How do you stack up? Your top 5 material handling questions answered!

Are you swimming in a sea of material handling compliance confusion? Fear not — where questions abound, we have answers! Let’s dive into the 5 most common material handling questions we receive. Whether you're a seasoned professional or new to the field, these answers will help you navigate your warehouse and storage with ease!

1. How high can materials be stacked on pallets for storage?

OSHA doesn’t have a specific regulation that sets a height for materials stacked on pallets or shelving. However, the Agency does require in 1910.176(b) that:

“Storage of material shall not create a hazard. Bags, containers, bundles, etc., stored in tiers shall be stacked, blocked, interlocked and limited in height so that they are stable and secure against sliding or collapse.”

Additionally, OSHA does have a requirement in 1910.159(c)(10) regarding sprinkler clearance. A minimum 18” vertical clearance must be maintained between the sprinkler heads and stored materials to ensure effective sprinkler operation.

It’s important to also remember there could be height limitations based on the type of materials and potential fire load (for example, empty pallets can pose a hazard from fast developing fire and intense heat released from pallet stacks. Due to this, there are height limitations based on type of material, sprinkler system, and whether storage is indoor/outdoor, etc. Employers should always check with their local fire authority for additional guidance.

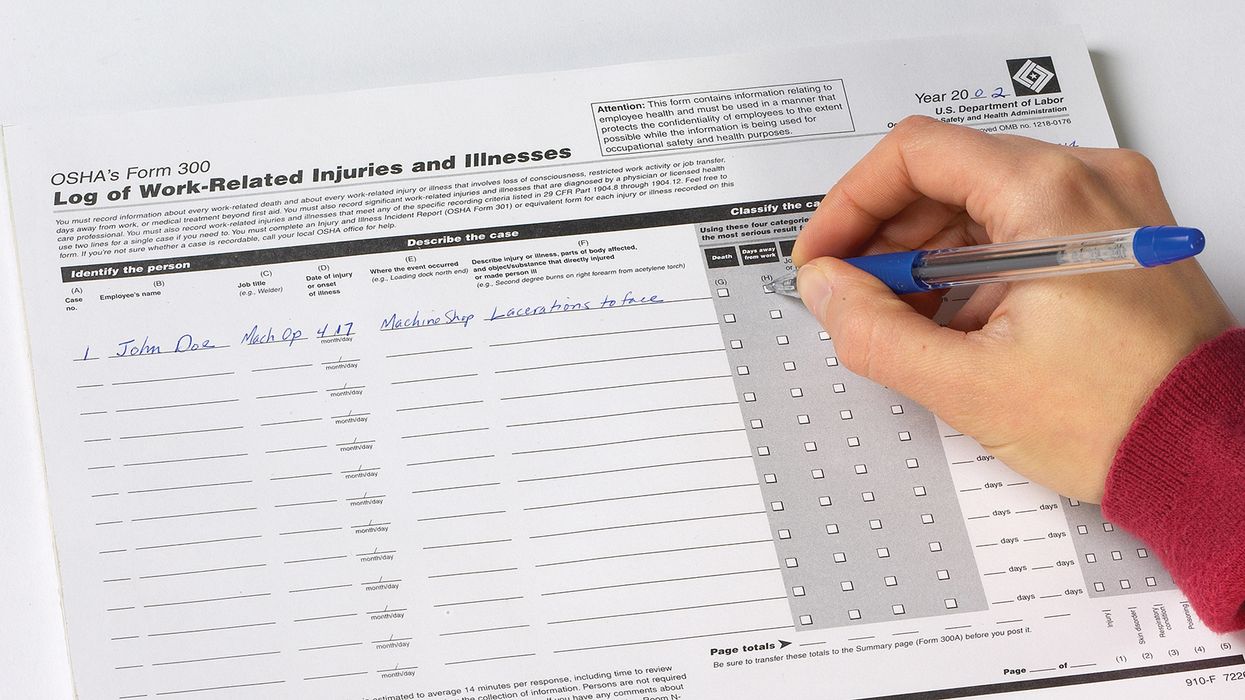

2. How long do we have to keep the daily inspection records for material handling equipment, such as forklifts and pickers?

