NHTSA final rule: Child Restraint Systems Safety Standards

This final rule amends a Federal Motor Vehicle Safety Standard (FMVSS) regarding child restraint systems. The amendments, mandatory in one year, modernize the standard by, among other things, updating CRS owner registration program requirements, labeling requirements on correctly using child restraints, requirements for add-on school bus-specific child restraint systems, and provisions for NHTSA's use of test dummies in NHTSA compliance tests. Amendments mandatory in three years include adding a new FMVSS that updates to standard seat assemblies on which NHTSA tests child restraint systems for compliance with frontal crash performance requirements. This final rule fulfills a mandate of the Moving Ahead for Progress in the 21st Century Act (MAP–21) that directs NHTSA to update the standard seat assembly. The purpose of this final rule is to ensure continued effectiveness of child restraint systems in current and future vehicles.

DATES:

Effective date: February 5, 2024.

IBR date: The incorporation by reference of certain publications listed in the rule is approved by the Director of the Federal Register as of February 5, 2024. The incorporation by reference of certain other publications listed in the rule was approved by the Director as of February 6, 2012.

Compliance date: The compliance date for the amendments to FMVSS No. 213 is December 5, 2024. The compliance date for meeting FMVSS No. 213b is December 5, 2026. Optional early compliance with the standards is permitted.

Reconsideration date: If you wish to petition for reconsideration of this rule, your petition must be received by January 19, 2024.

Published in the Federal Register December 5, 2023, page 84514.

| §571.5 Matter incorporated by reference. | ||

| (b)(3) | Added | View text |

| (d)(16) | Revised | View text |

| (d)(22)-(d)(39) | Redesignated | View text |

| (k)(6)-(7) | Added | View text |

| (l)(3)-(4) | Revised | View text |

| §571.213 Child restraint systems; Applicable unless a vehicle or child restraint system is certified to §571.213b. | ||

| Entire section | Revised | View text |

| §571.213b Standard No. 213b; Child restraint systems; Mandatory applicability beginning | ||

| Entire section | Added | View text |

New Text

§571.5 Matter incorporated by reference.

* * * *

(d)(16) ASTM D1056-07, Standard Specification for Flexible Cellular Materials-Sponge or Expanded Rubber, approved March 1, 2007; into §§571.213; 571.213b.

* * * *

(l)(3) SAE Recommended Practice J211, Instrumentation for Impact Tests, revised June 1980; into §571.218.

(l)(4) SAE Recommended Practice J211/1, Instrumentation for Impact Tests—Part 1— Electronic Instrumentation; revised March 1995; §§571.202a; 571.208;571.213; 571.213a; 571.213b; 571.218; 571.403.

§571.213 Child restraint systems; Applicable unless a vehicle or child restraint system is certified to § 571.213b.

S1. Scope. This standard specifies requirements for child restraint systems used in motor vehicles and aircraft.

S2. Purpose. The purpose of this standard is to reduce the number of children killed or injured in motor vehicle crashes and in aircraft.

S3. Application. This standard applies to passenger cars, multipurpose passenger vehicles, trucks and buses, and to child restraint systems for use in motor vehicles and aircraft, manufactured before December 5, 2026. FMVSS No. 213b applies to child restraint systems manufactured on or after December 5, 2026.

S4. Definitions.

Add-on child restraint system

means any portable child restraint system.

Backless child restraint system

means a child restraint, other than a belt-positioning seat, that consists of a seating platform that does not extend up to provide a cushion for the child’s back or head and has a structural element designed to restrain forward motion of the child’s torso in a forward impact.

Belt-positioning seat

means a child restraint system that positions a child on a vehicle seat to improve the fit of a vehicle Type II belt system on the child and that lacks any component, such as a belt system or a structural element, designed to restrain forward movement of the child’s torso in a forward impact.

Booster seat

means either a backless child restraint system or a belt-positioning seat.

Built-in child restraint system

means a child restraint system that is designed to be an integral part of and permanently installed in a motor vehicle.

Car bed

means a child restraint system designed to restrain or position a child in the supine or prone position on a continuous flat surface.

Child restraint anchorage system

is defined in S3 of FMVSS No. 225 (§571.225).

Child restraint system

means any device, except Type I or Type II seat belts, designed for use in a motor vehicle or aircraft to restrain, seat, or position children who weigh 36 kilograms (kg) (80 lb) or less.

Contactable surface

means any child restraint system surface (other than that of a belt, belt buckle, or belt adjustment hardware) that may contact any part of the head or torso of the appropriate test dummy, specified in S7, when a child restraint system is tested in accordance with S6.1.

Factory-installed built-in child restraint system

means a built-in child restraint system that has been or will be permanently installed in a motor vehicle before that vehicle is certified as a completed or altered vehicle in accordance with part 567 of this chapter.

Harness

means a combination pelvic and upper torso child restraint system that consists primarily of flexible material, such as straps, webbing or similar material, and that does not include a rigid seating structure for the child.

Rear-facing child restraint system

means a child restraint system, except a car bed, that positions a child to face in the direction opposite to the normal direction of travel of the motor vehicle.

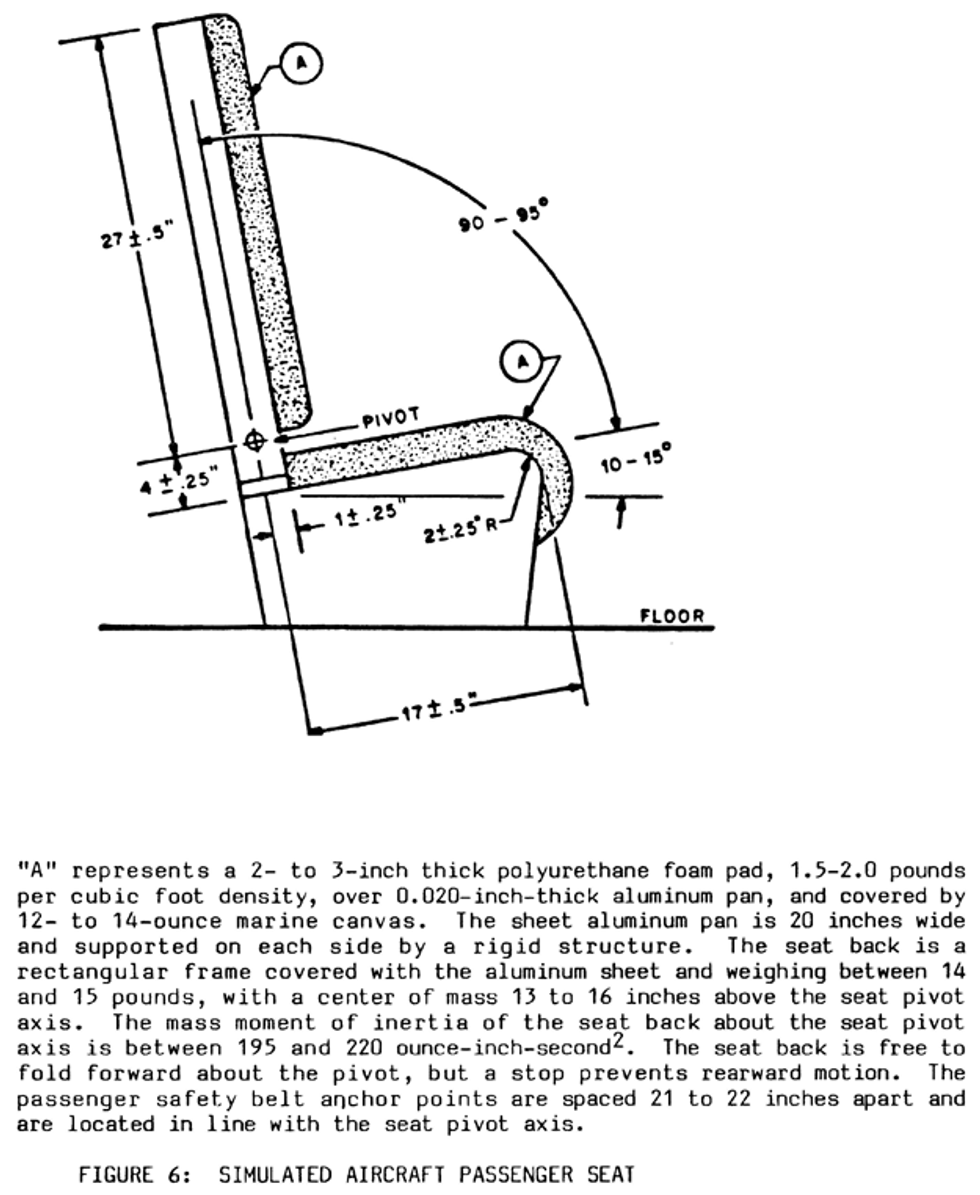

Representative aircraft passenger seat

means either a Federal Aviation Administration approved production aircraft passenger seat or a simulated aircraft passenger seat conforming to Figure 6.

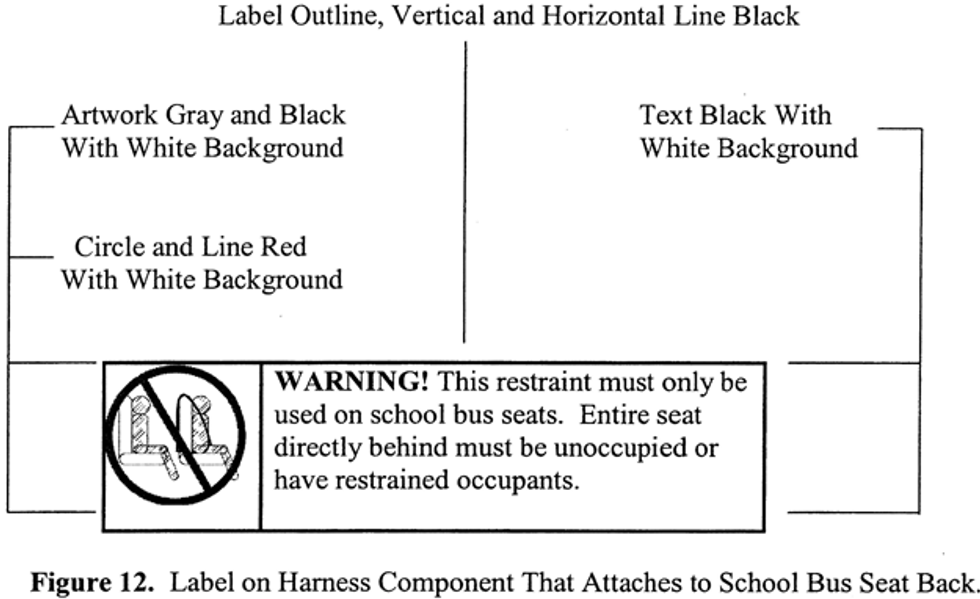

School bus child restraint system means an add-on child restraint system (including a harness) manufactured and sold only for use on school bus seats, that has a label conforming with S5.3.1(b). (This definition applies to child restraint systems manufactured on or after December 5, 2024.)

