09-26-2024 Letter of Interpretation Added - Ergonomic Hazards in Ultrasound Sonography

2024-09-26T05:00:00Z

The following Letter of Interpretation has been added:

The following Letter of Interpretation has been added:

The following Letter of Interpretation has been added:

Specialized Industries

Go beyond the regulations! Visit the Institute for in-depth guidance on a wide range of compliance subjects in safety and health, transportation, environment, and human resources.

J. J. Keller® COMPLIANCE NETWORK is a premier online safety and compliance community, offering members exclusive access to timely regulatory content in workplace safety (OSHA), transportation (DOT), environment (EPA), and human resources (DOL).

Interact With Our Compliance Experts

Puzzled by a regulatory question or issue? Let our renowned experts provide the answers and get your business on track to full compliance!

Upcoming Events

Reference the Compliance Network Safety Calendar to keep track of upcoming safety and compliance events. Browse by industry or search by keyword to see relevant dates and observances, including national safety months, compliance deadlines, and more.

The Environmental Protection Agency (EPA) published the Fall 2024 Semiannual Agenda of Regulatory and Deregulatory Actions on December 13, 2024. The agenda reveals the agency’s upcoming regulatory actions and where each action is in the rulemaking process.

The agenda includes major EPA updates, such as:

This article highlights some of the major rules we’re watching closely. You’ll want to review the entire agenda to learn about all the rulemakings on EPA’s docket. Please note that the agenda dates are tentative; they're when the agency seeks to publish the rulemakings in the Federal Register.

| Final Rule Stage | |

| Projected Publication Date | Title |

| December 2024 | New Source Performance Standards (NSPS) and Emission Guidelines (EG) for Large Municipal Waste Combustors (MWCs) |

| December 2024 | Removal of Affirmative Defense Provisions From Specified New Source Performance Standards and National Emission Standards for Hazardous Air Pollutants |

| January 2025 | Water System Restructuring Assessment Rule |

| March 2025 | Regulatory Requirements for New HAP Additions to Part 63 |

| July 2025 | Listing of Specific PFAS as Hazardous Constituents |

| August 2025 | Clean Water Act Effluent Limitations Guidelines and Standards for the Meat and Poultry Products Point Source Category |

| October 2025 | Revisions to Standards for the Open Burning/Open Detonation of Waste Explosives |

| November 2025 | Stationary Combustion Turbines New Source Performance Standards (NSPS) Technology Review |

| Proposed Rule Stage | |

| Projected publication date of Notice of Proposed Rulemaking | Title |

| December 2024 | Reconsideration of Standards of Performance for New, Reconstructed and Modified Sources and Emissions Guidelines for Existing Sources: Oil and Natural Gas Sector Climate Review |

| January 2025 | National Emission Standards for Hazardous Air Pollutants for the Polyether Polyols Production Industry |

| March 2025 | Clean Water Act Effluent Limitations Guidelines and Standards for PFAS Manufacturers Under the Organic Chemicals, Plastics and Synthetic Fibers Point Source Category |

| April 2025 | Phasedown of Hydrofluorocarbons: Reconsideration of Technology Transitions Final Rule Under the American Innovation and Manufacturing Act of 2020 |

| May 2025 | National Emission Standards for Hazardous Air Pollutants: Stationary Combustion Turbines; Amendments |

| June 2025 | Improving Recycling and Management of Renewable Energy Wastes: Universal Waste Regulations for Solar Panels and Lithium Batteries |

| June 2025 | PFAS Requirements in NPDES Permit Applications |

| June 2025 | Tiered Data Reporting to Inform Prioritization, Risk Evaluation and Risk Management Under the Toxic Substances Control Act (TSCA) |

| November 2025 | Revisions to Establish the Sixth Unregulated Contaminant Monitoring Rule (UCMR 6) for Public Water Systems |

| November 2025 | Revise/Update the Standards of Performance and Emission Guidelines for Municipal Solid Waste Landfills |

| Pre-Rule Stage | |

| Projected publication date or other action | Title |

| December 2024 (Notice of Proposed Rulemaking) | Lead Wheel Weights; Regulatory Investigation Under the Toxic Substances Control Act (TSCA) |

| January 2025 (End Review) | 610 Review of Standards of Performance for New Residential Wood Heaters, New Residential Hydronic Heaters and Forced-Air Furnaces |

| January 2025 (Advanced Notice of Proposed Rulemaking Comment Period End) | Regulatory Investigation of N-(1,3-Dimethylbutyl)-N′-phenyl-p-phenylenediamine ("6PPD") and its Transformation Product, 6PPD-quinone, Under the Toxic Substances Control Act (TSCA) |

Before a new chemical substance can enter the marketplace, it first travels through the New Chemicals Review Program. Section 5 of the Toxic Substances Control Act (TSCA) requires the Environmental Protection Agency (EPA) to review new chemicals for any unreasonable risk of injury they may pose to human or environmental health. The agency determines (a) whether the substances can enter the marketplace and (b) if they require restrictions to manage any unreasonable risk.

To manufacture (including import) a chemical for commercial purposes that’s not on the TSCA Chemical Substance Inventory (i.e., a new chemical), you have to submit a premanufacture notice (PMN) to EPA. In December 2024, EPA finalized the new chemicals review rule. It clarifies that when you submit a PMN, you may not manufacture the new chemical substance until the agency issues a safety determination and completes any associated actions (like developing rules to limit its use).

Start the PMN process by conducting your own review! Evaluate and prepare for the possible determinations EPA will make for your new chemical substance.

Submitting a PMN sparks the beginning of the new chemicals review process. EPA completes the review process by making one of five possible safety determinations for the new chemical.

It’s important to note that three types of determinations fall under the scope of Section 5(e) actions. If EPA makes any determination under Section 5(e), it must issue a Section 5(e) order with requirements that limit or ban the manufacture, processing, distribution in commerce, use, or disposal of the new chemical. Examples include toxicity testing, personal protective equipment for exposed workers, and environmental release restrictions.

Let’s take a look at each one.

In the most straightforward scenario, EPA can find that the new chemical isn’t likely to pose an unreasonable risk.

In this case, the agency will notify you and publish its findings in the Federal Register. Once you receive the Section 5(a)(3)(C) notice from EPA, you may begin manufacturing the new chemical substance, even if the applicable review period isn’t over.

The agency may find that a new chemical presents an unreasonable risk of injury.

It will use Section 5(f) to limit or ban the manufacture, processing, distribution in commerce, use, or disposal of the new chemical through either:

The agency may determine that it doesn’t have enough information to make a “reasoned evaluation” of the new chemical’s impact on health and the environment.

EPA will issue a Section 5(e) order with restrictions to mitigate or eliminate the unreasonable risk.

If EPA doesn’t have enough information, it can alternatively determine that the new chemical poses an unreasonable risk due to insufficient information.

The agency will issue a Section 5(e) order with restrictions to mitigate or eliminate the unreasonable risk.

On the other hand, EPA may determine that the new chemical will be produced in substantial quantities that could (a) be released in large amounts to the environment or (b) result in significant human exposure.

EPA will issue a Section 5(e) order with restrictions to mitigate or eliminate the unreasonable risk.

In December 2024, EPA finalized changes to the rule for new chemical reviews. It clarifies that the agency must make one of five statutory determinations for each PMN, significant new use notice, and microbial commercial activity notice it receives.

The final rule also:

Key to remember: EPA reviews each new chemical and makes one of five possible safety determinations that dictate both if and how the substance can enter the marketplace.

In 2022, the National Institute for Occupational Safety and Health (NIOSH) reported a staggering 658,000 workers were exposed to harmful chemicals, resulting in 839 fatalities. These statistics highlight the significant health and safety risks that an unexpected exposure to a hazardous chemical, or a substantial threat of a hazardous substance release, can pose to workers, organizations, and communities. A thorough understanding of chemical management regulations is crucial to ensure potential hazardous exposures are minimized.

OSHA’s HazCom standard (29 CFR 1910.1200) is designed to inform workers about chemical hazards and how to protect themselves.

Key definitions: A "hazardous chemical" is any chemical which is classified as a physical hazard or a health hazard, a simple asphyxiant, combustible dust, or other hazards not that may not be classified but still pose a serious danger.

Indicators: Any workplace where hazardous chemicals are used, stored, or processed needs a hazard communication program. Labels, safety data sheets (SDSs), and employee training are essential components.

Training requirements: Training must cover how to read and understand labels, the purpose and location of SDSs, and specific protective measures when handling hazardous chemicals. Training must be provided upon initial assignment and updated whenever new chemical hazards are introduced.

