CSB comes under fire and delivers results

The second half of this year has been a busy one for the Chemical Safety Board (CSB) as the organization addresses two very different tasks. First, the CSB has been called into question by congress for what appears to be concern over productivity of the department, and second, the CSB has been finalizing and publishing multiple investigation reports.

Congress looks for CSB progress

Beginning in the spring, congress and CSB leadership have been in communication about recent operations and investigation results from the organization. The correspondence started with a letter from the Energy and Commerce Committee to CSB Chairperson and CEO Dr. Katherine A. Lemos. The letter requested the Chairman address five specific areas of interest, all centered around staffing issues and delay in action. Less than a month later in early June, Dr. Lemos sent a response to the Committee. In that letter, Dr. Lemos shared that many of the staff openings have been filled, which has allowed for all open investigations to be staffed and actively worked. The letter also highlighted a larger effort that CSB has been undertaking for more than a year to improve efficiency in the organization and use resources in the most productive way.

During a congressional hearing on September 29, 2021, Chairperson Lemos reiterated the CSB’s commitment to their mission to “drive chemical safety change through independent investigations to protect people and the environment.” Through the months of scrutiny, CSB has been able to demonstrate this commitment by turning out clear results in the publication of three final investigation reports.

Two investigation reports finalized

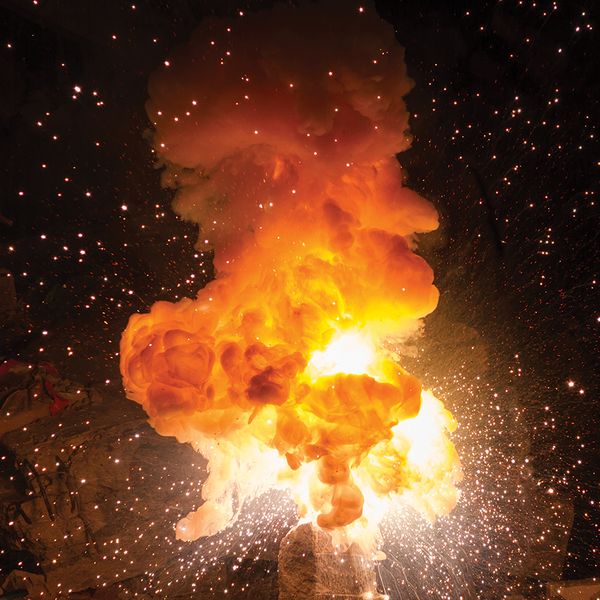

The most recent investigation reports that CSB was able to finalize were both published on September 24, 2021. The first report provided investigation details, recommendations, and industry lessons from a fatal fire and explosion that occurred on May 3, 2019, at AB Specialty Silicones, LLC (AB Specialty) in Waukegan, IL. While AB Specialty was given the bulk of recommendations (with three being given to the company), the other two were issued to OSHA and EPA. Each agency was assigned the task of revising the catastrophic release standards (Process Safety Management and Accidental Release Prevention) to specifically cover potential reactive releases.

The second report concluded the investigation from a fatal fire that occurred almost exactly one year earlier. The fire occurred at a paper mill in North Carolina on September 21, 2020, during maintenance work inside two connected process vessels. The report identified a number of causes related to confined space and hot work hazard identification. Recommendations from this investigation included two for OSHA and six for the paper mill and construction companies involved.

Like all CSB investigations, each of the two recent reports includes key lessons that can be applied across other industrial facilities. For example, lessons from these two reports include:

- Companies should make manual operations easy to do right and hard to do wrong.

- Equipment with the potential to vent hazardous gases should be vented to a safe location, away from personnel and away from structures that could confine the hazardous gases.

- Hot work encompasses any task that can cause a fire and not only those tasks that produce sparks or open flames. This includes heat guns and other heating tools that can ignite flammable or combustible materials.

- Emergency response personnel should be involved in planning and coordination of activities involving the use of flammable materials in confined spaces. And those emergency response personnel need to be trained in confined space entry, confined space rescue, and fire response.

Key to remember: CSB is taking action to speed up investigation reports and follow-up.

Three ways CSB investigations can be a resource for your organization

- Review the “Key Lessons” section of each report for broadly applicable best practices. Many of the items in this section of each report are good learnings for industries and businesses of all types.

- Use the reports and related Safety Videos in training provided to your employees. The videos are exceptionally well done and provide great real-world teaching opportunities.

- Get early indications of regulatory changes that will be worked on in the future. Often the report recommendations given to EPA, OSHA, and other regulatory agencies focus on revisions to regulation (such as Process Safety Management).