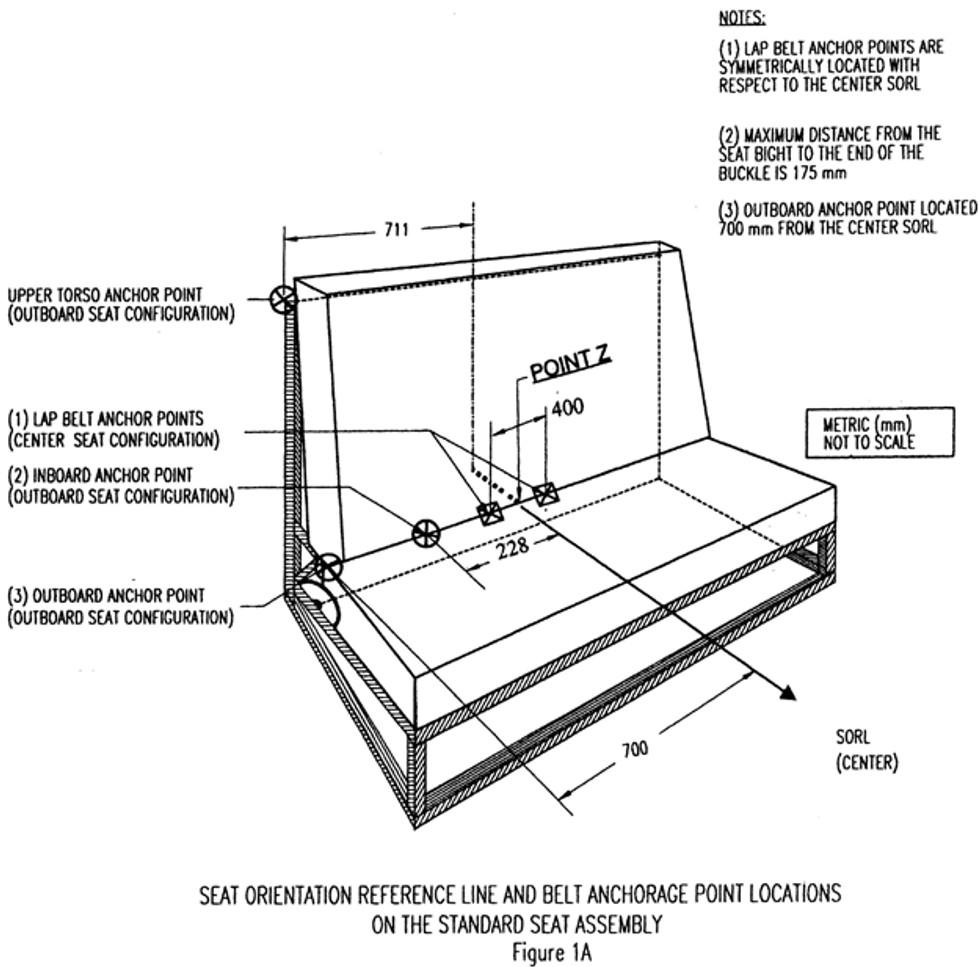

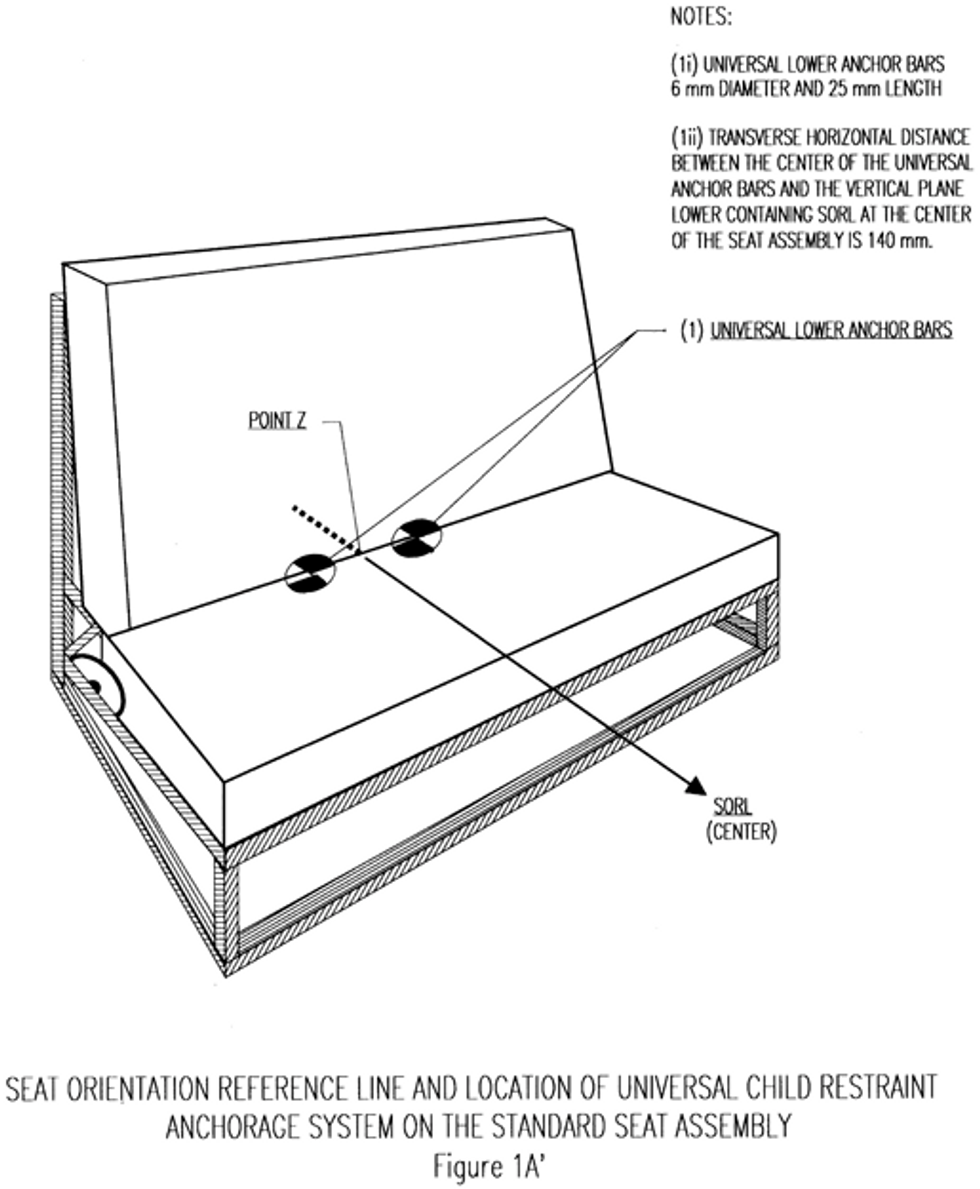

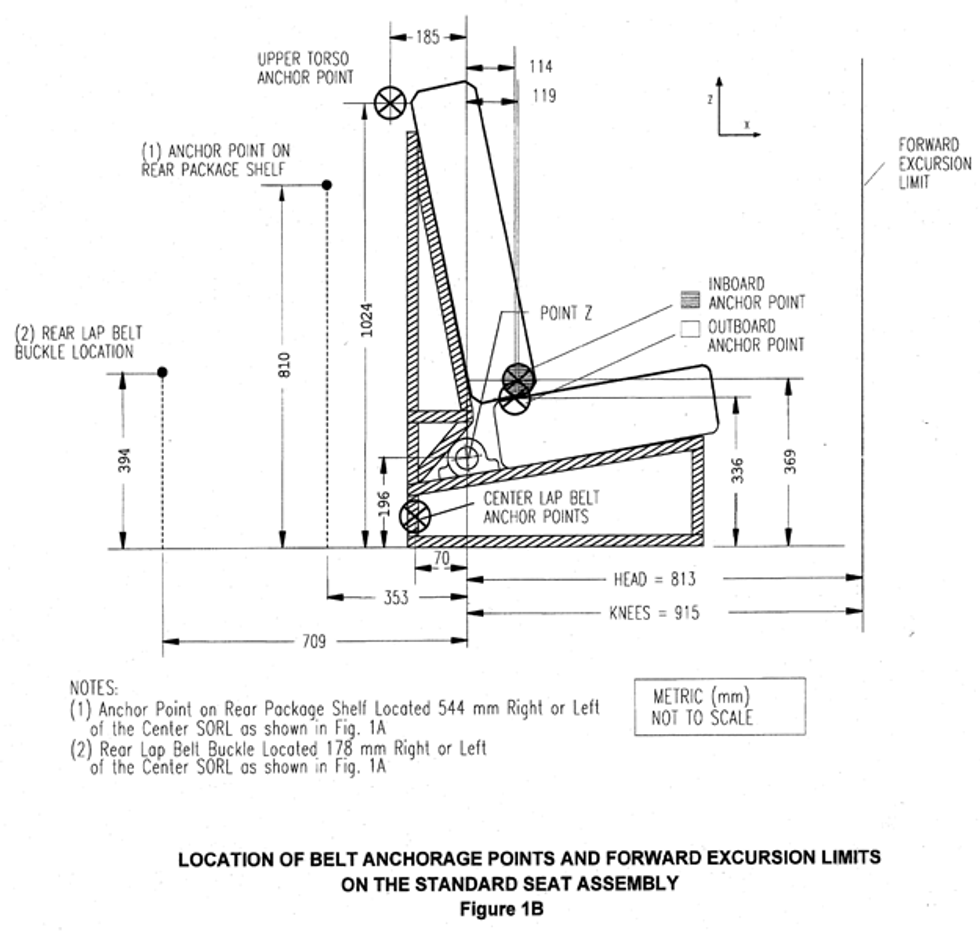

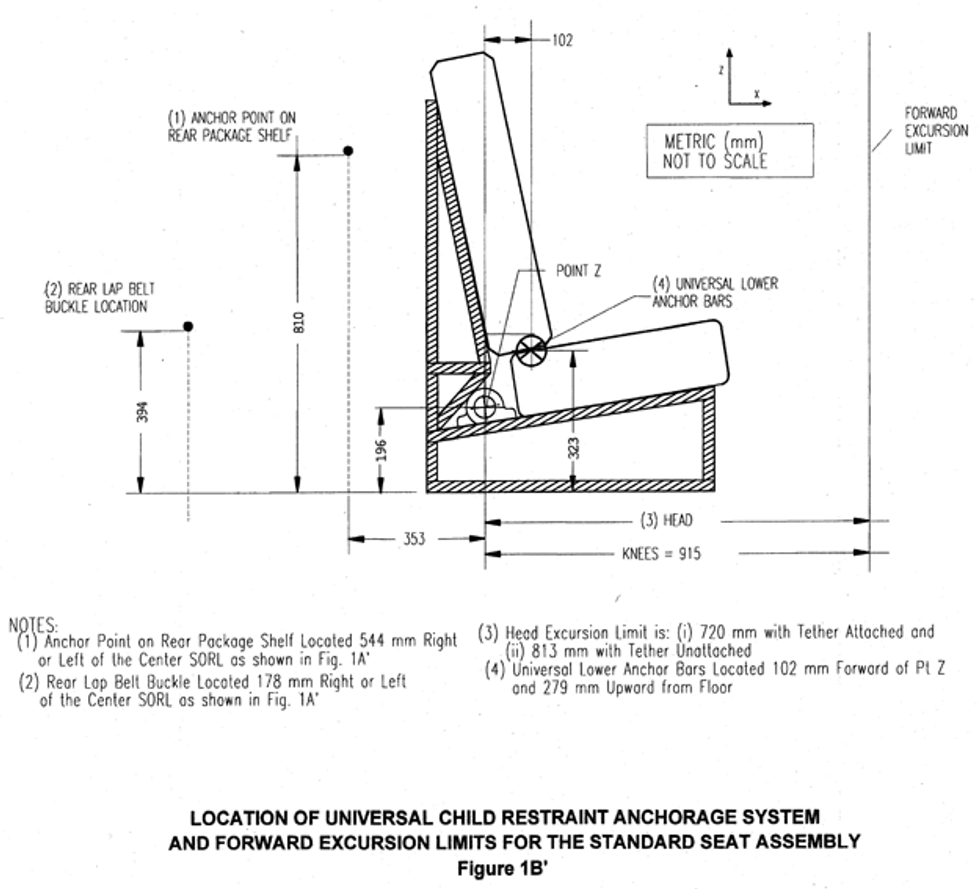

Seat orientation reference line or SORL

means the horizontal line through Point Z as illustrated in Figure 1A.

Specific vehicle shell

means the actual vehicle model part into which the built-in child restraint system is or is intended to be fabricated, including the complete surroundings of the built-in system. If the built-in child restraint system is or is intended to be fabricated as part of any seat other than a front seat, these surroundings include the back of the seat in front, the interior rear side door panels and trim, the floor pan, adjacent pillars (e.g., the B and C pillars), and the ceiling. If the built-in system is or is intended to be fabricated as part of the front seat, these surroundings include the dashboard, the steering mechanism and its associated trim hardware, any levers and knobs installed on the floor or on a console, the interior front side door panels and trim, the front seat, the floor pan, the A pillars and the ceiling.

Tether anchorage

is defined in S3 of FMVSS No. 225 (§571.225).

Tether strap

is defined in S3 of FMVSS No. 225 (§571.225).

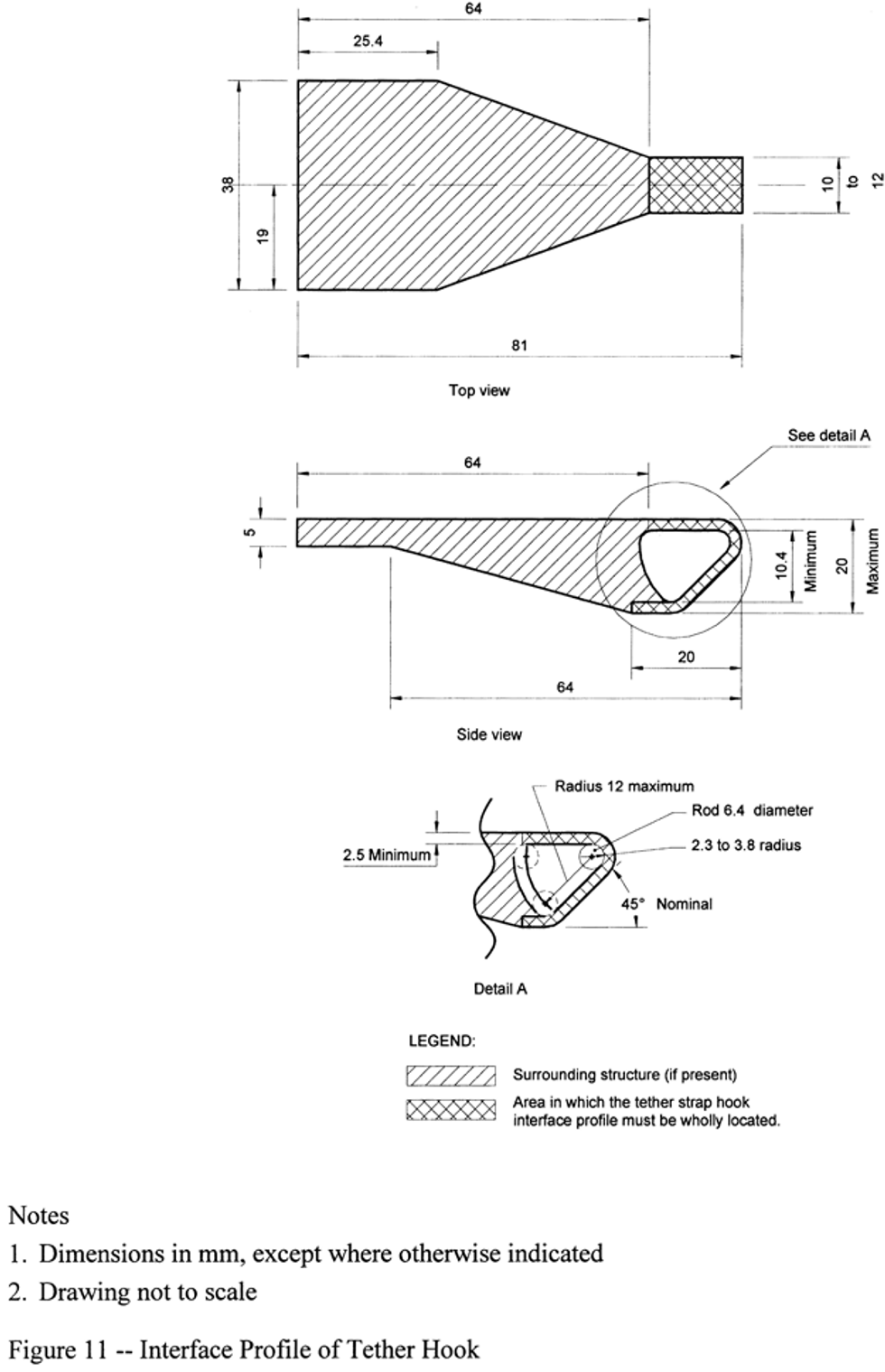

Tether hook

is defined in S3 of FMVSS No. 225 (§571.225).

Torso

means the portion of the body of a seated anthropomorphic test dummy, excluding the thighs, that lies between the top of the child restraint system seating surface and the top of the shoulders of the test dummy.

S5. Requirements. (a) Each motor vehicle with a built-in child restraint system shall meet the requirements in this section when, as specified, tested in accordance with S6.1 and this paragraph.

(b) Each child restraint system manufactured for use in motor vehicles shall meet the requirements in this section when, as specified, tested in accordance with S6.1 and this paragraph. Each add-on system shall meet the requirements at each of the restraint’s seat back angle adjustment positions and restraint belt routing positions, when the restraint is oriented in the direction recommended by the manufacturer (e.g., forward, rearward or laterally) pursuant to S5.6, and tested with the test dummy specified in S7.

(c) Each child restraint system manufactured for use in aircraft shall meet the requirements in this section and the additional requirements in S8.

(d) Each child restraint tested with a Part 572 Subpart S dummy need not meet S5.1.2 and S5.1.3.

(e) Each child restraint system tested with a part 572 subpart T dummy need not meet S5.1.2.1(a).