The DOT’s hazmat regulations (DOT 49 CFR Parts 171-180) include substances that, if transported improperly, can harm people, property, or the environment. By correctly handling and moving these materials, organizations can avoid accidents and safeguard both public health and the environment.

Key definitions: A "hazardous material" is any substance or material capable of posing an unreasonable risk when transported in commerce. This can include flammable, toxic, and reactive substances.

Indicators: Activities involving the loading, unloading, and handling of hazardous materials require adherence to hazmat regulations. This requirement also applies to organizations that make or maintain packaging, or a part of packaging, that's marked or sold as suitable for transporting hazardous materials commercially.

Training requirements: Workers handling hazmat must undergo specific training on material classification, safe handling, emergency response, and transportation. Training must be provided within 90 days of initial assignment and a refresher at least once every three years. Training must also be documented and retained for a minimum of three years.

The EPA’s hazwaste regulations (40 CFR Parts 260-299) refer to any waste material that could potentially harm the environment or human health if not managed correctly. Additionally, many states have hazardous waste requirements beyond EPA regulations.

Key Definitions: Hazardous waste includes materials classified as toxic, ignitable, corrosive, or reactive, based on specific criteria.

Indicators: Managing hazardous waste follows the material’s entire lifecycle including the generation, transportation, treatment, storage, and disposal, known as "cradle-to-grave." Requirements are based on the quantity of waste generated.

Training requirements: Employees involved in hazardous waste management must receive training on waste handling, storage, labeling, and disposal procedures. Annual training requirements are based on generator quantity status.

OSHA’s HAZWOPER standard (29 CFR 1910.120) protects workers involved in hazardous waste management and emergency response. HAZWOPER covers a wide range of activities, including cleanup operations and responses to hazardous substance releases.

Key definitions: A hazardous substance is any material that can harm health and safety if released into the environment. In the context of HAZWOPER, this includes materials that pose risks in emergencies, such as spills, leaks, or other uncontrolled releases.

Indicators: Workers and organizations tasked with hazardous waste cleanup, spill response, and emergency operations require specialized training, equipment, and procedures.

Training requirements: HAZWOPER training is intensive and includes specific requirements depending on job roles. Training levels include 24-hour, 40-hour, and 8-hour refresher courses for different exposure risks. Employees learn about hazardous substance properties, emergency response procedures, PPE use, and decontamination processes.

OSHA’s PSM standard (29 CFR 1910.119) aims to prevent accidental chemical releases that could seriously harm employees or the environment by including safety measures, risk assessments, and employee training to ensure safe operations. It is especially important in industries handling highly hazardous chemicals including facilities with high-risk chemical processes.

Key definitions: OSHA defines a "highly hazardous chemical" as any substance that poses a significant risk of causing serious harm to people, property, or the environment due to its toxic, reactive, flammable, or explosive properties.

Indicators: Any workplace handling large volumes of hazardous chemicals or using complex chemical processes including chemicals that are specifically listed by OSHA in appendix A of the standard, are present in quantities above specified thresholds, or exhibit properties that make them likely to cause a major incident.

Training requirements: PSM training covers safe operating procedures, hazard analysis, and incident investigation for employees involved in high-risk processes. Training must be provided at initial assignment and a refresher at least once every three years.

Key to remember: Chemical management is a complex task. Understanding what regulatory requirements apply will ensure compliance as well as minimize the chance for dangerous incidents.

December 2024 marks the 40th anniversary of one of history’s worst industrial incidents — the release of a deadly gas at a chemical plant in Bhopal, India. This incident, along with another in West Virginia in 1985, spurred U.S. legislative and regulatory action. However, some might say that work is not finished.

Think of the Emergency Planning and Community Right-to-Know Act (EPCRA) of 1986, the EPA Risk Management Program (RMP) standard, and the OSHA Process Safety Management (PSM) standard, for example. You’ll find roots to the Bhopal disaster.

It was late on December 2, 1984, at a chemical facility. A faulty valve leaked water into a tank of methyl isocyanate (or MIC). This prompted a violent reaction inside the tank. History tells us that at about 1:00 a.m. on that fateful December 3, the failure of a safety valve triggered a massive release. A dense, lethal cloud of MIC and other chemicals drifted over the city of Bhopal.

By dawn, thousands of residents were dead, along with birds, dogs, cows, and other animals. The injured flocked to hospitals in overwhelming numbers. A lack of information about just what the chemicals were, however, compounded the catastrophe.

India officials reported half a million or more chemical exposures. Estimates vary, but as many as 10,000 people perished in the initial few days. Tens of thousands died prematurely in the decades to follow, according to sources.

In August 1985, a chemical release in Institute, West Virginia, showed Americans that a “Bhopal-like” incident could happen here. Aldicarb oxime and other chemicals released from the facility, and over 125 residents landed in the hospital. Again, a lack of available chemical information was noteworthy. Many U.S. citizens began to fear they faced catastrophic risks.

In the wake of the incidents, Congress enacted laws:

Together, they required EPA and OSHA to issue regulations to:

Congress also established the Chemical Safety and Hazard Investigation Board (CSB) to investigate chemical incidents and recommend measures to prevent them. Despite these actions, the U.S. continues to experience serious chemical incidents. A visit to the CSB or National Response Center (NRC) websites reveals countless incident reports since 1990. A look at the 2024 data finds:

Ten years ago, on the 30th anniversary of the Bhopal disaster, CSB posted a six-minute video explaining how the tragedy occurred. The video also examines more recent U.S. incidents. It emphasizes what more could be done to prevent similar incidents.

CSB investigations around the time of the video found deficiencies in design and PSM, similar to those uncovered in Bhopal! CSB Chairperson Rafael Moure-Eraso argued: “Process safety management regulations are in need of reform. There must be more emphasis on preventing the occurrence of major chemical accidents through safer design. Responding to emergencies and punishing people after the fact are not enough.”

Another headline-making incident in April 2013 involved a massive explosion of ammonium nitrate at a fertilizer storage/distribution facility in West, Texas. It fatally injured 12 volunteer firefighters and two members of the public and caused hundreds of injuries. The incident prompted the Executive Order on Improving Chemical Facility Safety and Security (EO 13650) on August 1, 2013. The order directed the federal government to:

The feds held listening sessions and issued a flurry of fact sheets, alerts, and enforcement policy changes (See here and here.). Note that the RMP regulation at 40 CFR 68 was eventually amended this year on March 11, 2024. The PSM standard remains unchanged, despite a request for information on December 9, 2013. In an about-face, Congress allowed the Chemical Facility Anti-Terrorism Standards program (at 6 CFR 27) to expire on July 28, 2023, but many in Congress and industry would like to see its return.

This month marks the 40th anniversary of the Bhopal chemical disaster. It sparked the U.S. Congress to take steps back then to prevent such a disaster from occurring here. Those actions did not spell the end to all chemical disasters in the U.S. In response, a renewed push for regulatory reforms popped up in the last decade.

Leak detection on an underground tank storing petroleum or other hazardous materials can be the factor that prevents a release from turning into a contamination catastrophe. A leak (or release) detection system alerts tank operators and owners of potential releases, allowing them to respond and limit contamination quickly.

The Environmental Protection Agency (EPA) requires regulated underground storage tanks (USTs) to have release detection systems. Here are five things you should know about complying with UST leak detection requirements.

EPA’s release detection requirements (40 CFR Part 280 Subpart D) apply to USTs and any underground piping connected to the tanks.

Owners and operators must equip each regulated UST and piping with leak detection that:

The UST’s date of installation or replacement determines the release detection methods that owners and operators can use for the tank. There are three categories of release detection methods:

Owners and operators of USTs installed on or before April 11, 2016, choose at least one leak detection method from the range of interstitial, internal, and external options (or another method approved by the implementing agency). However, owners and operators of USTs installed or replaced after April 11, 2016, must use secondary containment with interstitial monitoring.

The release detection methods for piping that UST owners and operators can use are based on (a) the date of installation or replacement and (b) the type of piping.

Pressurized piping installed on or before April 11, 2016, must:

Pressurized piping installed or replaced after April 11, 2016, must also have an automatic line leak detector and use secondary containment with interstitial monitoring.

Suction piping installed on or before April 11, 2016, must use monthly monitoring or line testing every three years (unless the piping is exempt from requirements). Suction piping installed or replaced after April 11, 2016, must use secondary containment with interstitial monitoring (unless the piping is exempt from requirements).

