (NWAPA), 1600 South Second St., Mount Vernon, WA 98273-5202, http://www.nwair.org/

(iv) Olympic Regional Clean Air Agency (ORCAA), 909 Sleater-Kinney Road S.E., Suite 1, Lacey, WA 98503-1128, http://www.orcaa.org/

(v) Puget Sound Clean Air Agency (PSCAA), 110 Union Street, Suite 500, Seattle, WA 98101-2038, http://www.pscleanair.org/

(vi) Spokane County Air Pollution Control Authority (SCAPCA), West 1101 College, Suite 403, Spokane, WA 99201, http://www.scapca.org/

(vii) Southwest Clean Air Agency (SWCAA), 1308 NE. 134th St., Vancouver, WA 98685-2747, http://www.swcleanair.org/

(viii) Yakima Regional Clean Air Authority (YRCAA), 6 South 2nd Street, Suite 1016, Yakima, WA 98901, http://co.yakima.wa.us/cleanair/default.htm

(ix) The following table lists the delegation status of the New Source Performance Standards for the State of Washington. An “X” indicates the subpart has been delegated, subject to all the conditions and limitations set forth in Federal law and the letters granting delegation. Some authorities cannot be delegated and are retained by EPA. Refer to the letters granting delegation for a discussion of these retained authorities. The dates noted at the end of the table indicate the effective dates of Federal rules that have been delegated. Authority for implementing and enforcing any amendments made to these rules after these effective dates are not delegated.

| Subpart 1 | Washington | |||||||

|---|---|---|---|---|---|---|---|---|

| Ecology 2 | BCAA 3 | NWAPA 4 | ORCAA 5 | PSCAA 6 | SCAPCA 7 | SWCAA 8 | YRCAA 9 | |

| A General Provisions | X | X | X | X | X | X | X | X |

| B Adoption and Submittal of State Plans for Designated Facilities | ||||||||

| C Emission Guidelines and Compliance Times | ||||||||

| Cb Large Municipal Waste Combustors that are Constructed on or before September 20, 1994 (Emission Guidelines and Compliance Times) | ||||||||

| Cc Municipal Solid Waste Landfills (Emission Guidelines and Compliance Times) | ||||||||

| Cd Sulfuric Acid Production Units (Emission Guidelines and Compliance Times) | ||||||||

| Ce Hospital/Medical/Infectious Waste Incinerators (Emission Guidelines and Compliance Times) | ||||||||

| D Fossil-Fuel-Fired Steam Generators for which Construction is Commenced after August 17, 1971 | X | X | X | X | X | X | X | X |

| Da Electric Utility Steam Generating Units for which Construction is Commenced after September 18, 1978 | X | X | X | X | X | X | X | X |

| Db Industrial-Commercial-Institutional Steam Generating Units | X | X | X | X | X | X | X | X |

| Dc Small Industrial-Commercial-Institutional Steam Generating Units | X | X | X | X | X | X | X | X |

| E Incinerators | X | X | X | X | X | X | X | X |

| Ea Municipal Waste Combustors for which Construction is Commenced after December 20, 1989 and on or before September 20, 1994 | X | X | X | X | X | X | X | X |

| Eb - Large Municipal Waste Combustors | X | X | X | X | ||||

| Ec - Hospital/Medical/Infectious Waste Incinerators | X | X | X | X | X | X | ||

| F Portland Cement Plants | X | X | X | X | X | X | X | X |

| G Nitric Acid Plants | X | X | X | X | X | X | X | X |

| H Sulfuric Acid Plants | X | X | X | X | X | X | X | X |

| I Hot Mix Asphalt Facilities | X | X | X | X | X | X | X | X |

| J Petroleum Refineries | X | X | X | X | X | X | X | X |

| K Storage Vessels for Petroleum Liquids for which Construction, Reconstruction, or Modification Commenced after June 11, 1973 and prior to May 19, 1978 | X | X | X | X | X | X | X | X |

| Ka Storage Vessels for Petroleum Liquids for which Construction, Reconstruction, or Modification Commenced after May 18, 1978 and prior to July 23, 1984 | X | X | X | X | X | X | X | X |

| Kb VOC Liquid Storage Vessels (including Petroleum Liquid Storage Vessels) for which Construction, Reconstruction, or Modification Commenced after July 23, 1984 | X | X | X | X | X | X | X | X |

| L Secondary Lead Smelters | X | X | X | X | X | X | X | X |

| M Secondary Brass and Bronze Production Plants | X | X | X | X | X | X | X | X |

| N Primary Emissions from Basic Oxygen Process Furnaces for which Construction is Commenced after June 11, 1973 | X | X | X | X | X | X | X | X |

| Na Secondary Emissions from Basic Oxygen Process Steel-making Facilities for which Construction is Commenced after January 20, 1983 | X | X | X | X | X | X | X | X |