(f) Each child restraint system that is equipped with an internal harness or other internal components to restrain the child need not meet this standard when attached to the lower anchors of the child restraint anchorage system on the standard seat assembly if the sum of the weight of the child restraint system (in pounds) and the average weight of child represented by the test dummy used to test the child restraint in accordance with S7 of this standard, shown in the table below, exceeds 65 pounds. Such a child restraint must meet this standard when tested using its internal harness or components to restrain such a test dummy while installed using the standard seat belt assembly specified in S5.3.2 of this standard.

| Test dummy

(specified in S7 of this standard) | Average weight of child represented by test dummy

(pounds) |

| CRABI 12-month-old infant dummy (49 CFR Part 572, Subpart R) | 22 |

| Hybrid III 3-year-old dummy(49 CFR Part 572, Subpart P) | 31 |

| Hybrid III 6-year-old dummy 49 CFR Part 572, Subpart N) | 45 |

| Hybrid III 6-year-old weighted child test dummy (49 CFR Part 572 Subpart S) | 62 |

| Hybrid II 6-year-old dummy (49, CFR Part 572, Subpart I) | 45 |

(g) Each add-on child restraint system manufactured for use in motor vehicles, that is recommended for children in a weight range that includes weights up to 18 kilograms (40 pounds), or for children in a height range that includes heights up to 1100 millimeters, shall meet the requirements in this standard and the additional side impact protection requirements in Standard No. 213a (§571.213a). Excepted from Standard No. 213a are harnesses and car beds. [Change Notice]

S5.1 Dynamic performance.

S5.1.1 Child restraint system integrity. When tested in accordance with S6.1, each child restraint system shall meet the requirements of paragraphs (a) through (c) of this section.

(a) Exhibit no complete separation of any load bearing structural element and no partial separation exposing either surfaces with a radius of less than 1⁄ 4 inch or surfaces with protrusions greater than 3⁄ 8 inch above the immediate adjacent surrounding contactable surface of any structural element of the system.

(b)(1) If adjustable to different positions, remain in the same adjustment position during the testing that it was in immediately before the testing, except as otherwise specified in paragraph (b)(2).

(2)(i) Subject to paragraph (b)(2)(ii), a rear-facing child restraint system may have a means for repositioning the seating surface of the system that allows the system’s occupant to move from a reclined position to an upright position and back to a reclined position during testing.

(ii) No opening that is exposed and is larger than 1⁄ 4 inch before the testing shall become smaller during the testing as a result of the movement of the seating surface relative to the restraint system as a whole.

(c) If a front facing child restraint system, not allow the angle between the system’s back support surfaces for the child and the system’s seating surface to be less than 45 degrees at the completion of the test.

S5.1.2 Injury criteria. When tested in accordance with S6.1 and with the test dummies specified in S7, each child restraint system manufactured before August 1, 2005, that, in accordance with S5.5.2, is recommended for use by children whose mass is more than 10 kg shall—

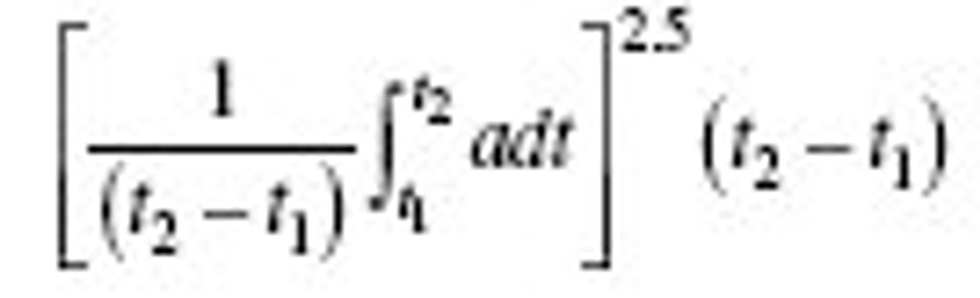

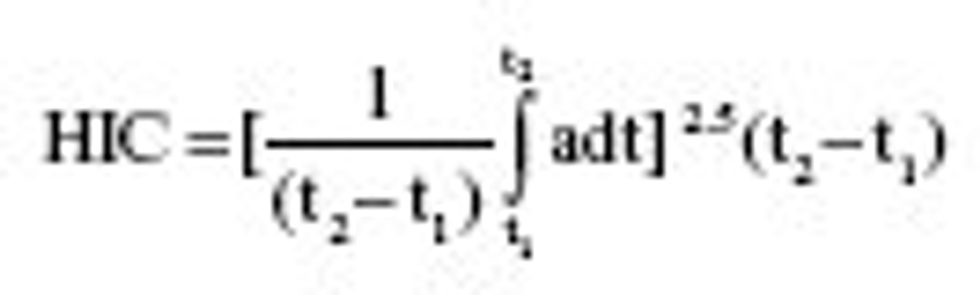

(a) Limit the resultant acceleration at the location of the accelerometer mounted in the test dummy head as specified in part 572 such that the expression:

shall not exceed 1,000, where a is the resultant acceleration expressed as a multiple of g (the acceleration of gravity), and t 1 and t 2 are any two moments during the impacts.

(b) Limit the resultant acceleration at the location of the accelerometer mounted in the test dummy upper thorax as specified in part 572 to not more than 60 g’s, except for intervals whose cumulative duration is not more than 3 milliseconds.

S5.1.2.1 When tested in accordance with S6.1 and with the test dummies specified in S7, each child restraint system manufactured on or after August 1, 2005 shall’

(a) Limit the resultant acceleration at the location of the accelerometer mounted in the test dummy head such that, for any two points in time, t

1 and t

2, during the event which are separated by not more than a 36 millisecond time interval and where t

1 is less than t

2, the maximum calculated head injury criterion (HIC

36 ) shall not exceed 1,000, determined using the resultant head acceleration at the center of gravity of the dummy head, ar, expressed as a multiple of g (the acceleration of gravity), calculated using the expression:

(b) The resultant acceleration calculated from the output of the thoracic instrumentation shall not exceed 60 g’s, except for intervals whose cumulative duration is not more than 3 milliseconds.

S5.1.2.2 At the manufacturer’s option (with said option irrevocably selected prior to, or at the time of, certification of the restraint), child restraint systems manufactured before August 1, 2005 may be tested to the requirements of S5 while using the test dummies specified in S7.1.2 of this standard according to the criteria for selecting test dummies specified in that paragraph. That paragraph specifies the dummies used to test child restraint systems manufactured on or after August 1, 2005. If a manufacturer selects the dummies specified in S7.1.2 to test its product, the injury criteria specified by S5.1.2.1 of this standard must be met. Child restraints manufactured on or after August 1, 2005 must be tested using the test dummies specified in S7.1.2.

S5.1.3 Occupant excursion. When tested in accordance with S6.1 and the requirements specified in this section, each child restraint system shall meet the applicable excursion limit requirements specified in S5.1.3.1-S5.1.3.3.

S5.1.3.1 Child restraint systems other than rear-facing ones and car beds. Each child restraint system, other than a rear-facing child restraint system or a car bed, shall retain the test dummy’s torso within the system.

(a) For each add-on child restraint system:

(1) No portion of the test dummy’s head shall pass through a vertical transverse plane that is 720 mm or 813 mm (as specified in the table in this S5.1.3.1) forward of point Z on the standard seat assembly, measured along the center SORL (as illustrated in figure 1B of this standard); and

(2) Neither knee pivot point shall pass through a vertical transverse plane that is 915 mm forward of point Z on the standard seat assembly, measured along the center SORL.

| When this type of child restraint | Is tested in accordance with— | These excursion limits apply | Explanatory note: in the test specified in 2nd column, the child restraint is attached to the test seat assembly in the manner described below, subject to certain conditions |

|---|---|---|---|

| Harnesses and restraints designed for use by children with physical disabilities | S6.1.2(a)(1)(i)(A) | Head 813 mm; Knee 915 mm | Attached with lap belt; in addition, if a tether is provided, it is attached. |

| Harnesses labeled per S5.3.1(b)(i) through S5.3.1(b)(iii) and Figure 12 | S6.1.2(a)(1)(i)(A) | Head 813 mm; Knee 915 mm | Attached with seat back mount. |

| Belt-positioning seats | S6.1.2(a)(1)(ii) | Head 813 mm; Knee 915 mm | Attached with lap and shoulder belt; no tether is attached. |

| All other child restraints ( i.e., other than harnesses, restraints designed for use by children with physical disabilities, harnesses manufactured exclusively for school buses, and belt-positioning seats) | S6.1.2(a)(1)(i)(B) | Head 813 mm; Knee 915 mm | Attached with a lap belt, without a tether attached; and, Attached to lower anchorages of a child restraint anchorage system; no tether is attached. |

| All other child restraints ( i.e., other than harnesses, restraints designed for use by children with physical disabilities, harnesses labeled per S5.3.1(b)(i) through S5.3.1(b)(iii) and Figure 12, and belt-positioning seats) | S6.1.2(a)(1)(i)(A), S6.1.2(a)(1)(i)(C) | Head 720 mm; Knee 915 mm | Attached with a lap belt, with a tether attached; and, Attached to lower anchorages of child restraint anchorage system, with a tether attached. |

| When this type of child restraint | Is tested in accordance with— | These excursion limits apply | Explanatory note: in the test specified in 2nd column, the excursion requirement must be met when the child restraint system is attached to the test seat assembly in the manner described below, subject to certain conditions |

|---|---|---|---|

| Harnesses and restraints designed for use by children with physical disabilities | S6.1.2(a)(1)(i)(A) | Head 813 mm; Knee 915 mm | Attached with lap and shoulder belt; in addition, if a tether is provided, it is attached. |

| School bus child restraint systems | S6.1.2(a)(1)(i)(A) | Head 813 mm; Knee 915 mm | Attached with seat back mount, or, seat back, and, seat pan mounts. |

| Booster seats | S6.1.2(a)(1)(ii) | Head 813 mm; Knee 915 mm | Attached with lap and shoulder belt; no tether is attached. |

| Child restraints other than harnesses, restraints designed for use by children with physical disabilities, school bus child restraint systems, and booster seats | S6.1.2(a)(1)(i)(B) | Head 813 mm; Knee 915 mm | Attached with a lap belt; without a tether attached. Attached to lower anchorages of child restraint anchorage system; with no tether attached. |

| Child restraints other than harnesses, restraints designed for use by children with physical disabilities, and school bus child restraint systems | S6.1.2(a)(1)(i)(A), S6.1.2(a)(1)(i)(C) | Head 720 mm; Knee 915 mm | Attached with a lap belt, with a tether attached. Attached to lower anchorages of child restraint anchorage system, with a tether attached. |

| Child restraints equipped with a fixed or movable surface described in S5.2.2.2 that has belts that are not an integral part of that fixed or movable surface | S6.1.2(a)(2) | Head 813 mm; Knee 915 mm | Attached with lap belt, no tether is attached. |

(b) In the case of a built-in child restraint system, neither knee pivot point shall, at any time during the dynamic test, pass through a vertical transverse plane that is 305 mm forward of the initial pre-test position of the respective knee pivot point, measured along a horizontal line that passes through the knee pivot point and is parallel to the vertical longitudinal plane that passes through the vehicle’s longitudinal centerline.

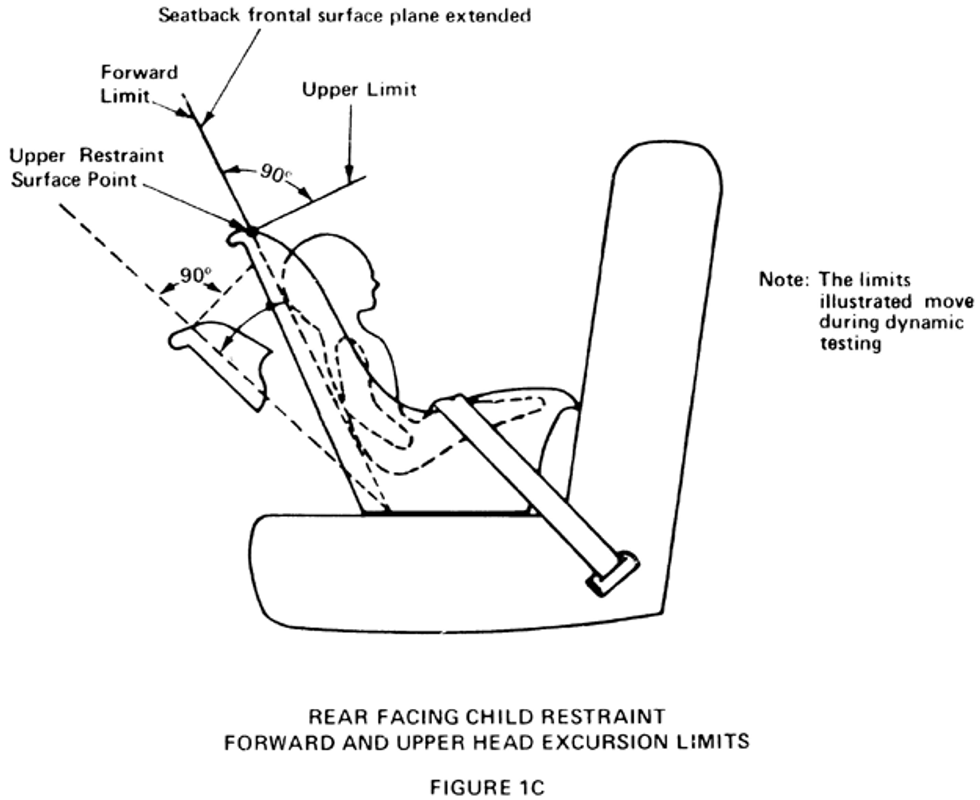

S5.1.3.2 Rear-facing child restraint systems. In the case of each rear-facing child restraint system, all portions of the test dummy’s torso shall be retained within the system and neither of the target points on either side of the dummy’s head and on the transverse axis passing through the center of mass of the dummy’s head and perpendicular to the head’s midsagittal plane, shall pass through the transverse orthogonal planes whose intersection contains the forward-most and top-most points on the child restraint system surfaces (illustrated in Figure 1C).

S5.1.3.3 Car beds. In the case of car beds, all portions of the test dummy’s head and torso shall be retained within the confines of the car bed.

S5.1.4 Back support angle. When a rear-facing child restraint system is tested in accordance with S6.1, the angle between the system’s back support surface for the child and the vertical shall not exceed 70 degrees.

S5.2 Force distribution.

S5.2.1 Minimum head support surface—child restraints other than car beds.