EPA revised the UST regulations in 2015, requiring all new and replaced tanks and piping to use secondary containment with interstitial monitoring for release detection. For example, say you have a UST installed before April 11, 2016, but you have to replace its piping. You must use secondary containment with interstitial monitoring for the replaced piping.

Secondary containment refers to a physical barrier between the UST and the environment, such as a double-walled tank or internally fitted liner. If the UST leaks, the barrier holds the leak between the tank and the barrier so it can be detected.

The interstitial monitor detects leaks between the tank and the barrier and alerts owners and operators of a potential leak. Monitoring devices range from physical dipsticks to high-tech pressure and liquid-detecting sensors.

Many states implement the UST regulatory program. State requirements must be at least equal to EPA’s, and in some cases, they may be more stringent.

Whether you have one UST at a facility or several at facilities across the country, it’s vital to check state requirements to ensure you comply with all applicable standards.

UST release detection systems can help your facility prevent potential leaks from turning into environmental — and compliance — disasters.

Key to remember: EPA requires underground storage tanks to have release detection systems that alert owners and operators quickly to potential leaks.

Future emission requirements for certain power plants and other industrial sources across 23 states remain up in the air. The Environmental Protection Agency (EPA) published the Third Final Interim Rule for its Good Neighbor Plan (GNP) in October 2024, officially pausing the federal emissions-control program in all affected states as legal battles continue.

So, the GNP requirements are paused, but what does that mean for the facilities covered by the rule?

The GNP is a federal program for 23 states that requires fossil fuel-fired power plants and other industrial facilities (such as manufacturers and solid waste incinerators) to lower emissions of ozone-forming nitrogen oxides (NOx) that hinder downwind states’ ability to achieve and maintain the 2015 Ozone National Ambient Air Quality Standards (NAAQS).

EPA issued the First and Second Interim Final Rules in 2023 in response to a judicial order to partially stay the agency’s disapproval of State Implementation Plans (SIPs) for implementing the NAAQS. The rules temporarily stopped enforcement of the GNP in 12 states.

In July 2024, the U.S. Supreme Court issued an order of stay for three other states challenging the GNP rule in a separate case. EPA responded to the Supreme Court with the Third Interim Final Rule. Although the Supreme Court’s order addresses only the states involved in the case, the rule pauses the GNP’s requirements for the emissions sources in all remaining 11 states.

Until the GNP rule is settled, power plants and industrial facilities must meet the less stringent 2008 Ozone NAAQS. Two rules address interstate emissions for this standard:

For the interim, power plants in states with previous interstate air pollution requirements for the 2008 Ozone NAAQS are subject to equivalent requirements established by the CSAPR and Revised CSAPR rules:

The interim rules also make allowances interchangeable for power plants in some states for Group 2 trading program compliance, including Illinois, Indiana, Kentucky, Louisiana, Maryland, Michigan, New Jersey, New York, Ohio, Pennsylvania, Virginia, and West Virginia.

Power plants in Alabama, Arkansas, Mississippi, Missouri, Oklahoma, and Texas retain their banked Group 2 allowances. Also, Kentucky, Louisiana, and West Virginia may convert banked 2021–22 Group 3 allowances to Group 2 allowances.

Power plants in Illinois, Indiana, Maryland, Michigan, New Jersey, New York, Ohio, Pennsylvania, Virginia, and Wisconsin may convert their 2021–23 Group 3 allowances to Group 2 allowances. However, EPA will recall the 2024 Group 3 allowances issued before the stay order.

Power plants in Minnesota, Nevada, and Utah weren’t covered by previous ozone NAAQS requirements, so they maintain the status quo. Additionally, California power plants aren’t subject to GNP requirements.

Most of the GNP’s requirements for industrial facilities don’t begin until the start of the 2026 ozone season (May 1, 2026). EPA won’t enforce the deadlines that occur before then for procedural requirements, such as submitting optional case-by-case emissions limits requests.

For now, the future of the GNP remains unclear due to ongoing litigation. EPA’s administrative stay remains in effect until:

Plus, if a state’s judicial stay order due to SIP disapproval is lifted, the agency won’t remove the stay for the state’s emissions sources until the Supreme Court lifts its stay order.

Key to remember: EPA’s final interim rules establish temporary compliance requirements for power plants and other industrial sources while the Good Neighbor Plan remains paused.

Hi everyone! Welcome to the monthly news roundup video, where we’ll review the most impactful environmental, health, and safety news. Please view the content links in the transcript for more information about the topics I’ll be covering today. Let’s get started!

A Government Accountability Office report says OSHA can do more to protect warehouse and delivery workers from ergonomic injuries. The report recommends several steps for OSHA to consider, including ensuring compliance officers can easily obtain data on when musculoskeletal disorders occurred.

OSHA updated its inspection guidance for animal slaughtering and processing industries. Inspections will focus on several hazards, including sanitation, ergonomics, and machine guarding. Among other changes, compliance officers will conduct inspections during off-shift times and identify workplace activities that impact employees most at risk such as temporary employees.

OSHA urges workers involved in hurricane cleanup and recovery efforts to be mindful of hazards, especially those associated with restoring electricity, removing debris, and trimming trees. Proper training, experience, and familiarity with related equipment helps ensure worker safety.

And finally, turning to environmental news, EPA extended the 2024 Chemical Data Reporting deadline to November 22 due to technical difficulties with its electronic reporting tool. The 2024 report covers activities that occurred between calendar years 2020 and 2023.

Thanks for tuning in to the monthly news roundup. We’ll see you next month!

As the year draws to a close, it’s essential for environmental professionals to take proactive steps to ensure a smooth transition into the new year. As an environmental professional working in the industry, I always took this time to address key tasks to avoid last-minute stress and position my organization for a successful environmental compliance year. Here are a few tips and reminders for you to consider.

It’s a good time to verify expiration dates and to ensure all permits and licenses are current and valid. Identify renewal requirements and gather necessary documentation and information for upcoming renewals. Take corrective actions to rectify any violations or deficiencies.

If Tier II reporting applies to your facility, start gathering information on hazardous chemicals stored or handled on-site. The March 1 deadline will approach quickly, and you’ll want to be prepared.

The end of the year provides an opportunity to review and assess your organization’s environmental performance and identify areas for improvement. Use your experience throughout the year to guide you as you develop corrective action plans. Review and update emergency response plans. Verify that contact information, procedures, and equipment are up to date.

File documents and store all environmental records in a systematic and organized manner. Consider scanning important documents to create electronic copies. Establish guidelines for retaining environmental records to comply with legal requirements.

Things can change rapidly during the year, and much-needed tasks can fall by the wayside. By carving out time at the end of the year to complete these tasks, you can set a strong foundation for a successful and compliant new year.

Are your aboveground storage tanks (ASTs) engineered to avoid overfills during oil transfers? EPA issued a technical alert to highlight the importance of overfill prevention measures. Having these systems is not enough, though. They must be properly designed, operated, maintained, and inspected.

The 13-page alert (EPA 540-S-24-001) aims at owners and operators of “substantial harm oil storage facilities.” These facilities are often covered by 40 CFR 112, including both the oil Spill Prevention, Control, and Countermeasure (SPCC) regulations and oil Facility Response Plan (FRP) regulations.

Implementing overfill prevention is mandated by part 112. That’s because these critical systems alert you to potential container overfills. Overfills are often the cause of oil discharges.

Overfills of large ASTs during high-volume oil transfers have led to:

The alert showcases two headline-making incidents to illustrate the danger:

Overfills can happen, but they are preventable! The alert explains that overfill prevention systems commonly used at facilities monitor liquid levels in tanks. These prevention systems include:

The trouble is, when these systems fail, overfills can still occur. Therefore, it’s critical to take other measures. Adequate system maintenance, inspection, implementation, nighttime security lighting, training, and procedures are examples.

So, oil discharges to the environment and waterways may be prevented and/or minimized with the help of overfill prevention systems. At the same time, however, owners and operators need to implement:

EPA’s technical alert addresses adequately designed, implemented, and maintained overfill prevention systems. The alert explores:

Thirteen references and their links are included. Two worth noting are:

If you have an SPCC- and/or FRP-regulated facility, EPA urges you to review the alert. You should also consider whether more action is needed to address these requirements at your oil storage facility.

EPA issued a technical alert to highlight the importance of overfill prevention measures. The agency says they must be properly designed, operated, maintained, and inspected.

Did you know that the chemicals your facility makes and processes could be subject to additional testing requirements? Through a Section 4 Test Order under the Toxic Substances Control Act (TSCA), the Environmental Protection Agency (EPA) can require manufacturers (including importers) and processors to test and submit information on existing chemicals and mixtures through the agency’s Central Data Exchange (CDX).

