EPA Final Rule: NESHAP for Primary Copper Smelting

This action finalizes the residual risk and technology review (RTR) conducted for the Primary Copper Smelting major source category regulated under national emission standards for hazardous air pollutants (NESHAP). This action also finalizes the technology review for the Primary Copper Smelting area source NESHAP. The final amendments for the major source NESHAP include particulate matter (PM) emission standards as a surrogate for metal hazardous air pollutants (HAP) other than mercury (primarily lead and arsenic) for anode refining point sources, process fugitive emissions from roofline vents, Hoboken converter process fugitive capture systems where they combine with anode refining point sources, and new converters. We are also finalizing emission standards for previously unregulated HAP including mercury, benzene, toluene, hydrogen chloride (HCl), chlorine, polycyclic aromatic hydrocarbons (PAH), and dioxins and furans (D/F). In addition, we are taking final action in the major source NESHAP to establish work practice standards for bypass stacks, and add a new emissions limit for lead and emissions control design standards to minimize process fugitive emissions at facilities with flash furnaces and Peirce-Smith converters. Final amendments for both the major source NESHAP and the area source NESHAP include removing exemptions and associated provisions for periods of startup, shutdown, and malfunction (SSM), specifying that the emission standards apply at all times, and requiring electronic reporting of performance test results and notification of compliance reports.

DATES: This final rule is effective May 13, 2024, except for changes to §63.14, which are effective July 15, 2024. This final rule is published in the Federal Register May 13, 2024, page 41648.

View final rule.

| §63.14 Incorporations by reference. | ||

| (f)(1) and (i)(95), (105), and (110) | Revised | View text |

| (o) | Added | View text |

| §63.14 Incorporations by reference. (Effective July 15, 20240 | ||

| (f)(1) and (i)(110) | Revised | View text |

| (o) | Revised | View text |

| Subpart QQQ - National Emission Standards for Hazardous Air Pollutants for Primary Copper Smelting | ||

| Entire subpart | Revised | View text |

| §63.11147 What are the standards and compliance requirements for existing sources not using batch copper converters? | ||

| (b)(6), (c)(1) and (5), (d), and (e) | Revised | View text |

| §63.11148 What are the standards and compliance requirements for existing sources using batch copper converters? | ||

| (a)(1), (a)(3)(ii), (a)(4)(iv), (b)(1), (b)(2)(i), (b)(4), (c)(2) and (4), (e)(3), (f)(1), (f)(4)(ii) and (iii), (f)(5), (g), and (h) | Revised | View text |

| §63.11149 What are the standards and compliance requirements for new sources? | ||

| Entire section | Revised | View text |

| §63.11151 What definitions apply to this subpart? | ||

| definition “Blowing” | Added | View text |

| definition “Capture system” | Revised | View text |

| §63.11152 Who implements and enforces this subpart? | ||

| (c) introductory text | Revised | View text |

| undesignated paragraph after paragraph (c)(5) | Removed | View text |

| (c)(6) | Added | View text |

| Table 1 to Subpart EEEEEE of Part 63 - Applicability of General Provisions to Subpart EEEEEE | ||

| Entire table | Revised | View text |

New Text

§63.14 Incorporations by reference. (Effective July 15, 20240

* * * * *

(f) * * *

(1) ANSI/ASME PTC 19.10-1981, Flue and Exhaust Gas Analyses [Part 10, Instruments and Apparatus], issued August 31, 1981, IBR approved for §§63.116(c); 63.116 and (h); 63.128(a); 63.145(i); 63.309(k); 63.365(b); 63.457(k); 63.490(g); 63.772(e) and (h); 63.865(b); 63.997(e); 63.1282(d) and (g); 63.1450(a), (b), and (e) through (g); 63.1625(b); table 5 to subpart EEEE; §§63.3166(a); 63.3360(e); 63.3545(a); 63.3555(a); 63.4166(a); 63.4362(a); 63.4766(a); 63.4965(a); 63.5160(d); table 4 to subpart UUUU; table 3 to subpart YYYY; §§63.7822(b); 63.7824(e); 63.7825(b); 63.8000(d); 63.9307(c); 63.9323(a); 63.9621(b) and (c); 63.11148(e); 63.11155(e); 63.11162(f); 63.11163(g); 63.11410(j); 63.11551(a); 63.11646(a); 63.11945; table 4 to subpart AAAAA; table 5 to subpart DDDDD; table 4 to subpart JJJJJ; table 4 to subpart KKKKK; table 4 to subpart SSSSS; tables 4 and 5 to subpart UUUUU; table 1 to subpart ZZZZZ; table 4 to subpart JJJJJJ.

* * * * *

(i) * * *

(110) ASTM D7520-16, Standard Test Method for Determining the Opacity of a Plume in the Outdoor Ambient Atmosphere, approved April 1, 2016; IBR approved for §§63.1450(c), (e), and (g); 63.1453(h); 63.1625(b); table 3 to subpart LLLLL; §§63.7823(c) through (f), 63.7833(g); 63.11423(c).

* * * * *

(o) U.S. Environmental Protection Agency, 1200 Pennsylvania Avenue NW., Washington, DC 20460, (202) 272-0167, http://www.epa.gov.

(1) EPA/100/R-10/005, Recommended Toxicity Equivalence Factors (TEFs) for Human Health Risk Assessments of 2, 3, 7, 8-Tetrachlorodibenzo-p-dioxin and Dioxin-Like Compounds, December 2010; IBR approved for §63.1459 and table 2 to subpart QQQ. (Available at https://www.epa.gov/sites/default/files/2013-09/documents/tefs-for-dioxin-epa-00-r-10-005-final.pdf).

(2) EPA-453/R-08-002, Protocol for Determining the Daily Volatile Organic Compound Emission Rate of Automobile and Light-Duty Truck Primer-Surfacer and Topcoat, published September 2008, IBR approved for §§63.3130(c), 63.3161(d) and (g), 63.3165(e), and appendix A to subpart IIII.

(3) EPA-453/R-01-005, National Emission Standards for Hazardous Air Pollutants (NESHAP) for Integrated Iron and Steel Plants - Background Information for Proposed Standards, Final Report, January 2001, IBR approved for §63.7491(g).

(4) EPA-454/B-08-002, Quality Assurance Handbook for Air Pollution Measurement Systems; Volume IV: Meteorological Measurements, Version 2.0 (Final), Issued March 2008, IBR approved for §63.7792(b).

(5) EPA-454/R-98-015, Office of Air Quality Planning and Standards (OAQPS), Fabric Filter Bag Leak Detection Guidance, September 1997, https://nepis.epa.gov/Exe/ZyPDF.cgi?Dockey=2000D5T6.PDF, IBR approved for §§63.548(e), 63.864(e), 63.7525(j), 63.8450(e), 63.8600(e), 63.9632(a), 63.9804(f), and 63.11224(f).

(6) EPA-454/R-99-005, Office of Air Quality Planning and Standards (OAQPS), Meteorological Monitoring Guidance for Regulatory Modeling Applications, February 2000, IBR approved for appendix A to this part: Method 325A.

(7) EPA/600/R-12/531, EPA Traceability Protocol for Assay and Certification of Gaseous Calibration Standards, May 2012, IBR approved for §63.2163(b).

(8) EPA-625/3-89-016, Interim Procedures for Estimating Risks Associated with Exposures to Mixtures of Chlorinated Dibenzo-p-Dioxins and -Dibenzofurans (CDDs and CDFs) and 1989 Update, March 1989. IBR approved for §63.1513(d).

(9) SW-846-0011, Sampling for Selected Aldehyde and Ketone Emissions from Stationary Sources, Revision 0, December 1996, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for table 4 to subpart DDDD.

(10) SW-846-3020A, Acid Digestion of Aqueous Samples And Extracts For Total Metals For Analysis By GFAA Spectroscopy, Revision 1, July 1992, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for table 6 to subpart DDDDD and table 5 to subpart JJJJJJ.