S5.2.1.1 Except as provided in S5.2.1.2, each child restraint system other than a car bed shall provide restraint against rearward movement of the head of the child (rearward in relation to the child) by means of a continuous seat back which is an integral part of the system and which—

(a) Has a height, measured along the system seat back surface for the child in the vertical longitudinal plane passing through the longitudinal centerline of the child restraint systems from the lowest point on the system seating surface that is contacted by the buttocks of the seated dummy, as follows:

| Weight 1 | Height 2 (mm) |

|---|---|

| Not more than 18 kg........................................ | 500 |

| More than 18 kg............................................... | 560 |

1 When a child restraint system is recommended under S5.5 for use by children of the above weights.

2 The height of the portion of the system seat back providing head restraint shall not be less than the above.

(b) Has a width of not less than 8 inches, measured in the horizontal plane at the height specified in paragraph (a) of this section. Except that a child restraint system with side supports extending at least 4 inches forward from the padded surface of the portion of the restraint system provided for support of the child’s head may have a width of not less than 6 inches, measured in the horizontal plane at the height specified in paragraph (a) of this section.

(c) Limits the rearward rotation of the test dummy head so that the angle between the head and torso of the dummy specified in S7. when tested in accordance with S6.1 is not more than 45 degrees greater than the angle between the head and torso after the dummy has been placed in the system in accordance with S6.1.2.3 and before the system is tested in accordance with S6.1.

S5.2.1.2 The applicability of the requirements of S5.2.1.1 to a front-facing child restraint, and the conformance of any child restraint other than a car bed to those requirements, is determined using the largest of the test dummies specified in S7 for use in testing that restraint, provided that the 6-year-old dummy described in subpart I or subpart N of part 572 of this title and the 10-year-old dummy described in subpart T of part 572 of this title, are not used to determine the applicability of or compliance with S5.2.1.1. A front facing child restraint system is not required to comply with S5.2.1.1 if the target point on either side of the dummy's head is below a horizontal plane tangent to the top of—

(a) The standard seat assembly, in the case of an add-on child restraint system, when the dummy is positioned in the system and the system is installed on the assembly in accordance with S6.1.2.

(b) The vehicle seat, in the case of a built-in child restraint system, when the system is activated and the dummy is positioned in the system in accordance with S6.1.2.

S5.2.2 Torso impact protection. Each child restraint system other than a car bed shall comply with the applicable requirements of S5.2.2.1 and S5.2.2.2.

S5.2.2.1(a) The system surface provided for the support of the child’s back shall be flat or concave and have a continuous surface area of not less than 85 square inches.

(b) Each system surface provided for support of the side of the child’s torso shall be flat or concave and have a continuous surface of not less than 24 square inches for systems recommended for children weighing 20 pounds or more, or 48 square inches for systems recommended for children weighing less than 20 pounds.

(c) Each horizontal cross section of each system surface designed to restrain forward movement of the child’s torso shall be flat or concave and each vertical longitudinal cross section shall be flat or convex with a radius of curvature of the underlying structure of not less than 2 inches.

S5.2.2.2 Each forward-facing child restraint system shall have no fixed or movable surface—

(a) Directly forward of the dummy and intersected by a horizontal line—

(1) Parallel to the SORL, in the case of the add-on child restraint system, or

(2) Parallel to a vertical plane through the longitudinal center line of the vehicle seat, in the case of a built-in child restraint system, and,

(b) Passing through any portion of the dummy, except for surfaces which restrain the dummy when the system is tested in accordance with S6.1.2(a)(2), so that the child restraint system shall conform to the requirements of S5.1.2 and S5.1.3.1.

S5.2.3 [Reserved]

S5.2.4 Protrusion limitation. Any portion of a rigid structural component within or underlying a contactable surface, or any portion of a child restraint system surface that is subject to the requirements of S5.2.3 shall, with any padding or other flexible overlay material removed, have a height above any immediately adjacent restraint system surface of not more than 3/8 inch and no exposed edge with a radius of less than 1/4 inch.

S5.3 Installation.

S5.3.1 Add-on child restraints shall meet either (a) or (b), as appropriate.

(a) Except for components designed to attach to a child restraint anchorage system, each add-on child restraint system must not have any means designed for attaching the system to a vehicle seat cushion or vehicle seat back and any component (except belts) that is designed to be inserted between the vehicle seat cushion and vehicle seat back.

(b) School bus child restraint systems (including harnesses manufactured for use on school bus seats) must have a label that conforms in content to Figure 12 and to the requirements of S5.3.1(b)(1) through S5.3.1(b)(3) of this standard. The label must be permanently affixed to the part of the school bus child restraint system, that attaches the system to a vehicle seat back.

(1) The label must be plainly visible when installed and easily readable.

(2) The message area must be white with black text. The message area must be no less than 20 square centimeters.

(3) The pictogram shall be gray and black with a red circle and slash on a white background. The pictogram shall be no less than 20 mm in diameter.

(c) The provision that add-on child restraint systems shall meet the requirements of this standard when installed solely by a Type 1 belt applies to child restraint systems manufactured before September 1, 2029. Except for harnesses, the requirement sunsets for child restraint systems manufactured on or after September 1, 2029. For harnesses, the requirement does not sunset and continues to apply to harnesses manufactured on or after September 1, 2029.

S5.3.2 Each add-on child restraint system shall be capable of meeting the requirements of this standard when installed solely by each of the means indicated in the following table for the particular type of child restraint system:

| Type of add-on child restraint system | Means of installation | ||||

|---|---|---|---|---|---|

| Type 1 seat belt assembly | Type 1 seat belt assembly plus a tether anchorage, if needed | Child restraint anchorage system (effective September 1, 2002) | Type II seat belt assembly | Seat back mount | |

| Harnesses labeled per S5.3.1(b)(1) through S5.3.1(b)(3) and Figure 12 | X | ||||

| Other harnesses | X | ||||

| Car beds | X | ||||

| Rear-facing restraints | X | X | |||

| Belt-positioning seats | X | ||||

| All other child restraints | X | X | X | ||

S5.3.2.1 School bus child restraint systems manufactured on or after December 5, 2024, shall be capable of meeting the requirements of this standard when installed by seat back mount, or, seat back mount and seat pan mount.

S5.3.3 Car beds. Each car bed shall be designed to be installed on a vehicle seat so that the car bed’s longitudinal axis is perpendicular to a vertical longitudinal plane through the longitudinal axis of the vehicle.

S5.4 Belts, belt buckles, and belt webbing.

S5.4.1 Performance requirements.

S5.4.1.1 Child restraint systems manufactured before September 1, 2007. The webbing of belts provided with a child restraint system and used to attach the system to the vehicle or to restrain the child within the system shall—

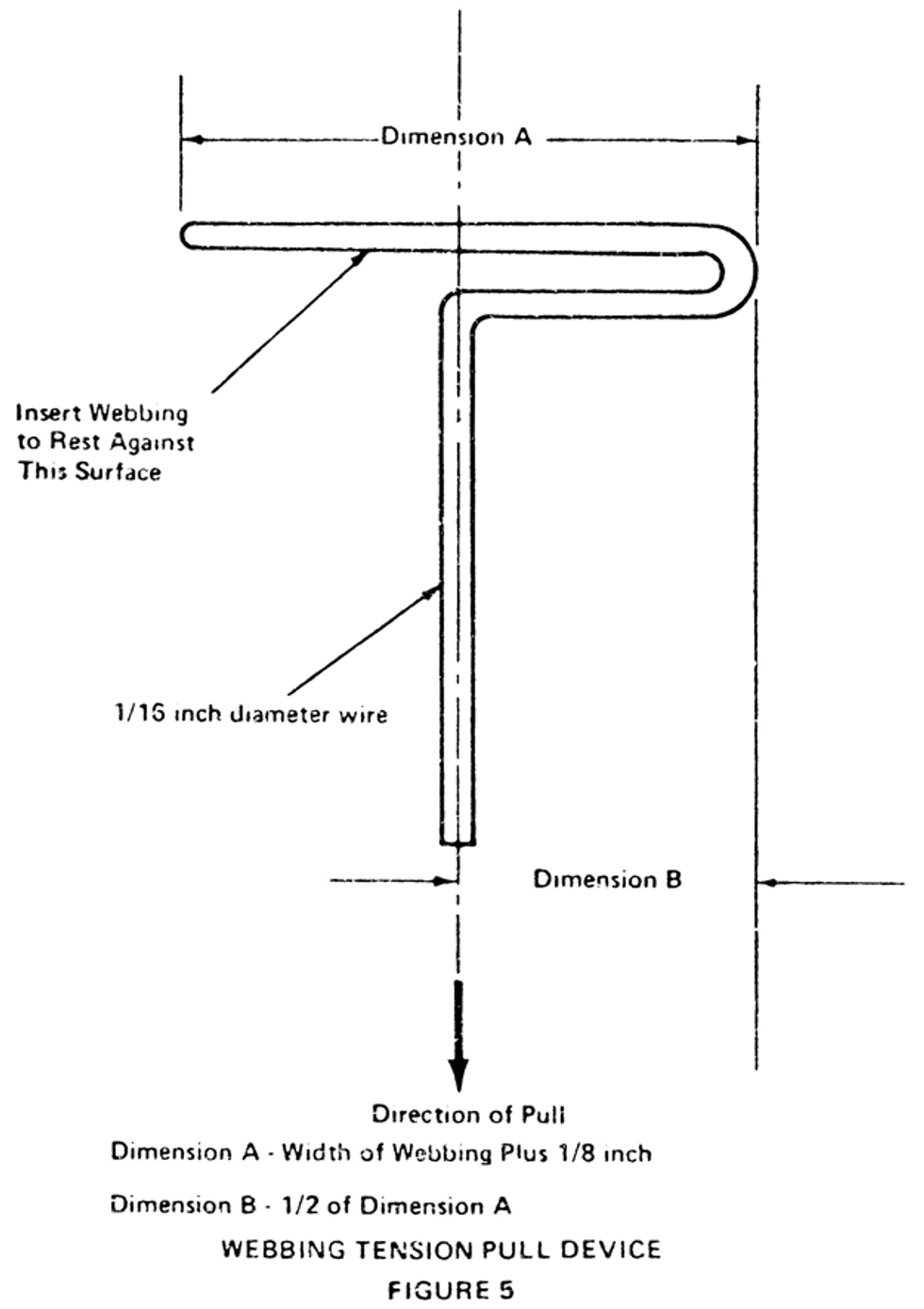

(a) After being subjected to abrasion as specified in S5.1(d) or S5.3(c) of FMVSS 209 ( §571.209 ), have a breaking strength of not less than 75 percent of the strength of the unabraded webbing when tested in accordance with S5.1(b) of FMVSS 209. A mass of 2.35 ±.05 kg shall be used in the test procedure in S5.1(d) of FMVSS 209 for webbing, including webbing used to secure a child restraint system to the tether and lower anchorages of a child restraint anchorage system, except that a mass of 1.5 ±.05 kg shall be used for webbing in pelvic and upper torso restraints of a belt assembly used in a child restraint system. The mass is shown as (B) in Figure 2 of FMVSS 209.

(b) Meet the requirements of S4.2 (e) and (f) of FMVSS No. 209 ( §571.209 ); and

(c) If contactable by the test dummy torso when the system is tested in accordance with S6.1, have a width of not less than 1 1/2 inches when measured in accordance with S5.4.1.3.

S5.4.1.2 Child restraint systems manufactured on or after September 1, 2007. The webbing of belts provided with a child restraint system and used to attach the system to the vehicle or to restrain the child within the system shall—

(a) Have a minimum breaking strength for new webbing of not less than 15,000 N in the case of webbing used to secure a child restraint system to the vehicle, including the tether and lower anchorages of a child restraint anchorage system, and not less than 11,000 N in the case of the webbing used to secure a child to a child restraint system when tested in accordance with S5.1 of FMVSS No. 209. Each value shall be not less than the 15,000 N and 11,000 N applicable breaking strength requirements, but the median value shall be used for determining the retention of breaking strength in paragraphs (b)(1), (c)(1), and (c)(2) of this section S5.4.1.2. ”New webbing” means webbing that has not been exposed to abrasion, light or micro-organisms as specified elsewhere in this section.

(b)(1) After being subjected to abrasion as specified in S5.1(d) or S5.3(c) of FMVSS 209 ( §571.209 ), have a breaking strength of not less than 75 percent of the new webbing strength, when tested in accordance with S5.1(b) of FMVSS

(2) A mass of 2.35 ±.05 kg shall be used in the test procedure in S5.1(d) of FMVSS 209 for webbing, including webbing to secure a child restraint system to the tether and lower anchorages of a child restraint anchorage system, except that a mass of 1.5 ±.05 kg shall be used for webbing in pelvic and upper torso restraints of a belt assembly used in a child restraint system. The mass is shown as (B) in Figure 2 of FMVSS 209.

(c)(1) After exposure to the light of a carbon arc and tested by the procedure specified in S5.1(e) of FMVSS 209 ( §571.209 ), have a breaking strength of not less than 60 percent of the new webbing, and shall have a color retention not less than No. 2 on the AATCC Gray Scale for Evaluating Change in Color (incorporated by reference, see §571.5 ).

(2) After being subjected to micro-organisms and tested by the procedures specified in S5.1(f) of FMVSS 209 ( §571.209 ), shall have a breaking strength not less than 85 percent of the new webbing.

(d) If contactable by the test dummy torso when the system is tested in accordance with S6.1, have a width of not less than 1 1/2 inches when measured in accordance with S5.4.1.3.

S5.4.1.3 Width test procedure. Condition the webbing for 24 hours in an atmosphere of any relative humidity between 48 and 67 percent, and any ambient temperature between 70° and 77 °F. Measure belt webbing width under a tension of 5 pounds applied lengthwise.

S5.4.2 Belt buckles and belt adjustment hardware. Each belt buckle and item of belt adjustment hardware used in a child restraint system shall conform to the requirements of S4.3(a) and S4.3(b) of FMVSS No. 209 ( §571.209 ).

S5.4.3 Belt Restraint.

S5.4.3.1 General. Each belt that is part of a child restraint system and that is designed to restrain a child using the system shall be adjustable to snugly fit any child whose height and weight are within the ranges recommended in accordance with S5.5.2(f) and who is positioned in the system in accordance with the instructions required by S5.6.

S5.4.3.2 Direct restraint. Except for belt-positioning seats, each belt that is part of a child restraint system and that is designed to restrain a child using the system and to attach the system to the vehicle, and each Type I and lap portion of a Type II vehicle belt that is used to attach the system to the vehicle shall, when tested in accordance with S6.1, impose no loads on the child that result from the mass of the system, or—

(a) In the case of an add-on child restraint system, from the mass of the seat back of the standard seat assembly specified in S6.1, or

(b) In the case of a built-in child restraint system, from the mass of any part of the vehicle into which the child restraint system is built.

