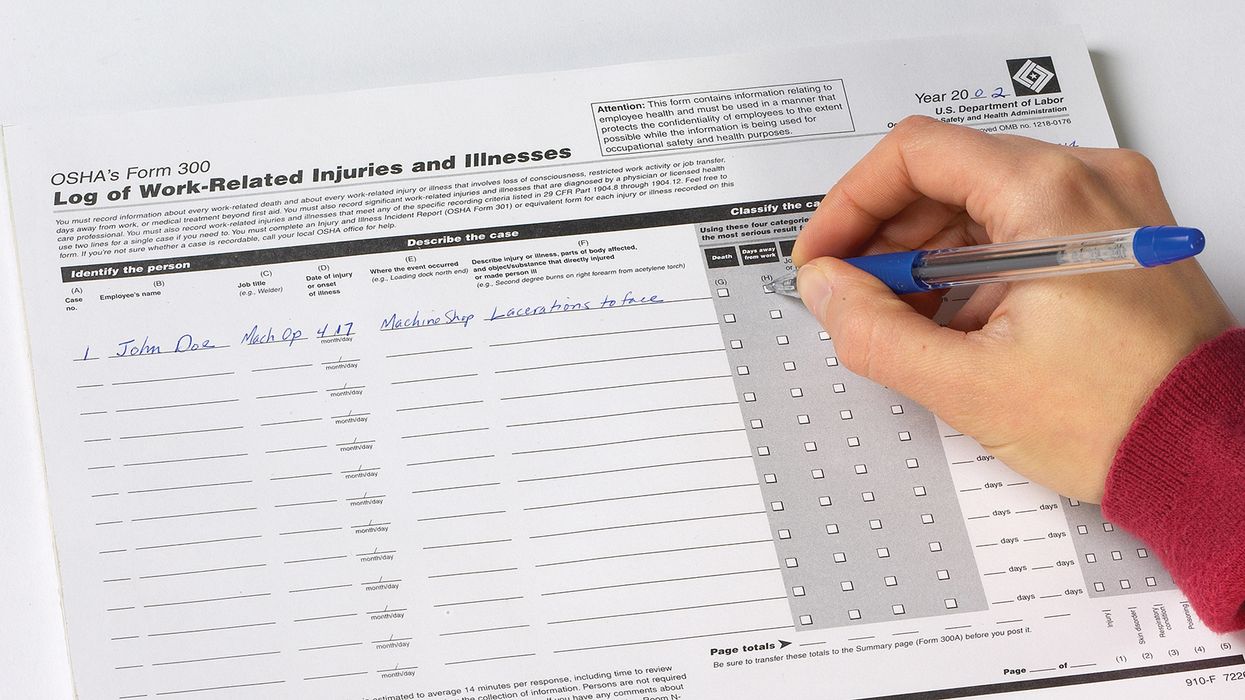

‘Must-see’ CSB video warns OSHA to take regulatory action

What would you do if you were working at a chemical plant on a platform five stories up when suddenly a white, gaseous cloud of corrosive hydrogen chloride (HCl) spews out of a pipe in front of you? You quickly slip on your “escape” respirator, but the gas is now burning your skin because you’re not wearing a chemical protective suit.

Every second of exposure seems like an eternity. You realize you face three hard choices:

- Rush directly into the blinding, corrosive cloud to access the single staircase on the other side of the platform to exit; or

- Go over the guardrail on your side of the platform and attempt to climb down 70 feet of piping without fall protection; or

- Stay put and suffer through the chemical release for who knows how long until it runs out of gas and dissipates enough for you to evacuate via the staircase.

Real workers, real casualties

This sounds like something out of a movie, but it happened in real life at a silicone manufacturing plant in Tennessee four years ago. Seven workers were on the platform:

- Three workers fell while attempting to climb down the piping, with one worker fatally and two seriously injured.

- One worker ran toward the staircase, only to bump into equipment and have his respirator knocked off. He was seriously burned and moved back to the opposite side of the platform, where three workers placed him in a safety shower.