| O Sewage Treatment Plants | X | X | X | X | X | X | X | X |

| P Primary Copper Smelters | X | X | X | X | X | X | X | X |

| Q Primary Zinc Smelters | X | X | X | X | X | X | X | X |

| R Primary Lead Smelters | X | X | X | X | X | X | X | X |

| S Primary Aluminum Reduction Plants 10 | X | |||||||

| T Phosphate Fertilizer Industry: Wet Process Phosphoric Acid Plants | X | X | X | X | X | X | X | X |

| U Phosphate Fertilizer Industry: Superphosphoric Acid Plants | X | X | X | X | X | X | X | X |

| V Phosphate Fertilizer Industry: Diammonium Phosphate Plants | X | X | X | X | X | X | X | X |

| W Phosphate Fertilizer Industry: Triple Superphosphate Plants | X | X | X | X | X | X | X | X |

| X Phosphate Fertilizer Industry: Granular Triple Superphosphate Storage Facilities | X | X | X | X | X | X | X | X |

| Y Coal Preparation Plants | X | X | X | X | X | X | X | X |

| Z Ferroalloy Production Facilities | X | X | X | X | X | X | X | X |

| AA Steel Plants: Electric Arc Furnaces Constructed after October 21, 1974 and on or before August 17, 1983 | X | X | X | X | X | X | X | X |

| AAa Steel Plants: Electric Arc Furnaces and Argon-Oxygen Decarburization Vessels Constructed after August 7, 1983 | X | X | X | X | X | X | X | X |

| BB Kraft Pulp Mills 11 | X | |||||||

| CC Glass Manufacturing Plants | X | X | X | X | X | X | X | X |

| DD Grain Elevators | X | X | X | X | X | X | X | X |

| EE Surface Coating of Metal Furniture | X | X | X | X | X | X | X | X |

| GG Stationary Gas Turbines | X | X | X | X | X | X | X | X |

| HH Lime Manufacturing Plants | X | X | X | X | X | X | X | X |

| KK Lead-Acid Battery Manufacturing Plants | X | X | X | X | X | X | X | X |

| LL Metallic Mineral Processing Plants | X | X | X | X | X | X | X | X |

| MM Automobile and Light Duty Truck Surface Coating Operations | X | X | X | X | X | X | X | X |

| NN Phosphate Rock Plants | X | X | X | X | X | X | X | X |

| PP Ammonium Sulfate Manufacture | X | X | X | X | X | X | X | X |

| QQ Graphic Arts Industry: Publication Rotogravure Printing | X | X | X | X | X | X | X | X |

| RR Pressure Sensitive Tape and Label Surface Coating Standards | X | X | X | X | X | X | X | X |

| SS Industrial Surface Coating: Large Appliances | X | X | X | X | X | X | X | X |

| TT Metal Coil Surface Coating | X | X | X | X | X | X | X | X |

| UU Asphalt Processing and Asphalt Roof Manufacture | X | X | X | X | X | X | X | X |

| VV Equipment Leaks of VOC in Synthetic Organic Chemical Manufacturing Industry | X | X | X | X | X | X | X | X |

| WW Beverage Can Surface Coating Industry | X | X | X | X | X | X | X | X |

| XX Bulk Gasoline Terminals | X | X | X | X | X | X | X | X |

| AAA New Residential Wood Heaters | ||||||||

| BBB Rubber Tire Manufacturing Industry | X | X | X | X | X | X | X | X |

| DDD VOC Emissions from Polymer Manufacturing Industry | X | X | X | X | X | X | X | X |

| FFF Flexible Vinyl and Urethane Coating and Printing | X | X | X | X | X | X | X | X |

| GGG Equipment Leaks of VOC in Petroleum Refineries | X | X | X | X | X | X | X | X |

| HHH Synthetic Fiber Production Facilities | X | X | X | X | X | X | X | X |

| III VOC Emissions from Synthetic Organic Chemical Manufacturing Industry Air Oxidation Unit Processes | X | X | X | X | X | X | X | X |

| JJJ Petroleum Dry Cleaners | X | X | X | X | X | X | X | X |

| KKK Equipment Leaks of VOC from Onshore Natural Gas Processing Plants | X | X | X | X | X | X | X | X |

| LLL Onshore Natural Gas Processing: SO2 Emissions | X | X | X | X | X | X | X | X |

| NNN VOC Emissions from Synthetic Organic Chemical Manufacturing Industry Distillation Operations | X | X | X | X | X | X | X | X |

| OOO Nonmetallic Mineral Processing Plants | X | X | X | |||||

| PPP Wool Fiberglass Insulation Manufacturing Plants | X | X | X | X | X | X | X | X |

| QQQ VOC Emissions from Petroleum Refinery Wastewater Systems | X | X | X | X | X | X | X | X |

| RRR VOCs from Synthetic Organic Chemical Manufacturing Industry Reactor Processes | X | X | X | X | X | X | X | X |

| SSS Magnetic Tape Coating Facilities | X | X | X | X | X | X | X | X |

| TTT Industrial Surface Coating: Surface Coating of Plastic Parts for Business Machines | X | X | X | X | X | X | X | X |

| UUU Calciners and Dryers in Mineral Industries | X | X | X | X | X | X | X | X |