For example, EPA issued the fifth TSCA Section 4 Test Order for per- and polyfluoroalkyl substances (PFAS) in October 2024. Five companies must submit information on the PFAS commonly known as 6:2 FTAc (used to manufacture plastics, resins, textiles, apparel, leather, and other chemicals), which the agency found may present an unreasonable risk of injury to human health or the environment.

How will your facility respond if it receives a TSCA Section 4 Test Order? Let’s look at the four response options.

Entities that receive a test order must first submit an identification response within 30 days of the order’s effective date. You can identify as a manufacturer, processor, or both.

If you don’t manufacture or process the chemical or believe EPA mistakenly sent you the order, you may claim that you’re not subject to the order. Provide supporting information with the claim in the identification response.

Companies subject to the test order then submit an initial response to tell EPA how it will comply. There are four response options:

You can choose a different response for every test required by the order. Let’s zoom in on each option.

The most straightforward response is to conduct the test(s) and generate the information. The order contains everything you need to know, including:

Alternatively, if you believe EPA hasn’t considered relevant information, you can submit an existing study and/or other relevant information. Include a rationale document that explains how the existing information you present fulfills the test order’s requirements and which information it covers (i.e., Does it provide parts of or all the needed information?).

If EPA finds any of the existing data you submit acceptable, the agency will remove the obligations in the test order that the existing information fulfills. However, if the agency determines the existing information isn’t acceptable, you must submit a different response option within 10 days of EPA’s rejection.

EPA grants exemptions to avoid duplicating information. You may be exempt from a test order if:

Include with your exemption application a rationale document that identifies:

You must also include a sworn statement of financial responsibility to reimburse the entity(ies) that paid the costs to submit the testing information if your exemption is granted.

EPA allows companies subject to the same test order to form a consortium to share the costs of generating the required information (including testing and fees).

To begin, inform EPA individually of the specific chemicals and tests you plan to address through a consortium. The individual designated as the lead in the consortium then submits the initial response on behalf of all entities in the group.

Organizations interested in joining a consortium must contact EPA’s TSCA Hotline by email (tsca-hotline@epa.gov) or phone call ((202) 554-1404).

Consider these helpful tips when choosing how to respond to a TSCA Section 4 Test Order:

Key to remember: EPA’s TSCA Section 4 Test Orders require manufacturers (including importers) and processors to develop information on existing chemicals. Companies subject to the order have four response options.

ENVIRONMENTAL PROTECTION AGENCY

40 CFR Parts 9 and 721

[EPA-HQ-OPPT-2020-0497; FRL-8215-01-OCSPP]

RIN 2070-AB27

Significant New Use Rules on Certain Chemical Substances (20-10.B)

AGENCY: Environmental Protection Agency (EPA).

ACTION: Final rule.

SUMMARY: EPA is issuing significant new use rules (SNURs) under the Toxic Substances Control Act (TSCA) for chemical substances which were the subject of premanufacture notices (PMNs). This action requires persons to notify EPA at least 90 days before commencing manufacture (defined by statute to include import) or processing of any of these chemical substances for an activity that is designated as a significant new use by this rule. This action further requires that persons not commence manufacture or processing for the significant new use until they have submitted a Significant New Use Notice (SNUN), EPA has conducted a review of the notice, made an appropriate determination on the notice, and has taken any risk management actions as are required as a result of that determination.

DATES: This rule is effective on January 14, 2022. For purposes of judicial review, this rule shall be promulgated at 1 p.m. (e.s.t.) on November 29, 2021.

FOR FURTHER INFORMATION CONTACT:

For technical information contact: William Wysong, New Chemicals Division (7405M), Office of Pollution Prevention and Toxics, Environmental Protection Agency, 1200 Pennsylvania Ave. NW, Washington, DC 20460-0001; telephone number: (202) 564-4163; email address: wysong.william@epa.gov.

For general information contact: The TSCA-Hotline, ABVI-Goodwill, 422 South Clinton Ave., Rochester, NY 14620; telephone number: (202) 554-1404; email address: TSCA-Hotline@epa.gov.

SUPPLEMENTARY INFORMATION:

I. General Information

A. Does this action apply to me?

You may be potentially affected by this action if you manufacture, process, or use the chemical substances contained in this rule. The following list of North American Industrial Classification System (NAICS) codes is not intended to be exhaustive, but rather provides a guide to help readers determine whether this document applies to them. Potentially affected entities may include:

This action may also affect certain entities through pre-existing import certification and export notification rules under TSCA, which would include the SNUR requirements. Chemical importers are subject to the TSCA section 13 (15 U.S.C. 2612) import provisions. The EPA policy in support of import certification appears at 40 CFR part 707, subpart B. In addition, pursuant to 40 CFR 721.20, any persons who export or intend to export a chemical substance that is the subject of this rule are subject to the export notification provisions of TSCA section 12(b) (15 U.S.C. 2611(b)), and must comply with the export notification requirements in 40 CFR part 707, subpart D.

B. How can I access the docket?

The docket includes information considered by the Agency in developing the proposed and final rules. The docket for this action, identified by docket identification (ID) number EPA-HQ-OPPT-2020-0497, is available at https://www.regulations.gov and at the Office of Pollution Prevention and Toxics Docket (OPPT Docket), Environmental Protection Agency Docket Center (EPA/DC), West William Jefferson Clinton Bldg., Rm. 3334, 1301 Constitution Ave. NW, Washington, DC. The Public Reading Room is open from 8:30 a.m. to 4:30 p.m., Monday through Friday, excluding legal holidays. The telephone number for the Public Reading Room is (202) 566-1744, and the telephone number for the OPPT Docket is (202) 566-0280. Please review the visitor instructions and additional information about the docket available at https://www.epa.gov/dockets.

Due to the public health emergency, the EPA Docket Center (EPA/DC) and Reading Room is closed to visitors with limited exceptions. The staff continues to provide remote customer service via email, phone, and webform. For the latest status information on EPA/DC services and docket access, visit https://www.epa.gov/dockets.

II. Background

A. What action is the Agency taking?

EPA is finalizing SNURs under TSCA section 5(a)(2) for chemical substances which were the subject of PMNs P-18-289, P-18-330, P-18-334, P-18-335, and P-18-337. These SNURs require persons who intend to manufacture or process any of these chemical substances for an activity that is designated as a significant new use to notify EPA at least 90 days before commencing that activity.

Previously, in the Federal Register of October 20, 2020 (85 FR 66506) (FRL-10015-28), EPA proposed SNURs for these chemical substances. More information on the specific chemical substances subject to this final rule can be found in the Federal Register document proposing the SNURs. The docket includes information considered by the Agency in developing the proposed and final rules, including public comments and EPA's responses to the public comments received on the proposed rules, as described in Unit IV.

B. What is the Agency's authority for taking this action?

TSCA section 5(a)(2) (15 U.S.C. 2604(a)(2)) authorizes EPA to determine that a use of a chemical substance is a “significant new use.” EPA must make this determination by rule after considering all relevant factors, including the four TSCA section 5(a)(2) factors listed in Unit III.

C. Do the SNUR general provisions apply?

General provisions for SNURs appear in 40 CFR part 721, subpart A. These provisions describe persons subject to the rule, recordkeeping requirements, exemptions to reporting requirements, and applicability of the rule to uses occurring before the effective date of the rule. Provisions relating to user fees appear at 40 CFR part 700. Pursuant to 40 CFR 721.1(c), persons subject to these SNURs must comply with the same SNUN requirements and EPA regulatory procedures as submitters of PMNs under TSCA section 5(a)(1)(A). In particular, these requirements include the information submission requirements of TSCA sections 5(b) and 5(d)(1), the exemptions authorized by TSCA sections 5(h)(1), 5(h)(2), 5(h)(3), and 5(h)(5) and the regulations at 40 CFR part 720. Once EPA receives a SNUN, EPA must either determine that the significant new use is not likely to present an unreasonable risk of injury or take such regulatory action as is associated with an alternative determination before manufacture or processing for the significant new use can commence. If EPA determines that the significant new use is not likely to present an unreasonable risk, EPA is required under TSCA section 5(g) to make public, and submit for publication in the Federal Register , a statement of EPA's findings.

