Be Part of the Ultimate Safety & Compliance Community

Trending news, knowledge-building content, and more – all personalized to you!

SUMMARY: The Environmental Protection Agency (EPA) is finalizing amendments to the new source performance standards (NSPS) for electric arc furnaces (EAF) and argon-oxygen decarburization (AOD) vessels in the steel industry pursuant to the review required by the Clean Air Act.

DATES:Effective date: This final rule is effective August 25, 2023. The incorporation by reference of certain publications listed in the rule is approved by the Director of the Federal Register as of August 25, 2023, published in the Federal Register 58442, August 25, 2023.

View final rule.

| §60.17 Incorporation by reference. | ||

| (g)(14) | Revised | View text |

| (h)(206) | Revised | View text |

| (j)(2) | Revised | View text |

| §60.270 Applicability and designation of affected facility. | ||

| (b) | Revised | View text |

| §60.271 Definitions. | ||

| Entire section | Revised | View text |

| §60.272 Standard for particulate matter. | ||

| (a)(2) | Revised | View text |

| (a)(3) introductory text | Revised | View text |

| (b) | Revised | View text |

| §60.273 Emission monitoring. | ||

| Entire section | Revised | View text |

| §60.274 Monitoring of operations. | ||

| (b) through (g), (i) | Revised | View text |

| §60.275 Test methods and procedures. | ||

| Entire section | Revised | View text |

| §60.276 Recordkeeping and reporting requirements. | ||

| Entire section | Revised | View text |

| §60.270a Applicability and designation of affected facility. | ||

| (b) | Revised | View text |

| §60.271a Definitions. | ||

| Definitions for “capture system”, “charge”, “Direct-shell evacuation control system (DEC system),” “Dust-handling system”, “Electric arc furnace (EAF)”, “Heat cycle”, “Meltdown and refining period”, “Refining”, “Shop”, and “Shop opacity” | Revised | View text |

| Definitions for “Charging period” and “Damper” | Added | View text |

| §60.272a Standard for particulate matter. | ||

| Entire section | Revised | View text |

| §60.273a Emission monitoring. | ||

| (c)-(g) | Revised | View text |

| §60.274a Monitoring of operations. | ||

| (b)-(h) | Revised | View text |

| §60.275a Test methods and procedures. | ||

| (a)-(c), (e) | Revised | View text |

| (h)-(j) | Redesignated | View text |

| §60.276a Recordkeeping and reporting requirements. | ||

| Entire section | Revised | View text |

| Subpart AAb—Standards of Performance for Steel Plants: Electric Arc Furnaces and Argon-Oxygen Decarbonization Vessels Constructed After May 16, 2022 | ||

| Entire subpart | Added | View text |

Previous Text

§60.17 Incorporation by reference.

* * * *

(g)(14) ASME/ANSI PTC 19.10–1981, Flue and Exhaust Gas Analyses [Part 10, Instruments and Apparatus], Issued August 31, 1981; IBR approved for §§60.56c(b); 60.63(f); 60.106(e); 60.104a(d), (h), (i), and (j); 60.105a(b), (d), (f), and (g); 60.106a(a); 60.107a(a), (c), and (d); tables 1 and 3 to subpart EEEE; tables 2 and 4 to subpart FFFF; table 2 to subpart JJJJ; §§60.285a(f); 60.396a(a); 60.2145(s) and (t); 60.2710(s) and (t); 60.2730(q); 60.4415(a); 60.4900(b); 60.5220(b); tables 1 and 2 to subpart LLLL; tables 2 and 3 to subpart MMMM; §§60.5406(c); 60.5406a(c); 60.5407a(g); 60.5413(b); 60.5413a(b); 60.5413a(d).

* * * *

(h)(206) ASTM D7520-16, Standard Test Method for Determining the Opacity of a Plume in the Outdoor Ambient Atmosphere, approved April 1, 2016; IBR approved for §60.374a(d).

* * * *

(j)(2) EPA-454/R-98-015, Office of Air Quality Planning and Standards (OAQPS), Fabric Filter Bag Leak Detection Guidance, September 1997, https://nepis.epa.gov/Exe/ZyPDF.cgi?Dockey=2000D5T6.PDF; IBR approved for §§60.373a(b); 60.2145(r); 60.2710(r); 60.4905(b); 60.5225(b).

§60.270 Applicability and designation of affected facility.

* * * *

(b) The provisions of this subpart apply to each affected facility identified in paragraph (a) of this section that commenced construction, modification, or reconstruction after October 21, 1974, and on or before August 17, 1983.

§60.271 Definitions.

As used in this subpart, all terms not defined herein shall have the meaning given them in the Act and in subpart A of this part.

(a) Electric arc furnace (EAF) means a furnace that produces molten steel and heats the charge materials with electric arcs from carbon electrodes. Furnaces that continuously feed direct-reduced iron ore pellets as the primary source of iron are not affected facilities within the scope of this definition.

(b) Dust-handling equipment means any equipment used to handle particulate matter collected by the control device and located at or near the control device for an EAF subject to this subpart.

(c) Control device means the air pollution control equipment used to remove particulate matter generated by an EAF(s) from the effluent gas stream.

(d) Capture system means the equipment (including ducts, hoods, fans, dampers, etc.) used to capture or transport particulate matter generated by an EAF to the air pollution control device.

(e) Charge means the addition of iron and steel scrap or other materials into the top of an electric arc furnace.

(f) Charging period means the time period commencing at the moment an EAF starts to open and ending either three minutes after the EAF roof is returned to its closed position or six minutes after commencement of opening of the roof, whichever is longer.

(g) Tap means the pouring of molten steel from an EAF.

(h) Tapping period means the time period commencing at the moment an EAF begins to pour molten steel and ending either three minutes after steel ceases to flow from an EAF, or six minutes after steel begins to flow, whichever is longer.

(i) Meltdown and refining means that phase of the steel production cycle when charge material is melted and undesirable elements are removed from the metal.

