Every safety warning ignored is a tragedy looming!

Tragedies are just waiting for the opportunity to strike in your workplace. When safety is ignored, even minor hazards can turn into serious incidents with devastating consequences. Whether it's an overlooked inspection, a neglected repair, or a dismissed concern, the cost of inaction is often far greater than the effort to address risks early.

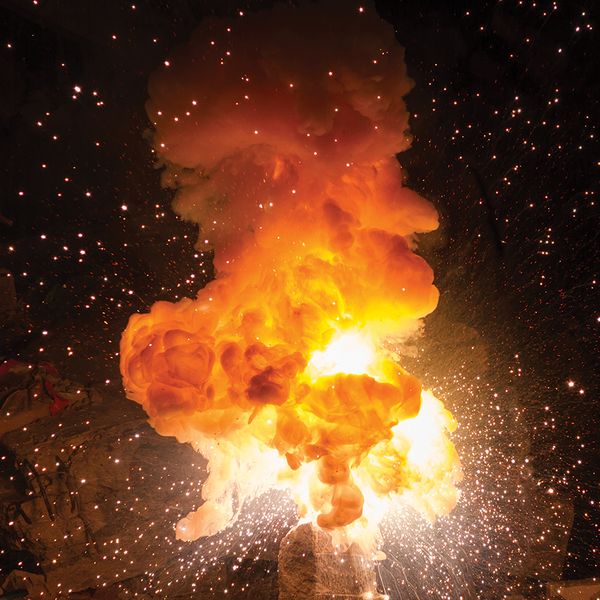

The explosive truth in one month

Two southern factories are great examples of how safety “hints” can turn deadly when not enough attention is given to workplace warnings. A Tennessee factory and a Kentucky plant both could have possibly averted October 2025 catastrophes, by looking a little further into signs and symptoms of existing dangers.

Tennessee OSHA (TOSHA) had cited a munitions factory with safety violations six years prior to its October 10th explosion after investigating why multiple employees were having seizures and other symptoms of dangerous chemical exposures.

Air monitoring confirmed that employees likely weren’t exposed to explosive cyclonite powder through inhalation. However, the inspection revealed that employees were not adequately protected from exposure through ingestion or skin absorption. Inspections found that employees were being exposed to surface contamination and ingestion risks from being allowed to consume food and beverages without proper hygiene practices being enforced.

The U.S. Chemical Safety and Hazard Investigation Board (CSB), working closely with the Bureau of Alcohol, Tobacco, Firearms, and Explosives (ATF), are still investigating the fatal explosion. The ATF believes the blast originated where mixed explosive materials were heated in production kettles followed by additional explosions occurring on the same floor of the facility after the original blast.

Just north and a few days earlier, an explosion occurred at a Kentucky chemical plant thought to be caused by an overflow of calcium carbide from a furnace. Though OSHA and local law enforcement continue to investigate, a preliminary review revealed that the calcium carbine actually landed on the ground, contributing to the explosion.

Though the explosion didn’t result in any fatalities, the same factory had experienced an explosion in March 2011 that did claim the lives of two workers while injuring two others. The CSB concluded the explosion was due to an electric arc furnace that over-pressurized, ejecting solid and powdered debris, flammable gases, and molten calcium carbide toward the workers. Accumulations of hazardous carbide and water were also thought to have contributed to the incident.

Looking back

In retrospect, if each employer had identified the potential for an explosive environment, based on prior incidents and employee exposures, and taken appropriate protective measures, the events of October 2025 could have been avoided.

By performing thorough investigations into how explosive materials were accumulating, and by implementing necessary changes to eliminate exposure risks, almost 20 lives might have been saved, and numerous serious injuries as well as extensive damage to both facilities could have been prevented.

Employers can reduce the risk of workplace explosions and fatalities by adopting a proactive approach that includes comprehensive safety protocols through:

- Performing workplace risk assessments and process hazard analysis;

- Conducting regular inspections to ensure proper ventilation and housekeeping;

- Managing ignition sources and flammable materials by using appropriate storage and handling procedures;

- Implementing explosion prevention systems that detect, isolate, and suppress explosive conditions;

- Maintaining infrastructure and equipment by addressing sparking concerns, faulty wiring, leaks, and instrumentation malfunctions;

- Training employees in recognizing explosion risks and safe work practices;

- Promoting a safe work culture through preparedness training, committees, and other employee engagement; and

- Complying with OSHA and other related standards.

Key to remember: Ignoring safety warnings not only endangers lives but also leads to preventable tragedies that impact employees and their families, operations and the community, and often, organizational reputation.