(11) SW-846-3050B, Acid Digestion of Sediments, Sludges, and Soils, Revision 2, December 1996, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for table 6 to subpart DDDDD and table 5 to subpart JJJJJJ.

(12) SW-846-5030B, Purge-And-Trap For Aqueous Samples, Revision 2, December 1996, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for §63.2492(b) and (c).

(13) SW-846-5031, Volatile, Nonpurgeable, Water-Soluble Compounds by Azeotropic Distillation, Revision 0, December 1996, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for §63.2492(b) and (c).

(14) SW-846-8015C, Nonhalogenated Organics by Gas Chromatography, Revision 3, February 2007, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for §§63.11960, 63.11980, and table 10 to subpart HHHHHHH.

(15) SW-846-8260B, Volatile Organic Compounds by Gas Chromatography/Mass Spectrometry (GC/MS), Revision 2, December 1996, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for §§63.1107(a), 63.11960, 63.11980, and table 10 to subpart HHHHHHH.

(16) SW-846-8270D, Semivolatile Organic Compounds by Gas Chromatography/Mass Spectrometry (GC/MS), Revision 4, February 2007, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for §§63.1107(a), 63.11960, 63.11980, and table 10 to subpart HHHHHHH.

(17) SW-846-8315A, Determination of Carbonyl Compounds by High Performance Liquid Chromatography (HPLC), Revision 1, December 1996, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for §§63.11960 and 63.11980, and table 10 to subpart HHHHHHH.

(18) SW-846-8260D, Volatile Organic Compounds By Gas Chromatography/Mass Spectrometry, Revision 4, June 2018, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for §63.2492(b) and (c).

(19) SW-846-6010C, Inductively Coupled Plasma-Atomic Emission Spectrometry, Revision 3, February 2007, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for table 6 to subpart DDDDD.

(20) SW-846-6020A, Inductively Coupled Plasma-Mass Spectrometry, Revision 1, February 2007, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for table 6 to subpart DDDDD.

(21) SW-846-7060A, Arsenic (Atomic Absorption, Furnace Technique), Revision 1, September 1994, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for table 6 to subpart DDDDD.

(22) SW-846-7740, Selenium (Atomic Absorption, Furnace Technique), Revision 0, September 1986, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for table 6 to subpart DDDDD.

(23) SW-846-9056, Determination of Inorganic Anions by Ion Chromatography, Revision 1, February 2007, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for table 6 to subpart DDDDD.

(24) SW-846-9076, Test Method for Total Chlorine in New and Used Petroleum Products by Oxidative Combustion and Microcoulometry, Revision 0, September 1994, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for table 6 to subpart DDDDD.

(25) SW-846-9250, Chloride (Colorimetric, Automated Ferricyanide AAI), Revision 0, September 1986, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for table 6 to subpart DDDDD.

(26) Method 200.8, Determination of Trace Elements in Waters and Wastes by Inductively Coupled Plasma - Mass Spectrometry, Revision 5.4, 1994, IBR approved for table 6 to subpart DDDDD.

(27) Method 1631 Revision E, Mercury in Water by Oxidation, Purge and Trap, and Cold Vapor Atomic Absorption Fluorescence Spectrometry, Revision E, EPA-821-R-02-019, August 2002, IBR approved for table 6 to subpart DDDDD.

(28) SW-846-9250, Chloride (Colorimetric, Automated Ferricyanide AAI), Revision 0, September 1986, in EPA Publication No. SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods, Third Edition, IBR approved for table 6 to subpart DDDDD.

(29) Method 200.8, Determination of Trace Elements in Waters and Wastes by Inductively Coupled Plasma—Mass Spectrometry, Revision 5.4, 1994, IBR approved for table 6 to subpart DDDDD.

(30) Method 1631 Revision E, Mercury in Water by Oxidation, Purge and Trap, and Cold Vapor Atomic Absorption Fluorescence Spectrometry, Revision E, EPA-821-R-02-019, August 2002, IBR approved for table 6 to subpart DDDDD.

(31) EPA/100/R-10/005, Recommended Toxicity Equivalence Factors (TEFs) for Human Health Risk Assessments of 2, 3, 7, 8-Tetrachlorodibenzo-p-dioxin and Dioxin-Like Compounds, December 2010; IBR approved for §63.1459 and table 2 to subpart QQQ. (Available at https://www.epa.gov/sites/default/files/2013-09/documents/tefs-for-dioxin-epa-00-r-10-005-final.pdf.)

* * * * *

Previous Text

§63.14 Incorporations by reference.

* * * * *

(f) * * *

(1) ANSI/ASME PTC 19.10-1981, Flue and Exhaust Gas Analyses [Part 10, Instruments and Apparatus], issued August 31, 1981; IBR approved for §§63.309(k); 63.365(b); 63.457(k); 63.772(e) and (h); 63.865(b); 63.997(e); 63.1282(d) and (g); 63.1625(b); table 5 to subpart EEEE; §§63.3166(a); 63.3360(e); 63.3545(a); 63.3555(a); 63.4166(a); 63.4362(a); 63.4766(a); 63.4965(a); 63.5160(d); table 4 to subpart UUUU; table 3 to subpart YYYY; §§63.7822(b); 63.7824(e); 63.7825(b); 63.8000(d); 63.9307(c); 63.9323(a); 63.9621(b) and (c); 63.11148(e); 63.11155(e); 63.11162(f); 63.11163(g); 63.11410(j); 63.11551(a); 63.11646(a); 63.11945; table 4 to subpart AAAAA; table 5 to subpart DDDDD; table 4 to subpart JJJJJ; table 4 to subpart KKKKK; table 4 to subpart SSSSS; tables 4 and 5 of subpart UUUUU; table 1 to subpart ZZZZZ; and table 4 to subpart JJJJJJ.

* * * * *

(i) * * *

(95) ASTM D6420-99 (Reapproved 2010), Standard Test Method for Determination of Gaseous Organic Compounds by Direct Interface Gas Chromatography-Mass Spectrometry, Approved October 1, 2010, IBR approved for §§63.670(j), Table 4 to subpart UUUU, 63.7142(b), and appendix A to this part: Method 325B.

* * * * *

(105) ASTM D6784–16, Standard Test Method for Elemental, Oxidized, Particle-Bound and Total Mercury in Flue Gas Generated from Coal-Fired Stationary Sources (Ontario Hydro Method), Approved March 1, 2016; IBR approved for §§63.9621(d); table 5 to subpart UUUUU; appendix A to subpart UUUUU.

* * * * *

(110) ASTM D7520-16, Standard Test Method for Determining the Opacity of a Plume in the Outdoor Ambient Atmosphere, approved April 1, 2016; IBR approved for §§63.1625(b); table 3 to subpart LLLLL; 63.7823(c) through (e), 63.7833(g); 63.11423(c).

* * * * *

Subpart QQQ - National Emission Standards for Hazardous Air Pollutants for Primary Copper Smelting

§63.1440 What is the purpose of this subpart?

This subpart establishes national emission standards for hazardous air pollutants (NESHAP) for primary copper smelters. This subpart also establishes requirements to demonstrate initial and continuous compliance with all applicable emission limitations, work practice standards, and operation and maintenance requirements in this subpart.

§63.1441 Am I subject to this subpart?

You are subject to this subpart if you own or operate a primary copper smelter that is (or is part of) a major source of hazardous air pollutant (HAP) emissions and your primary copper smelter uses batch copper converters as defined in §63.1459. Your primary copper smelter is a major source of HAP if it emits or has the potential to emit any single HAP at the rate of 10 tons or more per year or any combination of HAP at a rate of 25 tons or more per year.

§63.1442 What parts of my plant does this subpart cover?

(a) This subpart applies to each new and existing affected source at your primary copper smelter. The affected sources are each copper concentrate dryer, each smelting furnace, each slag cleaning vessel, each copper converter department, and the entire group of fugitive emission sources, as defined in §63.1459.