(j) Meltdown and refining period means the time period commencing at the termination of the initial charging period and ending at the initiation of the tapping period, excluding any intermediate charging periods and times when power to the EAF is off.

(k) Shop opacity means the arithmetic average of 24 or more opacity observations of emissions from the shop taken in accordance with Method 9 of appendix A of this part for the applicable time periods.

(l) Heat time means the period commencing when scrap is charged to an empty EAF and terminating when the EAF tap is completed.

(m) Shop means the building which houses one or more EAF's.

(n) Direct shell evacuation system means any system that maintains a negative pressure within the EAF above the slag or metal and ducts these emissions to the control device.

(o) Bag leak detection system means a system that is capable of continuously monitoring relative particulate matter (dust) loadings in the exhaust of a baghouse to detect bag leaks and other conditions that result in increases in particulate loadings. A bag leak detection system includes, but is not limited to, an instrument that operates on triboelectric, electrodynamic, light scattering, light transmittance, or other effect to continuously monitor relative particulate matter loadings.

§60.272 Standard for particulate matter.

* * * *

(a)(2) Exit from a control device and exhibit three percent opacity or greater.

(a)(3) Exit from a shop and, due solely to operations of any EAF(s), exhibit 6 percent opacity or greater except:

* * * *

(b) On and after the date on which the performance test required to be conducted by §60.8 is completed, no owner or operator subject to the provisions of this subpart shall cause to be discharged into the atmosphere from dust-handling equipment any gases which exhibit 10 percent opacity or greater.

§60.273 Emission monitoring.

(a) A continuous monitoring system for the measurement of the opacity of emissions discharged into the atmosphere from the control device(s) shall be installed, calibrated, maintained, and operated by the owner or operator subject to the provisions of this subpart.

(b) For the purpose of reports under §60.7(c), all six-minute periods during which the average opacity is three percent or greater shall indicate a period of excess emission, and shall be reported to the Administrator semi-annually.

(c) A continuous monitoring system for the measurement of the opacity of emissions discharged into the atmosphere from the control device(s) is not required on any modular, multi-stack, negative-pressure or positive-pressure fabric filter if observations of the opacity of the visible emissions from the control device are performed by a certified visible emission observer; or on any single-stack fabric filter if visible emissions from the control device are performed by a certified visible emission observer and the owner installs and continuously operates a bag leak detection system according to paragraph (e) of this section. Visible emission observations shall be conducted at least once per day for at least three 6-minute periods when the furnace is operating in the melting and refining period. All visible emissions observations shall be conducted in accordance with Method 9 of appendix A to this part. If visible emissions occur from more than one point, the opacity shall be recorded for any points where visible emissions are observed. Where it is possible to determine that a number of visible emission sites relate to only one incident of the visible emission, only one set of three 6-minute observations will be required. In that case, the Method 9 observations must be made for the site of highest opacity that directly relates to the cause (or location) of visible emissions observed during a single incident. Records shall be maintained of any 6-minute average that is in excess of the emission limit specified in §60.272(a).

(d) A furnace static pressure monitoring device is not required on any EAF equipped with a DEC system if observations of shop opacity are performed by a certified visible emission observer as follows: Shop opacity observations shall be conducted at least once per day when the furnace is operating in the meltdown and refining period. Shop opacity shall be determined as the arithmetic average of 24 or more consecutive 15-second opacity observations of emissions from the shop taken in accordance with Method 9. Shop opacity shall be recorded for any point(s) where visible emissions are observed in proximity to an affected EAF. Where it is possible to determine that a number of visible emission sites relate to only one incident of visible emissions, only one observation of shop opacity will be required. In this case, the shop opacity observations must be made for the site of highest opacity that directly relates to the cause (or location) of visible emissions observed during a single incident.

(e) A bag leak detection system must be installed and continuously operated on all single-stack fabric filters if the owner or operator elects not to install and operate a continuous opacity monitoring system as provided for under paragraph (c) of this section. In addition, the owner or operator shall meet the visible emissions observation requirements in paragraph (c) of this section. The bag leak detection system must meet the specifications and requirements of paragraphs (e)(1) through (8) of this section.

(1) The bag leak detection system must be certified by the manufacturer to be capable of detecting particulate matter emissions at concentrations of 1 milligram per actual cubic meter (0.00044 grains per actual cubic foot) or less.

(2) The bag leak detection system sensor must provide output of relative particulate matter loadings and the owner or operator shall continuously record the output from the bag leak detection system using electronic or other means (e.g., using a strip chart recorder or a data logger.)

(3) The bag leak detection system must be equipped with an alarm system that will sound when an increase in relative particulate loading is detected over the alarm set point established according to paragraph (e)(4) of this section, and the alarm must be located such that it can be heard by the appropriate plant personnel.

(4) For each bag leak detection system required by paragraph (e) of this section, the owner or operator shall develop and submit to the Administrator or delegated authority, for approval, a site-specific monitoring plan that addresses the items identified in paragraphs (i) through (v) of this paragraph (e)(4). For each bag leak detection system that operates based on the triboelectric effect, the monitoring plan shall be consistent with the recommendations contained in the U.S. Environmental Protection Agency guidance document “Fabric Filter Bag Leak Detection Guidance” (EPA-454/R-98-015). The owner or operator shall operate and maintain the bag leak detection system according to the site-specific monitoring plan at all times. The plan shall describe:

(i) Installation of the bag leak detection system;

(ii) Initial and periodic adjustment of the bag leak detection system including how the alarm set-point will be established;

(iii) Operation of the bag leak detection system including quality assurance procedures;

(iv) How the bag leak detection system will be maintained including a routine maintenance schedule and spare parts inventory list; and

(v) How the bag leak detection system output shall be recorded and stored.

(5) The initial adjustment of the system shall, at a minimum, consist of establishing the baseline output by adjusting the sensitivity (range) and the averaging period of the device, and establishing the alarm set points and the alarm delay time (if applicable).