| VVV Polymeric Coating of Supporting Substrates Facilities | X | X | X | X | X | X | X | X |

| WWW Municipal Solid Waste Landfills | X | X | X | X | X | X | X | X |

| AAAA Small Municipal Waste Combustion Units for which Construction is Commenced after August 30, 1999 or for which Modification or Reconstruction is Commenced after June 6, 2001 | X | X | X | X | X | X | ||

| BBBB Small Municipal Waste Combustion Units Constructed on or before August 30, 1999 (Emission Guidelines and Compliance Times) | ||||||||

| CCCC Commercial and Industrial Solid Waste Incineration Units for which Construction is Commenced after November, 30, 1999 or for which Modification or Reconstruction is Commenced on or after June 1, 2001 | X | X | X | X | X | X | ||

| DDDD Commercial and Industrial Solid Waste Incineration Units that Commenced Construction on or before November 30, 1999 (Emission Guidelines and Compliance Times) | ||||||||

| 1 Any authority within any subpart of this part that is not delegable, is not delegated. Please refer to Attachment B to the delegation letters for a listing of the NSPS authorities excluded from delegation. 2 Washington State Department of Ecology, for 40 CFR 60.17(h)(1), (h)(2), (h)(3) and 40 CFR part 60, subpart AAAA, as in effect on June 6, 2001; for 40 CFR part 60, subpart CCCC, as in effect on June 1, 2001; and for all other NSPS delegated, as in effect February 20, 2001. 3 Benton Clean Air Authority, for 40 CFR 60.17(h)(1), (h)(2), (h)(3) and 40 CFR part 60, subpart AAAA, as in effect on June 6, 2001; for 40 CFR part 60, subpart CCCC, as in effect on June 1, 2001; and for all other NSPS delegated, as in effect February 20, 2001. 4 Northwest Air Pollution Authority, for all NSPS delegated, as in effect on July 1, 2000. 5 Olympic Regional Clean Air Authority, for 40 CFR 60.17(h)(1), (h)(2), (h)(3) and 40 CFR part 60, subpart AAAA, as in effect on June 6, 2001; for 40 CFR part 60, subpart CCCC, as in effect on June 1, 2001; and for all other NSPS delegated, as in effect February 20, 2001. 6 Puget Sound Clean Air Authority, for all NSPS delegated, as in effect on July 1, 2002. 7 Spokane County Air Pollution Control Authority, for 40 CFR 60.17(h)(1), (h)(2), (h)(3) and 40 CFR part 60, subpart AAAA, as in effect on June 6, 2001; for 40 CFR part 60, subpart CCCC, as in effect on June 1, 2001; and for all other NSPS delegated, as in effect February 20, 2001. 8 Southwest Clean Air Agency, for all NSPS delegated, as in effect on July 1, 2000. 9 Yakima Regional Clean Air Authority, for 40 CFR 60.17(h)(1), (h)(2), (h)(3) and 40 CFR part 60, subpart AAAA, as in effect on June 6, 2001; for 40 CFR part 60, subpart CCCC, as in effect on June 1, 2001; and for all other NSPS delegated, as in effect February 20, 2001. 10 Subpart S of this part is not delegated to local agencies in Washington because the Washington State Department of Ecology retains sole authority to regulate Primary Aluminum Plants, pursuant to Washington Administrative Code 173-415-010. 11 Subpart BB of this part is not delegated to local agencies in Washington because the Washington State Department of Ecology retains sole authority to regulate Kraft and Sulfite Pulping Mills, pursuant to Washington State Administrative Code 173-405-012 and 173-410-012. | ||||||||

(50) State of West Virginia, Department of Environmental Protection, Division of Air Quality, 601 57th Street, SE., Charleston, West Virginia 25304.

(51) State of Wisconsin: Wisconsin Department of Natural Resouces, 101 South Webster St., P.O. Box 7921, Madison, Wisconsin 53707-7921.

(52) State of Wyoming, Department of Environmental Quality, Air Quality Division, Herschler Building, 122 West 25th Street, Cheyenne, WY 82002.

Note:

For a table listing Region VIII's NSPS delegation status, see paragraph (c) of this section.

(53) Territory of Guam: Guam Environmental Protection Agency, P.O. Box 22439 GMF, Barrigada, Guam 96921.

Note:

For tables listing the delegation status of agencies in Region IX, see paragraph (d) of this section.

(54) Commonwealth of Puerto Rico: Commonwealth of Puerto Rico Environmental Quality Board, P.O. Box 11488, Santurce, PR 00910, Attention: Air Quality Area Director (see table under §60.4(b)(FF)(1)).

(55) U.S. Virgin Islands: U.S. Virgin Islands Department of Conservation and Cultural Affairs, P.O. Box 578, Charlotte Amalie, St. Thomas, VI 00801.

(56) American Samoa: American Samoa Environmental Protection Agency, P.O. Box PPA, Pago Pago, American Samoa 96799.

Note:

For tables listing the delegation status of agencies in Region IX, see paragraph (d) of this section.

(57) Commonwealth of the Northern Mariana Islands: CNMI Division of Environmental Quality, P.O. Box 501304, Saipan, MP 96950.