(b) An affected source at your primary copper smelter is existing if you commenced construction or reconstruction of the affected source before April 20, 1998.

(c) An affected source at your primary copper smelter is new if you commenced construction or reconstruction of the affected source on or after April 20, 1998. An affected source is reconstructed if it meets the definition of “reconstruction” in §63.2.

§63.1443 When do I have to comply with this subpart?

(a) If you have an existing affected source, you must comply with each emission limitation, work practice standard, and operation and maintenance requirement in this subpart that applies to you no later than June 13, 2005.

(b) If you have a new affected source and its initial startup date is on or before June 12, 2002, you must comply with each emission limitation, work practice standard, and operation and maintenance requirement in this subpart that applies to you by June 12, 2002.

(c) If you have a new affected source and its initial startup date is after June 12, 2002, you must comply with each emission limitation, work practice standard, and operation and maintenance requirement in this subpart that applies to you upon initial startup.

(d) If your primary copper smelter is an area source that becomes a major source of HAP, the compliance dates listed in paragraphs (d)(1) and (2) of this section apply to you.

(1) Any portion of the existing primary copper smelter that is a new affected source or a new reconstructed source must be in compliance with this subpart upon startup.

(2) All other parts of the primary copper smelter must be in compliance with this subpart no later than 3 years after it becomes a major source.

(e) You must meet the notification and schedule requirements in §63.1454. Several of these notifications must be submitted before the compliance date for your affected source.

§63.1444 What emissions limitations and work practice standards must I meet for my copper concentrate dryers, smelting furnaces, slag cleaning vessels, and copper converter departments?

(a) Copper concentrate dryers. For each copper concentrate dryer, you must comply with the emission limitation in paragraph (a)(1) or (2) of this section that applies to you.

(1) For each existing copper concentrate dryer, you must not cause to be discharged to the atmosphere from the dryer vent any gases that contain total particulate matter in excess of 50 milligrams per dry standard cubic meter (mg/dscm) as measured using the test methods specified in §63.1450(a).

(2) For each new copper concentrate dryer, you must not cause to be discharged to the atmosphere from the dryer vent any gases that contain total particulate matter in excess of 23 mg/dscm as measured using the test methods specified in §63.1450(a).

(b) Smelting furnaces. For each smelting furnace, you must comply with the emission limitations and work practice standards in paragraphs (b)(1) and (2) of this section.

(1) For each smelting furnace, you must not cause to be discharged to the atmosphere any process off-gas that contains nonsulfuric acid particulate matter in excess of 6.2 mg/dscm as measured using the test methods specified in §63.1450(b). Process off-gas from a smelting furnace is generated when copper ore concentrates and fluxes are being smelted to form molten copper matte and slag layers.

(2) For each smelting furnace, you must control the process fugitive emissions released when tapping copper matte or slag from the smelting furnace according to paragraphs (b)(2)(i) and (ii) of this section.

(i) At all times when copper matte or slag is tapped from the smelting furnace, you must operate a capture system that collects the gases and fumes released from the tapping port in use. The design and placement of this capture system must be such that the tapping port opening, launder, and receiving vessel (e.g., ladle, slag pot) are positioned within the confines or influence of the capture system's ventilation draft during those times when the copper matte or slag is flowing from the tapping port opening.

(ii) You must not cause to be discharged to the atmosphere from the capture system used to comply with paragraph (b)(2)(i) of this section any gases that contain total particulate matter in excess of 23 mg/dscm as measured using the test methods specified in §63.1450(a).

(c) Slag cleaning vessels. For each slag cleaning vessel, you must comply with the emission limitations and work practice standards in paragraphs (c)(1) through (3) of this section that apply to you.

(1) For each slag cleaning vessel, except as provided for in paragraph (c)(2) of this section, you must not cause to be discharged to the atmosphere any process off-gas that contains nonsulfuric acid particulate matter in excess of 6.2 mg/dscm as measured using the test methods specified in §63.1450(b).

(2) As an alternative to complying with the emission limit for nonsulfuric acid particulate matter in paragraph (c)(1) of this section, for each existing slag cleaning vessel you may choose to comply with the emission limit for total particulate matter specified in this paragraph (c)(2). You must not cause to be discharged to the atmosphere any process off-gas that contains total particulate matter in excess of 46 mg/dscm as measured using the test methods specified in §63.1450(a).

(3) For each slag cleaning vessel, you must control process fugitive emissions released when tapping copper matte or slag from the slag cleaning vessel according to paragraphs (c)(3)(i) and (ii) of this section.

(i) At all times when copper matte or slag is tapped from the slag cleaning vessel, you must operate a capture system that collects the gases and fumes released from the tapping port in use. The design and placement of this capture system must be such that the tapping port opening, launder, and receiving vessel (e.g., ladle, slag pot) are positioned within the confines or influence of the capture system's ventilation draft during those times when the copper matte or slag is flowing from the tapping port opening.

(ii) You must not cause to be discharged to the atmosphere from the capture system used to comply with paragraph (c)(3)(i) of this section any gases that contain total particulate matter in excess of 23 mg/dscm as measured using the test methods specified in §63.1450(a).

(d) Existing copper converter departments. For each existing copper converter department, you must comply with the emission limitations and work practice standards in paragraphs (d)(1) through (6) of this section that apply to you.

(1) You must operate a capture system that collects the process off gas vented from each batch copper converter. At all times when one or more batch copper converters are blowing, you must operate the capture system according to the written operation and maintenance plan that has been prepared according to the requirements in §63.1447(b).

(2) If your copper converter department uses Pierce-Smith converters, the capture system design must include use of a primary hood that covers the entire mouth of the converter vessel when the copper converter is positioned for blowing. Additional hoods (e.g., secondary hoods) or other capture devices must be included in the capture system design as needed to achieve the opacity limit in paragraph (d)(4) of this section. The capture system design may use multiple intake and duct segments through which the ventilation rates are controlled independently of each other, and individual duct segments may be connected to separate control devices.

(3) If your copper converter department uses Hoboken converters, the capture system must collect all process off-gas vented during blowing through the side-flue intake on each converter vessel.

(4) You must operate the capture system such that any visible emissions exiting the roof monitors or roof exhaust fans on the building housing the copper converter department meet the opacity limit as specified in paragraphs (d)(4)(i) and (ii) of this section.

(i) The opacity of any visible emissions exiting the roof monitors or roof exhaust fans on the building housing the copper converter department must not exceed 4 percent as determined by a performance test conducted according to §63.1450(c).

(ii) The opacity limit in paragraph (d)(4)(i) of this section applies only at those times when a performance test is conducted according to §63.1450(c). The requirements for compliance with opacity and visible emission standards specified in §63.6(h) do not apply to this opacity limit.

(5) You must not cause to be discharged to the atmosphere from any Pierce-Smith converter primary hood capture system or Hoboken converter side-flue intake capture system any process off-gas that contains nonsulfuric acid particulate matter in excess of 6.2 mg/dscm as measured using the test methods specified in §63.1450(b).

(6) You must not cause to be discharged to the atmosphere from any secondary capture system any gases that contain total particulate matter in excess of 23 mg/dscm as measured using the test methods specified in §63.1450(a).

(e) New copper converter departments. For each new copper converter department for which construction commenced on or after April 20, 1998, the use of batch copper converters is prohibited.

(f) Baghouses. For each baghouse applied to meet any total particulate matter emission limit in paragraphs (a) through (d) of this section, you must operate the baghouse such that the bag leak detection system does not alarm for more than 5 percent of the total operating time in any semiannual reporting period.

(g) Venturi wet scrubbers. For each venturi wet scrubber applied to meet any total particulate matter emission limit in paragraphs (a) through (d) of this section, you must maintain the hourly average pressure drop and scrubber water flow rate at or above the minimum levels established during the initial or subsequent performance test.

(h) Other control devices. For each control device other than a baghouse or venturi wet scrubber applied to meet any total particulate matter emission limit in paragraphs (a) through (d) of this section, you must operate the control device as specified in paragraphs (h)(1) and (2) of this section.