III. Significant New Use Determination

A. Determination Factors

TSCA section 5(a)(2) states that EPA's determination that a use of a chemical substance is a significant new use must be made after consideration of all relevant factors, including:

In determining what would constitute a significant new use for the chemical substances that are the subject of these SNURs, EPA considered relevant information about the toxicity of the chemical substances, and potential human exposures and environmental releases that may be associated with the substances, in the context of the four bulleted TSCA section 5(a)(2) factors listed in this unit. During its review of these chemicals, EPA identified certain conditions of use that are not intended by the submitters, but reasonably foreseen to occur. EPA is designating those reasonably foreseen conditions of use as well as certain other circumstances of use as significant new uses.

B. Procedures for Significant New Uses Claimed as Confidential Business Information (CBI)

By this rule, EPA is establishing certain significant new uses which have been claimed as CBI subject to Agency confidentiality regulations at 40 CFR part 2 and 40 CFR part 720, subpart E. Absent a final determination or other disposition of the confidentiality claim under 40 CFR part 2 procedures, EPA is required to keep this information confidential. EPA promulgated a procedure to deal with the situation where a specific significant new use is CBI, at 40 CFR 721.1725(b)(1) and has referenced it to apply to other SNURs.

Under these procedures a manufacturer or processor may request EPA to determine whether a specific use would be a significant new use under the rule. The manufacturer or processor must show that it has a bona fide intent to manufacture or process the chemical substance and must identify the specific use for which it intends to manufacture or process the chemical substance. If EPA concludes that the person has shown a bona fide intent to manufacture or process the chemical substance, EPA will tell the person whether the use identified in the bona fide submission would be a significant new use under the rule. Since most of the chemical identities of the chemical substances subject to these SNURs are also CBI, manufacturers and processors can combine the bona fide submission under the procedure in 40 CFR 721.1725(b)(1) with that under 40 CFR 721.11 into a single step.

If EPA determines that the use identified in the bona fide submission would not be a significant new use, i.e., the use does not meet the criteria specified in the rule for a significant new use, that person can manufacture or process the chemical substance so long as the significant new use trigger is not met. In the case of a production volume trigger, this means that the annual production volume limit is not exceeded by the amount identified in the bona fide submission to EPA. Because of confidentiality concerns, EPA does not typically disclose the actual production volume that constitutes the use trigger. Thus, if the person later intends to exceed that volume, a new bona fide submission would be necessary to determine whether that higher volume would be a significant new use.

IV. Public Comments

EPA received a public comment from one identifying entity on the proposed rule. The Agency's response is described in a separate Response to Public Comments document that is available in the public docket for this rulemaking. In addition, EPA received three anonymous comments. They were either general in nature and did not pertain to the proposed rule or were broadly supportive of the rule and requested no changes to the rule itself; therefore, no response is required. EPA made no changes to the final rule based on these comments.

V. Substances Subject to This Rule

EPA is establishing significant new use and recordkeeping requirements for chemical substances in 40 CFR part 721, subpart E. In Unit IV. of the proposed SNUR, EPA provided the following information for each chemical substance:

The regulatory text section of these rules specifies the activities designated as significant new uses. Certain new uses, including production volume limits and other uses designated in the rules, may be claimed as CBI.

VI. Rationale and Objectives of the Rule

A. Rationale

During review of the PMNs submitted for the chemical substances that are the subject of these SNURs and as further discussed in Unit IV. of the proposed rule, EPA identified certain other reasonably foreseen conditions of use in addition to those conditions of use intended by the submitter. EPA has determined that the chemical under the intended conditions of use is not likely to present an unreasonable risk. However, EPA has not assessed risks associated with the reasonably foreseen conditions of use. EPA is designating these conditions of use as well as certain other circumstances of use as significant new uses. As a result, those significant new uses cannot occur without going through a separate, subsequent EPA review and determination process associated with a SNUN.

B. Objectives

EPA is issuing these SNURs because the Agency wants:

Issuance of a SNUR for a chemical substance does not signify that the chemical substance is listed on the TSCA Inventory. Guidance on how to determine if a chemical substance is on the TSCA Inventory is available on the internet at https://www.epa.gov/tsca-inventory.

VII. Applicability of the Rules to Uses Occurring Before the Effective Date of the Final Rule

To establish a significant new use, EPA must determine that the use is not ongoing. The chemical substances subject to this rule were undergoing premanufacture review at the time of signature of the proposed rule and were not on the TSCA inventory. In cases where EPA has not received a notice of commencement (NOC) and the chemical substance has not been added to the TSCA Inventory, no person may commence such activities without first submitting a PMN. Therefore, for the chemical substances subject to these SNURs, EPA concluded at the time of signature of the proposed rule that the designated significant new uses were not ongoing.

EPA designated October 7, 2020 (the date of web posting of the proposed rule) as the cutoff date for determining whether the new use is ongoing. The objective of EPA's approach is to ensure that a person cannot defeat a SNUR by initiating a significant new use before the effective date of the final rule.

Persons who began commercial manufacture or processing of the chemical substances for a significant new use identified on or after that date will have to cease any such activity upon the effective date of the final rule. To resume their activities, these persons would have to first comply with all applicable SNUR notification requirements and EPA would have to take action under TSCA section 5 allowing manufacture or processing to proceed.

VIII. Development and Submission of Information

EPA recognizes that TSCA section 5 does not require development of any particular new information (e.g., generating test data) before submission of a SNUN. There is an exception: If a person is required to submit information for a chemical substance pursuant to a rule, Order or consent agreement under TSCA section 4, then TSCA section 5(b)(1)(A) requires such information to be submitted to EPA at the time of submission of the SNUN.

In the absence of a rule, Order, or consent agreement under TSCA section 4 covering the chemical substance, persons are required only to submit information in their possession or control and to describe any other information known to or reasonably ascertainable by them (see 40 CFR 720.50). However, upon review of PMNs and SNUNs, the Agency has the authority to require appropriate testing. Unit IV. of the proposed rule lists potentially useful information for all SNURs listed here. Descriptions are provided for informational purposes. The potentially useful information identified in Unit IV. of the proposed rule will be useful to EPA's evaluation in the event that someone submits a SNUN for the significant new use. Companies who are considering submitting a SNUN are encouraged, but not required, to develop the information on the substance, which may assist with EPA's analysis of the SNUN.

EPA strongly encourages persons, before performing any testing, to consult with the Agency pertaining to protocol election. Furthermore, pursuant to TSCA section 4(h), which pertains to reduction of testing in vertebrate animals, EPA encourages consultation with the Agency on the use of alternative test methods and strategies (also called New Approach Methodologies, or NAMs), if available, to generate the recommended test data. EPA encourages dialog with Agency representatives to help determine how best the submitter can meet both the data needs and the objective of TSCA section 4(h). For more information on alternative test methods and strategies to reduce vertebrate animal testing, visit https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/alternative-test-methods-and-strategies-reduce.

The potentially useful information described in Unit IV. of the proposed rule may not be the only means of providing information to evaluate the chemical substance associated with the significant new uses. However, submitting a SNUN without any test data may increase the likelihood that EPA will take action under TSCA sections 5(e) or 5(f). EPA recommends that potential SNUN submitters contact EPA early enough so that they will be able to conduct the appropriate tests.

SNUN submitters should be aware that EPA will be better able to evaluate SNUNs which provide detailed information on the following:

IX. SNUN Submissions

According to 40 CFR 721.1(c), persons submitting a SNUN must comply with the same notification requirements and EPA regulatory procedures as persons submitting a PMN, including submission of test data on health and environmental effects as described in 40 CFR 720.50. SNUNs must be submitted on EPA Form No. 7710-25, generated using e-PMN software, and submitted to the Agency in accordance with the procedures set forth in 40 CFR 720.40 and 721.25. E-PMN software is available electronically at https://www.epa.gov/reviewing-new-chemicals-under-toxic-substances-control-act-tsca.

X. Economic Analysis

EPA has evaluated the potential costs of establishing SNUN requirements for potential manufacturers and processors of the chemical substances subject to this rule. EPA's complete economic analysis is available in the docket for this rulemaking.

XI. Statutory and Executive Order Reviews

Additional information about these statutes and executive orders can be found at https://www.epa.gov/laws-regulations-and-executive-orders.

A. Executive Order 12866: Regulatory Planning and Review and Executive Order 13563: Improving Regulations and Regulatory Review

This action establishes SNURs for new chemical substances that were the subject of PMNs. The Office of Management and Budget (OMB) has exempted these types of actions from review under Executive Orders 12866 (58 FR 51735, October 4, 1993) and 13563 (76 FR 3821, January 21, 2011).