Under 1910.178, OSHA doesn't set any specific retention periods for this material handling equipment's daily inspection. Technically, the regulation doesn’t even require documentation, but they do require the inspections to be completed.

As a best practice, employers should determine how long inspection records should be retained and document the retention period in the company policy/program. Additionally, some employers also keep inspection records that identify issues or maintenance needs for a longer period as a systematic process focused on keeping machinery and equipment in optimal working condition.

3. Is there a specific OSHA regulation that requires all stored workplace containers with liquid to be securely sealed and labeled?

OSHA’s materials handling and storage standard at 1910.176(b) states that “storage of material shall not create a hazard.” From an OSHA standpoint, employers must assess how chemicals are stored and managed to minimize hazard potential to workers. Additionally, OSHA’s HazCom standard at 1910.1200 requires that containers of hazardous chemicals be specifically labeled.

The agency expects employers to:

- Develop and maintain a written hazard communication program for the workplace, including a list or inventory of hazardous chemicals;

- Label chemical containers, as well as containers of chemicals being stored for shipment;

- Prepare and/or provide safety data sheets (SDSs) to employees and downstream employers; and

- Develop and implement employee training programs regarding hazards of chemicals and associated protective measures.

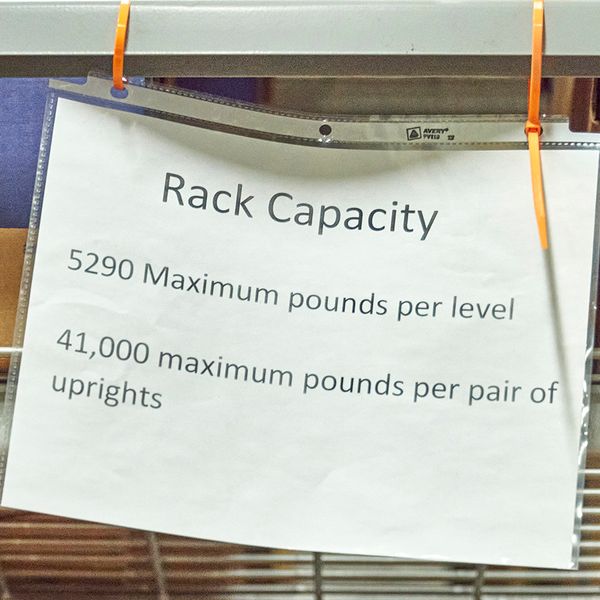

4. Do storage racks have to be labeled with the load capacities?

OSHA regulations also don’t specifically specify that capacity ratings or load limits be placed on storage racks; however, the agency has used the General Duty Clause (GDC) to cite for this in cases where a rack collapsed from overloading. To justify a GDC citation, OSHA may refer to the rack manufacturer’s recommendations or to the American National Standards Institute consensus standard ANSI/MH 16.1.

5. I know that storage racks must be set so they don’t tip or fall, but does OSHA or ANSI have any guidance to how many bolts are required for material handling storage racks?

Though the Material Handling and Storage standard at 1910.176(b) tells us, “Storage of material shall not create a hazard,” OSHA does not give exact details on HOW one would ensure their storage systems don’t create hazards. In these cases, the situation would likely fall under the General Duty Clause.

As an example, OSHA issued a citation in 2015 to a facility in which pallet racks were not anchored and bolted to the ground. As part of this citation, OSHA mentions that “one feasible and acceptable method to correct the hazards noted are to follow the manufacturer installation instructions and/or conform with installation and assembly instructions and the American National Standards Institute (ANSI) standard MH16.1-2012 (a revision of MH16.1-2008): Specifications for the Design, Testing and Utilization of Industrial Steel Storage Racks...”

Key to remember: OSHA material handling and storage regulations require, “Storage of material shall not create a hazard” which includes securing materials and shelving, ensuring adequate clearances for sprinkler systems, and maintaining clear exit routes.