(1) You must select one or more operating parameters, as appropriate for the control device design, that can be used as representative and reliable indicators of the control device operation.

(2) You must maintain the hourly average value for each of the selected parameters at or above the minimum level or at or below the maximum level, as appropriate for the selected parameter, established during the initial or subsequent performance test.

§63.1445 What work practice standards must I meet for my fugitive dust sources?

(a) You must control particulate matter emissions from fugitive dust sources at your primary copper smelter by operating according to a written fugitive dust control plan that has been approved by the designated authority. For the purpose of complying with this paragraph (a) you may use an existing fugitive dust control plan provided that the plan complies with the requirements of this section. A fugitive dust control plan is considered to be approved if the plan has been incorporated in your applicable State implementation plan, and the document addresses the fugitive dust sources specified in paragraph (b) of this section and includes the information specified in paragraph (c) of this section.

(b) Your fugitive dust control plan must address each of the fugitive dust emission sources listed in paragraphs (b)(1) through (6) of this section that are located at your primary copper smelter.

(1) On-site roadways used by trucks or other motor vehicles (e.g., front-end loaders) when transporting bulk quantities of fugitive dust materials. Paved roads and parking areas that are not used by these vehicles do not need to be included in the plan (e.g., employee and visitor parking lots).

(2) Unloading of fugitive dust materials from trucks or railcars.

(3) Outdoor piles used for storage of fugitive dust materials.

(4) Bedding areas used for blending copper concentrate and other feed constituents.

(5) Each transfer point in conveying systems used to transport fugitive dust materials. These points include, but are not limited to, transfer of material from one conveyor belt to another and transfer of material to a hopper or bin.

(6) Other site-specific sources of fugitive dust emissions that the Administrator or delegated permitting authority designate to be included in your fugitive dust control plan.

(c) Your fugitive dust control plan must describe the control measures you use to control fugitive dust emissions from each source addressed in the plan, as applicable and appropriate for your site conditions. Examples of control measures include, but are not limited to, locating the source inside a building or other enclosure, installing and operating a local hood capture system over the source and venting the captured gas stream to a control device, placing material stockpiles below grade, installing wind screens or wind fences around the source, spraying water on the source as weather conditions require, applying appropriate dust suppression agents on the source, or combinations of these control measures.

(d) The requirement for you to operate according to a written fugitive dust control plan must be incorporated in your operating permit that is issued by the designated permitting authority under part 70 of this chapter. A copy of your fugitive dust control plan must be sent to the designated permitting authority on or before the compliance date for your primary copper smelter, as specified in §63.1443.

§63.1446 What alternative emission limitation may I meet for my combined gas streams?

(a) For situations where you combine gas streams from two or more affected sources for discharge to the atmosphere through a single vent, you may choose to meet the requirements in paragraph (b) of this section as an alternative to complying with the individual total particulate matter emission limits specified in §63.1444 that apply to you. This alternative emission limit for a combined gas stream may be used for any combination of the affected source gas steams specified in paragraphs (a)(1) through (5) of this section.

(1) Gas stream discharged from a copper concentrate dryer vent that would otherwise be subject to §63.1444(a)(1) or (2);

(2) Gas stream discharged from a smelting furnace capture system that would otherwise be subject to §63.1444(b)(2)(ii);

(3) Process off-gas stream discharged from a slag cleaning vessel that would otherwise be subject to §63.1444(c)(2);

(4) Gas stream discharged from a slag cleaning vessel capture system that would otherwise be subject to §63.1444(c)(3)(ii); and

(5) Gas stream discharged from a batch copper converter secondary capture system that would otherwise be subject to §63.1444(d)(5).

(b) You must meet the requirements specified in paragraphs (b)(1) and (2) of this section for the combined gas stream discharged through a single vent.

(1) For each combined gas stream discharged through a single vent, you must not cause to be discharged to the atmosphere any gases that contain total particulate matter in excess of the emission limit calculated using the procedure in paragraph (b)(2) of this section and measured using the test methods specified in §63.1450(a).

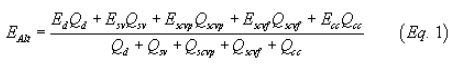

(2) You must calculate the alternative total particulate matter emission limit for your combined gas stream using Equation 1 of this section. The volumetric flow rate value for each of the individual affected source gas streams that you use for Equation 1 (i.e., the flow rate of the gas stream discharged from the affected source but before this gas stream is combined with the other gas streams) is to be the average of the volumetric flow rates measured using the test method specified in §63.1450(a)(1)(ii):

Where

EAlt = Alternative total particulate matter emission limit for the combined gas stream discharged to atmosphere through a single vent (mg/dscm);

Ed = Total particulate matter emission limit applicable to copper concentrate dryer as specified in §63.1444(a)(1) or (2) (mg/dscm);

Qd = Copper concentrate dryer exhaust gas stream volumetric flow rate before being combined with other gas streams (dscm);

Esv = Total particulate matter emission limit for smelting furnace capture system as specified in §63.1444(b)(2)(ii) (mg/dscm);

Qsv = Smelting furnace capture system exhaust gas stream volumetric flow rate before being combined with other gas streams (dscm);

Escvp = Total particulate matter emission limit for slag cleaning vessel process off-gas as specified in §63.1444(c)(2) (mg/dscm);

Qscvp = Slag cleaning vessel process off-gas volumetric flow rate before being combined with other gas streams (dscm);

Escvf = Total particulate matter emission limit for slag cleaning vessel capture system as specified in §63.1444(c)(3)(ii) (mg/dscm);

Qscvf = Slag cleaning vessel capture system exhaust gas stream volumetric flow rate before being combined with other gas streams (dscm);

Ecc = Total particulate emission limit for the batch copper converter secondary capture system as specified in §63.1544(d)(5) (mg/dscm); and

Qcc = Batch copper converter capture system exhaust gas stream volumetric flow rate before being combined with other gas streams (dscm).

(c) For each baghouse applied to meet any total particulate matter emission limit in paragraph (b) of this section, you must operate the baghouse such that the bag leak detection system does not alarm for more than 5 percent of the total operating time in any semiannual reporting period.

(d) For each venturi wet scrubber applied to meet any total particulate matter emission limit in paragraph (b) of this section, you must maintain the hourly average pressure drop and scrubber water flow rate at or above the minimum levels established during the initial or subsequent performance test.

(e) For each control device other than a baghouse or venturi wet scrubber applied to meet any total particulate matter emission limit in paragraph (b) of this section, you must operate the control device as specified in paragraphs (e)(1) and (2) of this section.

(1) You must select one or more operating parameters, as appropriate for the control device design, that can be used as representative and reliable indicators of the control device operation.

(2) You must maintain the hourly average value for each of the selected parameters at or above the minimum level or at or below the maximum level, as appropriate for the selected parameter, established during the initial or subsequent performance test.

§63.1447 What are my operation and maintenance requirements?

(a) As required by §63.6(e)(1)(i), you must always operate and maintain your affected source, including air pollution control and monitoring equipment, in a manner consistent with good air pollution control practices for minimizing emissions at least to the levels required by this subpart.

(b) You must prepare and operate at all times according to a written operation and maintenance plan for each capture system and control device subject to standards in §63.1444 or §63.1446. The plan must address the requirements in paragraphs (b)(1) through (3) of this section as applicable to the capture system or control device.

(1) Preventative maintenance. You must perform preventative maintenance for each capture system and control device according to written procedures specified in your operation and maintenance plan. The procedures must include a preventative maintenance schedule that is consistent with the manufacturer's instructions for routine and long-term maintenance.

(2) Capture system inspections. You must conduct monthly inspections of the equipment components of the capture system that can affect the performance of the system to collect the gases and fumes emitted from the affected source (e.g., hoods, exposed ductwork, dampers, fans) according to written procedures specified in your operation and maintenance plan. The inspection procedure must include the requirements in paragraphs (b)(2)(i) through (iii) of this section as applicable to the capture system or control device.