(6) Following initial adjustment, the owner or operator shall not adjust the averaging period, alarm set point, or alarm delay time without approval from the Administrator or delegated authority except as provided for in paragraphs (e)(6)(i) and (ii) of this section.

(i) Once per quarter, the owner or operator may adjust the sensitivity of the bag leak detection system to account for seasonal effects including temperature and humidity according to the procedures identified in the site-specific monitoring plan required under paragraphs (e)(4) of this section.

(ii) If opacities greater than zero percent are observed over four consecutive 15-second observations during the daily opacity observations required under paragraph (c) of this section and the alarm on the bag leak detection system does not sound, the owner or operator shall lower the alarm set point on the bag leak detection system to a point where the alarm would have sounded during the period when the opacity observations were made.

(7) For negative pressure, induced air baghouses, and positive pressure baghouses that are discharged to the atmosphere through a stack, the bag leak detection sensor must be installed downstream of the baghouse and upstream of any wet scrubber.

(8) Where multiple detectors are required, the system's instrumentation and alarm may be shared among detectors.

(f) For each bag leak detection system installed according to paragraph (e) of this section, the owner or operator shall initiate procedures to determine the cause of all alarms within 1 hour of an alarm. Except as provided for in paragraph (g) of this section, the cause of the alarm must be alleviated within 3 hours of the time the alarm occurred by taking whatever corrective action(s) are necessary. Corrective actions may include, but are not limited to the following:

(1) Inspecting the baghouse for air leaks, torn or broken bags or filter media, or any other condition that may cause an increase in particulate emissions;

(2) Sealing off defective bags or filter media;

(3) Replacing defective bags or filter media or otherwise repairing the control device;

(4) Sealing off a defective baghouse compartment;

(5) Cleaning the bag leak detection system probe or otherwise repairing the bag leak detection system; or

(6) Shutting down the process producing the particulate emissions.

(g) In approving the site-specific monitoring plan required in paragraph (e)(4) of this section, the Administrator or delegated authority may allow owners or operators more than 3 hours to alleviate specific conditions that cause an alarm if the owner or operator identifies the condition that could lead to an alarm in the monitoring plan, adequately explains why it is not feasible to alleviate the condition within 3 hours of the time the alarm occurred, and demonstrates that the requested additional time will ensure alleviation of the condition as expeditiously as practicable.

§60.274 Monitoring of operations.

* * * *

(b) Except as provided under paragraph (d) of this section, the owner or operator subject to the provisions of this subpart shall check and record on a once-per-shift basis furnace static pressure (if a DEC system is in use, and a furnace static pressure gauge is installed according to paragraph (f) of this section) and either: check and record the control system fan motor amperes and damper positions on a once-per-shift basis; install, calibrate, and maintain a monitoring device that continuously records the volumetric flow rate through each separately ducted hood; or install, calibrate, and maintain a monitoring device that continuously records the volumetric flow rate at the control device inlet and check and record damper positions on a once-per-shift basis. The monitoring device(s) may be installed in any appropriate location in the exhaust duct such that reproducible flow rate monitoring will result. The flow rate monitoring device(s) shall have an accuracy of ±10 percent over its normal operating range and shall be calibrated according to the manufacturer's instructions. The Administrator may require the owner or operator to demonstrate the accuracy of the monitoring device(s) relative to Methods 1 and 2 of appendix A of this part.

(c) When the owner or operator of an affected facility is required to demonstrate compliance with the standards under §60.272(a)(3) and at any other time that the Administrator may require (under section 114 of the CAA, as amended) either: the control system fan motor amperes and all damper positions, the volumetric flow rate through each separately ducted hood, or the volumetric flow rate at the control device inlet and all damper positions shall be determined during all periods in which a hood is operated for the purpose of capturing emissions from the affected facility subject to paragraph (b) of this section. The owner or operator may petition the Administrator for reestablishment of these parameters whenever the owner or operator can demonstrate to the Administrator's satisfaction that the EAF operating conditions upon which the parameters were previously established are no longer applicable. The values of these parameters as determined during the most recent demonstration of compliance shall be maintained at the appropriate level for each applicable period. Operation at other than baseline values may be subject to the requirements of §60.276(a).

(d) The owner or operator may petition the Administrator to approve any alternative method that will provide a continuous record of operation of each emission capture system.

(e) The owner or operator shall perform monthly operational status inspections of the equipment that is important to the performance of the total capture system (i.e., pressure sensors, dampers, and damper switches). This inspection shall include observations of the physical appearance of the equipment (e.g., presence of hole in ductwork or hoods, flow constrictions caused by dents or accumulated dust in ductwork, and fan erosion). Any deficiencies shall be noted and proper maintenance performed.

(f) Except as provided for under §60.273(d), where emissions during any phase of the heat time are controlled by use of a direct shell evacuation system, the owner or operator shall install, calibrate, and maintain a monitoring device that continuously records the pressure in the free space inside the EAF. The pressure shall be recorded as 15-minute integrated averages. The monitoring device may be installed in any appropriate location in the EAF or DEC duct prior to the introduction of ambient air such that reproducible results will be obtained. The pressure monitoring device shall have an accuracy of ±5 mm of water gauge over its normal operating range and shall be calibrated according to the manufacturer's instructions.

(g) Except as provided for under §60.273(d), when the owner or operator of an EAF is required to demonstrate compliance with the standard under §60.272(a)(3) and at any other time the Administrator may require (under section 114 of the Act, as amended), the pressure in the free space inside the furnace shall be determined during the meltdown and refining period(s) using the monitoring device under paragraph (f) of this section. The owner or operator may petition the Administrator for reestablishment of the 15-minute integrated average pressure whenever the owner or operator can demonstrate to the Administrator's satisfaction that the EAF operating conditions upon which the pressures were previously established are no longer applicable. The pressure determined during the most recent demonstration of compliance shall be maintained at all times the EAF is operating in a meltdown and refining period. Operation at higher pressures may be considered by the Administrator to be unacceptable operation and maintenance of the affected facility.