S5.4.3.3 Seating systems. Except for child restraint systems subject to S5.4.3.4, each child restraint system that is designed for use by a child in a seated position and that has belts designed to restrain the child, shall, with the test dummy specified in S7 positioned in the system in accordance with S10 provide:

(a) Upper torso restraint in the form of:

(i) Belts passing over each shoulder of the child, or

(ii) A fixed or movable surface that complies with S5.2.2.1(c), and

(b) Lower torso restraint in the form of:

(i) A lap belt assembly making an angle between 45° and 90° with the child restraint seating surface at the lap belt attachment points, or

(ii) A fixed or movable surface that complies with S5.2.2.1(c), and

(c) In the case of each seating system recommended for children whose masses are more than 10 kg, crotch restraint in the form of:

(i) A crotch belt connectable to the lap belt or other device used to restrain the lower torso, or

(ii) A fixed or movable surface that complies with S5.2.2.1(c).

S5.4.3.4 Harnesses. Each child harness shall:

(a) Provide upper torso restraint, including belts passing over each shoulder of the child;

(b) Provide lower torso restraint by means of lap and crotch belt; and

(c) Prevent a child of any height for which the restraint is recommended for use pursuant to S5.5.2(f) from standing upright on the vehicle seat when the child is placed in the device in accordance with the instructions required by S5.6.

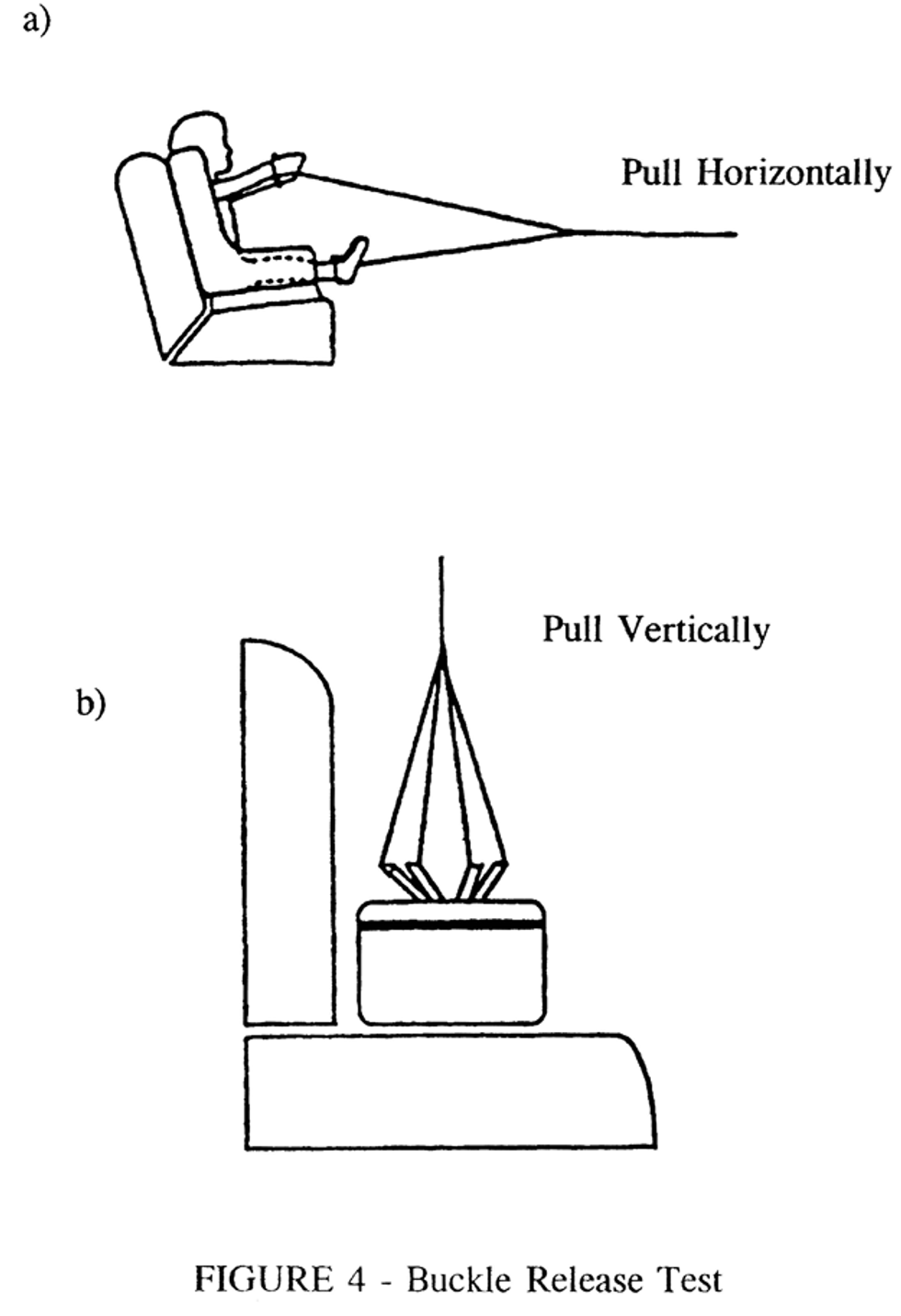

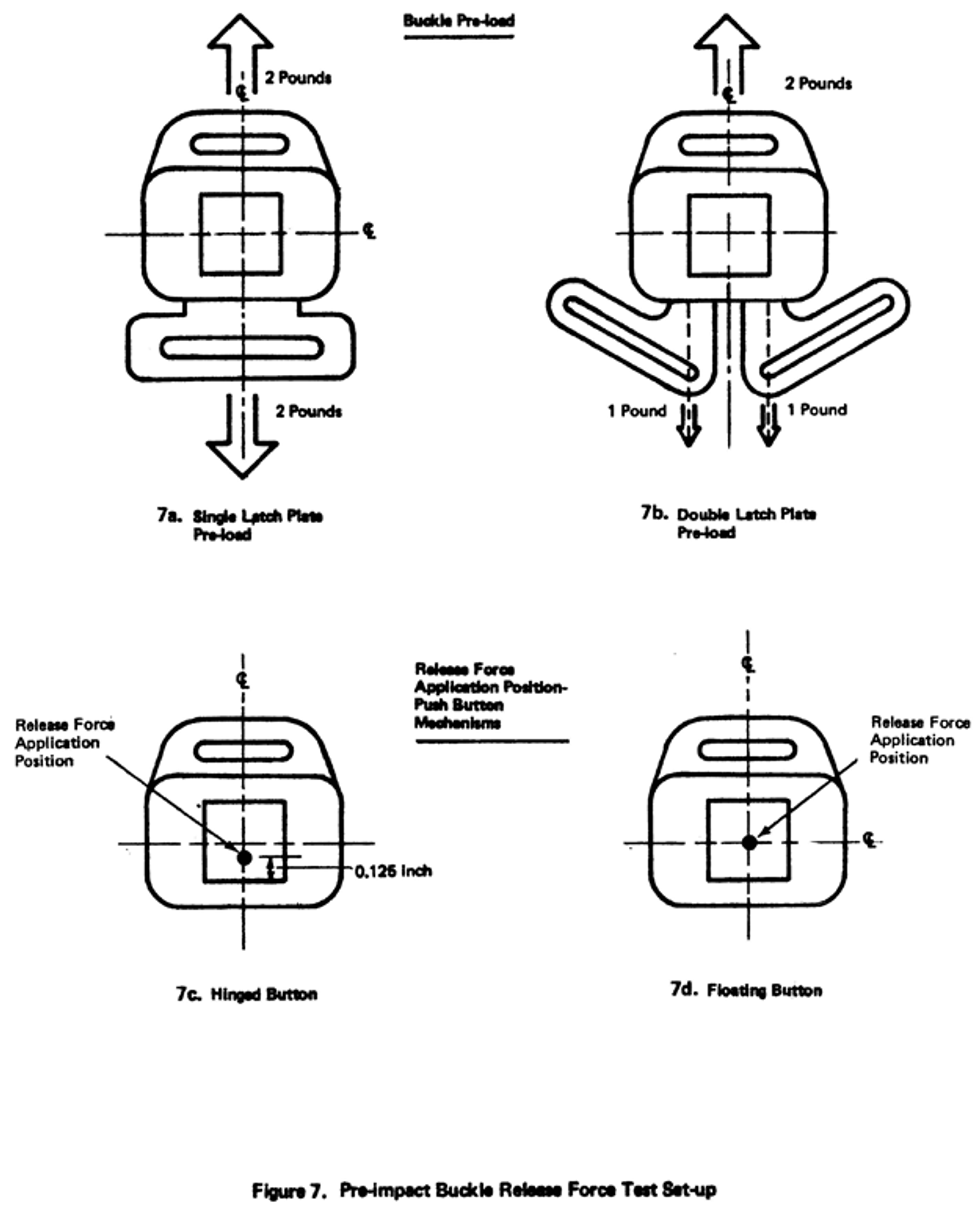

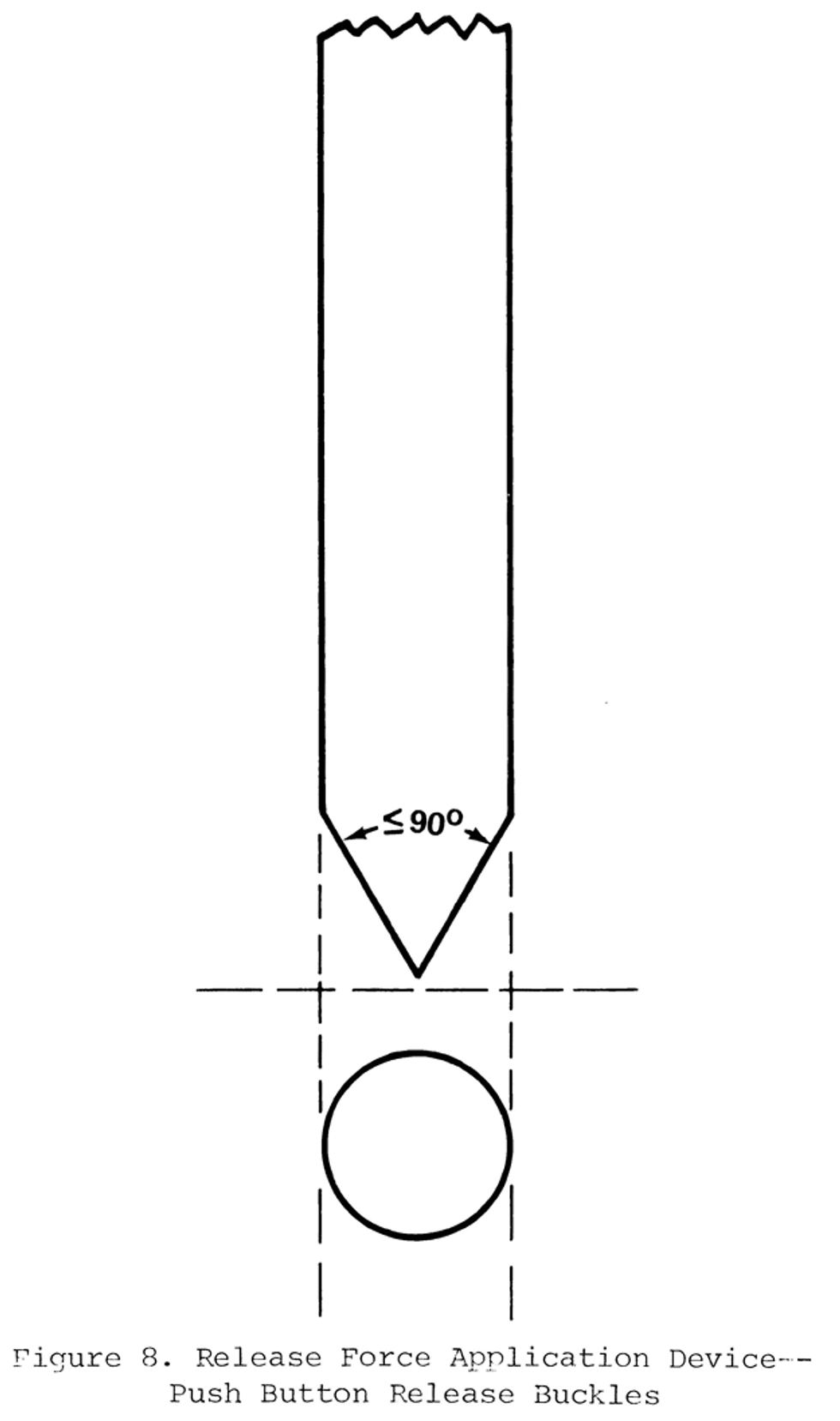

S5.4.3.5 Buckle release. Any buckle in a child restraint system belt assembly designed to restrain a child using the system shall:

(a) When tested in accordance with S6.2.1 prior to the dynamic test of S6.1, not release when a force of less than 40 newtons (N) is applied and shall release when a force of not more than 62 N is applied;

(b) After the dynamic test of S6.1, when tested in accordance with the appropriate sections of S6.2, release when a force of not more than 71 N is applied, provided, however, that the conformance of any child restraint to this requirement is determined using the largest of the test dummies specified in S7 for use in testing that restraint when the restraint is facing forward, rearward, and/or laterally;

(c) Meet the requirements of S4.3(d)(2) of FMVSS No. 209 ( § 571.209 ), except that the minimum surface area for child restraint buckles designed for push button application shall be 0.6 square inch;

(d) Meet the requirements of S4.3(g) of FMVSS No. 209 ( § 571.209 ) when tested in accordance with S5.2(g) of FMVSS No. 209; and

(e) Not release during the testing specified in S6.1.

S5.5 Labeling. Any labels or written instructions provided in addition to those required by this section shall not obscure or confuse the meaning of the required information or be otherwise misleading to the consumer. Any labels or written instructions other than in the English language shall be an accurate translation of English labels or written instructions.

S5.5.1 Each add-on child restraint system shall be permanently labeled with the information specified in S5.5.2 (a) through (m).

S5.5.2 The information specified in paragraphs (a) through (m) of this section shall be stated in the English language and lettered in letters and numbers that are not smaller than 10 point type. Unless otherwise specified, the information shall be labeled on a white background with black text. Unless written in all capitals, the information shall be stated in sentence capitalization.

(a) The model name or number of the system.

(b) The manufacturer’s name. A distributor’s name may be used instead if the distributor assumes responsibility for all duties and liabilities imposed on the manufacturer with respect to the system by the National Traffic and Motor Vehicle Safety Act, as amended.

(c) The statement: “Manufactured in ll,” inserting the month and year of manufacture.

