ELD malfunction? How to ensure your drivers can manage Canadian HOS logbooks

In the age of Electronic Logging Devices (ELDs), it is easy to assume that the days of manually completing Hours of Service (HOS) logbooks are behind us. However, ensuring your drivers are proficient in both digital and paper logbooks is not just a regulatory necessity but a critical component of fleet preparedness.

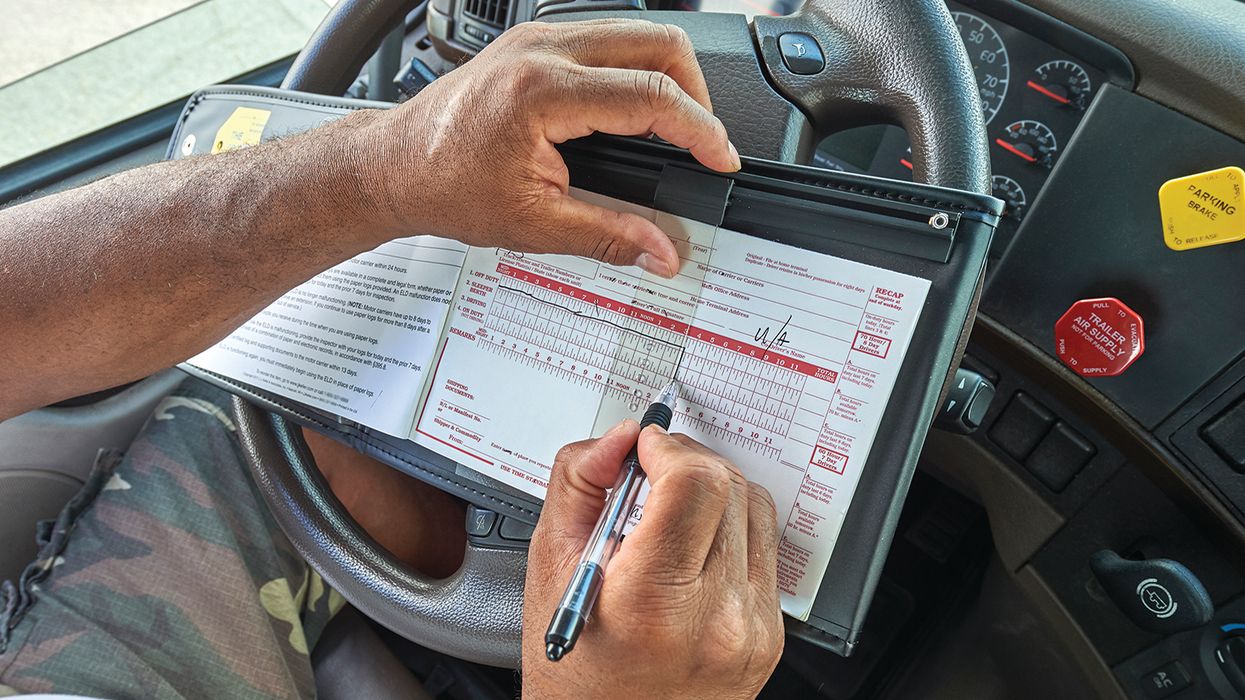

Imagine an ELD malfunction in the middle of a crucial delivery—would your drivers know how to seamlessly switch to a manual logbook and stay compliant?

The importance of Canadian HOS logbook knowledge

- Backup in case of ELD malfunction: ELDs, like any electronic device, can malfunction. In such cases, drivers must revert to paper logbooks to ensure continuous compliance with HOS regulations;

- Regulatory requirements: The Canadian Council of Motor Transport Administrators (CCMTA) mandates that drivers maintain paper logs for at least 14 days if their ELD malfunctions; and

- Flexibility and preparedness: Knowing how to complete a logbook ensures that drivers are prepared for any situation, including inspections and audits where paper logs might be requested.

How to ensure drivers know how to complete a Canadian HOS logbook

Training and education

- Initial training: Incorporate HOS logbook training into your onboarding process. Ensure that new drivers understand both ELD and manual logbook procedures.

- Regular refresher courses: Conduct periodic training sessions to refresh drivers' knowledge. This can be done through workshops, online courses, or hands-on practice sessions.

- Use real-life scenarios: Simulate situations where drivers might need to use a logbook, such as ELD malfunctions or during inspections. This practical approach helps reinforce their learning.

Provide clear instructions and resources

- Step-by-Step guides: Create easy-to-follow guides that outline the steps for completing a logbook. Include visual aids and examples to make the process clear.

- Accessible resources: Ensure that drivers always have access to these guides. This can be through printed manuals, digital documents, or an internal company app.

Regular audits and feedback

- Conduct audits: Periodically review drivers' logbooks to ensure they are completed correctly. This helps identify any gaps in knowledge and provides an opportunity for corrective action.

- Provide feedback: Offer constructive feedback to drivers on their logbook entries. Highlight areas of improvement and acknowledge correct entries to encourage good practices.

Encourage a culture of compliance

- Lead by example: Management should emphasize the importance of HOS compliance and demonstrate best practices.

- Open communication: Foster an environment where drivers feel comfortable asking questions and seeking clarification on HOS regulations and logbook procedures.

Practical tips for drivers

- Keep a logbook handy: Always have a blank logbook in the vehicle as a backup;

- Understand the basics: Know the key components of a logbook, including date, total miles driven, truck or tractor and trailer number, name of carrier, driver’s signature, 24-hour period starting time, primary office address, remarks, and co-driver’s name (if applicable);

- Accurate entries: Ensure all entries are accurate and legible. Mistakes or illegible entries can lead to compliance issues; and

- Stay updated: Keep abreast of any changes in HOS regulations and logbook requirements. Regularly review guidelines and company policies.

While ELDs have revolutionized the way your drivers log their hours, the ability to manually complete a Canadian HOS logbook remains an essential skill. By providing comprehensive training, clear instructions, regular audits, and fostering a culture of compliance, you can ensure that your drivers are well-prepared for any situation.

Key to remember: Making sure your drivers know how to maintain a logbook not only ensures regulatory compliance, but it also enhances the safety and efficiency of your fleet operations.