* * * *

(i) During any performance test required under §60.8, and for any report thereof required by §60.276(c) of this subpart or to determine compliance with §60.272(a)(3) of this subpart, the owner or operator shall monitor the following information for all heats covered by the test:

§60.275 Test methods and procedures.

(a) During performance tests required in §60.8, the owner or operator shall not add gaseous diluent to the effluent gas after the fabric in any pressurized fabric collector, unless the amount of dilution is separately determined and considered in the determination of emissions.

(b) When emissions from any EAF(s) are combined with emissions from facilities not subject to the provisions of this subpart but controlled by a common capture system and control device, the owner or operator shall use either or both of the following procedures during a performance test (see also §60.276(b)):

(1) Determine compliance using the combined emissions.

(2) Use a method that is acceptable to the Administrator and that compensates for the emissions from the facilities not subject to the provisions of this subpart.

(c) When emissions from any EAF(s) are combined with emissions from facilities not subject to the provisions of this subpart, the owner or operator shall use either or both of the following procedures to demonstrate compliance with §60.272(a)(3):

(1) Determine compliance using the combined emissions.

(2) Shut down operation of facilities not subject to the provisions of this subpart during the performance test.

(d) In conducting the performance tests required in §60.8, the owner or operator shall use as reference methods and procedures the test methods in appendix A of this part or other methods and procedures as specified in this section, except as provided in §60.8(b).

(e) The owner or operator shall determine compliance with the particulate matter standards in §60.272 as follows:

(1) Method 5 shall be used for negative-pressure fabric filters and other types of control devices and Method 5D shall be used for positive-pressure fabric filters to determine the particular matter concentration and, if applicable, the volumetric flow rate of the effluent gas. The sampling time and sample volume for each run shall be at least 4 hours and 4.5 dscm (160 dscf) and, when a single EAF is sampled, the sampling time shall include an integral number of heats.

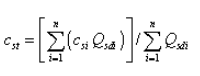

(2) When more than one control device serves the EAF(s) being tested, the concentration of particulate matter shall be determined using the following equation:

where:

cst = average concentration of particulate matter, mg/dscm (gr/dscf).

csi = concentration of particulate matter from control device “i”, mg/dscm (gr/dscf).

n = total number of control devices tested.

Qsdi = volumetric flow rate of stack gas from control device “i”, dscm/hr (dscf/hr).

(3) Method 9 and the procedures of §60.11 shall be used to determine opacity.

(4) To demonstrate compliance with §60.272(a) (1), (2), and (3), the Method 9 test runs shall be conducted concurrently with the particulate matter test runs, unless inclement weather interferes.

(f) To comply with §60.274 (c), (f), (g), and (i), the owner or operator shall obtain the information in these paragraphs during the particulate matter runs.

(g) Where emissions from any EAF(s) are combined with emissions from facilities not subject to the provisions of this subpart but controlled by a common capture system and control device, the owner or operator may use any of the following procedures during a performance test:

(1) Base compliance on control of the combined emissions.

(2) Utilize a method acceptable to the Administrator which compensates for the emissions from the facilities not subject to the provisions of this subpart.

(3) Any combination of the criteria of paragraphs (g)(1) and (g)(2) of this section.

(h) Where emissions from any EAF(s) are combined with emissions from facilities not subject to the provisions of this subpart, the owner or operator may use any of the following procedures for demonstrating compliance with §60.272(a)(3):

(1) Base compliance on control of the combined emissions.

(2) Shut down operation of facilities not subject to the provisions of this subpart.

(3) Any combination of the criteria of paragraphs (h)(1) and (h)(2) of this section.

(i) If visible emissions observations are made in lieu of using a continuous opacity monitoring system, as allowed for by §60.273(c), visible emission observations shall be conducted at least once per day for at least three 6-minute periods when the furnace is operating in the melting and refining period. All visible emissions observations shall be conducted in accordance with Method 9. If visible emissions occur from more than one point, the opacity shall be recorded for any points where visible emissions are observed. Where it is possible to determine that a number of visible emission sites relate to only one incident of the visible emission, only one set of three 6-minute observations will be required. In that case, the Method 9 observations must be made for the site of highest opacity that directly relates to the cause (or location) of visible emissions observed during a single incident. Records shall be maintained of any 6-minute average that is in excess of the emission limit specified in §60.272(a).

(j) Unless the presence of inclement weather makes concurrent testing infeasible, the owner or operator shall conduct concurrently the performance tests required under §60.8 to demonstrate compliance with §60.272(a) (1), (2), and (3) of this subpart.

* * * *

§60.276 Recordkeeping and reporting requirements.

(a) Operation at a furnace static pressure that exceeds the value established under §60.274(g) and either operation of control system fan motor amperes at values exceeding ±15 percent of the value established under §60.274(c) or operation at flow rates lower than those established under §60.274(c) may be considered by the Administrator to be unacceptable operation and maintenance of the affected facility. Operation at such values shall be reported to the Administrator semiannually.

(b) When the owner or operator of an EAF is required to demonstrate compliance with the standard under §60.275 (b)(2) or a combination of (b)(1) and (b)(2), the owner or operator shall obtain approval from the Administrator of the procedure(s) that will be used to determine compliance. Notification of the procedure(s) to be used must be postmarked at least 30 days prior to the performance test.

(c) For the purpose of this subpart, the owner or operator shall conduct the demonstration of compliance with §60.272(a) of this subpart and furnish the Administrator a written report of the results of the test. This report shall include the following information:

(1) Facility name and address;

(2) Plant representative;

(3) Make and model of process, control device, and continuous monitoring equipment;

(4) Flow diagram of process and emission capture equipment including other equipment or process(es) ducted to the same control device;

(5) Rated (design) capacity of process equipment;

(6) Those data required under §60.274(i) of this subpart;

(i) List of charge and tap weights and materials;

(ii) Heat times and process log;

(iii) Control device operation log; and

(iv) Continuous opacity monitor or Method 9 data.