(i) Observations of the physical appearance of the equipment to confirm the physical integrity of the equipment (e.g., verify by visual inspection no holes in ductwork or hoods, no flow constrictions caused by dents, or accumulated dust in ductwork).

(ii) Inspection, and if necessary testing, of equipment components to confirm that the component is operating as intended (e.g., verify by appropriate measures that flow or pressure sensors, damper plates, automated damper switches and motors are operating according to manufacture or engineering design specifications).

(iii) In the event that a defective or damaged component is detected during an inspection, you must initiate corrective action according to written procedures specified in your operation and maintenance plan to correct the defect or deficiency as soon as practicable.

(3) Copper converter department capture system operating limits. You must establish, according to the requirements in paragraph (b)(3)(i) through (iii) of this section, operating limits for the capture system that are representative and reliable indicators of the performance of capture system when it is used to collect the process off-gas vented from batch copper converters during blowing.

(i) Select operating limit parameters appropriate for the capture system design that are representative and reliable indicators of the performance of the capture system when it is used to collect the process off-gas vented from batch copper converters during blowing. At a minimum, you must use appropriate operating limit parameters that indicate the level of the ventilation draft and the damper position settings for the capture system when operating to collect the process off-gas from the batch copper converters during blowing. Appropriate operating limit parameters for ventilation draft include, but are not limited to, volumetric flow rate through each separately ducted hood, total volumetric flow rate at the inlet to control device to which the capture system is vented, fan motor amperage, or static pressure. Any parameter for damper position setting may be used that indicates the duct damper position relative to the fully open setting.

(ii) For each operating limit parameter selected in paragraph (b)(3)(i) of this section, designate the value or setting for the parameter at which the capture system operates during batch copper converter blowing. If your blister copper production operations allow for more than one batch copper converter to be operating simultaneously in the blowing mode, designate the value or setting for the parameter at which the capture system operates during each possible batch copper converter blowing configuration that you may operate at your smelter (i.e., the operating limits with one converter blowing, with two converters blowing, with three converters blowing, as applicable to your smelter).

(iii) Include documentation in the plan to support your selection of the operating limits established for the capture system. This documentation must include a description of the capture system design, a description of the capture system operation during blister copper production, a description of each selected operating limit parameter, a rationale for why you chose the parameter, a description of the method used to monitor the parameter according to the requirements in §63.1452(a), and the data used to set the value or setting for the parameter for each of your batch copper converter configurations.

(4) Baghouse leak detection corrective actions. In the event a bag leak detection system alarm is triggered, you must initiate corrective action according to written procedures specified in your operation and maintenance plan to determine the cause of the alarm within 1 hour of the alarm, initiate corrective action to correct the cause of the problem within 24 hours of the alarm, and complete the corrective action as soon as practicable. Corrective actions may include, but are not limited to, the activities listed in paragraphs (b)(3)(i) through (vi) of this section.

(i) Inspecting the baghouse for air leaks, torn or broken bags or filter media, or any other condition that may cause an increase in emissions.

(ii) Sealing off defective bags or filter media.

(iii) Replacing defective bags or filter media or otherwise repairing the control device.

(iv) Sealing off a defective baghouse compartment.

(v) Cleaning the bag leak detection system probe, or otherwise repair the bag leak detection system.

(vi) Shutting down the process producing the particulate emissions.

§63.1448 What are my general requirements for complying with this subpart?

(a) You must be in compliance with the emission limitations, work practice standards, and operation and maintenance requirements in this subpart at all times, except during periods of startup, shutdown, and malfunction as defined in §63.2.

(b) During the period between the compliance date specified for your affected source in §63.1443, and the date upon which continuous monitoring systems have been installed and certified and any applicable operating limits have been set, you must maintain a log detailing the operation and maintenance of the process and emissions control equipment.

(c) You must develop a written startup, shutdown, and malfunction plan according to the provisions in §63.6(e)(3).

§63.1449 By what dates must I conduct performance tests or other initial compliance demonstrations?

(a) As required in §63.7(a)(2), you must conduct a performance test within 180 calendar days of the compliance date that is specified in §63.1443 for your affected source to demonstrate initial compliance with each emission and opacity limit in §§63.1443 and 63.1446 that applies to you.

(b) For each work practice standard and operation and maintenance requirement that applies to you where initial compliance is not demonstrated using a performance test or opacity observation, you must demonstrate initial compliance within 30 calendar days after the compliance date that is specified for your affected source in §63.1443.

§63.1450 What test methods and other procedures must I use to demonstrate initial compliance with the emission limitations?

(a) Total particulate matter emission limits. You must conduct each performance test to determine compliance with the total particulate matter emission limits in §63.1444 or §63.1446 that apply to you according to the requirements for representative test conditions specified in §63.7(e)(1) and using the test methods and procedures in paragraphs (a)(1) through (5) of this section.

(1) Determine the concentration of total particulate matter according to the test methods in appendix A to part 60 of this chapter as specified in paragraphs (a)(1)(i) through (iii) of this section.

(i) Method 1 to select sampling port locations and the number of traverse points. Sampling ports must be located at the outlet of the control device and prior to any releases to the atmosphere.

(ii) Method 2, 2F, or 2G to determine the volumetric flow rate of the stack gas.

(iii) Method 3, 3A, or 3B to determine the dry molecular weight of the stack gas.

(iv) Method 4 to determine the moisture content of the stack gas.

(v) Method 5, 5D, or 17, as applicable, to determine the concentration of total particulate matter. You can also use ASTM D4536-96 incorporated by reference in §63.14 as an alternative to the sampling equipment and operating procedures in Method 5 or 17 when testing a positive pressure baghouse, but you must use the sample traverse location and number of sampling points described in Method 5D.

(2) As an alternative to using the applicable method specified in paragraph (a)(1)(v) of this section, you may determine total particulate matter emissions from the control device using Method 29 in appendix A of part 60 of this chapter provided that you follow the procedures and precautions prescribed in Method 29. If the control device is a positive pressure baghouse, you must also follow the measurement procedure specified in sections 4.1 through 4.3 of Method 5D.

(3) You must conduct three separate test runs for each performance test. Each test run must have a minimum sampling time of 60 minutes and a minimum sampling volume of 0.85 dscm. For the purpose of determining compliance with the applicable total particulate matter emission limit, the arithmetic mean of the results for the three separate test runs is used.

(4) For a venturi wet scrubber applied to emissions from an affected source and subject to operating limits in §63.1444(g) or §63.1446(d) for pressure drop and scrubber water flow rate, you must establish site-specific operating limits according to the procedures in paragraph (a)(4)(i) and (ii) of this section.

(i) Using the continuous parameter monitoring system (CPMS) required in §63.1452, measure and record the pressure drop and scrubber water flow rate during each run of the particulate matter performance test.

(ii) Compute and record the hourly average pressure drop and scrubber water flow rate for each individual test run. Your operating limits are the lowest average pressure drop and scrubber water flow rate value in any of the three runs that meet the applicable emission limit.

(5) For a control device other than a baghouse or venturi wet scrubber applied to emissions from an affected source and subject to site-specific operating limit(s) in §63.1444(h) or §63.1446(e) for appropriate, site-specific operating parameters that are representative and reliable indicators of the control device performance, you must establish a site-specific operating limit(s) according to the procedures in paragraph (a)(5)(i) through (iv) of this section.

(i) Select one or more operating parameters, as appropriate for the control device design, that can be used as representative and reliable indicators of the control device operation.

(ii) Using the CPMS required in §63.1452, measure and record the selected operating parameters for the control device during each run of the total particulate matter performance test.

(iii) Compute and record the hourly average value for each of the selected operating parameters for each individual test run. Your operating limits are the lowest value or the highest value, as appropriate for the selected operating parameter, measured in any of the three runs that meet the applicable emission limit.