Note:

For tables listing the delegation status of agencies in Region IX, see paragraph (d) of this section.

(c) The delegation status table for New Source Performance Standards for Region VIII can be found online at http://www2.epa.gov/region8/air-program.

(d) The following tables list the specific part 60 standards that have been delegated unchanged to the air pollution control agencies in Region IX. The (X) symbol is used to indicate each standard that has been delegated. The following provisions of this subpart are not delegated: §§60.4(b), 60.8(b), 60.9, 60.11(b), 60.11(e), 60.13(a), 60.13(d)(2), 60.13(g), 60.13(i).

(1) Arizona. The following table identifies delegations for Arizona:

| Subpart | Air pollution control agency | ||||

| Arizona DEQ | Maricopa County | Pima County | Pinal County | ||

| A | General Provisions | X | X | X | X |

| D | Fossil-Fuel Fired Steam Generators Constructed After August 17, 1971 | X | X | X | X |

| Da | Electric Utility Steam Generating Units Constructed After September 18, 1978 | X | X | X | X |

| Db | Industrial-Commercial-Institutional Steam Generating Units | X | X | X | X |

| Dc | Small Industrial-Commercial-Institutional Steam Generating Units | X | X | X | X |

| E | Incinerators | X | X | X | X |

| Ea | Municipal Waste Combustors Constructed After December 20, 1989 and On or Before September 20, 1994 | X | X | X | X |

| Eb | Large Municipal Waste Combustors Constructed After September 20, 1994 | X | X | X | |

| Ec | Hospital/Medical/Infectious Waste Incinerators for Which Construction is Commenced After June 20, 1996 | X | X | X | |

| F | Portland Cement Plants | X | X | X | |

| G | Nitric Acid Plants | X | X | X | X |

| Ga | Nitric Acid Plants For Which Construction, Reconstruction or Modification Commenced After October 14, 2011 | X | X | ||

| H | Sulfuric Acid Plant | X | X | X | X |

| I | Hot Mix Asphalt Facilities | X | X | X | X |

| J | Petroleum Refineries | X | X | X | |

| Ja | Petroleum Refineries for Which Construction, Reconstruction, or Modification Commenced After May 14, 2007 | X | |||

| K | Storage Vessels for Petroleum Liquids for Which Construction, Reconstruction, or Modification Commenced After June 11, 1973, and Prior to May 19, 1978 | X | X | X | X |

| Ka | Storage Vessels for Petroleum Liquids for Which Construction, Reconstruction, or Modification Commenced After May 18, 1978, and Prior to July 23, 1984 | X | X | X | X |

| Kb | Volatile Organic Liquid Storage Vessels (Including Petroleum Liquid Storage Vessels) for Which Construction, Reconstruction, or Modification Commenced After July 23, 1984 | X | X | X | X |

| L | Secondary Lead Smelters | X | X | X | |

| M | Secondary Brass and Bronze Production Plants | X | X | X | X |

| N | Primary Emissions from Basic Oxygen Process Furnaces for Which Construction is Commenced After June 11, 1973 | X | X | X | X |

| Na | Secondary Emissions from Basic Oxygen Process Steelmaking Facilities for Which Construction is Commenced After January 20, 1983 | X | X | X | X |

| O | Sewage Treatment Plants | X | X | X | X |

| P | Primary Copper Smelters | X | X | X | |

| Q | Primary Zinc Smelters | X | X | X | |

| R | Primary Lead Smelters | X | X | X | |

| S | Primary Aluminum Reduction Plants | X | X | X | X |

| T | Phosphate Fertilizer Industry: Wet Process Phosphoric Acid Plants | X | X | X | X |

| U | Phosphate Fertilizer Industry: Superphosphoric Acid Plants | X | X | X | X |

| V | Phosphate Fertilizer Industry: Diammonium Phosphate Plants | X | X | X | X |

| W | Phosphate Fertilizer Industry: Triple Superphosphate Plants | X | X | X | X |

| X | Phosphate Fertilizer Industry: Granular Triple Superphosphate Storage Facilities | X | X | X | X |

| Y | Coal Preparation and Processing Plants | X | X | X | X |

| Z | Ferroalloy Production Facilities | X | X | X | X |

| AA | Steel Plants: Electric Arc Furnaces Constructed After October 21, 1974 and On or Before August 17, 1983 | X | X | X | X |

| AAa | Steel Plants: Electric Arc Furnaces and Argon-Oxygen Decarburization Vessels Constructed After August 7, 1983 | X | X | X | X |

| BB | Kraft Pulp Mills | X | X | X | X |

| BBa | Kraft Pulp Mill Sources for which Construction, Reconstruction or Modification Commenced after May 23, 2013 | X | X | ||

