Do your storage rack safety measures stack up?

Storage racks aren’t just used in general industry applications. They are commonly used on construction sites, too, particularly in warehouses or in laydown areas. The height and size of any racking system vary depending on its purpose and location. Regardless, storage racks can pose a real danger if not properly installed, used, and maintained.

It’s worth mentioning these hazards since material handling often involves removing or placing materials on racks. I’ve been on many projects that had racks onsite or in an offsite warehouse that was rented. I always found safety hazards that needed immediate attention. Even if the construction work is temporary, the racks still need to be installed properly. I’ve found that project management often overlooks this purposely, not wanting to spend added costs for something that’s not going to be part of the permanent structure. Also, proper rack systems must be used for material handling, not makeshift shelving using other means like scaffolding.

OSHA requirements

OSHA’s requirements for storing materials are fairly basic under 1926.250, General requirements for storage. The Agency only says, “materials stored in tiers shall be stacked, racked, blocked, interlocked, or otherwise secured to prevent sliding, falling, or collapse.” If a hazard existed because of materials on storage racks, OSHA would expect some method of safeguarding to be implemented; otherwise, they could cite under 1926.250(a)(1) or possibly the General Duty Clause. As such, OSHA often references the manufacturer’s instructions and standards/specifications from the American National Standards Institute (ANSI) and Rack Manufacturers Institute, Inc. (RMI).

Design

While OSHA does not prohibit creating homemade storage racks, the Agency says the company should conform to the requirements in ANSI MH 16.1, Specification for Industrial Steel Storage Racks, to determine designated load sizes and ratings. A professional engineer should certify all rack designs.

Load ratings

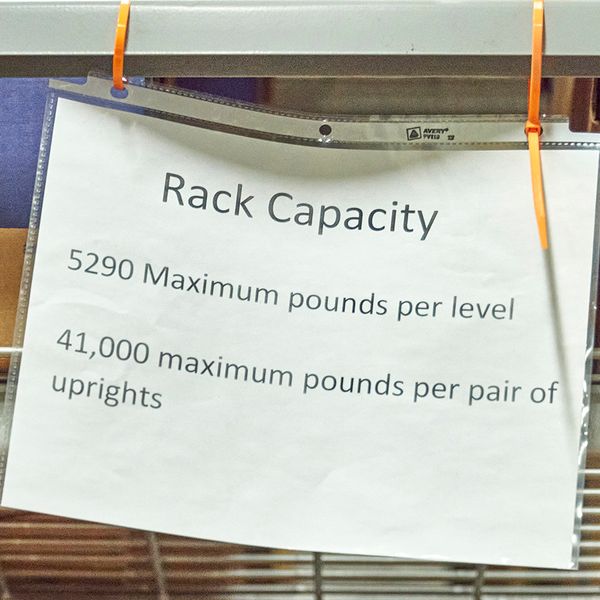

OSHA does not address load ratings of storage racks in any standard. However, the Agency has cited companies under its General Duty Clause for not having rating plaques on racks. In one citation, the Agency said, “The rated load capacities of the storage racks were unknown, and the load capacities were not marked on the storage racks.”

For guidance, consult ANSI MH 16.1. Specifically, the ANSI standard says that all rack installations should display in “one or more conspicuous locations” a permanent load plaque. Additionally, the Standard provides information regarding the content and design of the plaque.

The RMI says that load plaques serve as a constant reminder of the rack’s rated load capacity and may also serve as a record of the rack’s manufacturer.

Also, local building/safety codes may have specific requirements for load rating postings.

Anchoring

OSHA suggests anchoring storage rack systems and has cited companies for not doing so. The Agency recommends following the manufacturer’s instructions and/or guidance provided by ANSI or the RMI. The ANSI/RMI specification for industrial steel storage racks says that all rack columns should be anchored.

Inspection and maintenance

Regular inspection and maintenance can ensure storage racks are loaded and anchored correctly. Also, the damage that may affect the integrity of racks can be readily identified. Damaged racks should either be removed from service or fixed according to the manufacturer’s instructions or guidance from ANSI or RMI.

Neither ANSI nor RMI addresses preventing damage to racks via bumpers, fenders, or deflectors. OSHA would expect, however, the racks to be safe. Contact your rack supplier for available damage-prevention solutions based on their operations.

Key to remember

Don’t overlook safety hazards with your storage racks onsite. Make sure to mark their load ratings and anchor them properly.