(iv) You must prepare written documentation to support your selection of the operating parameters used for the control device. This documentation must include a description of each selected parameter, a rationale for why you chose the parameter, a description of the method used to monitor the parameter, and the data recorded during the performance test and used to set the operating limit(s).

(b) Nonsulfuric acid particulate matter emission limits. You must conduct each performance test to determine compliance with the nonsulfuric acid particulate matter emission limits in §63.1444 that apply to you according to the requirements for representative test conditions specified in §63.7(e)(1) and using the test methods and procedures in paragraphs (b)(1) and (2) of this section.

(1) Determine the concentration of nonsulfuric acid particulate matter according to the test methods in appendix A to part 60 of this chapter as specified in paragraphs (b)(1)(i) through (v) of this section.

(i) Method 1 to select sampling port locations and the number of traverse points. Sampling ports must be located at the outlet of the control device and prior to any releases to the atmosphere.

(ii) Method 2, 2F, or 2G to determine the volumetric flow rate of the stack gas.

(iii) Method 3, 3A, or 3B to determine the dry molecular weight of the stack gas.

(iv) Method 4 to determine the moisture content of the stack gas.

(v) Method 5B to determine the nonsulfuric acid particulate matter emissions.

(2) You must conduct three separate test runs for each performance test. Each test run must have a minimum sampling time of 240 minutes and a minimum sampling volume of 3.4 dscm. For the purpose of determining compliance with the nonsulfuric acid particulate matter emission limit, the arithmetic mean of the results for the three separate test runs is used.

(c) Copper converter department capture system opacity limit. You must conduct each performance test to determine compliance with the opacity limit in §63.1444 using the test methods and procedures in paragraphs (c)(1) through (9) of this section.

(1) You must conduct the performance test during the period when the primary copper smelter is operating under conditions representative of the smelter's normal blister copper production rate. You may not conduct a performance test during periods of startup, shutdown, or malfunction. Before conducting the performance test, you must prepare a written test plan specifying the copper production conditions to be maintained throughout the opacity observation period and including a copy of the written documentation you have prepared according to paragraph (a)(3) of this section to support the established operating limits for the copper converter department capture system. You must submit a copy of the test plan for review and approval by the Administrator or delegated authority. During the observation period, you must collect appropriate process information and copper converter department capture system operating information to prepare documentation sufficient to verify that all opacity observations were made during the copper production and capture system operating conditions specified in the approved test plan.

(2) You must notify the Administrator or delegated authority before conducting the opacity observations to allow the Administrator or delegated authority the opportunity to have authorized representatives attend the test. Written notification of the location and scheduled date for conducting the opacity observations must be received by the Administrator on or before 30 calendar days before this scheduled date.

(3) You must gather the data needed for determining compliance with the opacity limit using qualified visible emission observers and process monitors as described in paragraphs (c)(3)(i) and (ii) of this section.

(i) Opacity observations must be performed by a sufficient number of qualified visible emission observers to obtain two complete concurrent sets of opacity readings for the required observation period. Each visible emission observer must be certified as a qualified observer by the procedure specified in section 3 of Method 9 in appendix A of part 60 of this chapter. The entire set of readings during the required observation period does not need to be made by the same two observers. More than two observers may be used to allow for substitutions and provide for observer rest breaks. The owner or operator must obtain proof of current visible emission reading certification for each observer.

(ii) A person (or persons) familiar with the copper production operations conducted at the smelter must serve as the indoor process monitor. The indoor process monitor is stationed at a location inside the building housing the batch copper converters such that he or she can visually observe and record operations that occur in the batch copper converter aisle during the times that the visible emission observers are making opacity readings. More than one indoor process monitor may be used to allow for substitutions and provide for rest breaks.

(4) You must make all opacity observations using Method 9 in appendix A to part 60 of this chapter and following the procedures described in paragraphs (c)(4)(i) and (ii) of this section.

(i) Each visible emission observer must make his or her readings at a position from the outside of the building that houses the copper converter department such that the observer's line-of-sight is approximately perpendicular to the longer axis of the converter building, and the observer has an unobstructed view of the building roof monitor sections or roof exhaust fan outlets that are positioned over each of the batch copper converters inside the building. Opacity readings can only be made during those times when the observer's position meets the sun orientation and other conditions specified in section 2.1 of Method 9.

(ii) At 15-second intervals, each visible emission observer views the building roof monitor sections or roof exhaust fan outlets that are positioned over each of the batch copper converters inside the building and reads the opacity of the visible plumes. If no plume is visible, the observer records zero as the opacity value for the 15-second interval. In situations when it is possible for an observer to distinguish two or more visible emission plumes from the building roof monitor sections or roof exhaust fan outlets, the observer must identify, to the extent feasible, the plume having the highest opacity and record his or her opacity reading for that plume as the opacity value for the 15-second interval.

(5) You must make opacity observations for a period of sufficient duration to obtain a minimum of 120 1-minute intervals during which at least one copper converter is blowing and no interferences have occurred from other copper production events, as specified in paragraph (c)(7) of this section, which generate visible emissions inside the building that potentially can interfere with the visible emissions from the converter capture systems as seen by the outside observers. To obtain the required number of 1-minute intervals, the observation period may be divided into two or more segments performed on the same day or on different days if conditions prevent the required number of opacity readings from being obtained during one continuous time period. Examples of these conditions include, but are not limited to, changes in the sun's orientation relative to visible emission observers' positions such that the Method 9 conditions are no longer met or an unexpected thunder storm. If the total observation period is divided into two or more segments, all opacity observations must be made during the same set of copper production conditions described in your approved test plan as required by paragraph (c)(1) of this section.

(6) You must gather indoor process information during all times that the visible emission observers are making opacity readings outside the building housing the copper converter department. The indoor process monitor must continually observe the operations occurring in the copper converter department and prepare a written record of his or her observations using the procedure specified in paragraphs (c)(6)(i) through (iv) of this section.

(i) At the beginning of each observation period or segment, the clock time setting on the watch or clock to be used by the indoor process monitor must be synchronized with the clock time settings for the timepieces to be used by the outdoor opacity observers.

(ii) During each period or segment when opacity readings are being made by the visible emission observers, the indoor process monitor must continuously observe the operations occurring in the copper converter department and record his or her observations in a log book, on data sheets, or other type of permanent written format.

(iii) When a batch copper converter is blowing, a record must be prepared for the converter that includes, but is not limited to, the clock times for when blowing begins and when blowing ends and the converter blowing rate. This information may be recorded by the indoor process monitor or by a separate, automated computer data system.

(iv) The process monitor must record each event other than converter blowing that occurs in or nearby the converter aisle that he or she observes to generate visible emissions inside the building. The recorded entry for each event must include, but is not limited to, a description of the event and the clock times when the event begins and when the event ends.

(7) You must prepare a summary of the data for the entire observation period using the information recorded during the observation period by the outdoor visible emission observers and the indoor process monitor and the procedure specified in paragraphs (c)(7)(i) through (iv) of this section.

(i) Using the field data sheets, identify the 1-minute clock times for which a total of eight opacity readings were made and recorded by both observers at 15-second intervals according to the test procedures (i.e., a total of four opacity values have been recorded for the 1-minute interval by each of the two observers). Calculate the average of the eight 15-second interval readings recorded on the field data sheets by the two observers during the clock time minute interval (add the four consecutive 15-second interval opacity readings made by Observer A during the specified clock time minute, plus the four consecutive 15-second interval opacity readings made by Observer B during the same clock time minute, and divide the resulting total by eight). Record the clock time and the opacity average for the 1-minute interval on a data summary sheet. Figure 1 of this subpart shows an example of the format for the data summary sheet you may use, but are not required to use.

(ii) Using the data summary sheets prepared according to paragraph (c)(7)(i) of this section and the process information recorded according to paragraph (c)(6)(iii) of this section, identify those 1-minute intervals for which at least one of the batch copper converters was blowing.