B. Paperwork Reduction Act (PRA)

According to PRA, 44 U.S.C. 3501 et seq., an agency may not conduct or sponsor, and a person is not required to respond to a collection of information that requires OMB approval under PRA, unless it has been approved by OMB and displays a currently valid OMB control number. The OMB control numbers for EPA's regulations in title 40 of the CFR, after appearing in the Federal Register, are listed in 40 CFR part 9, and included on the related collection instrument or form, if applicable.

The information collection requirements related to this action have already been approved by OMB pursuant to PRA under OMB control number 2070-0012 (EPA ICR No. 574). This action does not impose any burden requiring additional OMB approval. If an entity were to submit a SNUN to the Agency, the annual burden is estimated to average between 30 and 170 hours per response. This burden estimate includes the time needed to review instructions, search existing data sources, gather and maintain the data needed, and complete, review, and submit the required SNUN.

The listing of the OMB control numbers of the collection instruments and their subsequent codification in the table in 40 CFR 9.1 satisfies the display requirements of the PRA and OMB's implementing regulations at 5 CFR part 1320. Since this ICR was previously subject to public notice and comment prior to OMB approval, and given the technical nature of the table in 40 CFR part 9, EPA finds that further notice and comment to amend it is unnecessary. As a result, EPA finds that there is “good cause” under section 553(b)(3)(B) of the Administrative Procedure Act (5 U.S.C. 553(b)(3)(B)) to amend this table in 40 CFR 9.1 without further notice and comment.

C. Regulatory Flexibility Act (RFA)

Pursuant to RFA section 605(b), 5 U.S.C. 601 et seq., I hereby certify that promulgation of this SNUR would not have a significant adverse economic impact on a substantial number of small entities. The requirement to submit a SNUN applies to any person (including small or large entities) who intends to engage in any activity described in the final rule as a “significant new use.” Because these uses are “new,” based on all information currently available to EPA, it appears that no small or large entities presently engage in such activities. A SNUR requires that any person who intends to engage in such activity in the future must first notify EPA by submitting a SNUN. Although some small entities may decide to pursue a significant new use in the future, EPA cannot presently determine how many, if any, there may be. However, EPA's experience to date is that, in response to the promulgation of SNURs covering over 1,000 chemicals, the Agency receives only a small number of notices per year. For example, the number of SNUNs received was seven in Federal fiscal year (FY) 2013, 13 in FY2014, six in FY2015, 12 in FY2016, 13 in FY2017, and 11 in FY2018. Only a fraction of these were from small businesses. In addition, the Agency currently offers relief to qualifying small businesses by reducing the SNUN submission fee from $16,000 to $2,800. This lower fee reduces the total reporting and recordkeeping of cost of submitting a SNUN to about $10,116 for qualifying small firms. Therefore, the potential economic impacts of complying with this SNUR are not expected to be significant or adversely impact a substantial number of small entities. In a SNUR that published in the Federal Register of June 2, 1997 (62 FR 29684) (FRL-5597-1), the Agency presented its general determination that final SNURs are not expected to have a significant economic impact on a substantial number of small entities, which was provided to the Chief Counsel for Advocacy of the Small Business Administration.

D. Unfunded Mandates Reform Act (UMRA)

Based on EPA's experience with proposing and finalizing SNURs, State, local, and Tribal governments have not been impacted by these rulemakings, and EPA does not have any reasons to believe that any State, local, or Tribal government will be impacted by this action. As such, EPA has determined that this action does not impose any enforceable duty, contain any unfunded mandate, or otherwise have any effect on small governments subject to the requirements of UMRA sections 202, 203, 204, or 205 (2 U.S.C. 1501 et seq. ).

E. Executive Order 13132: Federalism

This action will not have federalism implications because it is not expected to have a substantial direct effect on States, on the relationship between the National Government and the States, or on the distribution of power and responsibilities among the various levels of government, as specified in Executive Order 13132 (64 FR 43255, August 10, 1999).

F. Executive Order 13175: Consultation and Coordination With Indian Tribal Governments

This action will not have Tribal implications because it is not expected to have substantial direct effects on Indian Tribes, significantly or uniquely affect the communities of Indian Tribal governments and does not involve or impose any requirements that affect Indian Tribes. Accordingly, the requirements of Executive Order 13175 (65 FR 67249, November 9, 2000), do not apply to this action.

G. Executive Order 13045: Protection of Children From Environmental Health and Safety Risks

This action is not subject to Executive Order 13045 (62 FR 19885, April 23, 1997), because this is not an economically significant regulatory action as defined by Executive Order 12866, and this action does not address environmental health or safety risks disproportionately affecting children.

H. Executive Order 13211: Actions Concerning Regulations That Significantly Affect Energy Supply, Distribution, or Use

This action is not subject to Executive Order 13211 (66 FR 28355, May 22, 2001), because this action is not a significant regulatory action under Executive Order 12866.

I. National Technology Transfer and Advancement Act (NTTAA)

In addition, since this action does not involve any technical standards, NTTAA section 12(d), 15 U.S.C. 272 note, does not apply to this action.

J. Executive Order 12898: Federal Actions To Address Environmental Justice in Minority Populations and Low-Income Populations

This action does not entail special considerations of environmental justice related issues as delineated by Executive Order 12898 (59 FR 7629, February 16, 1994).

K. Congressional Review Act (CRA)

This action is subject to the CRA, 5 U.S.C. 801 et seq., and EPA will submit a rule report containing this rule and other required information to each House of the Congress and to the Comptroller General of the United States. This action is not a “major rule” as defined by 5 U.S.C. 804(2).

List of Subjects

40 CFR Part 9

Environmental protection, Reporting and recordkeeping requirements.

40 CFR Part 721

Environmental protection, Chemicals, Hazardous substances, Reporting and recordkeeping requirements.

Dated: October 26, 2021.

Tala Henry,

Deputy Director, Office of Pollution Prevention and Toxics.

Therefore, for the reasons stated in the preamble, EPA is amending 40 CFR chapter I as follows:

PART 9—OMB APPROVALS UNDER THE PAPERWORK REDUCTION ACT

1. The authority citation for part 9 continues to read as follows:

Authority:

7 U.S.C. 135 et seq., 136-136y; 15 U.S.C. 2001, 2003, 2005, 2006, 2601-2671; 21 U.S.C. 331j, 346a; 31 U.S.C. 9701; 33 U.S.C. 1251 et seq., 1311, 1313d, 1314, 1318, 1321, 1326, 1330, 1342, 1344, 1345 (d) and (e), 1361; E.O. 11735, 38 FR 21243, 3 CFR, 1971-1975 Comp. p. 973; 42 U.S.C. 241, 242b, 243, 246, 300f, 300g, 300g-1, 300g-2, 300g-3, 300g-4, 300g-5, 300g-6, 300j-1, 300j-2, 300j-3, 300j-4, 300j-9, 1857 et seq., 6901-6992k, 7401-7671q, 7542, 9601-9657, 11023, 11048.

2. In §9.1, amend the table by adding entries for §§721.11561 through 721.11565 in numerical order under the undesignated center heading “Significant New Uses of Chemical Substances” to read as follows:

§9.1

OMB approvals under the Paperwork Reduction Act.

* * * * *

| 40 CFR citation | OMB control No. |

| * * * * * | |

| Significant New Uses of Chemical Substances | |

| * * * * * | |

| 721.11561 | 2070-0012 |

| 721.11562 | 2070-0012 |

| 721.11563 | 2070-0012 |

| 721.11564 | 2070-0012 |

| 721.11565 | 2070-0012 |

| * * * * * | |

* * * * *

PART 721—SIGNIFICANT NEW USES OF CHEMICAL SUBSTANCES

3. The authority citation for part 721 continues to read as follows:

Authority:

15 U.S.C. 2604, 2607, and 2625(c).

4. Add §§721.11561 through 721.11565 to subpart E to read as follows:

Subpart E—Significant New Uses for Specific Chemical Substances

Sec.

* * * * *

§721.11561 2-[2-(methylcarboxymonocyclic)amino)ethoxy]alcohol (generic).

§721.11562 Formaldehyde, polymer with alkyl aryl ketone (generic).

§721.11563 Propanedioic acid, 1,3-dihexyl ester.

§721.11564 Propanedioic acid, 1,3-dicyclohexyl ester.

§721.11565Propanedioic acid, 2,2-bis(hydroxymethyl)-, 1,3-dicyclohexyl ester.

* * * * *

§721.11561 2-[2-(methylcarboxymonocyclic)amino)ethoxy]alcohol (generic).