| CC | Glass Manufacturing Plants | X | X | X | X |

| DD | Grain Elevators | X | X | X | X |

| EE | Surface Coating of Metal Furniture | X | X | X | X |

| FF | (Reserved) | ||||

| GG | Stationary Gas Turbines | X | X | X | X |

| HH | Lime Manufacturing Plants | X | X | X | X |

| KK | Lead-Acid Battery Manufacturing Plants | X | X | X | X |

| LL | Metallic Mineral Processing Plants | X | X | X | X |

| MM | Automobile and Light Duty Trucks Surface Coating Operations | X | X | X | X |

| NN | Phosphate Rock Plants | X | X | X | X |

| PP | Ammonium Sulfate Manufacture | X | X | X | X |

| Graphic Arts Industry: Publication Rotogravure Printing | X | X | X | X | |

| RR | Pressure Sensitive Tape and Label Surface Coating Operations | X | X | X | X |

| SS | Industrial Surface Coating: Large Appliances | X | X | X | X |

| TT | Metal Coil Surface Coating | X | X | X | X |

| UU | Asphalt Processing and Asphalt Roofing Manufacture | X | X | X | X |

| VV | Equipment Leaks of VOC in the Synthetic Organic Industry Chemicals Manufacturing | X | X | X | X |

| VVa | Equipment Leaks of VOC in the Synthetic Organic Industry for Which Construction, Reconstruction, or Chemicals Manufacturing Modification Commenced After November 7, 2006 | X | X | X | |

| WW | Beverage Can Surface Coating Industry | X | X | X | X |

| XX | Bulk Gasoline Terminals | X | X | X | X |

| AAA | New Residential Wood Heaters | X | X | X | X |

| BBB | Rubber Tire Manufacturing Industry | X | X | X | X |

| CCC | (Reserved) | ||||

| DDD | Volatile Organic Compounds (VOC) Emissions from the Polymer Manufacturing Industry | X | X | X | X |

| EEE | (Reserved) | ||||

| FFF | Flexible Vinyl and Urethane Coating and Printing | X | X | X | X |

| GGG | Equipment Leaks of VOC in Petroleum Refineries | X | X | X | |

| GGGa | Equipment Leaks of VOC in Petroleum Refineries for Which Construction, Reconstruction, or Modification Commenced After November 7, 2006 | X | X | ||

| HHH | Synthetic Fiber Production Facilities | X | X | X | X |

| III | Volatile Organic Compound (VOC) Emissions From the Synthetic Organic Chemical Manufacturing Industry (SOCMI) Air Oxidation Unit Processes | X | X | X | X |

| JJJ | Petroleum Dry Cleaners | X | X | X | X |

| KKK | Equipment Leaks of VOC From Onshore Natural Gas Processing Plants | X | X | X | X |

| LLL | Onshore Natural Gas Processing: SO 2 Emissions | X | X | X | X |

| MMM | (Reserved) | ||||

| NNN | Volatile Organic Compound (VOC) Emissions From Synthetic Organic Chemical Manufacturing Industry (SOCMI) Distillation Operations | X | X | X | X |

| OOO | Nonmetallic Mineral Processing Plants | X | X | X | X |

| PPP | Wool Fiberglass Insulation Manufacturing Plants | X | X | X | X |

| QQQ | VOC Emissions From Petroleum Refinery Wastewater Systems | X | X | X | |

| RRR | Volatile Organic Compound Emissions from Synthetic Organic Chemical Manufacturing Industry (SOCMI) Reactor Processes | X | X | X | |

| SSS | Magnetic Tape Coating Facilities | X | X | X | X |

| TTT | Industrial Surface Coating: Surface Coating of Plastic Parts for Business Machines | X | X | X | X |

| UUU | Calciners and Dryers in Mineral Industries | X | X | X | |

| VVV | Polymeric Coating of Supporting Substrates Facilities | X | X | X | X |

| WWW | Municipal Solid Waste Landfills | X | X | X | |

| XXX | Municipal Solid Waste Landfills that Commenced Construction, Reconstruction, or Modification After July 17, 2014 | X | X | ||

| AAAA | Small Municipal Waste Combustion Units for Which Construction is Commenced After August 30, 1999 or for Which Modification or Reconstruction is Commended After June 6, 2001 | X | X | X | |

| CCCC | Commercial and Industrial Solid Waste Incineration Units for Which Construction Is Commenced After November 30, 1999 or for Which Modification or Reconstruction Is Commenced on or After June 1, 2001 | X | X | X | |

| EEEE | Other Solid Waste Incineration Units for Which Construction is Commenced After December 9, 2004, or for Which Modification or Reconstruction is Commenced on or After June 16, 2006 | X | X | X | |

| GGGG | (Reserved) | ||||

| HHHH | (Reserved) | ||||

| IIII | Stationary Compression Ignition Internal Combustion Engines | X | X | X | |

| JJJJ | Stationary Spark Ignition Internal Combustion Engines | X | X | ||

| KKKK | Stationary Combustion Turbines | X | X | X | |

| LLLL | New Sewage Sludge Incineration Units | X | |||

| MMMM | Emissions Guidelines and Compliance Times for Existing Sewage Sludge Incineration Units | X | |||

| OOOO | Crude Oil and Natural Gas Production, Transmission, and Distribution | X | X | ||

| OOOOa | Standards of Performance for Crude Oil and Natural Gas Facilities for Which Construction, Modification or Reconstruction Commenced After September 18, 2015 | X | X | ||

| QQQQ | Standards of Performance for New Residential Hydronic Heaters and Forced-Air Furnaces | X | X | ||

| TTTT | Standards of Performance for Greenhouse Gas Emissions for Electric Generating Units | X | X | ||

(2) California. The following tables identify delegations for each of the local air pollution control agencies of California.