(iii) Using the data summary sheets prepared according to paragraph (c)(7)(ii) of this section and the process information recorded according to paragraph (c)(6)(iv) of this section, identify the 1-minute intervals during which at least one copper converter was blowing but none of the interference events listed in paragraphs (c)(7)(iii)(A) through (F) of this section occurred. Other ancillary activities not listed but conducted in or adjacent to the converter aisle during the opacity observations are not considered to be interference events (e.g., converter aisle cleaning, placement of smoking ladles or skulls on the converter aisle floor).

(A) Charging of copper matte, reverts, or other materials to a batch copper converter;

(B) Skimming slag or other molten materials from a batch copper converter;

(C) Pouring of blister copper or other molten materials from a batch copper converter;

(D) Return of slag or other molten materials to the flash smelting furnace or slag cleaning vessel;

(E) Roll-out or roll-in of the batch copper converter; or

(F) Smoke and fumes generated inside the converter building by operation of the smelting furnace, the slag cleaning vessel (if used), anode refining and casting processes that drift into the copper converter department.

(iv) Using the data summary sheets prepared according to paragraph (c)(7)(iii) of this section, up to five 1-minute intervals following an interference event may be eliminated from data used for the compliance determination calculation specified in paragraph (c)(8) of this section by applying a time delay factor. The time delay factor must be a constant number of minutes not to exceed 5 minutes that is added to the clock time recorded when cessation of the interference event occurs. The same time delay factor must be used for all interference events (i.e., a constant time delay factor for the smelter of 1 minute, 2 minutes, 3 minutes, 4 minutes, or 5 minutes). The number of minutes to be used for the time delay factor is determined based on the site-specific equipment and converter building configuration. An explanation of the rationale for selecting the value used for the time delay factor must be prepared and included in the test report.

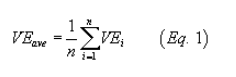

(8) You must use the data summary prepared in paragraph (c)(7) of this section to calculate the average opacity value for a minimum of 120 1-minute intervals during which at least one copper converter was blowing with no interference events as determined according to paragraphs (c)(7)(iii) and (iv) of this section. Average opacity is calculated using Equation 1 of this section:

Where

VEave = Average opacity to be used for compliance determination (percent);

n = Total number of 1-minute intervals during which at least one copper converter was blowing with no interference events as determined according to paragraphs (c)(7)(iii) and (iv) of this section (at least 120 1-minute intervals);

i = 1-minute interval “i” during which at least one copper converter was blowing with no interference events as determined according to paragraphs (c)(7)(iii) and (iv) of this section; and

VEi = Average opacity value calculated for the eight opacity readings recorded during 1-minute interval “i” (percent).

(9) You must certify that the copper converter department capture system operated during the performance test at the operating limits established in your capture system operation and maintenance plan using the procedure specified in paragraphs (c)(9)(i) through (iv) of this section.

(i) Concurrent with all opacity observations, measure and record values for each of the operating limit parameters in your capture system operation and maintenance plan according to the monitoring requirements specified in §63.1452(a).

(ii) For any dampers that are manually set and remain in the same position at all times the capture system is operating, the damper position must be visually checked and recorded at the beginning and end of each opacity observation period segment.

(iii) Review the recorded monitoring data. Identify and explain any times during batch copper converter blowing when the capture system operated outside the applicable operating limits.

(iv) Certify in your performance test report that during all observation period segments, the copper converter department capture system was operating at the values or settings established in your capture system operation and maintenance plan.

§63.1451 How do I demonstrate initial compliance with the emission limitations, work practice standards, and operation and maintenance requirements that apply to me?

(a) Total particulate matter emission limits. For each copper concentrate dryer, smelting furnace, slag cleaning vessel, and copper converter department subject to a total particulate matter emission limits in §63.1444 or §63.1446 that applies to you, you have demonstrated initial compliance if you meet both of the conditions in paragraphs (a)(1) and (2) of this section.

(1) The average concentration of total particulate matter from a control device applied to emissions from the affected source, measured according to the performance test procedures in §63.1450(a), did not exceed the applicable emission limit.

(2) You have submitted a notification of compliance status according to the requirements in §63.1454(e).

(b) Nonsulfuric acid particulate matter emissions limits. For each smelting furnace, slag cleaning vessel, and copper converter departments subject to the nonsulfuric acid particulate matter emissions limit in §63.1444 as applies to you, you have demonstrated initial compliance if you meet both of the conditions in paragraphs (b)(1) and (2) of this section.

(1) The average concentration of nonsulfuric acid particulate matter in the process off-gas discharged from the affected source, measured according to the performance test procedures in §63.1450(b), did not exceed 6.2 mg/dscm.

(2) You have submitted a notification of compliance status according to the requirements in §63.1454(e).

(c) For each existing copper converter department subject to the opacity limit in §63.1444, you have demonstrated initial compliance if you meet both of the conditions in paragraphs (c)(1) and (2) of this section.

(1) The opacity of visible emissions exiting the roof monitors or roof exhaust fans on the building housing the copper converter department measured according to the performance test procedures in §63.1450(c), did not exceed 4 percent opacity.

(2) You have submitted a notification of compliance status according to the requirements in §63.1454(e).

(d) Copper converter department capture systems. You have demonstrated initial compliance of the copper converter department capture system if you meet all of the conditions in paragraphs (d)(1) through (4) of this section.

(1) Prepared the capture system operation and maintenance plan according to the requirements of paragraph (a) of this section;

(2) Conducted an initial performance test according to the procedures of §63.1450(c) demonstrating the opacity of any visible emissions exiting the roof monitors or roof exhaust fans on the building housing the copper converter department does not exceed 4 percent opacity;

(3) Included in your notification of compliance status a copy of your written capture system operation and maintenance plan and have certified in your notification of compliance status that you will operate the copper converter department capture system at all times during blowing at the values or settings established for the operating limits in that plan; and

(4) Submitted a notification of compliance status according to the requirements in §63.1454(e).

(e) Baghouses. For each baghouse subject to operating limits in §63.1444(f) or §63.1446(c), you have demonstrated initial compliance if you meet all of the conditions in paragraphs (e)(1) through (3) of this section.

(1) You have included in your written operation and maintenance plan required under §63.1447(b) detailed descriptions of the procedures you use for inspection, maintenance, bag leak detection, and corrective action for the baghouse.

(2) You have certified in your notification of compliance status that you will operate the baghouse according to your written operation and maintenance plan.

(3) You have submitted the notification of compliance status according to the requirements in §63.1454(e).

(f) Venturi wet scrubbers. For each venturi wet scrubber subject to operating limits in §63.1444(g) or §63.1446(d), you have demonstrated initial compliance if you meet all of the conditions in paragraphs (f)(1) through (3) of this section.

(1) Established site-specific operating limits for pressure drop and scrubber water flow rate and have a record of the pressure drop and scrubber water flow rate measured during the performance test you conduct to demonstrate initial compliance with paragraph (a) of this section.

(2) Certified in your notification of compliance status that you will operate the venturi wet scrubber within the established operating limits for pressure drop and scrubber water flow rate.

(3) Submitted a notification of compliance status according to the requirements in §63.1454(e).

(g) Other control devices. For each control device other than a baghouse or venturi wet scrubber subject to operating limits in §63.1444(h) or §63.1446(e), you have demonstrated initial compliance if you meet all of the conditions in paragraphs (g)(1) through (4) of this section.

(1) Selected one or more operating parameters, as appropriate for the control device design, that can be used as representative and reliable indicators of the control device operation.

(2) Established site-specific operating limits for each of the selected operating parameters based on values measured during the performance test you conduct to demonstrate initial compliance with paragraph (a) of this section and have prepared written documentation according to the requirements in §63.1450(a)(5)(iv).

(3) Included in your notification of compliance status a copy of the written documentation you have prepared to demonstrate compliance with paragraph (g)(2) of this section and have certified in your notification of compliance status that you will operate the control device within the established operating limits.