(a) Chemical substance and significant new uses subject to reporting. (1) The chemical substance identified generically as 2-[2-(methylcarboxymonocyclic)amino)ethoxy]alcohol (generic).(PMN P-18-289) is subject to reporting under this section for the significant new uses described in paragraph (a)(2) of this section.

(2) The significant new uses are:

(i) Industrial, commercial, and consumer activities. Requirements as specified in §721.80(j) and (s). For purposes of §721.80(s), the annual manufacture and importation volume is 80,000 kilograms.

(ii) [Reserved]

(b) Specific requirements. The provisions of subpart A of this part apply to this section except as modified by this paragraph (b).

(1) Recordkeeping. Recordkeeping requirements as specified in §721.125(a) through (c) and (i) are applicable to manufacturers and processors of this substance.

(2) Limitation or revocation of certain notification requirements. The provisions of §721.185 apply to this section.

(3) Determining whether a specific use is subject to this section. The provisions of §721.1725(b)(1) apply to paragraph (a)(2)(i) of this section.

§721.11562 Formaldehyde, polymer with alkyl aryl ketone (generic).

(a) Chemical substance and significant new uses subject to reporting. (1) The chemical substance identified generically as formaldehyde, polymer with alkyl aryl ketone (PMN P-18-330) is subject to reporting under this section for the significant new uses described in paragraph (a)(2) of this section.

(2) The significant new uses are:

(i) Industrial, commercial, and consumer activities. Requirements as specified in §721.80(o).

(ii) Release to water. Requirements as specified in §721.90(a)(4), (b)(4), and (c)(4), where N=770.

(b) Specific requirements. The provisions of subpart A of this part apply to this section except as modified by this paragraph (b).

(1) Recordkeeping. Recordkeeping requirements as specified in §721.125(a) through (c), (i) and (k) are applicable to manufacturers and processors of this substance.

(2) Limitation or revocation of certain notification requirements. The provisions of §721.185 apply to this section.

§721.11563 Propanedioic acid, 1,3-dihexyl ester.

(a) Chemical substance and significant new uses subject to reporting. (1) The chemical substance identified as propanedioic acid, 1,3-dihexyl ester (PMN P-18-334; CAS No. 1431-37-4) is subject to reporting under this section for the significant new uses described in paragraph (a)(2) of this section.

(2) The significant new uses are:

(i) Industrial, commercial, and consumer activities. Requirements as specified in §721.80(g).

(ii) Release to water. Requirements as specified in §721.90(a)(4), (b)(4), and (c)(4), where N=3.

(b) Specific requirements. The provisions of subpart A of this part apply to this section except as modified by this paragraph (b).

(1) Recordkeeping. Recordkeeping requirements as specified in §721.125(a) through (c), (i) and (k) are applicable to manufacturers and processors of this substance.

(2) Limitation or revocation of certain notification requirements. The provisions of §721.185 apply to this section.

§721.11564 Propanedioic acid, 1,3-dicyclohexyl ester.

(a) Chemical substance and significant new uses subject to reporting. (1) The chemical substance identified as propanedioic acid, 1,3-dicyclohexyl ester (PMN P-18-335; CAS No. 1152-57-4) is subject to reporting under this section for the significant new uses described in paragraph (a)(2) of this section.

(2) The significant new uses are:

(i) Industrial, commercial, and consumer activities. Requirements as specified in §721.80(g).

(ii) Release to water. Requirements as specified in §721.90(a)(4), (b)(4), and (c)(4), where N=6.

(b) Specific requirements. The provisions of subpart A of this part apply to this section except as modified by this paragraph (b).

(1) Recordkeeping. Recordkeeping requirements as specified in §721.125(a) through (c), (i) and (k) are applicable to manufacturers and processors of this substance.

(2) Limitation or revocation of certain notification requirements. The provisions of §721.185 apply to this section.

§721.11565Propanedioic acid, 2,2-bis(hydroxymethyl)-, 1,3-dicyclohexyl ester.

(a) Chemical substance and significant new uses subject to reporting. (1) The chemical substance identified as propanedioic acid, 2,2- bis(hydroxymethyl)-, 1,3-dicyclohexyl ester (PMN P-18-337; CAS No. 2222732-46-7) is subject to reporting under this section for the significant new uses described in paragraph (a)(2) of this section.

(2) The significant new uses are:

(i) Release to water. Requirements as specified in §721.90(a)(4), (b)(4), and (c)(4), where N=95.

(ii) [Reserved]

(b) Specific requirements. The provisions of subpart A of this part apply to this section except as modified by this paragraph (b).

(1) Recordkeeping. Recordkeeping requirements as specified in §721.125(a) through (c) and (k) are applicable to manufacturers and processors of this substance.

(2) Limitation or revocation of certain notification requirements. The provisions of §721.185 apply to this section.

[FR Doc. 2021-24789 Filed 11-12-21; 8:45 am]

BILLING CODE 6560-50-P

Hi everyone! Welcome to the monthly news roundup video, where we’ll review the most impactful environmental, health, and safety news. Please view the content links in the transcript for more information about the topics I’ll be covering today. Let’s get started!

OSHA published its proposed heat illness rule on August 30. It applies to both indoor and outdoor work in general industry, construction, agriculture, and maritime. Comments on the proposal will be accepted until December 30. OSHA encourages both employers and workers to submit comments.

Fall protection for construction remained number one on OSHA’s list of Top 10 violations for the 14th year in a row. There was little movement among the other Top 10 entries, with Hazard Communication at number 2 and ladders at number 3.

OSHA may exclude volunteer emergency response organizations from its proposed emergency response rule. During the rule’s public comment period, the agency received numerous comments that raised serious economic feasibility concerns.

During its silica enforcement inspections, OSHA also found violations of the hazard communication, respiratory protection, and noise standards. Over 200 companies were targeted as part of the agency’s respirable crystalline silica emphasis program.

Employers can view workplace injury and illness trends using OSHA’s Severe Injury Report dashboard. This new online tool allows users to search the agency’s severe injury report database. Severe injuries and illnesses are those that result in inpatient hospitalization, amputation, or loss of an eye.

And finally, turning to environmental news, an EPA final rule impacts facilities that reclassify from major to area source status under the National Emission Standards for Hazardous Air Pollutants program. These facilities must continue to meet the major source emission standards for seven hazardous air pollutants.

Thanks for tuning in to the monthly news roundup. We’ll see you next month!

ENVIRONMENTAL PROTECTION AGENCY

40 CFR Part 141

[EPA-HQ-OW-2020-0530; FRL-6791-03-OW]

RIN 2040-AF89

Revisions to the Unregulated Contaminant Monitoring Rule (UCMR 5) for Public Water Systems and Announcement of Public Meetings

AGENCY: Environmental Protection Agency (EPA).

ACTION: Final rule and notice of public meetings.

SUMMARY: The U.S. Environmental Protection Agency (EPA) is finalizing a Safe Drinking Water Act (SDWA) rule that requires certain public water systems (PWSs) to collect national occurrence data for 29 per- and polyfluoroalkyl substances (PFAS) and lithium. Subject to the availability of appropriations, EPA will include all systems serving 3,300 or more people and a representative sample of 800 systems serving 25 to 3,299 people. If EPA does not receive the appropriations needed for monitoring all of these systems in a given year, EPA will reduce the number of systems serving 25 to 10,000 people that will be asked to perform monitoring. This final rule is a key action to ensure science-based decision-making and prioritize protection of disadvantaged communities in accordance with EPA's PFAS Strategic Roadmap. EPA is also announcing plans for public webinars to discuss implementation of the fifth Unregulated Contaminant Monitoring Rule (UCMR 5).

DATES: This final rule is effective on January 26, 2022. The incorporation by reference of certain publications listed in this final rule is approved by the Director of the Federal Register as of January 26, 2022.

ADDRESSES: EPA has established a docket for this action under Docket ID No. EPA-HQ-OW-2020-0530. All documents in the docket are listed on the https://www.regulations.gov website. Although listed in the index, some information is not publicly available, e.g., CBI or other information whose disclosure is restricted by statute. Certain other material, such as copyrighted material, is not placed on the internet and will be publicly available only in hard copy form. Publicly available docket materials are available electronically through https://www.regulations.gov.