- The remaining three workers tried their best to shield each other as they waited three minutes until all the gas escaped the system.

All four on the platform then evacuated using the staircase.

See it for yourself

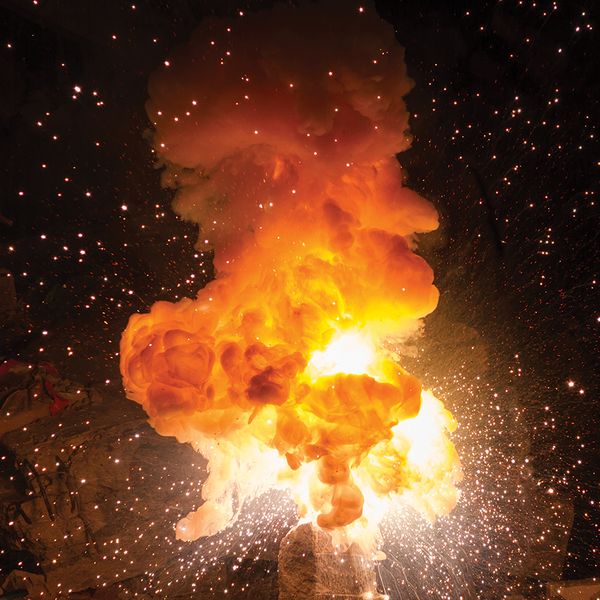

The Chemical Safety and Hazard Investigation Board (CSB) released a new 17-minute animated video, “No Way Down,” about the incident, its causes, and recommendations. The video follows a final investigation report dated June 15, 2023.

While both the video and the report are specific to the incident, the lessons learned can be applied broadly at other chemical plants and even other work facilities nationwide. CSB member Catherine Sandoval said, “The CSB believes that our findings and recommendations will … prevent another needless tragedy.”

Safety issues

The Board explains that the cause of the incident was the inadvertent over-torquing of bolts on an HCl piping flange connection to a heat exchanger. This resulted in a pipe fracture and the release of the gas in the vicinity of seven contract workers. However, the latest video and report address four key safety issues that CSB found contributed to the incident:

- Missing written procedures — The company tasked a contractor (consisting of three workers on a pipefitter crew) to torque bolts on active chemical piping. The company did not have a written procedure to execute the task. Instead, it relied on the equipment manual to communicate torque requirements. The manual did not include torque requirements for some of the bolts. As a result, the contractor ended up over-torquing them.

- No control of hazardous energy — The company did not consider the torquing operation to be a line break or an activity that required isolation of hazardous energy. The company thought since it was not opening the line, lockout/tagout was not needed. Therefore, the company did not assess the risk of the task or implement precautions. Such precautions might have restricted a second contractor from being in the area.

- Simultaneous operations — The company did not have a policy/procedure for evaluating simultaneous operations (SIMOPs). A pipefitter crew was working on one end of the 19x38 foot platform while a pipe insulation crew was working on the opposite end of the platform. The company did not evaluate the risks associated with the simultaneous tasks in near proximity. Also, the pipe insulation crew had insufficient personal protective equipment and was unnecessarily exposed to the HCl release created by the torquing operation.

- Limited means of egress — The fifth-floor platform was equipped with only a single point of egress. This was based on building codes for an “unoccupiable equipment platform.”

CSB recommendations

The Board made 10 recommendations. Note that CSB urges OSHA to add or modify regulations to require employers to coordinate SIMOPs, including:

- Identifying potential SIMOPs and hazardous interactions,

- Implementing safeguards to allow for safe SIMOPs,

- Communicating between SIMOPs, and

- Involving emergency response personnel in planning/coordinating SIMOPs.

CSB suggests OSHA also issue guidance for SIMOPs. In addition, the investigation report calls on the International Code Council and the National Fire Protection Association to address conditions which require multiple means of egress from elevated structures containing hazardous materials.

Key to remember

CSB urges OSHA to add or modify regulations to require employers to coordinate SIMOPs. The Board also calls on others to address the need for multiple means of egress on elevated structures.