(d) The place of manufacture (city and State, or foreign country). However, if the manufacturer uses the name of the distributor, then it shall state the location (city and State, or foreign country) of the principal offices of the distributor.

(e) The statement: “This child restraint system conforms to all applicable Federal motor vehicle safety standards.”

(f) For child restraint systems manufactured before December 5, 2024, paragraph (f)(1) of this section applies. For child restraint systems manufactured on or after December 5, 2024, paragraph (f)(2) of this section applies.

(1) One of the following statements, as appropriate, inserting the manufacturer's recommendations for the maximum mass of children who can safely occupy the system, except that booster seats shall not be recommended for children whose masses are less than 13.6 kg. For child restraint systems that can only be used as belt-positioning seats, manufacturers must include the maximum and minimum recommended height, but may delete the reference to weight:

(i) Use only with children who weigh __ pounds (__ kg) or less and whose height is ( insert values in English and metric units; use of word “mass” in label is optional ) or less; or

(ii) Use only with children who weigh between __ and __ pounds ( insert appropriate English and metric values; use of word “mass” is optional ) and whose height is ( insert appropriate values in English and metric units ) or less and who are capable of sitting upright alone; or

(iii) Use only with children who weigh between __ and __ pounds ( insert appropriate English and metric values; use of word “mass” is optional ) and whose height is ( insert appropriate values in English and metric units ) or less.

(iv) Use only with children who weigh between __ and __ pounds ( insert appropriate English and metric values; use of word “mass” is optional ) and whose height is between __ and __ ( insert appropriate values in English and metric units ).

(2) For child restraint systems manufactured on or after December 5, 2024: Statements or a combination of statements and pictograms specifying the manufacturer's recommendations for the mass and height ranges (in English and metric units) of children who can safely occupy the system in each applicable mode (rear-facing, forward-facing, booster), except manufacturers shall not recommend forward-facing use for child restraint systems with internal harnesses for children of masses less than 12 kg (26.5 lb), and shall not recommend booster seats for children of masses less than 18.4 kg (40 lb).

(g) The statements specified in paragraphs (1) and (2):

(1) A heading as specified in S5.5.2(k)(3)(i), with the statement “WARNING! DEATH or SERIOUS INJURY can occur,” capitalized as written and followed by bulleted statements in the following order:

(i) As appropriate, the statements required by the following sections will be bulleted and placed after the statement required by 5.5.2(g)(1) in the following order: 5.5.2(k)(1), 5.5.2(h), 5.5.2(j), and 5.5.2(i). For child restraint systems manufactured on or after December 5, 2024, the statements required by 5.5.2(f) and 5.5.2(k)(2) need not be included.

(ii) Secure this child restraint with the vehicle's child restraint anchorage system, if available, or with a vehicle belt. [For car beds, harnesses, and belt positioning seats, the first part of the statement regarding attachment by the child restraint anchorage system is optional.] [For belt-positioning seats, the second part of the statement regarding attachment by the vehicle belt does not apply.] [For child restraints manufactured from February 27, 2014 to February 26, 2015, the following statement applies.] Child restraint systems equipped with internal harnesses to restrain the child and with components to attach to a child restraint anchorage system and for which the combined weight of the child restraint system and the maximum recommended child weight for use with internal harnesses exceeds 65 pounds, must be labeled with the following statement: “Do not use the lower anchors of the child restraint anchorage system (LATCH system) to attach this child restraint when restraining a child weighing more than * [*insert a recommended weight value in English and metric units such that the sum of the recommended weight value and the weight of the child restraint system does not exceed 65 pounds (29.5 kg)] with the internal harnesses of the child restraint.”

(iii) Follow all instructions on this child restraint and in the written instructions located ( insert storage location on the restraint for the manufacturer’s installation instruction booklet or sheet ).

(iv) Register your child restraint with the manufacturer.

(2) At the manufacturer’s option, the phrase “DEATH or SERIOUS INJURY can occur” in the heading can be on either a white or yellow background.

(3) More than one label may be used for the required bulleted statements. Multiple labels shall be placed one above the other unless that arrangement is precluded by insufficient space or shape of the child restraint. In that case, multiple labels shall be placed side by side. When using multiple labels, the mandated warnings must be in the correct order when read from top to bottom. If the labels are side-by-side, then the mandated warnings must appear top to bottom of the leftmost label, then top to bottom of the next label to its right, and so on. There shall be no intervening labels and the required heading shall only appear on the first label in the sequence.

(h) In the case of each child restraint system that has belts designed to restrain children using them and which do not adjust automatically to fit the child: Snugly adjust the belts provided with this child restraint around your child.

(i)(1) For a booster seat that is recommended for use with either a vehicle’s Type I or Type II seat belt assembly, one of the following statements, as appropriate:

(i) Use only the vehicle’s lap and shoulder belt system when restraining the child in this booster seat; or,

(ii) Use only the vehicle’s lap belt system, or the lap belt part of a lap/ shoulder belt system with the shoulder belt placed behind the child, when restraining the child in this seat.

(2)(i) Except as provided in paragraph (i)(2)(ii) of this section, for a booster seat which is recommended for use with both a vehicle’s Type I and Type II seat belt assemblies, the following statement: Use only the vehicle’s lap belt system, or the lap belt part of a lap/shoulder belt system with the shoulder belt placed behind the child, when restraining the child with the ( insert description of the system element provided to restrain forward movement of the child’s torso when used with a lap belt ( e.g., shield )), and only the vehicle’s lap and shoulder belt system when using the booster without the ( insert above description ).

(ii) A booster seat which is recommended for use with both a vehicle’s Type I and Type II seat belt assemblies is not subject to S5.5.2(i)(2)(i) if, when the booster is used with the shield or similar component, the booster will cause the shoulder belt to be located in a position other than in front of the child when the booster is installed. However, such a booster shall be labeled with a warning to use the booster with the vehicle’s lap and shoulder belt system when using the booster without a shield.

(j) In the case of each child restraint system equipped with a top anchorage strap, the statement: Secure the top anchorage strap provided with this child restraint.

(k) (1) In the case of each rear-facing child restraint system that is designed for infants only, the statement: Use only in a rear-facing position when using it in the vehicle.

(2) In the case of a child restraint system that is designed to be used rearward-facing for infants and forward-facing for older children, the statement: Use only in a rear-facing position when using it with an infant weighing less than ( insert a recommended weight that is not less than 20 pounds ).

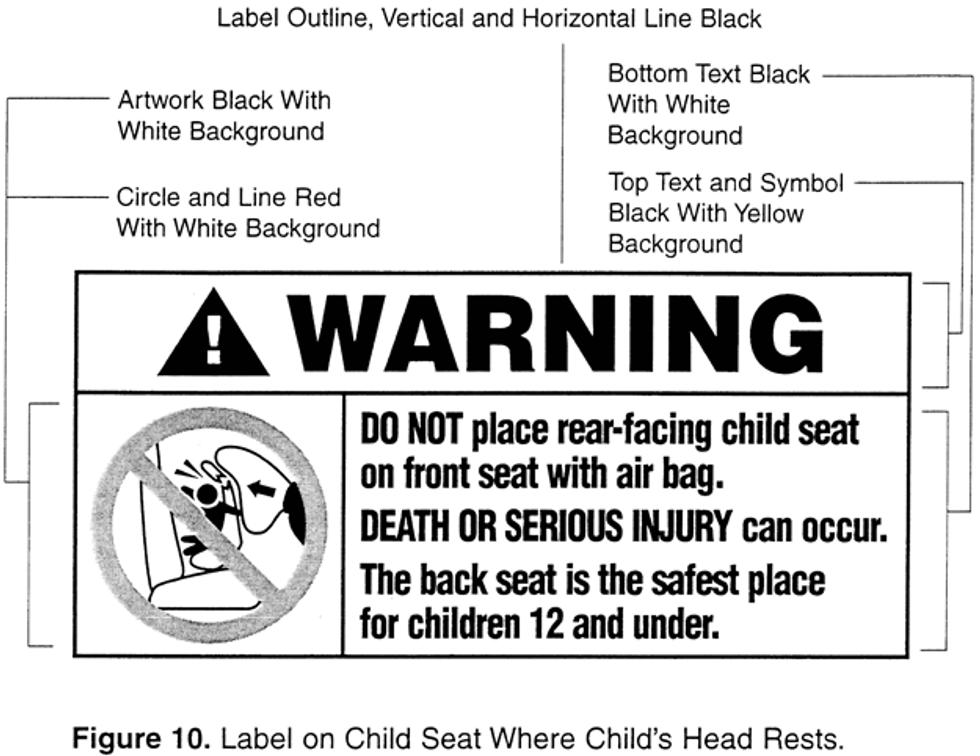

(3) Except as provided in (k)(4) of this section, each child restraint system that can be used in a rear-facing position shall have a label that conforms in content to Figure 10 and to the requirements of S5.5.2(k)(3)(i) through S5.5.2(k)(3)(iii) of this standard permanently affixed to the outer surface of the cushion or padding in or adjacent to the area where a child’s head would rest, so that the label is plainly visible and easily readable.

(i) The heading area shall be yellow with the word “warning” and the alert symbol in black.

(ii) The message area shall be white with black text. The message area shall be no less than 30 square cm.

(iii) The pictogram shall be black with a red circle and slash on a white background. The pictogram shall be no less than 30 mm in diameter.

(4) If a child restraint system is equipped with a device that deactivates the passenger-side air bag in a vehicle when and only when the child restraint is installed in the vehicle and provides a signal, for at least 60 seconds after deactivation, that the air bag is deactivated, the label specified in Figure 10 may include the phrase “unless air bag is off” after “on front seat with air bag.”

(l) An installation diagram showing the child restraint system installed in:

(1) A seating position equipped with a continuous-loop lap/shoulder belt;

(2) [Reserved]

(3) A seating position equipped with a child restraint anchorage system. For child restraint systems manufactured on or after February 27, 2015, the following paragraphs (l)(3)(i) and (ii) apply, as appropriate.

(i) If the child restraint system is designed to meet the requirements of this standard when installed by the child restraint anchorage system according to S5.3.2, and if the sum of the weight of the child restraint system and the maximum child weight recommended for the child restraint when used with the restraint's internal harness or components is greater than 65 lb when used forward-facing or rear-facing, include the following statement on this installation diagram: “Do not install by this method for a child weighing more than *.” At the manufacturer's option, “*” is the child weight limit in English units in accordance with S5.5.2(l)(3)(i)(A), (B) or (C). The corresponding child weight limit in metric units may also be included in the statement at the manufacturer's option.

(A) For forward-facing and rear-facing child restraints, * is less than or equal to 65 minus child restraint weight (pounds).

(B) For forward-facing child restraints, * is the child weight limit specified in the following table corresponding to the value CW, calculated as 65 minus child restraint weight (pounds).

| CW = 65-child restaint weight

(pounds) | Child weight limit "*"

(pounds) |

| 20 < CW ≤ 25 | 25 |

| 25 < CW ≤ 30 | 30 |

| 30 < CW ≤ 35 | 35 |

| 35 < CW ≤ 40 | 40 |

| 40 < CW ≤ 45 | 45 |

| 45 < CW ≤ 50 | 50 |

| 50 < CW ≤ 55 | 55 |

| 55 < CW ≤ 60 | 60 |

(C) For rear-facing child restraints, * is the child weight limit specified in the following table corresponding to the value CW, calculated as 60 minus child restraint weight (pounds).

| CW = 60-child restraint weight

(pounds) | Child weight limit "*"

(pounds) |

| 15 < CW ≤ 20 | 20 |

| 20 < CW ≤ 25 | 25 |

| 25 < CW ≤ 30 | 30 |

| 30 < CW ≤ 35 | 35 |

| 35 < CW ≤ 40 | 40 |

| 40 < CW ≤ 45 | 45 |

| 45 < CW ≤ 50 | 50 |

(ii) For child restraints designed to meet the requirements of this standard when installed forward-facing and rear-facing by the child restraint anchorage system according to S5.3.2, the following applies:

(A) If separate installation diagrams are provided for the child restraint installed forward-facing and rear-facing, S5.5.2(l)(3)(i) applies to each of the installation diagrams.

(B) If only one installation diagram is provided and if a statement specifying a child weight limit is required in only rear-facing or forward-facing mode pursuant to S5.5.2(l)(3)(i), then the diagram shall depict installation in that mode along with the corresponding child weight limit in accordance with S5.5.2(l)(3)(i).

(C) If a statement specifying a child weight limit is required for the child restraint installed forward-facing and rear-facing pursuant to S5.5.2(l)(3)(i) and only one installation diagram is provided, then the child weight limit shall be in accordance with S5.5.2(l)(3)(i)(A) or the lesser of the child weight limits described in S5.5.2(l)(3)(i)(B) and (C).