(7) Test dates and test times;

(8) Test company;

(9) Test company representative;

(10) Test observers from outside agency;

(11) Description of test methodology used, including any deviation from standard reference methods

(12) Schematic of sampling location;

(13) Number of sampling points;

(14) Description of sampling equipment;

(15) Listing of sampling equipment calibrations and procedures;

(16) Field and laboratory data sheets;

(17) Description of sample recovery procedures;

(18) Sampling equipment leak check results;

(19) Description of quality assurance procedures;

(20) Description of analytical procedures;

(21) Notation of sample blank corrections; and

(22) Sample emission calculations.

(d) The owner or operator shall maintain records of all shop opacity observations made in accordance with §60.273(d). All shop opacity observations in excess of the emission limit specified in §60.272(a)(3) of this subpart shall indicate a period of excess emission, and shall be reported to the Administrator semi-annually, according to §60.7(c).

(e) The owner or operator shall maintain the following records for each bag leak detection system required under §60.273(e):

(1) Records of the bag leak detection system output;

(2) Records of bag leak detection system adjustments, including the date and time of the adjustment, the initial bag leak detection system settings, and the final bag leak detection system settings; and

(3) An identification of the date and time of all bag leak detection system alarms, the time that procedures to determine the cause of the alarm were initiated, if procedures were initiated within 1 hour of the alarm, the cause of the alarm, an explanation of the actions taken, the date and time the cause of the alarm was alleviated, and if the alarm was alleviated within 3 hours of the alarm.

§60.270a Applicability and designation of affected facility.

* * * *

(b) The provisions of this subpart apply to each affected facility identified in paragraph (a) of this section that commences construction, modification, or reconstruction after August 17, 1983.

§60.271a Definitions.

* * * *

Capture system means the equipment (including ducts, hoods, fans, dampers, etc.) used to capture or transport particulate matter generated by an electric arc furnace or AOD vessel to the air pollution control device.

Charge means the addition of iron and steel scrap or other materials into the top of an electric arc furnace or the addition of molten steel or other materials into the top of an AOD vessel.

* * * *

Direct-shell evacuation control system (DEC system) means a system that maintains a negative pressure within the electric arc furnace above the slag or metal and ducts emissions to the control device.

Dust-handling system means equipment used to handle particulate matter collected by the control device for an electric arc furnace or AOD vessel subject to this subpart. For the purposes of this subpart, the dust-handling system shall consist of the control device dust hoppers, the dust-conveying equipment, any central dust storage equipment, the dust-treating equipment (e.g., pug mill, pelletizer), dust transfer equipment (from storage to truck), and any secondary control devices used with the dust transfer equipment.

Electric arc furnace (EAF) means a furnace that produces molten steel and heats the charge materials with electric arcs from carbon electrodes. For the purposes of this subpart, an EAF shall consist of the furnace shell and roof and the transformer. Furnaces that continuously feed direct-reduced iron ore pellets as the primary source of iron are not affected facilities within the scope of this definition.

Heat cycle means the period beginning when scrap is charged to an empty EAF and ending when the EAF tap is completed or beginning when molten steel is charged to an empty AOD vessel and ending when the AOD vessel tap is completed.

Meltdown and refining period means the time period commencing at the termination of the initial charging period and ending at the initiation of the tapping period, excluding any intermediate charging periods and times when power to the EAF is off.

* * * *

Refining means that phase of the steel production cycle during which undesirable elements are removed from the molten steel and alloys are added to reach the final metal chemistry.

Shop means the building which houses one or more EAF's or AOD vessels.

Shop opacity means the arithmetic average of 24 observations of the opacity of emissions from the shop taken in accordance with Method 9 of appendix A of this part.

§60.272a Standard for particulate matter.

(a) On and after the date of which the performance test required to be conducted by §60.8 is completed, no owner or operator subject to the provisions of this subpart shall cause to be discharged into the atmosphere from an EAF or an AOD vessel any gases which:

(1) Exit from a control device and con tain particulate matter in excess of 12 mg/dscm (0.0052 gr/dscf);

(2) Exit from a control device and exhibit 3 percent opacity or greater; and

(3) Exit from a shop and, due solely to the operations of any affected EAF(s) or AOD vessel(s), exhibit 6 percent opacity or greater.

(b) On and after the date on which the performance test required to be conducted by §60.8 is completed, no owner or operator subject to the provisions of this subpart shall cause to be discharged into the atmosphere from the dust-handling system any gases that exhibit 10 percent opacity or greater.

§60.273a Emission monitoring.

* * * *

(c) A continuous monitoring system for the measurement of the opacity of emissions discharged into the atmosphere from the control device(s) is not required on any modular, multi-stack, negative-pressure or positive-pressure fabric filter if observations of the opacity of the visible emissions from the control device are performed by a certified visible emission observer; or on any single-stack fabric filter if visible emissions from the control device are performed by a certified visible emission observer and the owner installs and continuously operates a bag leak detection system according to paragraph (e) of this section. Visible emission observations shall be conducted at least once per day for at least three 6-minute periods when the furnace is operating in the melting and refining period. All visible emissions observations shall be conducted in accordance with Method 9. If visible emissions occur from more than one point, the opacity shall be recorded for any points where visible emissions are observed. Where it is possible to determine that a number of visible emission sites relate to only one incident of the visible emission, only one set of three 6-minute observations will be required. In that case, the Method 9 observations must be made for the site of highest opacity that directly relates to the cause (or location) of visible emissions observed during a single incident. Records shall be maintained of any 6-minute average that is in excess of the emission limit specified in §60.272a(a).

(d) A furnace static pressure monitoring device is not required on any EAF equipped with a DEC system if observations of shop opacity are performed by a certified visible emission observer as follows: Shop opacity observations shall be conducted at least once per day when the furnace is operating in the meltdown and refining period. Shop opacity shall be determined as the arithmetic average of 24 consecutive 15-second opacity observations of emissions from the shop taken in accordance with Method 9. Shop opacity shall be recorded for any point(s) where visible emissions are observed. Where it is possible to determine that a number of visible emission sites relate to only one incident of visible emissions, only one observation of shop opacity will be required. In this case, the shop opacity observations must be made for the site of highest opacity that directly relates to the cause (or location) of visible emissions observed during a single incident.

