Cube-based storage — the automation of material handling and storage

Consumer demand for rapid delivery of goods and services has not slowed down, even as worker shortages plague the economy. One solution gaining popularity is a cube-based storage system that utilizes robots to retrieve product (e.g., AutoStore™). Companies evaluating this relatively new technology should be aware that automation does not always mean the absence of manual material handling and the safety precautions associated with it.

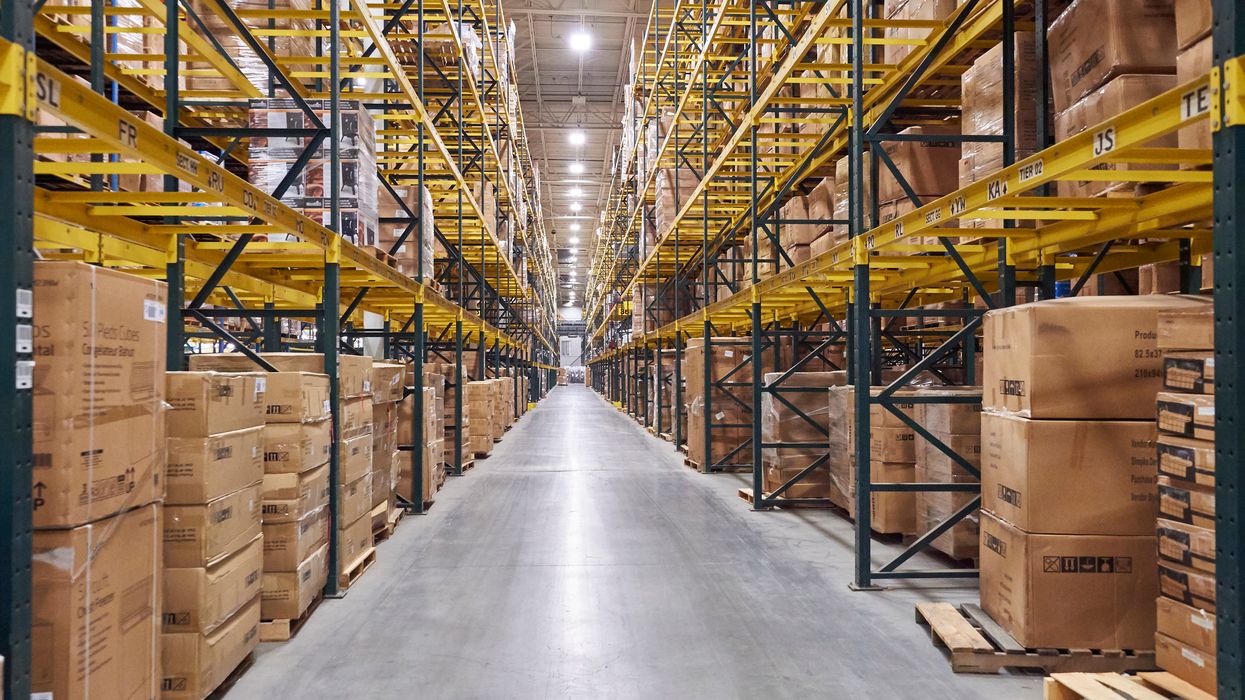

Cube-based storage works by loading, storing, sorting, and retrieving product-filled bins with the help of autonomous battery-powered robots. Workers manually load products in bins for storage until needed. These bins are stacked on top of and next to each other to efficiently use available space. When the product is needed, a worker programs a robot to deliver the bin to a workstation, where it will be unloaded and eventually shipped to the consumer.

Hazards depend on the size and shape of product being loaded and/or unloaded into the bins. When a system is initially installed, workers manually load the bins with product. This can be quite an undertaking, typically spanning several months to fully load the cube. Then there is the constant reloading of bins as product is depleted. Of course, one must also consider the unloading of the bin, and the subsequent repackaging, usually into a cardboard shipping box, to be sent to the customer.

OSHA’s material handling and storage regulations (1910.176) generally apply to all employers in General Industry. Incorporating proper material handling and storage will help to ensure the health and safety of those working with this cube-based system. When loading and unloading product, be sure to incorporate the following:

- Train workers on safe manual material handling practices, such as safe lifting. Make sure workers avoid bending or twisting.

- Use mechanical assists where possible, such as pallet jacks and height-adjustable tables.

- Store materials in a stable and secure manner. When storing material for loading into the cube system, verify the stacks are stable and do not create a hazard.

- When loading material into bins, ensure weight is evenly distributed and bin capacity is not exceeded. When unloading bins, do so in a similar fashion to loading.

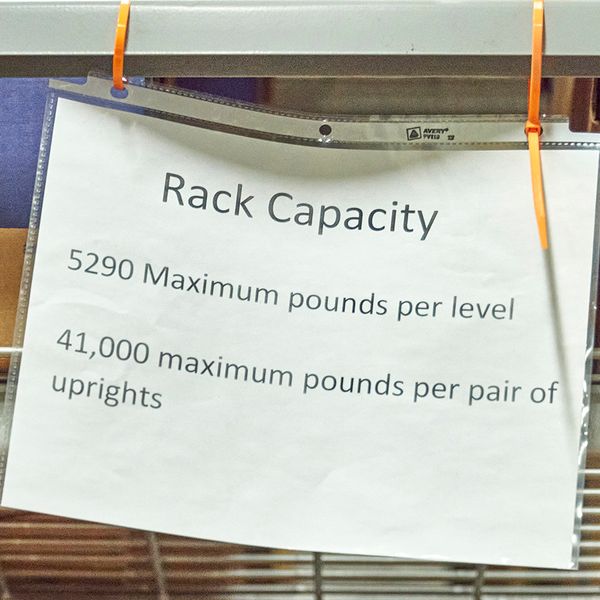

- Anchor storage racking to the floor and post a load capacity rating, if used to store material that will be loaded into the cube system.

- Ensure stored material does not block safety equipment, such as fire extinguishers, sprinklers, and eyewashes.

- Do not store materials in exit routes.

- Keep storage areas free from accumulated materials that cause tripping, fires, or explosions, or that may contribute to the harboring of rats or other pests.

As more companies look to the future and see the potential cost and space savings that an automated storage system can bring, they must not forgo OSHA safety standards as they relate to their remaining human workforce.