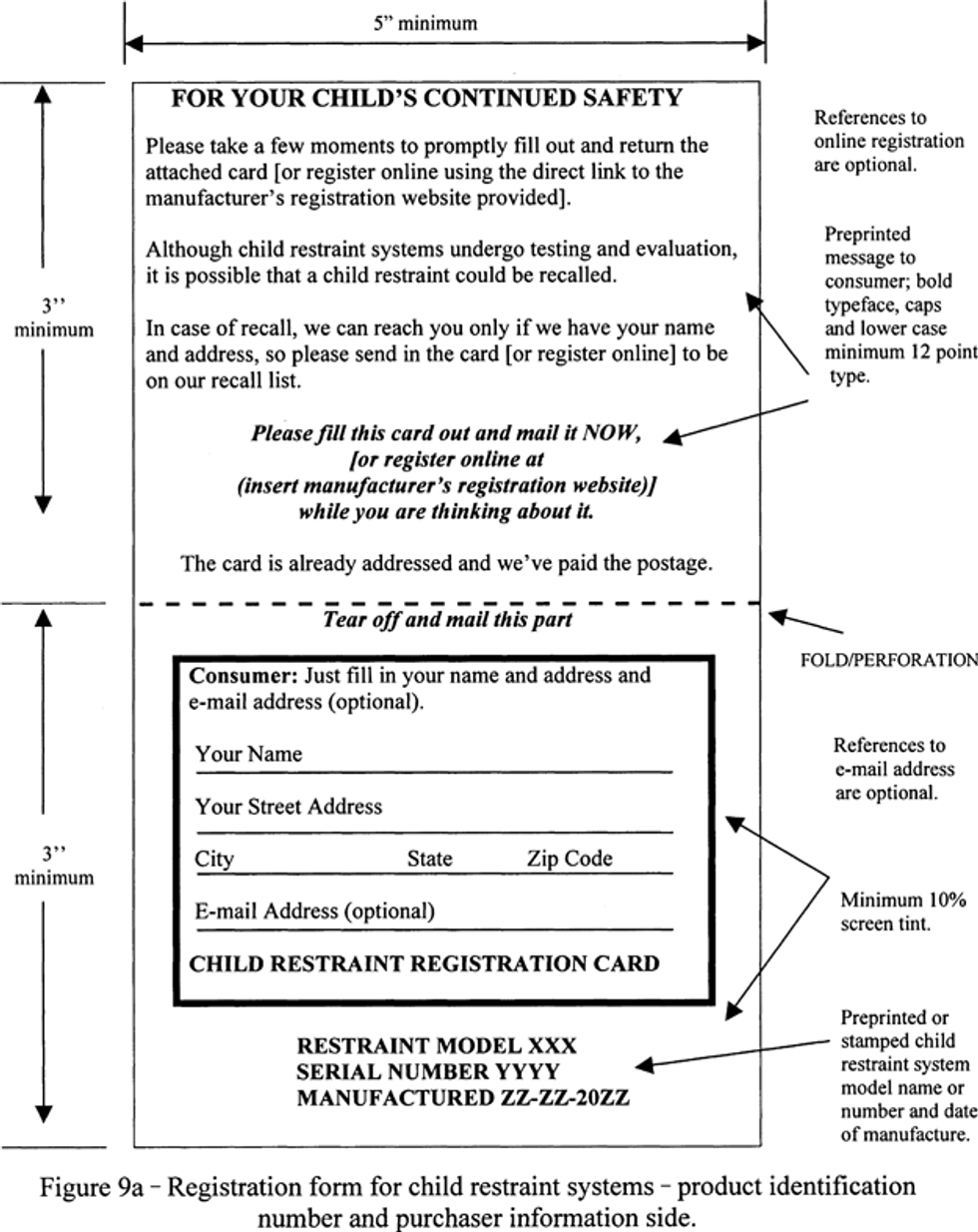

(m) One of the following statements, inserting an address and a U.S. telephone number. If a manufacturer opts to provide a Web site on the registration card as permitted in Figure 9a of this section, the manufacturer must include the statement in part (ii):

(i) “Child restraints could be recalled for safety reasons. You must register this restraint to be reached in a recall. Send your name, address, e-mail address if available (preceding four words are optional) and the restraint’s model number and manufacturing date to ( insert address ) or call ( insert a U.S. telephone number ). For recall information, call the U.S. Government’s Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153), or go to http://www.NHTSA.gov.”

(ii) “Child restraints could be recalled for safety reasons. You must register this restraint to be reached in a recall. Send your name, address, e-mail address if available [preceding four words are optional], and the restraint’s model number and manufacturing date to ( insert address ) or call ( insert a U.S. telephone number ) or register online at ( insert Web site for electronic registration form ). For recall information, call the U.S. Government’s Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153), or go to http:// www.NHTSA.gov.”

(n) Child restraint systems, other than belt-positioning seats, harnesses and backless child restraint systems, may be certified as complying with the provisions of S8. Child restraints that are so certified shall be labeled with the statement “This Restraint is Certified for Use in Motor Vehicles and Aircraft.” Belt-positioning seats, harnesses and backless child restraint systems shall be labeled with the statement “This Restraint is Not Certified for Use in Aircraft.” The statement required by this paragraph shall be in red lettering and shall be placed after the certification statement required by S5.5.2(e).

S5.5.3 The information specified in S5.5.2(f) through (l) shall be located on the add-on child restraint system so that it is visible when the system is installed as specified in S5.6.1, except that for child restraints with a detachable base, the installation diagrams specified in S5.5.2(l) are required to be visible only when the base alone is installed.

S5.5.4 (a) Each built-in child restraint system other than a factory-installed built-in restraint shall be permanently labeled with the information specified in S5.5.5 (a) through (l). The information specified in S5.5.5(a) through (j) and in S5.5.5(l) shall be visible when the system is activated for use.

(b) Each factory-installed built-in child restraint shall be permanently labeled with the information specified in S5.5.5(f) through (j) and S5.5.5(l), so that the information is visible when the restraint is activated for use. The information shall also be included in the vehicle owner’s manual.

S5.5.5 The information specified in paragraphs (a) through (l) of this section that is required by S5.5.4 shall be in English and lettered in letters and numbers using a not smaller than 10 point type. Unless specified otherwise, the information shall be labeled on a white background with black text. Unless written in all capitals, the information shall be stated in sentence capitalization.

(a) The model name or number of the system.

(b) The manufacturer’s name. A distributor’s or dealer’s name may be used instead if the distributor or dealer assumes responsibility for all duties and liabilities imposed on the manufacturer with respect to the system by the National Traffic and Motor Vehicle Safety Act, as amended.

(c) The statement: “Manufactured in ____,” inserting the month and year of manufacture.

(d) The place of manufacture (city and State, or foreign country). However, if the manufacturer uses the name of the distributor or dealer, then it shall state the location (city and State, or foreign country) of the principal offices of the distributor or dealer.

(e) The statement: “This child restraint system conforms to all applicable Federal motor vehicle safety standards.”

(f) One of the following statements, inserting the manufacturer’s recommendations for the maximum mass of children who can safely occupy the system, except that booster seats shall not be recommended for children whose masses are less than 13.6 kg. For seats that can only be used as belt-positioning seats, manufacturers must include the maximum and minimum recommended height, but may delete the reference to weight:

(1) Use only with children who weigh ___ pounds ( ___ kg) or less and whose height is ( insert values in English and metric units; use of word “mass” in label is optional ) or less; or

(2) Use only with children who weigh between ___ and ___ pounds ( ___ and ___ kg) and whose height is ( insert appropriate values in English and metric units; use of word “mass” in label is optional ) or less and who are capable of sitting upright alone; or

(3) Use only with children who weigh between ___ and ___ pounds ( ___ and ___ kg) and whose height is ( insert appropriate values in English and metric units; use of word “mass” in label is optional ) or less.

(4) Use only with children who weigh between ___ and ___ pounds ( insert appropriate English and metric values; use of word ”mass” is optional ) and whose height is between ___ and ___ ( insert appropriate values in English and metric units ).

(g) The heading and statement specified in paragraph (1), and if appropriate, the statements in paragraph (2) and (3). If used, the statements in paragraphs (2) and (3) shall be bulleted and precede the bulleted statement required by paragraph (1) after the heading.

(1) A heading as specified in S5.5.2(k)(3)(i), with the statement “WARNING! DEATH or SERIOUS INJURY can occur,” capitalized as written and followed by the bulleted statement: Follow all instructions on the child restraint and in the vehicle’s owner’s manual. At the manufacturer’s option, the phrase “DEATH or SERIOUS INJURY can occur” in the heading can be on either a white or yellow background.

(2) In the case of each built-in child restraint system which is not intended for use in motor vehicles in certain adjustment positions or under certain circumstances, an appropriate statement of the manufacturers restrictions regarding those positions or circumstances.

(3) As appropriate, the statements required by the following sections will be bulleted and placed after the statement required by 5.5.5(g)(1) in the following order: 5.5.5(g)(2), 5.5.5(f), S5.5.5(h) and S5.5.5(i).

(h) In the case of each built-in child restraint system that has belts designed to restrain children using them and which do not adjust automatically to fit the child: Snugly adjust the belts provided with this child restraint around your child.

(i) In the case of each built-in child restraint which can be used in a rear—

facing position, the following statement: Place an infant in a rear-facing position in this child restraint.

(j) A diagram or diagrams showing the fully activated child restraint system in infant and/or child configurations.

(k) One of the following statements, inserting an address and a U.S. telephone number. If a manufacturer opts to provide a Web site on the registration card as permitted in Figure 9a of this section, the manufacturer must include the statement in part (ii):

(i) “Child restraints could be recalled for safety reasons. You must register this restraint to be reached in a recall. Send your name, address, e-mail address if available (preceding four words are optional), and the restraint’s model number and manufacturing date to ( insert address ) or call ( insert a U.S. telephone number ). For recall information, call the U.S. Government’s Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153), or go to http:// www.NHTSA.gov.”

(ii) “Child restraints could be recalled for safety reasons. You must register this restraint to be reached in a recall. Send your name, address, e-mail address if available (preceding four words are optional), and the restraint’s model number and manufacturing date to ( insert address ) or call ( insert telephone number ) or register online at ( insert Web site for electronic registration form ). For recall information, call the U.S. Government’s Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153), or go to http:// www.NHTSA.gov.”

(l) In the case of a built-in belt-positioning seat that uses either the vehicle’s Type I or Type II belt systems or both, a statement describing the manufacturer’s recommendations for the maximum height and weight of children who can safely occupy the system and how the booster should be used (e.g., with or without shield) with the different vehicle belt systems.

S5.6 Printed Instructions for Proper Use. Any labels or written instructions provided in addition to those required by this section shall not obscure or confuse the meaning of the required information or be otherwise misleading to the consumer. Any labels or written instructions other than in the English language shall be an accurate translation of English labels or written instructions. Unless written in all capitals, the information required by S5.6.1 through S5.6.3 shall be stated in sentence capitalization.

S5.6.1 Add-on child restraint systems. Each add-on child restraint system shall be accompanied by printed installation instructions in English that provide a step-by-step procedure, including diagrams, for installing the system in motor vehicles, securing the system in the vehicles, positioning a child in the system, and adjusting the system to fit the child. For each child restraint system that has components for attaching to a tether anchorage or a child restraint anchorage system, the installation instructions shall include a step-by-step procedure, including diagrams, for properly attaching to that anchorage or system.

S5.6.1.1 In a vehicle with rear designated seating positions, the instructions shall alert vehicle owners that, according to accident statistics, children are safer when properly restrained in the rear seating positions than in the front seating positions.

S5.6.1.2 The instructions shall specify in general terms the types of vehicles, the types of seating positions, and the types of vehicle safety belts with which the add-on child restraint system can or cannot be used.

S5.6.1.3 The instructions shall explain the primary consequences of not following the warnings required to be labeled on the child restraint system in accordance with S5.5.2 (g) through (k).

S5.6.1.4 The instructions for each car bed shall explain that the car bed should position in such a way that the child’s head is near the center of the vehicle.

S5.6.1.5 The instructions shall state that add-on child restraint systems should be securely belted to the vehicle, even when they are not occupied, since in a crash an unsecured child restraint system may injure other occupants.

S5.6.1.6 Each add-on child restraint system shall have a location on the restraint for storing the manufacturer’s instructions.

S5.6.1.7(a) For child restraint systems manufactured before December 5, 2024, one of the following statements, inserting an address and a U.S. telephone number. If a manufacturer opts to provide a website on the registration card as permitted in Figure 9a of this section, the manufacturer must include the statement in paragraph S5.6.1.7(a)(2):

(1) “Child restraints could be recalled for safety reasons. You must register this restraint to be reached in a recall. Send your name, address, email address if available (preceding four words are optional), and the restraint's model number and manufacturing date to ( insert address ) or call ( insert a U.S. telephone number ). For recall information, call the U.S. Government's Vehicle Safety Hotline at 1–888–327–4236 (TTY: 1–800–424–9153), or go to www.NHTSA.gov. ”

(2) “Child restraints could be recalled for safety reasons. You must register this restraint to be reached in a recall. Send your name, address, email address if available (preceding four words are optional), and the restraint's model number and manufacturing date to ( insert address ) or call ( insert telephone number ) or register online at ( insert website for electronic registration form ). For recall information, call the U.S. Government's Vehicle Safety Hotline at 1–888–327–4236 (TTY: 1–800–424–9153), or go to www.NHTSA.gov. ”

(b) For child restraint systems manufactured on or after December 5, 2024, the child restraint system shall include statements informing the owner of the importance of registering the child restraint for recall purposes and instructing the owner how to register the child restraint at least by mail and by telephone, providing a U.S. telephone number. The following statement must also be provided: “For recall information, call the U.S. Government's Vehicle Safety Hotline at 1–888–327–4236 (TTY: 1–800–424–9153), or go to www.NHTSA.gov. ”

S5.6.1.8 In the case of each child restraint system that can be used in a position so that it is facing the rear of the vehicle, the instructions shall provide a warning against using rear-facing restraints at seating positions equipped with air bags, and shall explain the reasons for, and consequences of not following the warning. The instructions shall also include a statement that owners of vehicles with front passenger side air bags should refer to their vehicle owner’s manual for child restraint installation instructions.

S5.6.1.9 In the case of each rear-facing child restraint system that has a means for repositioning the seating surface of the system that allows the system’s occupant to move from a reclined position to an upright position during testing, the instructions shall include a warning against impeding the of the restraint to change adjustment position.

S5.6.1.10(a) For instructions for a booster seat that is recommended for use with either a vehicle’s Type I or Type II seat belt assembly, one of the following statements, as appropriate, and the reasons for the statement:

(1) Warning! Use only the vehicle’s lap and shoulder belt system when restraining the child in this booster seat; or,

(2) Warning! Use only the vehicle’s lap belt system, or the lap belt part of a lap/shoulder belt system with the shoulder belt placed behind the child, when restraining the child in this seat.

(b)(1) Except as provided in S5.6.1.10(b)(2), the instructions for a booster seat that is recommended for use with both a vehicle’s Type I and Type II seat belt assemblies shall include the following statement and the reasons therefor: Warning! Use only the vehicle’s lap belt system, or the lap belt part of a lap/shoulder belt system with the shoulder belt placed behind the child, when restraining the child with the ( insert description of the system element provided to restrain forward movement of the child’s torso when used with a lap belt (e.g., shield )), and only the vehicle’s lap and shoulder belt system when using this booster without the ( insert above description ).

(2) A booster seat which is recommended for use with both a vehicle’s Type I and Type II seat belt assemblies is not subject to S5.6.1.10(b)(1) if, when the booster is used with the shield or similar component, the booster will cause the shoulder belt to be located in a position other than in front of the child when the booster is installed. However, the instructions for such a booster shall include a warning to use the booster with the vehicle’s lap and shoulder belt system when using the booster without a shield.

(c) The instructions for belt-positioning seats shall include the statement, “This restraint is not certified for aircraft use,” and the reasons for this statement.

S5.6.1.11(a) For harnesses that are manufactured before December 5, 2024, for use on school bus seats, the instructions must include the following statement:

“WARNING! This restraint must only be used on school bus seats. Entire seat directly behind must be unoccupied or have restrained occupants.” The labeling requirement refers to a restrained occupant as: an occupant restrained by any user appropriate vehicle restraint or child restraint system ( e.g., lap belt, lap and shoulder belt, booster, child seat, harness . . .).