(e) A bag leak detection system must be installed and continuously operated on all single-stack fabric filters if the owner or operator elects not to install and operate a continuous opacity monitoring system as provided for under paragraph (c) of this section. In addition, the owner or operator shall meet the visible emissions observation requirements in paragraph (c) of this section. The bag leak detection system must meet the specifications and requirements of paragraphs (e)(1) through (8) of this section.

(1) The bag leak detection system must be certified by the manufacturer to be capable of detecting particulate matter emissions at concentrations of 1 milligram per actual cubic meter (0.00044 grains per actual cubic foot) or less.

(2) The bag leak detection system sensor must provide output of relative particulate matter loadings and the owner or operator shall continuously record the output from the bag leak detection system using electronic or other means (e.g., using a strip chart recorder or a data logger.)

(3) The bag leak detection system must be equipped with an alarm system that will sound when an increase in relative particulate loading is detected over the alarm set point established according to paragraph (e)(4) of this section, and the alarm must be located such that it can be heard by the appropriate plant personnel.

(4) For each bag leak detection system required by paragraph (e) of this section, the owner or operator shall develop and submit to the Administrator or delegated authority, for approval, a site-specific monitoring plan that addresses the items identified in paragraphs (i) through (v) of this paragraph (e)(4). For each bag leak detection system that operates based on the triboelectric effect, the monitoring plan shall be consistent with the recommendations contained in the U.S. Environmental Protection Agency guidance document “Fabric Filter Bag Leak Detection Guidance” (EPA-454/R-98-015). The owner or operator shall operate and maintain the bag leak detection system according to the site-specific monitoring plan at all times. The plan shall describe the following:

(i) Installation of the bag leak detection system;

(ii) Initial and periodic adjustment of the bag leak detection system including how the alarm set-point will be established;

(iii) Operation of the bag leak detection system including quality assurance procedures;

(iv) How the bag leak detection system will be maintained including a routine maintenance schedule and spare parts inventory list; and

(v) How the bag leak detection system output shall be recorded and stored.

(5) The initial adjustment of the system shall, at a minimum, consist of establishing the baseline output by adjusting the sensitivity (range) and the averaging period of the device, and establishing the alarm set points and the alarm delay time (if applicable).

(6) Following initial adjustment, the owner or operator shall not adjust the averaging period, alarm set point, or alarm delay time without approval from the Administrator or delegated authority except as provided for in paragraphs (e)(6)(i) and (ii) of this section.

(i) Once per quarter, the owner or operator may adjust the sensitivity of the bag leak detection system to account for seasonal effects including temperature and humidity according to the procedures identified in the site-specific monitoring plan required under paragraphs (e)(4) of this section.

(ii) If opacities greater than zero percent are observed over four consecutive 15-second observations during the daily opacity observations required under paragraph (c) of this section and the alarm on the bag leak detection system does not sound, the owner or operator shall lower the alarm set point on the bag leak detection system to a point where the alarm would have sounded during the period when the opacity observations were made.

(7) For negative pressure, induced air baghouses, and positive pressure baghouses that are discharged to the atmosphere through a stack, the bag leak detection sensor must be installed downstream of the baghouse and upstream of any wet scrubber.

(8) Where multiple detectors are required, the system's instrumentation and alarm may be shared among detectors.

(f) For each bag leak detection system installed according to paragraph (e) of this section, the owner or operator shall initiate procedures to determine the cause of all alarms within 1 hour of an alarm. Except as provided for under paragraph (g) of this section, the cause of the alarm must be alleviated within 3 hours of the time the alarm occurred by taking whatever corrective action(s) are necessary. Corrective actions may include, but are not limited to, the following:

(1) Inspecting the baghouse for air leaks, torn or broken bags or filter media, or any other condition that may cause an increase in particulate emissions;

(2) Sealing off defective bags or filter media;

(3) Replacing defective bags or filter media or otherwise repairing the control device;

(4) Sealing off a defective baghouse compartment;

(5) Cleaning the bag leak detection system probe or otherwise repairing the bag leak detection system; and

(6) Shutting down the process producing the particulate emissions.

(g) In approving the site-specific monitoring plan required in paragraph (e)(4) of this section, the Administrator or delegated authority may allow owners or operators more than 3 hours to alleviate specific conditions that cause an alarm if the owner or operator identifies the condition that could lead to an alarm in the monitoring plan, adequately explains why it is not feasible to alleviate the condition within 3 hours of the time the alarm occurred, and demonstrates that the requested additional time will ensure alleviation of the condition as expeditiously as practicable.

§60.274a Monitoring of operations

* * * *

(b) Except as provided under paragraph (e) of this section, the owner or operator subject to the provisions of this subpart shall check and record on a once-per-shift basis the furnace static pressure (if DEC system is in use, and a furnace static pressure gauge is installed according to paragraph (f) of this section) and either: check and record the control system fan motor amperes and damper position on a once-per-shift basis; install, calibrate, and maintain a monitoring device that continuously records the volumetric flow rate through each separately ducted hood; or install, calibrate, and maintain a monitoring device that continuously records the volumetric flow rate at the control device inlet and check and record damper positions on a once-per-shift basis. The monitoring device(s) may be installed in any appropriate location in the exhaust duct such that reproducible flow rate monitoring will result. The flow rate monitoring device(s) shall have an accuracy of ±10 percent over its normal operating range and shall be calibrated according to the manufacturer's instructions. The Administrator may require the owner or operator to demonstrate the accuracy of the monitoring device(s) relative to Methods 1 and 2 of appendix A of this part.

