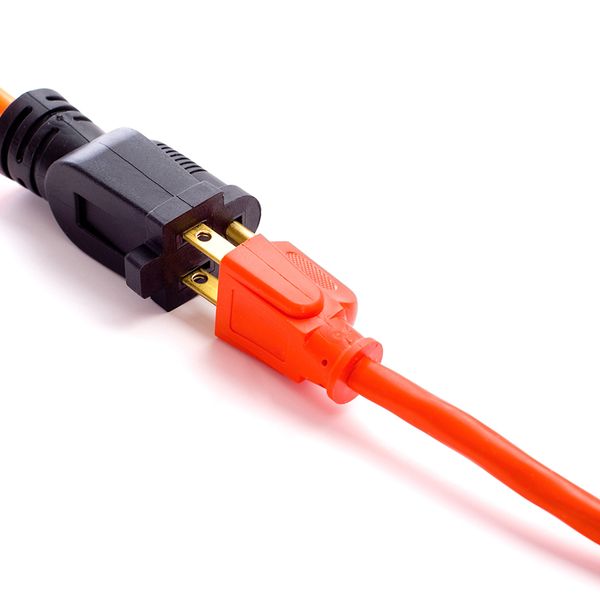

Inspect power chords before using tools

Employees may use extension cords or power strips when using power tools such as drills or when adding work lights to increase illumination. However, the Occupational Safety and Health Administration (OSHA) has a number of safety rules for using these cords, as well as portable tools with cords.

Portable equipment must be handled in a manner which will not cause damage. Flexible electric cords connected to equipment must not be used for raising, lowering, or carrying the tool. Flexible cords may not be fastened with staples or otherwise hung in a way that could damage the outer jacket or insulation.

In addition, flexible power cords or extension cords cannot be routed through walls, windows, ceilings, floors, or similar openings.

Inspect the equipment

Portable tools and extension cords must be visually inspected before use on any shift for defects (such as loose parts or damage to the cord) and for evidence of possible internal damage (such as pinched or crushed outer jacket). Tools and extension cords which remain connected once they are put in place and are not exposed to damage need not be visually inspected until they are relocated.

If a defect or evidence of damage might expose an employee to injury, the defective or damaged item must be removed from service. Similarly, flexible cords found damaged or defective must not be used.

Using electrical tape to cover minor nicks and abrasions in the outer jacket of a flexible cord is not recommended. The use of electrical tape can prevent a thorough visual inspection of the cord. According to OSHA, nicks and abrasions which do not penetrate completely through the outer jacket of a cord are not a significant safety concern, so repair or replacement is not required. However, when the outer jacket is penetrated or the conductors or their insulation inside are damaged, then repair or replacement is required.

In addition, OSHA warns that removing a damaged section of a flexible cord and installing an attachment plug and a cord connection on the end is not allowed. This would be considered temporary wiring and is not permitted for workplace use.

Power strips

If power strips are available, keep in mind that most are designed for use with low-powered loads such as computers, peripherals, or audio/video components. Power strips are not designed for high power loads such as space heaters or other tools which may exceed the recommended ampere ratings on the power strip.

When looking for electrical equipment, make sure it is listed and labeled by a nationally recognized testing laboratory and is installed as the manufacturer intended. In addition, the equipment must be marked with the manufacturer’s name or trademark, voltage, current, wattage, and/or other necessary information. Use equipment only for purposes intended by manufacturer.