Worker who died by electrocution found to be avoidable

OSHA cited an employer in January 2023 after allegedly failing to de-energize equipment while an worker performed service and maintenance activities on a rooftop air conditioning.

“This worker’s death was avoidable. Employers must follow well-known electrical safety procedures set forth in federal regulations and industry-recognized practices,” said an OSHA Area Director.

Electricity has long been recognized as a serious workplace hazard, exposing employees to such dangers as electrical shock, electrocution, burns, fires, and explosions.

The technician succumbed to his injuries after being shocked. Workers must understand the following:

- Causes of electrical accidents,

- Understanding what electrical shock is, and

- Applying safe work practices.

Understanding these topics is essential in avoiding an electrical accident.

What causes electrical accidents?

Electrical accidents are caused by one or more of the following:

- Unsafe equipment and/or installation.

- Unsafe workplaces caused by environmental factors.

- Unsafe work practices.

An accident such as high-voltage shocks can cause serious injury or even death.

How can it hurt me?

The effects of an electrical shock on the body can range from a tingle to immediate cardiac arrest.

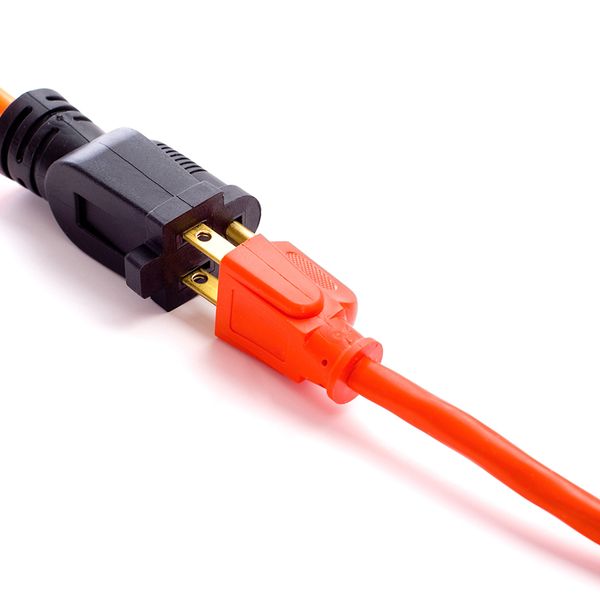

Electrical currents travel in closed circuits through conducting material. Workers can receive a shock when a part of their body comes into contact with the following:

- Both wires of an electrical circuit.

- One wire of an energized circuit and the ground.

- Part of a machine that is ’hot’ because it is contacting an energized wire and the ground.

Severe shock can cause more damage than can be seen by the naked eye.

Safety 101

Workers must:

- Always make sure equipment is de-energized.

- Maintain electrical equipment.

- Regularly inspect tools, cords, grounds, and accessories. Have damaged equipment taken out of service immediately.

- Always use safety features like three-pronged plugs, double-insulated tools, and safety switches.

- Make sure that all machine guards are in place.

- Keep electrical cables and cords clean and free from kinks. Never carry equipment by the cord.

- Avoid touching water, damp surfaces, ungrounded metal, or any bare wires if you are not protected. Wear approved rubber gloves when working with live wires or ungrounded surfaces. Rubber-soled shoes or boots should be worn when working on damp or wet surfaces.

- Avoid wearing jewelry or metal objects when working with electricity.

- Keep the required safe distance from energized parts.

If workers are working where there are electrical hazards, employers must provide them with the appropriate PPE. Ensure that the equipment remains de-energized during service and maintenance activities by using lockout/tagout procedures.

Key to remember

Ensure that workers are familiar with the safety procedures for the job they are assigned to do. They should always use good judgment and common sense when working around electricity.