(c) When the owner or operator of an affected facility is required to demonstrate compliance with the standards under §60.272a(a)(3) and at any other time that the Administrator may require (under section 114 of the CAA, as amended) either: the control system fan motor amperes and all damper positions, the volumetric flow rate through each separately ducted hood, or the volumetric flow rate at the control device inlet and all damper positions shall be determined during all periods in which a hood is operated for the purpose of capturing emissions from the affected facility subject to paragraph (b) of this section. The owner or operator may petition the Administrator for reestablishment of these parameters whenever the owner or operator can demonstrate to the Administrator's satisfaction that the affected facility operating conditions upon which the parameters were previously established are no longer applicable. The values of these parameters as determined during the most recent demonstration of compliance shall be maintained at the appropriate level for each applicable period. Operation at other than baseline values may be subject to the requirements of §60.276a(c).

(d) Except as provided under paragraph (e) of this section, the owner or operator shall perform monthly operational status inspections of the equipment that is important to the performance of the total capture system (i.e., pressure sensors, dampers, and damper switches). This inspection shall include observations of the physical appearance of the equipment (e.g., presence of holes in ductwork or hoods, flow constrictions caused by dents or accumulated dust in ductwork, and fan erosion). Any deficiencies shall be noted and proper maintenance performed.

(e) The owner or operator may petition the Administrator to approve any alternative to either the monitoring requirements specified in paragraph (b) of this section or the monthly operational status inspections specified in paragraph (d) of this section if the alternative will provide a continuous record of operation of each emission capture system.

(f) Except as provided for under §60.273a(d), if emissions during any phase of the heat time are controlled by the use of a DEC system, the owner or operator shall install, calibrate, and maintain a monitoring device that allows the pressure in the free space inside the EAF to be monitored. The pressure shall be recorded as 15-minute integrated averages. The monitoring device may be installed in any appropriate location in the EAF or DEC duct prior to the introduction of ambient air such that reproducible results will be obtained. The pressure monitoring device shall have an accuracy of ±5 mm of water gauge over its normal operating range and shall be calibrated according to the manufacturer's instructions.

(g) Except as provided for under §60.273a(d), when the owner or operator of an EAF controlled by a DEC is required to demonstrate compliance with the standard under §60.272a(a)(3), and at any other time the Administrator may require (under section 114 of the Clean Air Act, as amended), the pressure in the free space inside the furnace shall be determined during the meltdown and refining period(s) using the monitoring device required under paragraph (f) of this section. The owner or operator may petition the Administrator for reestablishment of the pressure whenever the owner or operator can demonstrate to the Administrator's satisfaction that the EAF operating conditions upon which the pressures were previously established are no longer applicable. The pressure determined during the most recent demonstration of compliance shall be maintained at all times when the EAF is operating in a meltdown and refining period. Operation at higher pressures may be considered by the Administrator to be unacceptable operation and maintenance of the affected facility.

(h) During any performance test required under §60.8, and for any report thereof required by §60.276a(f) of this subpart, or to determine compliance with §60.272a(a)(3) of this subpart, the owner or operator shall monitor the following information for all heats covered by the test:

(1) Charge weights and materials, and tap weights and materials;

(2) Heat times, including start and stop times, and a log of process operation, including periods of no operation during testing and the pressure inside an EAF when direct-shell evacuation control systems are used;

(3) Control device operation log; and

(4) Continuous opacity monitor or Method 9 data.

§60.275a Test methods and procedures.

(a) During performance tests required in §60.8, the owner or operator shall not add gaseous diluents to the effluent gas stream after the fabric in any pressurized fabric filter collector, unless the amount of dilution is separately determined a nd considered in the determination of emissions.

(b) When emissions from any EAF(s) or AOD vessel(s) are combined with emissions from facilities not subject to the provisions of this subpart but controlled by a common capture system and control device, the owner or operator shall use either or both of the following procedures during a performance test (see also §60.276a(e)):

(1) Determine compliance using the combined emissions.

(2) Use a method that is acceptable to the Administrator and that compensates for the emissions from the facilities not subject to the provisions of this subpart.

(c) When emission from any EAF(s) or AOD vessel(s) are combined with emissions from facilities not subject to the provisions of this subpart, the owner or operator shall demonstrate compliance with §60.272(a)(3) based on emissions from only the affected facility(ies).

* * * *

(e) The owner or operator shall determine compliance with the particulate matter standards in §60.272a as follows:

* * * *

(h) Where emissions from any EAF(s) or AOD vessel(s) are combined with emissions from facilities not subject to the provisions of this subpart but controlled by a common capture system and control device, the owner or operator may use any of the following procedures during a performance test:

(1) Base compliance on control of the combined emissions;

(2) Utilize a method acceptable to the Administrator that compensates for the emissions from the facilities not subject to the provisions of this subpart, or;

(3) Any combination of the criteria of paragraphs (h)(1) and (h)(2) of this section.

(i) Where emissions from any EAF(s) or AOD vessel(s) are combined with emissions from facilities not subject to the provisions of this subpart, determinations of compliance with §60.272a(a)(3) will only be based upon emissions originating from the affected facility(ies).

(j) Unless the presence of inclement weather makes concurrent testing infeasible, the owner or operator shall conduct concurrently the performance tests required under §60.8 to demonstrate compliance with §60.272a(a) (1), (2), and (3) of this subpart.

§60.276a Recordkeeping and reporting requirements.

(a) Records of the measurements required in §60.274a must be retained for at least 2 years following the date of the measurement.

(b) Each owner or operator shall submit a written report of exceedances of the control device opacity to the Administrator semi-annually. For the purposes of these reports, exceedances are defined as all 6-minute periods during which the average opacity is 3 percent or greater.

(c) Operation at a furnace static pressure that exceeds the value established under §60.274a(g) and either operation of control system fan motor amperes at values exceeding ±15 percent of the value established under §60.274a(c) or operation at flow rates lower than those established under §60.274a(c) may be considered by the Administrator to be unacceptable operation and maintenance of the affected facility. Operation at such values shall be reported to the Administrator semiannually.

