['Air Programs']

['Hazardous Air Pollutants']

12/26/2024

...

(a) Emission limits. You must meet the applicable vinyl chloride and total non-vinyl chloride organic HAP emission limits for stripped resin specified in Table 1 or 2 to this subpart.

(b) Determination of total non-vinyl chloride organic HAP. You must develop a facility-specific list of HAP that are expected to be present in each grade of resin produced by your PVCPU. This list must be continuously updated and must be available for inspection by the Administrator. This list must include the identification of each grade of resin produced, each HAP expected to be present in that grade of resin, and the CAS number for each HAP.

(1) For the purposes of demonstrating initial and continuous compliance as required in paragraphs (c) and (d) of this section, you must meet the requirements specified in paragraphs (b)(1)(i) and (b)(1)(ii) of this section.

(i) You must analyze each resin sample for all Table 10 HAP using the test methods specified in paragraph (e) of this section.

(ii) You must also analyze each resin sample for any HAP that are not a Table 10 HAP but are expected to be present in that resin sample based on your facility-specific list of HAP using the appropriate test method specified in paragraph (e) of this section.

(2) [Reserved]

(c) Demonstration of initial compliance. You must demonstrate initial compliance for each resin stripper or for each group of resin strippers used to process the same resin type.

(1) You must conduct an initial performance test for the resin stripper, measuring the concentration of vinyl chloride and total non-vinyl chloride organic HAP in the stripped resin at the outlet of each resin stripper as specified in paragraphs (c)(1)(i) through (iv) of this section.

(i) Use the test method(s) and procedures specified in paragraph (e) of this section.

(ii) Collect samples when the PVCPU is producing the resin grade of which you manufacture the most, based on the total mass per resin grade of a given resin type produced in the 12 months preceding the samplingevent.

(iii) For continuous processes, during a 24-hour sampling period, for each resin grade produced, collect 1 grab sample at intervals of 8 hours or per grade of PVC produced, whichever is more frequent. Each sample must be taken as the resin flows out of the stripper.

(iv) For batch processes, during a 24-hour sampling period, for each batch of each resin grade produced, collect 1 grab sample for each batch. Each sample must be taken immediately following the completion of the stripping operation.

(2) Demonstrate initial compliance with the vinyl chloride and total non-vinyl chloride organic HAP emission limits in Table 1 or 2 to this subpart as specified in paragraphs (c)(2)(i) and (ii) of this section.

(i) Calculate the 24-hour arithmetic average vinyl chloride and total non-vinyl chloride organic HAP concentrations for each stripper for each resin grade produced during the 24-hour sampling period, using the vinyl chloride and non vinyl-chloride HAP concentrations measured for the grab samples collected as specified in paragraph (c)(1)(iii) and (iv) of this section and using the calculation procedure specified in paragraph (f) of this section to determine the total non-vinyl chloride organic HAP concentration of each sample.

(ii) Demonstrate compliance with the vinyl chloride and total non-vinyl chloride organic HAP emission limits in Table 1 or 2 to this subpart based on the 24-hour arithmetic average concentrations calculated in either paragraph (c)(2)(ii)(A) or (B) of this section.

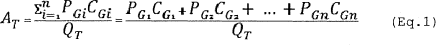

(A) If more than one resin grade was produced during the 24-hour sampling period, use Equation 1 of this section to calculate the 24-hour grade weighted arithmetic average vinyl chloride and total non-vinyl chloride organic HAP concentrations for each stripper, or for each group of strippers used to process the same type of resin, using the 24-hour average vinyl chloride and total non-vinyl chloride organic HAP concentrations calculated in paragraph (c)(2)(i) of this section and the mass of each resin grade produced during the 24-hour sampling period.

Where:

AT = 24-hour average concentration of resin type T, parts per million by weight (dry basis).

PGi = Production of resin grade Gi, pounds.

CGi = 24-hour average concentration of vinyl chloride or total non-vinyl chloride organic HAP in resin grade Gi, ppmw.

QT = Total production of resin type T over the 24-hour sampling period, pounds.

(B) If only one resin grade was produced during the 24-hour sampling event, use the 24-hour arithmetic average vinyl chloride and total non-vinyl chloride organic HAP concentrations for the one resin grade calculated as specified in paragraph (c)(2)(i) of this section for each stripper or calculate the 24-hour arithmetic average vinyl chloride and total non-vinyl chloride organic HAP concentrations for all strippers used to process the one grade of resin.

(d) Demonstration of continuous compliance. You must demonstrate continuous compliance for each resin stripper or for each group of resin strippers used to process the same resin type.

(1) On a daily basis, you must measure the concentration of vinyl chloride in stripped resin using the test method(s) and procedures specified in paragraph (e) of this section, and the procedures specified in paragraphs (c)(1)(iii) and (iv) of this section.

(2) On a monthly basis, you must measure the concentration of total non-vinyl chloride organic HAP in stripped resin using the test method(s) and procedures specified in paragraph (e) of this section, and the procedures specified in paragraphs (c)(1)(iii) and (iv) of this section.

(3) You must demonstrate continuous compliance with the vinyl chloride and total non-vinyl chloride organic HAP emission limit for stripped resin in Table 1 or 2 to this subpart as specified in paragraphs (c)(2)(i) and (ii) of this section.

(e) Test methods and procedures for determining concentration of vinyl chloride and total non-vinyl chloride organic HAP. You must determine the concentration of vinyl chloride and total non-vinyl chloride organic HAP using the test methods and procedures specified in paragraphs (e)(1) through (3) of this section. Upon request, the owner or operator shall make available to the Administrator such records as may be necessary to determine the conditions of performance tests.

(1) For measuring total non-vinyl chloride organic HAP, you must use the methods specified in paragraphs (e)(1)(i) through (iv) of this section.

(i) SW-846-8260B (incorporated by reference, see �63.14) for analysis of volatile organic compounds listed in Table 10 of this subpart.

(ii) SW-846-8270D (incorporated by reference, see �63.14) for analysis of semivolatile organic compounds listed in table 10 of this subpart.

(iii) SW-846-8315A (incorporated by reference, see �63.14) for analysis of aldehyde compounds listed in table 10 of this subpart.

(iv) SW-846-8015C (incorporated by reference, see �63.14) for analysis of alcohol compounds listed in table 10 of this subpart.

(2) For measuring vinyl chloride, you must use Method 107 at 40 CFR part 61, appendix B.

(3) When using the methods specified in paragraphs (e)(1) and (2) of this section, for sample collection, preservation, transport, and analysis, you must minimize loss of HAP and maintain sample integrity.

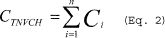

(f) Method for calculating total non-vinyl chloride organic HAP concentration. For each stripped resin sample analyzed using the methods specified in paragraph (e) of this section, calculate the sum of the measured concentrations of each HAP analyzed as required in paragraphs (b)(1)(i) and (b)(1)(ii) of this section by using Equation 2 to this section.

Where:

CTNVCH = Concentration of total non-vinyl chloride organic HAP compounds in the stripped resin sample, in parts per million by weight (ppmw).

Ci = Concentration of individual HAP present in the stripped resin sample analyzed pursuant to paragraphs (b)(1)(i) and (b)(1)(ii) of this section excluding vinyl chloride, in ppmw, where a value of zero should be used for any HAP concentration that is below the detection limit.

['Air Programs']

['Hazardous Air Pollutants']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.