Safety tidbits for your jobsite; not just a bucket of bolts

When I was a safety manager, I wore many hats. Depending on my project, I had environmental, payroll, human resource, and field-engineering duties. I learned a lot about utility notification systems. Each state has a similar process for excavators to notify utility and facility owners about their digging activities.

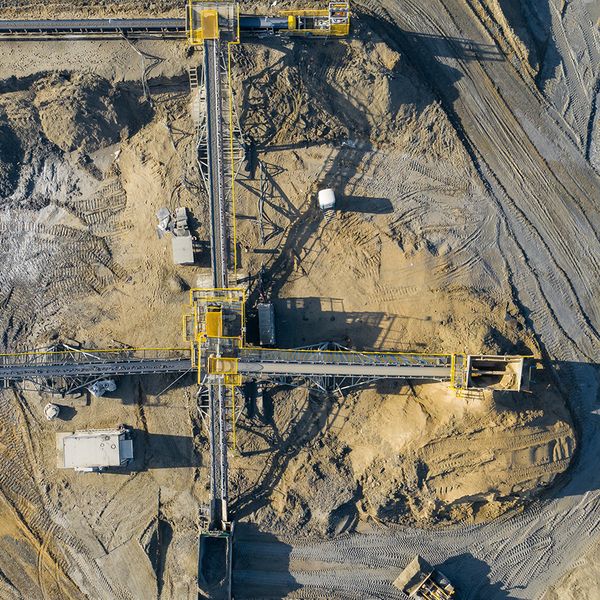

After receiving notification through the utility notification system, owners must mark their utility or structure and coordinate construction activities with the contractor. A main issue that arises is digging in the tolerance zone. I’ll discuss what this is and how to dig safely.

While planning fall-related protection for workers, contractors often miss a critical step and jump to ordering fall protection — the first step in addressing fall hazards is prevention. Two main philosophies I’ll discuss more in-depth are fall prevention and fall protection.

Being a good neighbor and environmental steward includes controlling dust generated from the jobsite. Dust suppression also benefits workers by eliminating or reducing their exposure to harmful or nuisance dust. I’ll provide tips on how to address these issues.

Workers often mistakenly mislabeled containers, forget to use SDSs for guidance, and stored chemicals and flammable liquids inside their company vehicles. Doing so can lead to injuries, property damage, or even fatalities. Train workers on how to avoid these issues.

As a safety manager, ensuring the proper handling of chemicals was a daily safety concern. I’ve provided some examples of controls I used at my jobsites and other best practices to help your workers avoid incidents and stay safe.