(4) Submitted a notification of compliance status according to the requirements in §63.1454(e).

(h) Fugitive dust sources. For all fugitive dust sources subject to work practice standards in §63.1445, you have demonstrated initial compliance if you meet all of the conditions in paragraphs (i)(1) through (3) of this section.

(1) Prepared a written fugitive dust control plan according to the requirements in §63.1454 and it has been approved by the designated authority.

(2) Certified in your notification of compliance status that you will control emissions from the fugitive dust sources according to the procedures in the approved plan.

(3) Submitted the notification of compliance status according to the requirements in §63.1454(e).

(i) Operation and maintenance requirements. You have demonstrated initial compliance with the operation and maintenance requirements that apply to you if you meet all of the conditions in paragraphs (i)(1) through (3) of this section.

(1) Prepared an operation and maintenance plan according to the requirements in §63.1454(b).

(2) Certified in your notification of compliance status that you will operate each capture system and control device according to the procedures in the plan.

(3) Submitted the notification of compliance status according to the requirements in §63.1454(e).

§63.1452 What are my monitoring requirements?

(a) Copper converter department capture systems. For each operating limit established under your capture system operation and maintenance plan, you must install, operate, and maintain an appropriate monitoring device according the requirements in paragraphs (a)(1) though (6) of this section to measure and record the operating limit value or setting at all times the copper converter department capture system is operating during batch copper converter blowing. Dampers that are manually set and remain in the same position at all times the capture system is operating are exempted from the requirements of this paragraph (a).

(1) Install the monitoring device, associated sensor(s), and recording equipment according to the manufacturers' specifications. Locate the sensor(s) used for monitoring in or as close to a position that provides a representative measurement of the parameter being monitored.

(2) If a flow measurement device is used to monitor the operating limit parameter, you must meet the requirements in paragraph (a)(2)(i) through (iv) of this section.

(i) Locate the flow sensor and other necessary equipment such as straightening vanes in a position that provides a representative flow.

(ii) Use a flow sensor with a minimum tolerance of 2 percent of the flow rate.

(iii) Reduce swirling flow or abnormal velocity distributions due to upstream and downstream disturbances.

(iv) Conduct a flow sensor calibration check at least semiannually.

(3) If a pressure measurement device is used to monitor the operating limit parameter, you must meet the requirements in paragraph (a)(3)(i) through (v) of this section.

(i) Locate the pressure sensor(s) in or as close to a position that provides a representative measurement of the pressure.

(ii) Minimize or eliminate pulsating pressure, vibration, and internal and external corrosion.

(iii) Use a gauge with a minimum tolerance of 0.5 inch of water or a transducer with a minimum tolerance of 1 percent of the pressure range.

(iv) Check pressure tap pluggage daily.

(v) Using a manometer, check gauge calibration quarterly and transducer calibration monthly.

(4) Conduct calibration and validation checks any time the sensor exceeds the manufacturer's specifications or you install a new sensor.

(5) At least monthly, inspect all components for integrity, all electrical connections for continuity, and all mechanical connections for leakage.

(6) Record the results of each inspection, calibration, and validation check.

(b) Baghouses. For each baghouse subject to the operating limit in §63.1444(f) or §63.1446(c) for the bag leak detection system alarm, you must at all times monitor the relative change in particulate matter loadings using a bag leak detection system according to the requirements in paragraph (b)(1) of this section and conduct regular inspections according to the requirements in paragraph (b)(2) of this section.

(1) You must install, operate, and maintain each bag leak detection system according to the requirements in paragraphs (b)(1)(i) through (vii) of this section.

(i) The system must be certified by the manufacturer to be capable of detecting emissions of particulate matter at concentrations of 10 milligrams per actual cubic meter (0.0044 grains per actual cubic foot) or less.

(ii) The system must provide output of relative changes in particulate matter loadings.

(iii) The system must be equipped with an alarm that will sound when an increase in relative particulate loadings is detected over a preset level. The alarm must be located such that it can be heard by the appropriate plant personnel.

(iv) Each system that works based on the triboelectric effect must be installed, operated, and maintained in a manner consistent with the guidance document, “Fabric Filter Bag Leak Detection Guidance,” EPA-454/R-98-015, September 1997. You may obtain a copy of this guidance document by contacting the National Technical Information Service (NTIS) at 800-553-6847. You may install, operate, and maintain other types of bag leak detection systems in a manner consistent with the manufacturer's written specifications and recommendations.

(v) To make the initial adjustment of the system, establish the baseline output by adjusting the sensitivity (range) and the averaging period of the device. Then, establish the alarm set points and the alarm delay time.

(vi) Following the initial adjustment, do not adjust the sensitivity or range, averaging period, alarm set points, or alarm delay time, except as detailed in your operation and maintenance plan. Do not increase the sensitivity by more than 100 percent or decrease the sensitivity by more than 50 percent over a 365-day period unless a responsible official certifies, in writing, that the baghouse has been inspected and found to be in good operating condition.

(vii) Where multiple detectors are required, the system's instrumentation and alarm may be shared among detectors.

(2) You must conduct baghouse inspections at their specified frequencies according to the requirements in paragraphs (b)(2)(i) through (viii) of this section.

(i) Monitor the pressure drop across each baghouse cell each day to ensure pressure drop is within the normal operating range identified in the manual.

(ii) Confirm that dust is being removed from hoppers through weekly visual inspections or other means of ensuring the proper functioning of removal mechanisms.

(iii) Check the compressed air supply for pulse-jet baghouses each day.

(iv) Monitor cleaning cycles to ensure proper operation using an appropriate methodology.

(v) Check bag cleaning mechanisms for proper functioning through monthly visual inspection or equivalent means.

(vi) Make monthly visual checks of bag tension on reverse air and shaker-type baghouses to ensure that bags are not kinked (kneed or bent) or laying on their sides. You do not have to make this check for shaker-type baghouses using self-tensioning (spring-loaded) devices.

(vii) Confirm the physical integrity of the baghouse through quarterly visual inspections of the baghouse interior for air leaks.

(viii) Inspect fans for wear, material buildup, and corrosion through quarterly visual inspections, vibration detectors, or equivalent means.

(c) Venturi wet scrubbers. For each venturi wet scrubber subject to the operating limits for pressure drop and scrubber water flow rate in §63.1444(g) or §63.1446(d), you must at all times monitor the hourly average pressure drop and water flow rate using a CPMS. You must install, operate, and maintain each CPMS according to the requirements in paragraphs (c)(1) and (2) of this section.

(1) For the pressure drop CPMS, you must meet the requirements in paragraphs (c)(1)(i) through (vi) of this section.

(i) Locate the pressure sensor(s) in or as close to a position that provides a representative measurement of the pressure and that minimizes or eliminates pulsating pressure, vibration, and internal and external corrosion.

(ii) Use a gauge with a minimum measurement sensitivity of 0.5 inch of water or a transducer with a minimum measurement sensitivity of 1 percent of the pressure range.

(iii) Check the pressure tap for pluggage daily.

(iv) Using a manometer, check gauge calibration quarterly and transducer calibration monthly.

(v) Conduct calibration checks any time the sensor exceeds the manufacturer's specified maximum operating pressure range, or install a new pressure sensor.

(vi) At least monthly, inspect all components for integrity, all electrical connections for continuity, and all mechanical connections for leakage.

(2) For the scrubber water flow rate CPMS, you must meet the requirements in paragraphs (c)(2)(i) through (iv) of this section.

(i) Locate the flow sensor and other necessary equipment in a position that provides a representative flow and that reduces swirling flow or abnormal velocity distributions due to upstream and downstream disturbances.

(ii) Use a flow sensor with a minimum measurement sensitivity of 2 percent of the flow rate.

(iii) Conduct a flow sensor calibration check at least semiannually according to the manufacturer's instructions.

(iv) At least monthly, inspect all components for integrity, all electrical connections for continuity, and all mechanical connections for leakage.