Beyond borders: Comparing Canada’s speed limiter policies with US practices

In the realm of road safety and vehicle regulations, speed limiters are a critical component that has seen varying implementations across different jurisdictions. Canada and the United States offer contrasting approaches to the use of speed limiters, reflecting differing priorities and regulatory philosophies.

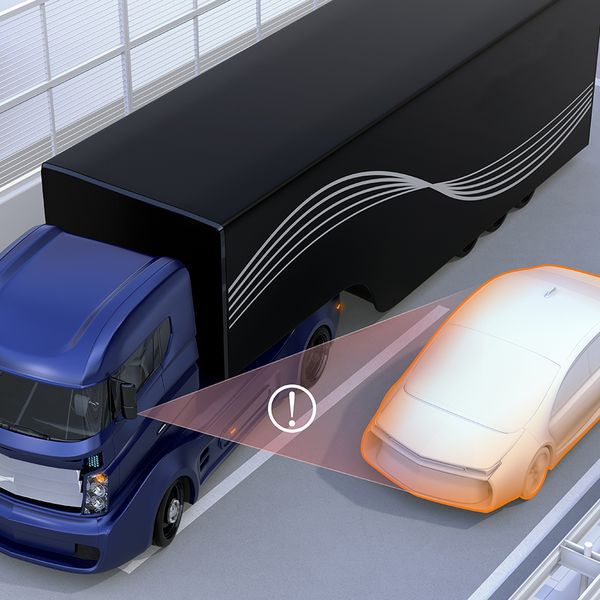

Speed limiters help to maintain a consistent and safe speed, preventing excessive acceleration and promote better fuel efficiency.

Canada’s approach to speed limiters

In Canada, regulations around speed limiters are multifaceted and certain provinces have been proactive in mandating speed limiters on heavy commercial vehicles. Speed limiters are seen as a means to enhance your driver's safe operation by reducing the frequency and severity of crashes. They can also serve to lower your operational costs by reducing fuel consumption and maintenance needs, thereby increasing your business efficiency and competitiveness.

Here’s a summary of the key points:

- Mandated Speed Limiters: The provinces of Ontario, BC and Quebec have mandated the installation of speed limiters on large trucks, setting the maximum operating speed at 105 km/h;

- Legislation Support: This regulation is supported by organizations such as the Canadian Trucking Alliance (CTA) and the jurisdictional trucking associations;

- Enforcement: Compliance with speed limiter regulations is strictly enforced. Noncompliance can result in penalties, including fines and driver penalty points; and

- Vehicle Requirements: The vehicle’s electronic control module must be accurately programmed, and tampering with the technology is prohibited.

US practices regarding speed limiters

The United States takes a more decentralized approach to speed regulation. Setting speed limits has traditionally been the responsibility of state and local governments, with the federal government only intermittently asserting authority.

Here’s a summary of the current situation:

- Federal Motor Carrier Safety Administration (FMCSA): The FMCSA has expressed intent to proceed with rulemaking regarding speed limiters. The agency is considering a carrier-based approach to impose speed limitations on Commercial Motor Vehicles (CMVs) operating in interstate commerce;

- Speed Limiter Mandate: The FMCSA is moving forward with a mandate that would require CMVs with a gross vehicle weight rating (GVWR) or gross vehicle weight (GVW) of 26,001 pounds or more to be equipped with an electronic engine control unit (ECU) capable of governing the maximum speed; and

- Public Comments and Concerns: There has been significant public comment on the proposal, with some truck drivers expressing concerns about potential increases in road rage and traffic issues if speed limiters are mandated.

As of now, the FMCSA has not proposed a maximum speed, nor has it provided regulatory text or estimates of the costs or safety benefits. The specifics of the speed limiter regulations, including the maximum speed limit, are still under consideration and have not been finalized.

Benefits of speed limiters

Speed limiters offer you a range of possible benefits from safety to environmental impact, making them an important feature in modern vehicle safety and regulatory systems.

Benefits of speed limiters include:

- Safety: By capping speeds, speed limiters reduce the risk of accidents caused by excessive velocity. Consistent speeds also enhance overall road safety;

- Fuel Efficiency: Vehicles traveling at high speeds consume more fuel. Speed limiters promote fuel conservation, benefiting both the environment and you the carrier; and

- Economic Impact: Efficient fuel usage translates to cost savings with reduced fuel expenses contributing to better profitability.

Key to remember: The faster your drivers travel, the higher the risk they are of losing control and being involved in a crash with a significantly higher risk of fatality or serious injury.