Evacuating safely: Signs, lighting, and assembly

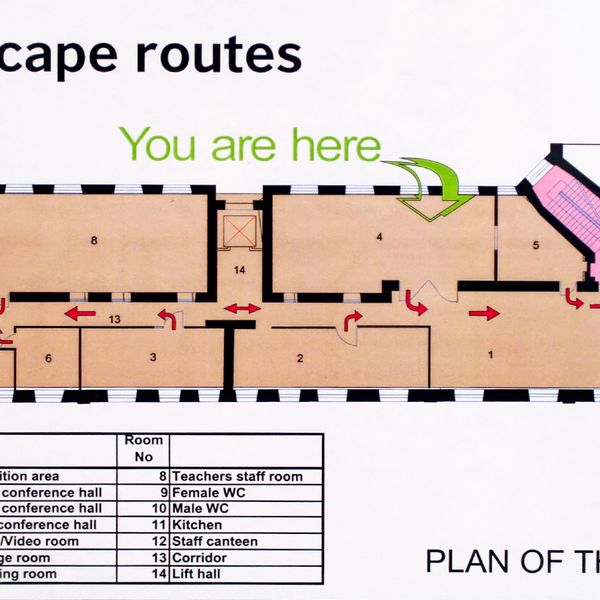

To evacuate safely, employees must be able to see an exit, walk to the door, and report to an assembly point. This requires proper placement and lighting of exit signs, sufficient lighting along exit routes, and careful selection of the assembly point location.

Visible exit signs

During a fire or similar emergency, employees will identify the nearest exits by the posted signs. Self-illuminating signs are common, but not actually required. However, the Occupational Safety and Health Administration (OSHA) says that exit signs must be illuminated to a specific level (at least five foot-candles) “by a reliable light source.”

Simple metal or plastic signs could be sufficiently visible, whether from ambient or directional light. However, signs must remain visible even during a loss of power. Emergency lights may be needed to ensure that non-illuminated signs can still be easily seen.

In addition, the employer must determine the number and location of signs. OSHA says the line-of-sight to an exit sign must be visible at all times. In short, wherever employees are working, they should be able to see signs pointing to the nearest exit. Make sure that stacked materials do not block line-of sight to any exit signs.

Walking the exit route

During an evacuation, employees must be able to see where they’re going as they walk to the door. Rather than listing a number of foot-candles, OSHA simply says, “Each exit route must be adequately lighted so that an employee with normal vision can see along the exit route.” Again, emergency lighting may be required to ensure adequate illumination during a power outage.

OSHA prohibits placing any materials or equipment within an exit route, even temporarily. Obstructing the route could cost lives, and OSHA cites this as a serious violation, with correspondingly high fines. Make sure that routes remain clear at all times, and that nothing is placed in an exit route. For example, a mail delivery cart cannot be left in the exit route aisle, not even for a short time.

In addition, some doors along an exit route may need to be marked “not an exit” or otherwise identified (e.g., storage closet) so those doors are not mistaken for exits.

Assembly areas

Once employees are safely outside, they should proceed to a designated assembly area. OSHA does not require a headcount, but most employers want to ensure that everyone got out safely, and notify responders if someone may still be inside. If you take a headcount, make sure everyone is accounted for and that you know who is out for the day (out sick, on vacation, etc.).

The assembly area might be in another building, outdoors, or even off the property. Employers must identify a safe location, and that may depend on the business. The safe distance from a chemical plant would be further than the safe distance from a coffee shop.

Employers should choose an assembly area carefully to make sure employees won’t interfere with emergency vehicles or responders, either while at the assembly point or while moving to that point.