(i) Delegations for Amador County Air Pollution Control District, Antelope Valley Air Quality Management District, Bay Area Air Quality Management District, and Butte County Air Quality Management District are shown in the following table:

| Subpart | Air pollution control agency | ||||

| Amador County APCD | Antelope Valley AQMD | Bay Area AQMD | Butte County AQMD | ||

| A | General Provisions | X | |||

| Ba | Adoption and Submittal of State Plans for Designated Facilities | X | |||

| Cf | Emission Guidelines and Compliance Times for Municipal Solid Waste Landfills | X | |||

| D | Fossil-Fuel Fired Steam Generators Constructed After August 17, 1971 | X | X | ||

| Da | Electric Utility Steam Generating Units Constructed After September 18, 1978 | X | X | ||

| Db | Industrial-Commercial-Institutional Steam Generating Units | X | X | ||

| Dc | Small Industrial-Commercial-Institutional Steam Generating Units | X | X | ||

| E | Incinerators | X | X | ||

| Ea | Municipal Waste Combustors Constructed After December 20, 1989 and On or Before September 20, 1994 | X | X | ||

| Eb | Large Municipal Waste Combustors Constructed After September 20, 1994 | X | |||

| Ec | Hospital/Medical/Infectious Waste Incinerators for Which Construction is Commenced After June 20, 1996 | X | |||

| F | Portland Cement Plants | X | X | ||

| G | Nitric Acid Plants | X | X | ||

| Ga | Nitric Acid Plants For Which Construction, Reconstruction or Modification Commenced After October 14, 2011 | X | |||

| H | Sulfuric Acid Plant | X | X | ||

| I | Hot Mix Asphalt Facilities | X | X | ||

| J | Petroleum Refineries | X | X | ||

| Ja | Petroleum Refineries for Which Construction, Reconstruction, or Modification Commenced After May 14, 2007 | X | |||

| K | Storage Vessels for Petroleum Liquids for Which Construction, Reconstruction, or Modification Commenced After June 11, 1973, and Prior to May 19, 1978 | X | X | ||

| Ka | Storage Vessels for Petroleum Liquids for Which Construction, Reconstruction, or Modification Commenced After May 18, 1978, and Prior to July 23, 1984 | X | X | ||

| Kb | Volatile Organic Liquid Storage Vessels (Including Petroleum Liquid Storage Vessels) for Which Construction, Reconstruction, or Modification Commenced After July 23, 1984 | X | X | ||

| L | Secondary Lead Smelters | X | X | ||

| M | Secondary Brass and Bronze Production Plants | X | X | ||

| N | Primary Emissions from Basic Oxygen Process Furnaces for Which Construction is Commenced After June 11, 1973 | X | X | ||

| Na | Secondary Emissions from Basic Oxygen Process Steelmaking Facilities for Which Construction is Commenced After January 20, 1983 | X | X | ||

| O | Sewage Treatment Plants | X | X | ||

| P | Primary Copper Smelters | X | X | ||

| Q | Primary Zinc Smelters | X | X | ||

| R | Primary Lead Smelters | X | X | ||

| S | Primary Aluminum Reduction Plants | X | X | ||

| T | Phosphate Fertilizer Industry: Wet Process Phosphoric Acid Plants | X | |||

| U | Phosphate Fertilizer Industry: Superphosphoric Acid Plants | X | X | ||

| V | Phosphate Fertilizer Industry: Diammonium Phosphate Plants | X | X | ||

| W | Phosphate Fertilizer Industry: Triple Superphosphate Plants | X | X | ||

| X | Phosphate Fertilizer Industry: Granular Triple Superphosphate Storage Facilities | X | X | ||

| Y | Coal Preparation and Processing Plants | X | X | ||

| Z | Ferroalloy Production Facilities | X | X | ||

| AA | Steel Plants: Electric Arc Furnaces Constructed After October 21, 1974 and On or Before August 17, 1983 | X | X | ||

| AAa | Steel Plants: Electric Arc Furnaces and Argon-Oxygen Decarburization Vessels Constructed After August 7, 1983 | X | X | ||

| BB | Kraft Pulp Mills | X | X | ||

| BBa | Kraft Pulp Mill Sources for which Construction, Reconstruction or Modification Commenced after May 23, 2013 | X | |||