(b) For school bus child restraint systems manufactured on or after December 5, 2024, the instructions must include the following statement:

“WARNING! This restraint must only be used on school bus seats. Entire seat directly behind must be unoccupied or have restrained occupants.” (The instruction's reference to a “restrained occupant” refers to an occupant restrained by any user-appropriate vehicle restraint or child restraint system ( e.g., lap belt, lap and shoulder belt, booster seat or other child restraint system.)

S5.6.1.12(a) Child restraint systems manufactured from February 27, 2014 to February 26, 2015. The instructions for child restraint systems equipped with an internal harness to restrain the child and with components to attach to a child restraint anchorage system, and for which the combined weight of the child restraint system and the maximum recommended child weight for use with the internal harness exceeds 65 pounds, must include the following statement: “Do not use the lower anchors of the child restraint anchorage system (LATCH system) to attach this child restraint when restraining a child weighing more than “*” [*insert a recommended weight value in English and metric units such that the sum of the recommended weight value and the weight of the child restraint system does not exceed 65 pounds (29.5 kg)] with the internal harness of the child restraint.”

(b) Child restraint systems manufactured on or after February 27, 2015. If the child restraint is designed to meet the requirements of this standard when installed by the child restraint anchorage system according to S5.3.2, the installation diagram showing the child restraint system installed using a child restraint anchorage system must meet the specifications in S5.5.2(l)(3).

S5.6.2 Built-in child restraint systems.

(a) Each built-in child restraint system shall be accompanied by printed instructions in English that provide a step-by-step procedure, including diagrams, for activating the restraint system, positioning a child in the system, adjusting the restraint and, if provided, the restraint harness to fit the child. The instructions for each built-in car bed shall explain that the child should be positioned in the bed in such a way that the child’s head is near the center of the vehicle.

(b) Each motor vehicle equipped with a factory-installed built-in child restraint shall have the information specified in paragraph (a) of this section included in its vehicle owner’s manual.

S5.6.2.1 The instructions shall explain the primary consequences of not following the manufacturer’s warnings for proper use of the child restraint system in accordance with S5.5.5 (f) through (i).

S5.6.2.2(a) For child restraint systems manufactured before December 5, 2024, the instructions for each built-in child restraint system other than a factory-installed restraint, shall include one of the following statements, inserting an address and a U.S. telephone number. If a manufacturer opts to provide a website on the registration card as permitted in Figure 9a of this section, the manufacturer must include the statement in S5.6.2.2(a)(2):

(1) “Child restraints could be recalled for safety reasons. You must register this restraint to be reached in a recall. Send your name, address, email address if available (preceding four words are optional), and the restraint's model number and manufacturing date to ( insert address ) or call ( insert a U.S. telephone number ). For recall information, call the U.S. Government's Vehicle Safety Hotline at 1–888–327–4236 (TTY: 1–800–424–9153), or go to www.NHTSA.gov. ”

(2) “Child restraints could be recalled for safety reasons. You must register this restraint to be reached in a recall. Send your name, address, email address if available (preceding four words are optional), and the restraint's model number and manufacturing date to ( insert address ) or call (insert U.S. telephone number) or register online at ( insert website for electronic registration form ). For recall information, call the U.S. Government's Vehicle Safety Hotline at 1–888–327–4236 (TTY: 1–800–424–9153), or go to www.NHTSA.gov. ”

(b) For child restraint systems manufactured on or after December 5, 2024, the instructions for each built-in child restraint system other than a factory-installed restraint shall include statements informing the owner of the importance of registering the child restraint for recall purposes and instructing the owner how to register the child restraint at least by mail and by telephone, providing a U.S. telephone number. The following statement must also be provided: “For recall information, call the U.S. Government's Vehicle Safety Hotline at 1–888–327–4236 (TTY: 1–800–424–9153), or go to www.NHTSA.gov. ”

S5.6.2.3. Each built-in child restraint system other than a factory-installed built-in restraint, shall have a location on the restraint for storing the instructions.

S5.6.2.4 Each built-in child restraint system, other than a system that has been installed in a vehicle or a factory-installed built-in system that is designed for a specific vehicle model and seating position, shall be accompanied by instructions in English that provide a step-by-step procedure for installing the system in a motor vehicle. The instructions shall specify the types of vehicles and the seating positions into which the restraint can or cannot be installed. The instructions for each car bed shall explain that the bed should be installed so that the child’s head will be near the center of the vehicle.

S5.6.2.5 In the case of a built-in belt-positioning seat that uses either the vehicle’s Type I or Type II belt systems or both, the instructions shall include a statement describing the manufacturer’s recommendations for the maximum height and weight of children who can safely occupy the system and how the booster must be used with the vehicle belt systems appropriate for the booster seat. The instructions shall explain the consequences of not following the directions. The instructions shall specify that, if the booster seat is recommended for use with only the lap-belt part of a Type II assembly, the shoulder belt portion of the assembly must be placed behind the child.

S5.6.3 Add-on and built-in child restraint systems. In the case of each child restraint system that has belts designed to restrain children using them and which do not adjust automatically to fit the child, the printed instructions shall include the following statement: A snug strap should not allow any slack. It lies in a relatively straight line without sagging. It does not press on the child’s flesh or push the child’s body into an unnatural position.

S5.7 Flammability. Each material used in a child restraint system shall conform to the requirements of S4 of FMVSS No. 302 (571.302). In the case of a built-in child restraint system, the requirements of S4 of FMVSS No. 302 shall be met in both the “in-use” and “stowed” positions.

S5.8 Information requirements—attached registration form and electronic registration form.

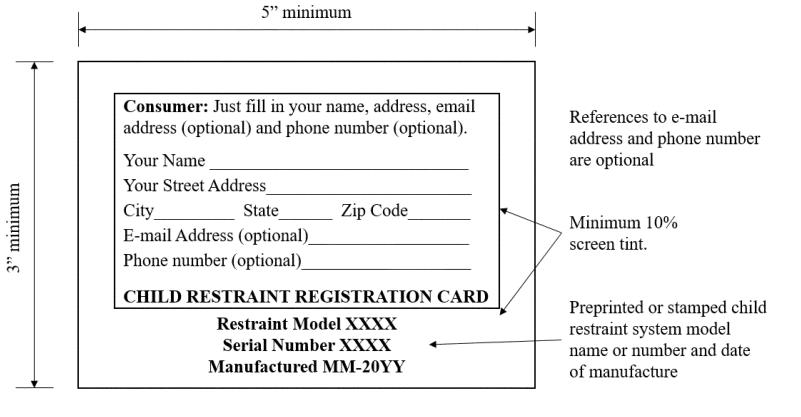

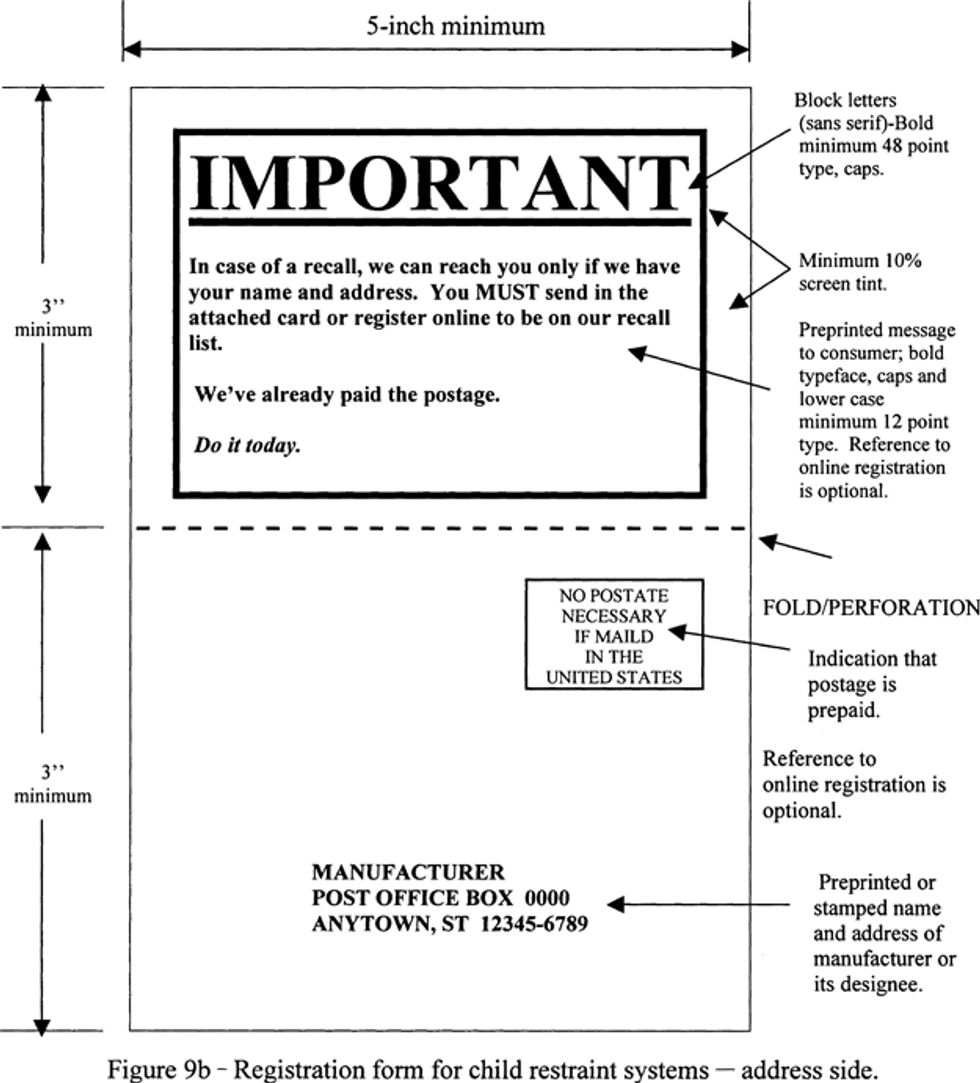

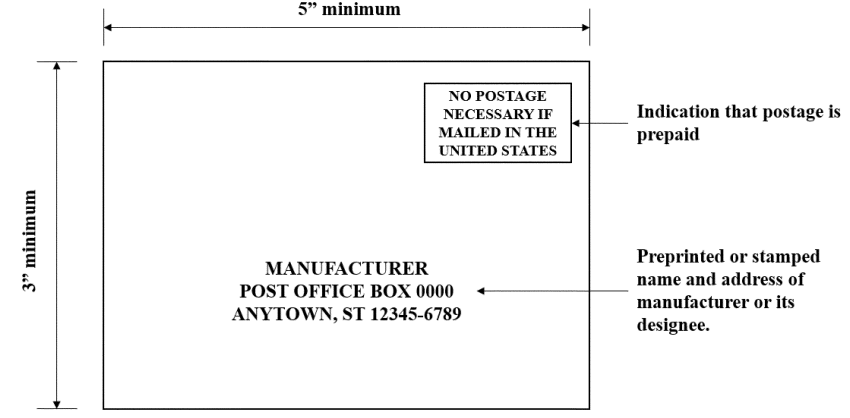

S5.8.1 Attached registration form.

(a) For child restraint systems manufactured before December 5, 2024, each child restraint system, except a factory-installed built-in restraint system, shall have a registration form attached to any surface of the restraint that contacts the dummy when the dummy is positioned in the system in accordance with S6.1.2 of Standard 213.

(b) Each attached form shall:

(1) Consist of a postcard that is attached at a perforation to an informational card;

(2) Conform in size, content and format to Figures 9a and 9b of this section; and

(3) Have a thickness of at least 0.007 inches and not more than 0.0095 inches.

(c) Each postcard shall provide the model name or number and date of manufacture (month, year) of the child restraint system to which the form is attached, shall contain space for the purchaser to record his or her name, mailing address, and at the manufacturer’s option, e-mail address, shall be addressed to the manufacturer, and shall be postage paid. No other information shall appear on the postcard, except identifying information that distinguishes a particular child restraint system from other systems of that model name or number may be preprinted in the shaded area of the postcard, as shown in figure 9a.

(d) Manufacturers may voluntarily provide a web address on the informational card enabling owners to register child restraints online, provided that the Web address is a direct link to the electronic registration form meeting the requirements of S5.8.2 of this section.

S5.8.1.1 Upgraded attached registration form. For child restraint systems manufactured on or after December 5, 2024, each child restraint system, except a factory-installed built-in restraint system, shall have a registration form attached to any surface of the restraint that contacts the dummy when the dummy is positioned in the system in accordance with S6.1.2 of Standard 213. The form shall not have advertising or any information other than that related to registering the child restraint system.

(a) Each attached registration form shall provide a mail-in postcard that conforms in size, and in basic content and format to the forms depicted in Figures 9a' and 9b' of this section.

(1) The mail-in postcard shall:

(i) Have a thickness of at least 0.007 inches and not more than 0.0095 inches;

(ii) Be pre-printed with the information identifying the child restraint system for recall purposes, such as the model name or number and date of manufacture (month, year) of the child restraint system to which the form is attached;

(iii) Contain space for the owner to record his or her name, mailing address, email address (optional), telephone number (optional), and other pertinent information;

(iv) Be addressed to the manufacturer, and be postage paid.

(v) Be detachable from the information card without the use of scissors or other tools.

(c) The registration form attached to the child restraint system shall also provide an information card with the following:

(1) Informing the owner of the importance of registering the child restraint system; and,

(2) Instructing the owner how to register the CRS.

(3) Manufacturers must provide statements informing the purchaser that the registration card is pre-addressed and that postage has been paid.

(4) Manufacturers may provide instructions to register the child restraint system electronically. If an electronic registration form is used or referenced, it must meet the requirements of S5.8.2 of this section.

(5) Manufacturers may optionally provide statements to the owner explaining that the registration card is not a warranty card, and that the information collected from the owner will not be used for marketing purposes

S5.8.2 Electronic registration form.

(a) Each electronic registration form provided for child restraint systems manufactured before December 5, 2024, shall:

(1) Contain the following statements at the top of the form:

(i) “FOR YOUR CHILD’S CONTINUED SAFETY” (Displayed in bold type face, caps, and minimum 12 point type.)

(ii) “Although child restraint systems undergo testing and evaluation, it is possible that a child restraint could be recalled.” (Displayed in bold typeface, caps and lower case, and minimum 12 point type.)

(iii) ”In case of a recall, we can reach you only if we have your name and address, so please fill in the registration form to be on our recall list.” (Displayed in bold typeface, caps and lower case, and minimum 12 point type.)

(iv) “In order to properly register your child restraint system, you will need to provide the model number, serial number and date of manufacture. This information is printed on the registration card and can also be found on a white label located on the back of the child restraint system.” (Displayed in bold typeface, caps and lower case, and minimum 12 point type.)