FOR FURTHER INFORMATION CONTACT: Brenda D. Bowden, Standards and Risk Management Division (SRMD), Office of Ground Water and Drinking Water (OGWDW) (MS 140), Environmental Protection Agency, 26 West Martin Luther King Drive, Cincinnati, Ohio 45268; telephone number: (513) 569-7961; email address: bowden.brenda@epa.gov; or Melissa Simic, SRMD, OGWDW (MS 140), Environmental Protection Agency, 26 West Martin Luther King Drive, Cincinnati, Ohio 45268; telephone number: (513) 569-7864; email address: simic.melissa@epa.gov. For general information, visit the Ground Water and Drinking Water web page at: https://www.epa.gov/ground-water-and-drinking-water.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. Summary Information

A. Purpose of the Regulatory Action

1. What action is EPA taking?

2. Does this action apply to me?

3. What is EPA's authority for taking this action?

4. What is the applicability date?

B. Summary of the Regulatory Action

C. Economic Analysis

1. What is the estimated cost of this action?

2. What are the benefits of this action?

II. Public Participation

A. What meetings have been held in preparation for UCMR 5?

B. How do I participate in the upcoming meetings?

1. Meeting Participation

2. Meeting Materials

III. General Information

A. How are CCL, UCMR, Regulatory Determination process, and NCOD interrelated?

B. What are the Consumer Confidence Reporting and Public Notice Reporting requirements for public water systems that are subject to UCMR?

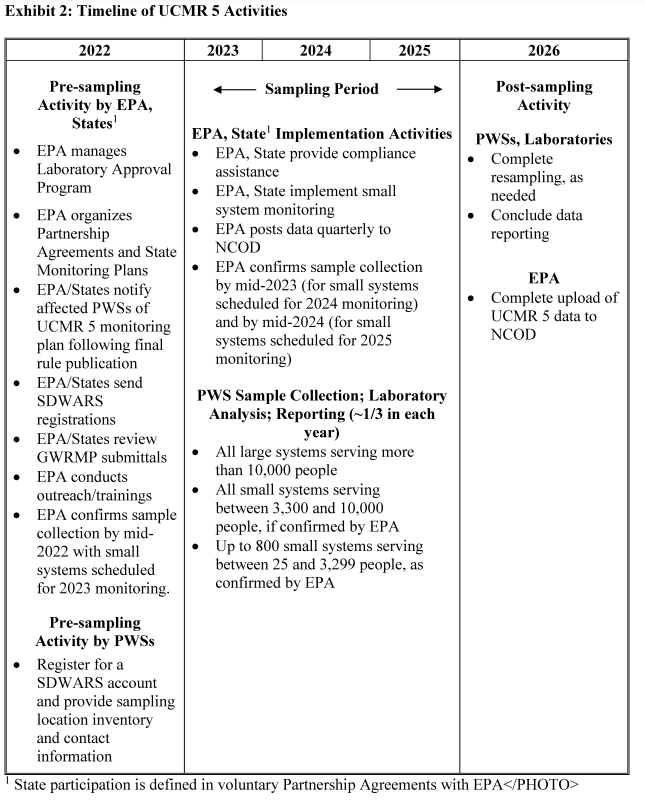

C. What is the UCMR 5 timeline?

D. What is the role of “States” in UCMR?

E. How did EPA consider Children's Environmental Health?

F. How did EPA address Environmental Justice?

G. How did EPA coordinate with Indian Tribal Governments?

H. How are laboratories approved for UCMR 5 analyses?

1. Request To Participate

2. Registration

3. Application Package

4. EPA's Review of Application Package

5. Proficiency Testing

6. Written EPA Approval

I. What documents are being incorporated by reference?

1. Methods From the U.S. Environmental Protection Agency

2. Alternative Methods From American Public Health Association—Standard Methods (SM)

3. Methods From ASTM International

IV. Description of Final Rule and Summary of Responses to Public Comments

A. What contaminants must be monitored under UCMR 5?

1. This Final Rule

2. Summary of Major Comments and EPA Responses

a. Aggregate PFAS Measure

b. Legionella Pneumophila

c. Haloacetonitriles

d. 1,2,3-Trichloropropane

B. What is the UCMR 5 sampling design?

1. This Final Rule

2. Summary of Major Comments and EPA Responses

C. What is the sampling frequency and timing?

1. This Final Rule

2. Summary of Major Comments and EPA Responses

D. Where are the sampling locations and what is representative monitoring?

1. This Final Rule

2. Summary of Major Comments and EPA Responses

E. How long do laboratories and PWSs have to report data?

1. This Final Rule

2. Summary of Major Comments and EPA Responses

F. What are the reporting requirements for UCMR 5?

1. This Final Rule

2. Summary of Major Comments and EPA Responses

a. Data Elements

b. Reporting State Data

G. What are the UCMR 5 Minimum Reporting Levels (MRLs) and how were they determined?

1. This Final Rule

2. Summary of Major Comments and EPA Responses

H. What are the requirements for laboratory analysis of field reagent blank samples?

1. This Final Rule

2. Summary of Major Comments and EPA Responses

I. How will EPA support risk communication for UCMR 5 results?

V. Statutory and Executive Order Reviews

A. Executive Order 12866: Regulatory Planning and Review and Executive Order 13563: Improving Regulation and Regulatory Review

B. Paperwork Reduction Act (PRA)

C. Regulatory Flexibility Act (RFA)

D. Unfunded Mandates Reform Act (UMRA)

E. Executive Order 13132: Federalism

F. Executive Order 13175: Consultation and Coordination With Indian Tribal Governments

G. Executive Order 13045: Protection of Children From Environmental Health Risks and Safety Risks

H. Executive Order 13211: Actions Concerning Regulations That Significantly Affect Energy Supply, Distribution or Use

I. National Technology Transfer and Advancement Act (NTTAA)

J. Executive Order 12898: Federal Actions To Address Environmental Justice in Minority Populations and Low-Income Populations

K. Congressional Review Act (CRA)

VI. References

Abbreviations and Acronyms

μg/L Microgram per Liter

11Cl-PF3OUdS 11-chloroeicosafluoro-3-oxaundecane-1-sulfonic Acid

4:2 FTS 1H, 1H, 2H, 2H-perfluorohexane Sulfonic Acid

6:2 FTS 1H, 1H, 2H, 2H-perfluorooctane Sulfonic Acid

8:2 FTS 1H, 1H, 2H, 2H-perfluorodecane Sulfonic Acid

9Cl-PF3ONS 9-chlorohexadecafluoro-3-oxanone-1-sulfonic Acid

ADONA 4,8-dioxa-3H-perfluorononanoic Acid

AES Atomic Emission Spectrometry

ASDWA Association of State Drinking Water Administrators

ASTM ASTM International

AWIA America's Water Infrastructure Act of 2018

CASRN Chemical Abstracts Service Registry Number

CBI Confidential Business Information

CCL Contaminant Candidate List

CCR Consumer Confidence Report

CFR Code of Federal Regulations

CRA Congressional Review Act

CWS Community Water System

DBP Disinfection Byproduct

DWSRF Drinking Water State Revolving Fund

EPA United States Environmental Protection Agency

EPTDS Entry Point to the Distribution System

FR Federal Register

FRB Field Reagent Blank

GW Ground Water

GWRMP Ground Water Representative Monitoring Plan

HFPO-DA Hexafluoropropylene Oxide Dimer Acid (GenX)

HRL Health Reference Level

ICP Inductively Coupled Plasma

ICR Information Collection Request

IDC Initial Demonstration of Capability

LCMRL Lowest Concentration Minimum Reporting Level

LC/MS/MS Liquid Chromatography/Tandem Mass Spectrometry

MDBP Microbial and Disinfection Byproduct

MRL Minimum Reporting Level

NAICS North American Industry Classification System

NCOD National Contaminant Occurrence Database

NDAA National Defense Authorization Act for Fiscal Year 2020

NEtFOSAA N-ethyl Perfluorooctanesulfonamidoacetic Acid

NFDHA Nonafluoro‐3,6‐dioxaheptanoic Acid

ng/L Nanogram per Liter

NMeFOSAA N-methyl Perfluorooctanesulfonamidoacetic Acid

NPDWR National Primary Drinking Water Regulation

NTNCWS Non-transient Non-community Water System

NTTAA National Technology Transfer and Advancement Act

NTWC National Tribal Water Council

OGWDW Office of Ground Water and Drinking Water

OMB Office of Management and Budget

PFAS Per- and Polyfluoroalkyl Substances

PFBA Perfluorobutanoic Acid

PFBS Perfluorobutanesulfonic Acid

PFDA Perfluorodecanoic Acid

PFDoA Perfluorododecanoic Acid

PFEESA Perfluoro (2‐ethoxyethane) Sulfonic Acid

PFHpA Perfluoroheptanoic Acid