| CC | Glass Manufacturing Plants | X | X | ||

| DD | Grain Elevators | X | X | ||

| EE | Surface Coating of Metal Furniture | X | X | ||

| FF | (Reserved) | ||||

| GG | Stationary Gas Turbines | X | X | ||

| HH | Lime Manufacturing Plants | X | X | ||

| KK | Lead-Acid Battery Manufacturing Plants | X | X | ||

| LL | Metallic Mineral Processing Plants | X | X | ||

| MM | Automobile and Light Duty Trucks Surface Coating Operations | X | X | ||

| NN | Phosphate Rock Plants | X | X | ||

| PP | Ammonium Sulfate Manufacture | X | X | ||

| Graphic Arts Industry: Publication Rotogravure Printing | X | X | |||

| RR | Pressure Sensitive Tape and Label Surface Coating Operations | X | X | ||

| SS | Industrial Surface Coating: Large Appliances | X | X | ||

| TT | Metal Coil Surface Coating | X | X | ||

| UU | Asphalt Processing and Asphalt Roofing Manufacture | X | X | ||

| VV | Equipment Leaks of VOC in the Synthetic Organic Industry Chemicals Manufacturing | X | X | ||

| VVa | Equipment Leaks of VOC in the Synthetic Organic Industry for Which Construction, Reconstruction, or Chemicals Manufacturing Modification Commenced After November 7, 2006 | X | |||

| WW | Beverage Can Surface Coating Industry | X | X | ||

| XX | Bulk Gasoline Terminals | ||||

| AAA | New Residential Wood Heaters | X | X | ||

| BBB | Rubber Tire Manufacturing Industry | X | X | ||

| CCC | (Reserved) | ||||

| DDD | Volatile Organic Compounds (VOC) Emissions from the Polymer Manufacturing Industry | X | X | ||

| EEE | (Reserved) | ||||

| FFF | Flexible Vinyl and Urethane Coating and Printing | X | X | ||

| GGG | Equipment Leaks of VOC in Petroleum Refineries | X | X | ||

| GGGa | Equipment Leaks of VOC in Petroleum Refineries for Which Construction, Reconstruction, or Modification Commenced After November 7, 2006 | X | |||

| HHH | Synthetic Fiber Production Facilities | X | X | ||

| III | Volatile Organic Compound (VOC) Emissions From the Synthetic Organic Chemical Manufacturing Industry (SOCMI) Air Oxidation Unit Processes | X | |||

| JJJ | Petroleum Dry Cleaners | X | X | ||

| KKK | Equipment Leaks of VOC From Onshore Natural Gas Processing Plants | X | X | ||

| LLL | Onshore Natural Gas Processing: SO 2 Emissions | X | |||

| MMM | (Reserved) | ||||

| NNN | Volatile Organic Compound (VOC) Emissions From Synthetic Organic Chemical Manufacturing Industry (SOCMI) Distillation Operations | X | X | ||

| OOO | Nonmetallic Mineral Processing Plants | X | X | ||

| PPP | Wool Fiberglass Insulation Manufacturing Plants | X | X | ||

| QQQ | VOC Emissions From Petroleum Refinery Wastewater Systems | X | |||

| RRR | Volatile Organic Compound Emissions from Synthetic Organic Chemical Manufacturing Industry (SOCMI) Reactor Processes | X | |||

| SSS | Magnetic Tape Coating Facilities | X | X | ||

| TTT | Industrial Surface Coating: Surface Coating of Plastic Parts for Business Machines | X | X | ||

| UUU | Calciners and Dryers in Mineral Industries | X | X | ||

| VVV | Polymeric Coating of Supporting Substrates Facilities | X | X | ||

| WWW | Municipal Solid Waste Landfills | X | |||

| XXX | Municipal Solid Waste Landfills that Commenced Construction, Reconstruction, or Modification After July 17, 2014 | X | |||

| AAAA | Small Municipal Waste Combustion Units for Which Construction is Commenced After August 30, 1999 or for Which Modification or Reconstruction is Commended After June 6, 2001 | X | |||

| CCCC | Commercial and Industrial Solid Waste Incineration Units for Which Construction Is Commenced After November 30, 1999 or for Which Modification or Reconstruction Is Commenced on or After June 1, 2001 | X | |||

| DDDD | Emissions Guidelines and Compliance Times for Commercial and Industrial Solid Waste Incineration Units | X | |||

| EEEE | Other Solid Waste Incineration Units for Which Construction is Commenced After December 9, 2004, or for Which Modification or Reconstruction is Commenced on or After June 16, 2006 | X | |||

| GGGG | (Reserved) | ||||

| HHHH | (Reserved) | ||||

| IIII | Stationary Compression Ignition Internal Combustion Engines | X | |||

| JJJJ | Stationary Spark Ignition Internal Combustion Engines | X | |||

| KKKK | Stationary Combustion Turbines | X | |||

| LLLL | New Sewage Sludge Incineration Units | X | |||

| MMMM | Emissions Guidelines and Compliance Times for Existing Sewage Sludge Incineration Units | X | |||

| OOOO | Crude Oil and Natural Gas Production, Transmission, and Distribution | X | |||

| OOOOa | Standards of Performance for Crude Oil and Natural Gas Facilities for Which Construction, Modification or Reconstruction Commenced After September 18, 2015 | X | |||

| TTTT | Standards of Performance for Greenhouse Gas Emissions for Electric Generating Units | X | |||

| UUUUa | Emission Guidelines for Greenhouse Gas Emissions From Existing Electric Utility Generating Units | X | |||

