Prioritizing protection: How robust risk management mitigates chemical hazards

In today’s world, protecting communities and workers is essential. The Environmental Protection Agency (EPA) recently sent a clear message in California: robust risk management isn’t just about following the law — it’s a duty to safeguard lives and the environment. The agency settled with several facilities to resolve alleged chemical safety violations under the Clean Air Act, imposing penalties totaling over $170,000. This enforcement activity reminds facility operators that safety measures and proactive risk management practices must always be a priority.

Overview of enforcement actions

During recent inspections, EPA uncovered significant safety issues at multiple facilities. One notable case involved a processing facility that produces packaged salads, fresh-cut vegetables, and other food products. In January 2024, EPA inspectors discovered serious deficiencies in the facility’s anhydrous ammonia refrigeration system. The inspection revealed that the facility failed to address critical safety recommendations, used inadequate safe work practices, and had an insufficient operation and maintenance program. These shortcomings led to the corrosion of essential equipment and an emergency ventilation system that didn’t meet safety standards.

Moreover, the facility’s documentation didn’t clearly demonstrate that its system was designed to prevent accidental releases of anhydrous ammonia, a chemical regulated under Section 112(r) of the Clean Air Act due to its severe health and flammability risks. For these violations, the facility agreed to settle by paying nearly $152,000.

Other facilities in California also fell short under EPA’s Risk Management Program (RMP) rules. For example, an entity in Los Angeles was found lacking accurate chlorine equipment diagrams, proper hazard evaluations, and timely inspections, resulting in an $8,000 penalty. In Fresno, another facility was penalized $2,000 for failing to submit its Risk Management Plan on time.

Even water treatment facilities in Benicia and Fairfield, along with facilities in Carson, San Pedro, Torrance, and Newark, received fines ranging from $800 to $1,800 due to administrative lapses, such as delayed submission of required RMP plans and failures to update emergency protocols.

RMP requirements

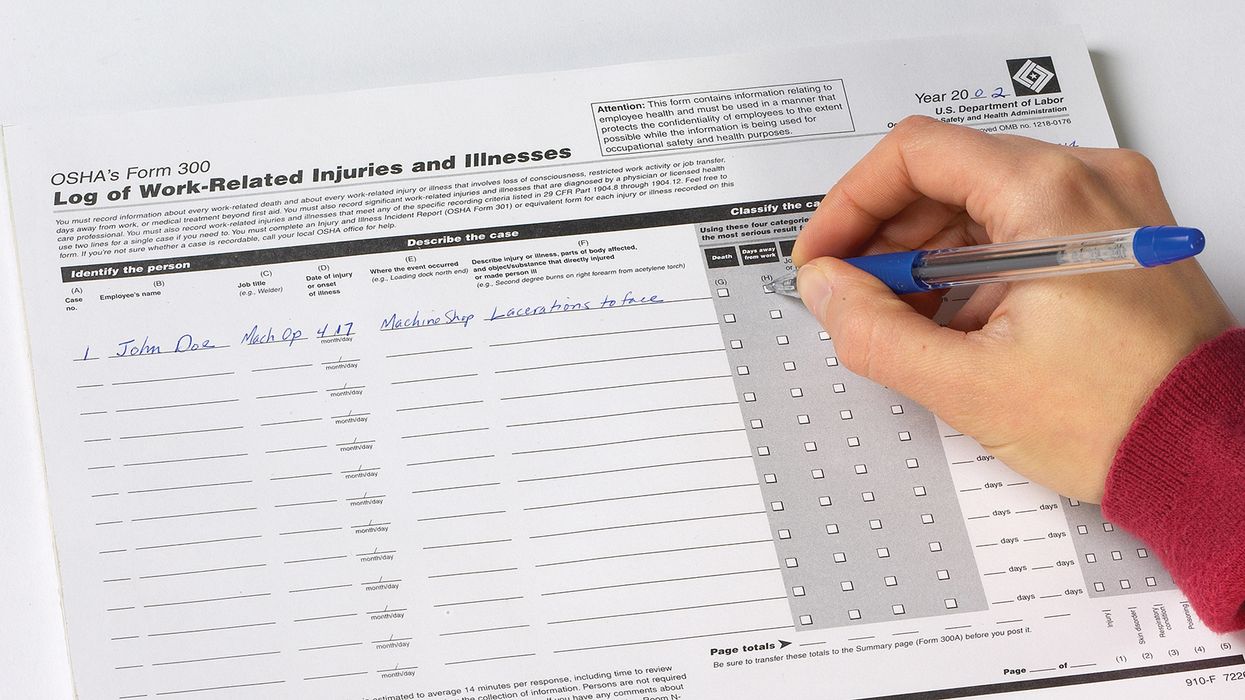

The RMP framework is designed to prevent chemical accidents and protect both workers and communities. Facilities that store or use extremely hazardous substances must adhere to a series of safety standards, including the following:

Hazard evaluations: Facilities must continually assess the potential risks associated with handling hazardous materials. This process involves identifying possible chemical leaks or accidents and addressing them before they can cause harm.

Maintenance and equipment integrity: Operators must maintain their equipment diligently to prevent malfunctions. Regular inspections, repairs, and upgrades are part of confirming that systems like refrigeration or ventilation continue to operate safely.

Documentation and emergency response: Accurate paperwork is critical. Facilities need to show that every safety measure is in place and that emergency procedures are robust and regularly updated. This documentation helps ensure that, in the event of an accident, responses are swift and effective.

These requirements aren’t mere paperwork; they’re at the core of a facility’s duty to mitigate risks. Strong RMP practices minimize the likelihood of chemical releases and reduce the potential impact when incidents occur.

Status of the RMP rule

Note that on March 12, 2025, EPA announced that it’s reconsidering the 2024 RMP rule to advance the current administration’s executive order. No further action has been taken as of June 2025, and the 2024 RMP rule requirements remain in effect.

Key to remember: EPA’s recent enforcement actions serve as a reminder for facilities to review and update their Risk Management Plans regularly, ensure that plant equipment is maintained, and implement best practices that prevent hazardous chemical releases.