Avoid these contributing factors to electrical incidents

Each year, workers continue getting shocked, burned, or worse — die from exposure to electrical hazards. These three hazards are contributing factors to many of the electrical incidents occurring on construction worksites:

- Working unsafely

- Exposure to unsafe conditions in the workplace

- Unsafe equipment or installation

Working unsafely

Besides following OSHA safety requirements, employers should establish standard operating procedures (SOPs) for workers to follow while working with or near electrical power. Sources for creating SOPs include manufacturer recommendations, best practices, lessons learned, and corrective actions.

Overloading circuits commonly result in fires and heated wires. I’ve seen this issue on jobsites when workers plug the microwave, coffee pot, and refrigerator into one outlet. Each time the breaker trips, a worker or electrician from the jobsite resets the breaker instead of removing the excess electrical loads from the circuit.

Overloading an electrical circuit, even while using protection like a GFCI, is dangerous. Tools can get damaged, and wire insulation can melt. When this happens, arcing and fires can occur.

Exposure to unsafe conditions

An example of an unsafe condition on jobsites is using an electrical tool on an undersized circuit. When setting up temporary power for the jobsite, electricians aren’t always aware of the circuit’s intended electrical load—but they should know this information.

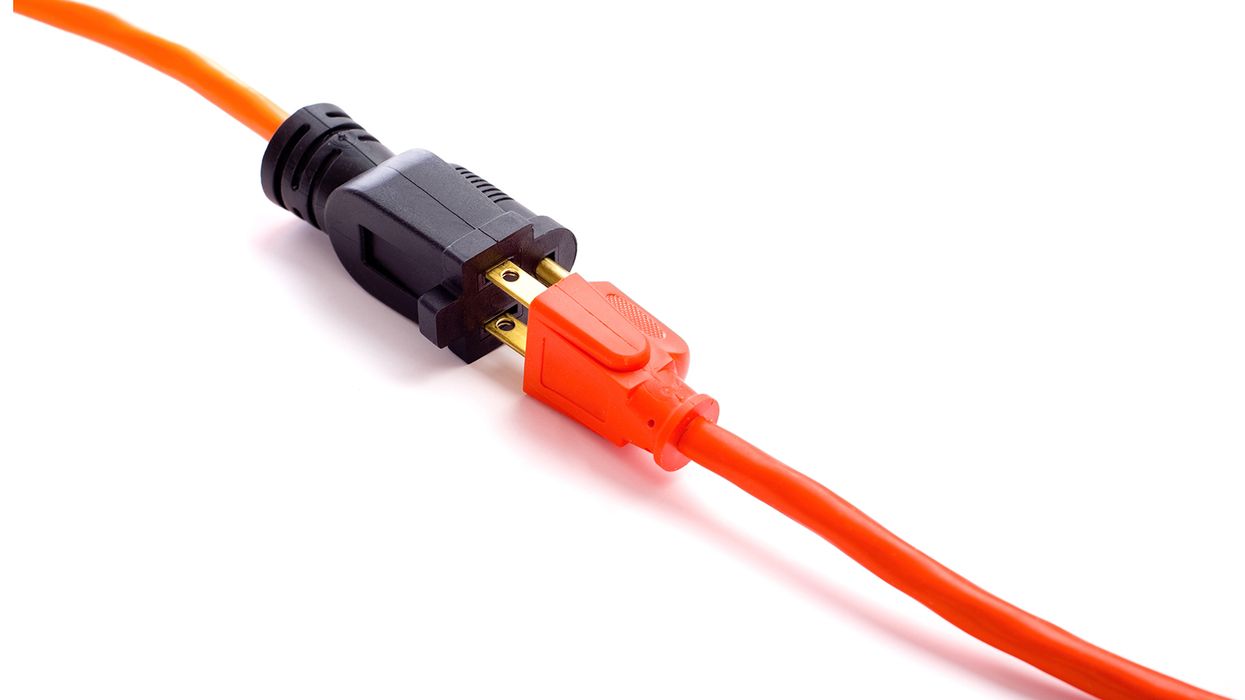

The electricians may have even installed the correct size circuit breaker and power supply. Still, a worker may use an undersized extension cord. Doing this can cause the tool to draw more power from the cord and exceed its rating. As a result, the cord can overheat and cause a fire to occur without tripping the circuit breaker.

Overhead powerlines are another common unsafe condition on jobsites. I’ve personally seen several dump-truck drivers leave the truck’s bucket raised and drive off. Unfortunately, the raised bucket contacted an overhead powerline causing an immediately dangerous to life or health hazard.

After a series of incidents on my jobs, I started installing overhead warning markers and plastic goalposts ahead of the powerlines. If a driver left the dump truck’s bucket raised accidentally, they’d contact the marker or goalpost first and stop before reaching the powerline.

Plan all electrical work activities and ensure nearby workers are aware of your planned electrical work.

In addition, workers should follow these essential electrical safety tips:

- Maintain 10 feet of distance from overhead powerlines,

- Post warning signs about overhead electrical hazards,

- Assume all powerlines are energized,

- Avoid using metal ladders and use wood or fiberglass ones,

- Use proper electrical PPE, and

- Attend electrical safety training.

Unsafe equipment or installation

Electrical equipment with missing guards, barriers, or covers exposes workers to live electrical parts. To avoid exposure:

- Cover all conductors going inside electrical equipment;

- Close all openings in electrical cabinets; and

- Use approved covers on all junction boxes, pull boxes, and fittings.

Ground all power supply systems, electrical circuits, and electrical equipment on the jobsite. Grounding creates a low-resistance pathway to the earth. Tools, circuits, and improperly grounded equipment may become energized, causing a shock to workers.