(ii) [Reserved]

(iii) Delegations for Glenn County Air Pollution Control District, Great Basin Unified Air Pollution Control District, Imperial County Air Pollution Control District, and Kern County Air Pollution Control District are shown in the following table:

| Subpart | Air pollution control agency | ||||

|---|---|---|---|---|---|

| Glenn

County APCD | Great Basin Unified APCD | Imperial County APCD | Kern County APCD | ||

| A | General Provisions | X | X | ||

| D | Fossil-Fuel Fired Steam Generators Constructed After August 17, 1971 | X | X | ||

| Da | Electric Utility Steam Generating Units Constructed After September 18, 1978 | X | X | ||

| Db | Industrial-Commercial-Institutional Steam Generating Units | X | X | ||

| Dc | Small Industrial Steam Generating Units | X | X | ||

| E | Incinerators | X | X | ||

| Ea | Municipal Waste Combustors Constructed After December 20, 1989 and On or Before September 20, 1994 | X | |||

| Eb | Municipal Waste Combustors Constructed After September 20, 1994 | ||||

| Ec | Hospital/Medical/Infectious Waste Incinerators for Which Construction is Commenced After June 20, 1996 | ||||

| F | Portland Cement Plants | X | X | ||

| G | Nitric Acid Plants | X | X | ||

| H | Sulfuric Acid Plants | X | |||

| I | Hot Mix Asphalt Facilities | X | X | ||

| J | Petroleum Refineries | X | X | ||

| K | Storage Vessels for Petroleum Liquids for Which Construction, Reconstruction, or Modification Commenced After June 11, 1973, and Prior to May 19, 1978 | X | X | ||

| Ka | Storage Vessels for Petroleum Liquids for Which Construction, Reconstruction, or Modification Commenced After May 18, 1978, and Prior to July 23, 1984 | X | X | ||

| Kb | Volatile Organic Liquid Storage Vessels (Including Petroleum Liquid Storage Vessels) for Which Construction, Reconstruction, or Modification Commenced After July 23, 1984 | X | X | ||

| L | Secondary Lead Smelters | X | X | ||

| M | Secondary Brass and Bronze Production Plants | X | X | ||

| N | Primary Emissions from Basic Oxygen Process Furnaces for Which Construction is Commenced After June 11, 1973 | X | X | ||

| Na | Secondary Emissions from Basic Oxygen Process Steelmaking Facilities for Which Construction is Commenced After January 20, 1983 | X | X | ||

| O | Sewage Treatment Plants | X | X | ||

| P | Primary Copper Smelters | X | X | ||

| Q | Primary Zinc Smelters | X | X | ||

| R | Primary Lead Smelters | X | X | ||

| S | Primary Aluminum Reduction Plants | X | X | ||

| T | Phosphate Fertilizer Industry: Wet Process Phosphoric Acid Plants | X | X | ||

| U | Phosphate Fertilizer Industry: Superphosphoric Acid Plants | X | X | ||

| V | Phosphate Fertilizer Industry: Diammonium Phosphate Plants | X | X | ||

| W | Phosphate Fertilizer Industry: Triple Superphosphate Plants | X | X | ||

| X | Phosphate Fertilizer Industry: Granular Triple Superphosphate Storage Facilities | X | X | ||

| Y | Coal Preparation Plants | X | X | ||

| Z | Ferroalloy Production Facilities | X | X | ||

| AA | Steel Plants: Electric Arc Furnaces Constructed After October 21, 1974 and On or Before August 17, 1983 | X | X | ||

| AAa | Steel Plants: Electric Arc Furnaces and Argon-Oxygen Decarburization Vessels Constructed After August 7, 1983 | X | X | ||

| BB | Kraft pulp Mills | X | X | ||

| CC | Glass Manufacturing Plants | X | X | ||

| DD | Grain Elevators | X | X | ||

| EE | Surface Coating of Metal Furniture | X | X | ||

| FF | (Reserved) | ||||

| GG | Stationary Gas Turbines | X | X | ||

| HH | Lime Manufacturing Plants | X | X | ||

| KK | Lead-Acid Battery Manufacturing Plants | X | X | ||

| LL | Metallic Mineral Processing Plants | X | X | ||

| MM | Automobile and Light Duty Trucks Surface Coating Operations | X | X | ||

| NN | Phosphate Rock Plants | X | X | ||

| PP | Ammonium Sulfate Manufacture | X | X | ||

| Graphic Arts Industry: Publication Rotogravure Printing | X | X | |||

| RR | Pressure Sensitive Tape and Label Surface Coating Operations | X | X | ||

| SS | Industrial Surface Coating: Large Appliances | X | X | ||

| TT | Metal Coil Surface Coating | X | X | ||

| UU | Asphalt Processing and Asphalt Roofing Manufacture | X | X | ||

| VV | Equipment Leaks of VOC in the Synthetic Organic Chemicals Manufacturing Industry | X | X | ||