Apply our bird’s-eye-view excavation safety tips

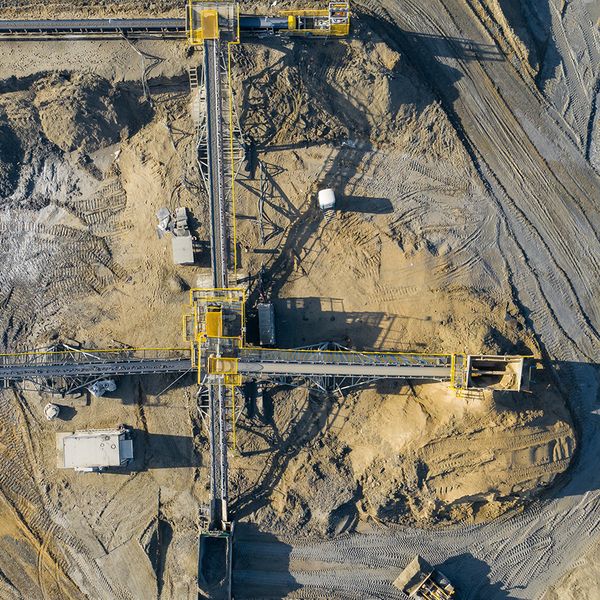

Excavation safety has been a regular focus by OSHA in the construction industry. I enjoy the civil phase on construction projects, especially new-build power plants. After the land is cleared of trees and stumps, the heavy equipment arrives. The bigger the project, the larger the equipment was.

We called the equipment “toys,” probably reminiscing our childhood days of playing with toy bulldozers and dump trucks. There was always somebody on each job which was lucky enough to have a parent who owned a bulldozer or dump truck and worked the equipment’s controls as a kid. There are two things that I could stand around and watch for hours on end: excavating and concrete finishing. Luckily, both work activities are part of a project’s civil phase.

The frightening reality of dirt work is how quickly things can go bad. One day, while I was watching a large bulldozer push dirt around, I was in a trance. As it got closer to me, I was amazed by its power. It weighed almost 200,000 pounds, was about 15 feet tall, 12 feet wide, and was almost 30 feet long.

Everything looked normal. Suddenly, I heard a loud popping sound and saw a section of the bulldozer’s track separate; it moved abruptly upwards and fell outward from the body of the bulldozer and towards my direction. It was at least 25 feet of track section. Luckily, I was back far enough, out of its line of fire. But that wasn’t always the case; other days, I had been much closer.

There’s a lot of guidance available about what to do or not to do. But here’s a bird’s-eye-view of six things I’ve successfully done to keep my workers safe that you should consider doing too:

“Build a plan, communicate the plan, and follow the plan.” I say it just like this. I put this in my training materials and PowerPoint presentation, and I often said it during training and safety meetings. It has a rhythm to it; workers can easily remember it.

Only a competent, trained person can perform a soil penetration test. When I was a green safety manager, workers did this all the time. I was told that anyone could do it. They told me to pick up some soil in my hand; it’s class A soil if you can’t press it, class B soil if you can kind of press it, and class C is it’s “like sand.” I’ve met very few “trained” workers that were able to perform the penetration test. It’s not a do-it-yourself thing. Many trenches and excavations have collapsed because somebody misclassified the soil type and used improper benching or shoring methods.

It’s okay if installing a trench box, shoring, or benching takes more time than the actual time it takes to do the work itself. I am all about safety, production, and scheduling flowing together. I agree they can co-exist, but not at the cost of sacrificing safety. Ensure that proper protections are put in place, are competently installed, inspected, and maintained before workers enter the excavation.

Identify line-of-fire hazards around your equipment and train workers about them. If equipment will be stationary for a while, use a red rope to barricade off the area. A rope is better than tape in windy conditions and for efficient setup and take-down ease. If it’s messy and not easy, the operator won’t use it when you’re not watching. Rope barricades are easy to store on the equipment. You can buy lightweight cones and stanchions with holes to feed the barricade rope through.

Consider “what if” something went wrong and what you’d do about it. Companies often train workers about what not to do and not what to do in emergencies. Conduct regular mock scenarios and practice rescue responses onsite. This was always a fun exercise for my projects. Afterward, we’d debrief while eating pizza and talk about what went right and what we needed to improve.

“Build a plan, communicate the plan, and follow the plan.” I know; it’s a repeat of the first bullet. It’s essential. Start and end with this message when you speak to your workers about excavation safety. Coin this phrase at your jobsite.

When the bulldozer’s track came off, I was fortunate that I wasn’t injured or killed. Too many workers haven’t been this lucky. Use the bulleted list above, keep it handy while doing inspections, and create pocket cards for your supervisors. When you put your worksite plan together, consider the safety requirements in OSHA Standard 1926.651, Specific excavation requirements. It discusses requirements for:

- Access and egress,

- Emergency rescue,

- Dewatering your excavation,

- Stability and protection, and

- Inspection requirements.

1926, Subpart P, Excavations, have other OSHA safety requirements that need to be included in your plan as they apply to your jobsite.