Safety solutions you can’t find in a toolbox talk

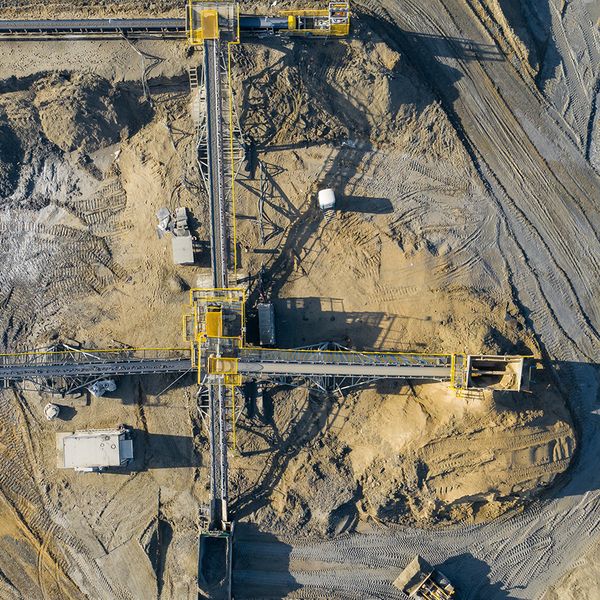

When I worked on construction sites as a safety manager, excavation work was always occurring throughout the job. It was a hazard that required constant attention and consideration while planning work activities. OSHA’s Excavations Standard, 1926.651, says to keep materials and equipment at least two feet away from the excavation’s leading edge. My supervisors used this distance as the standard for material and equipment placement. No matter if it was a gang box, an excavator, or a mobile crane’s outrigger, they set it two feet away, thinking that it was adequate because OSHA “said so.” We began having incidents with materials, equipment, and vehicles sliding into excavations. Two feet may be enough for some things, but not everything, and it shouldn’t be a default standard for your project. I’ll discuss some things to consider when determining how much distance is adequate and other hazards you should consider when making this assessment.

Another issue we had on many jobsites was overhead falling objects. My workers often assumed their hard hats offered enough protection from anything that might fall from above. As structures and buildings progressed vertically, workers had to work above one another more often. With more workers concentrated in enclosed areas and working over the top of one another, there were increased near-miss events. First, it was an issue of workers needing to flush their eyes more often because of falling dirt and grime from above. Eventually, workers started dropping building materials, tools, and even scaffolding parts. I had to step up our workers’ head protection from relying on hard hats and implemented five controls that I found especially useful. These controls are guardrails, restricted fall zones, overhead protections and barriers, standard operating procedures for storing and stacking materials, and realistic housekeeping procedures.

Other common issues on my jobsites were lone workers (online article), fleet safety, and substance abuse. On many of my jobs, there were plenty of places workers needed to work alone. I had to find ways of keeping a pulse of where my workers were. Fleet safety is another hazard on jobs, like excavations, that require constant time and attention and are often overlooked until the company receives a citation or an accident occurs. I’ll provide you with some resources and tips to consider steering your motor vehicle safety program in the proper direction. Finally, I’ll address a bit about substance abuse. When I first became a safety manager, this was a human resource exercise to get hired until I started seeing a trend of substance abuse as a contributing factor or root cause for incidents, accidents, and events occurring onsite. This issue will get you thinking creatively.