(d) The requirements of this section remain in force until and unless EPA, in delegating enforcement authority to a State under section 111(c) of the Act, approves reporting requirements or an alternative means of compliance surveillance adopted by such State. In that event, affected sources within the State will be relieved of the obligation to comply with this section, provided that they comply with the requirements established by the State.

(e) When the owner or operator of an EAF or AOD is required to demonstrate compliance with the standard under §60.275 (b)(2) or a combination of (b)(1) and (b)(2) the owner or operator shall obtain approval from the Administrator of the procedure(s) that will be used to determine compliance. Notification of the procedure(s) to be used must be postmarked at least 30 days prior to the performance test.

(f) For the purpose of this subpart, the owner or operator shall conduct the demonstration of compliance with §60.272a(a) of this subpart and furnish the Administrator a written report of the results of the test. This report shall include the following information:

(1) Facility name and address;

(2) Plant representative;

(3) Make and model of process, control device, and continuous monitoring equipment;

(4) Flow diagram of process and emission capture equipment including other equipment or process(es) ducted to the same control device;

(5) Rated (design) capacity of process equipment;

(6) Those data required under §60.274a(h) of this subpart;

(i) List of charge and tap weights and materials;

(ii) Heat times and process log;

(iii) Control device operation log; and

(iv) Continuous opacity monitor or Method 9 data.

(7) Test dates and test times;

(8) Test company;

(9) Test company representative;

(10) Test observers from outside agency;

(11) Description of test methodology used, including any deviation from standard reference methods;

(12) Schematic of sampling location;

(13) Number of sampling points;

(14) Description of sampling equipment;

(15) Listing of sampling equipment calibrations and procedures;

(16) Field and laboratory data sheets;

(17) Description of sample recovery procedures;

(18) Sampling equipment leak check results;

(19) Description of quality assurance procedures;

(20) Description of analytical procedures;

(21) Notation of sample blank corrections; and

(22) Sample emission calculations.

(g) The owner or operator shall maintain records of all shop opacity observations made in accordance with §60.273a(d). All shop opacity observations in excess of the emission limit specified in §60.272a(a)(3) of this subpart shall indicate a period of excess emission, and shall be reported to the administrator semi-annually, according to §60.7(c).

(h) The owner or operator shall maintain the following records for each bag leak detection system required under §60.273a(e):

(1) Records of the bag leak detection system output;

(2) Records of bag leak detection system adjustments, including the date and time of the adjustment, the initial bag leak detection system settings, and the final bag leak detection system settings; and

(3) An identification of the date and time of all bag leak detection system alarms, the time that procedures to determine the cause of the alarm were initiated, if procedures were initiated within 1 hour of the alarm, the cause of the alarm, an explanation of the actions taken, the date and time the cause of the alarm was alleviated, and if the alarm was alleviated within 3 hours of the alarm.

SUMMARY: The Environmental Protection Agency (EPA) is finalizing amendments to the new source performance standards (NSPS) for electric arc furnaces (EAF) and argon-oxygen decarburization (AOD) vessels in the steel industry pursuant to the review required by the Clean Air Act.

DATES:Effective date: This final rule is effective August 25, 2023. The incorporation by reference of certain publications listed in the rule is approved by the Director of the Federal Register as of August 25, 2023, published in the Federal Register 58442, August 25, 2023.

View final rule.

| §60.17 Incorporation by reference. | ||

| (g)(14) | Revised | View text |

| (h)(206) | Revised | View text |

| (j)(2) | Revised | View text |

| §60.270 Applicability and designation of affected facility. | ||

| (b) | Revised | View text |

| §60.271 Definitions. | ||

| Entire section | Revised | View text |

| §60.272 Standard for particulate matter. | ||

| (a)(2) | Revised | View text |

| (a)(3) introductory text | Revised | View text |

| (b) | Revised | View text |

| §60.273 Emission monitoring. | ||

| Entire section | Revised | View text |

| §60.274 Monitoring of operations. | ||

| (b) through (g), (i) | Revised | View text |

| §60.275 Test methods and procedures. | ||

| Entire section | Revised | View text |

| §60.276 Recordkeeping and reporting requirements. | ||

| Entire section | Revised | View text |

| §60.270a Applicability and designation of affected facility. | ||

| (b) | Revised | View text |

| §60.271a Definitions. | ||

| Definitions for “capture system”, “charge”, “Direct-shell evacuation control system (DEC system),” “Dust-handling system”, “Electric arc furnace (EAF)”, “Heat cycle”, “Meltdown and refining period”, “Refining”, “Shop”, and “Shop opacity” | Revised | View text |

| Definitions for “Charging period” and “Damper” | Added | View text |

| §60.272a Standard for particulate matter. | ||

| Entire section | Revised | View text |

| §60.273a Emission monitoring. | ||

| (c)-(g) | Revised | View text |

| §60.274a Monitoring of operations. | ||

| (b)-(h) | Revised | View text |

| §60.275a Test methods and procedures. | ||

| (a)-(c), (e) | Revised | View text |

| (h)-(j) | Redesignated | View text |

| §60.276a Recordkeeping and reporting requirements. | ||

| Entire section | Revised | View text |

| Subpart AAb—Standards of Performance for Steel Plants: Electric Arc Furnaces and Argon-Oxygen Decarbonization Vessels Constructed After May 16, 2022 | ||

| Entire subpart | Added | View text |

Previous Text

§60.17 Incorporation by reference.

* * * *

(g)(14) ASME/ANSI PTC 19.10–1981, Flue and Exhaust Gas Analyses [Part 10, Instruments and Apparatus], Issued August 31, 1981; IBR approved for §§60.56c(b); 60.63(f); 60.106(e); 60.104a(d), (h), (i), and (j); 60.105a(b), (d), (f), and (g); 60.106a(a); 60.107a(a), (c), and (d); tables 1 and 3 to subpart EEEE; tables 2 and 4 to subpart FFFF; table 2 to subpart JJJJ; §§60.285a(f); 60.396a(a); 60.2145(s) and (t); 60.2710(s) and (t); 60.2730(q); 60.4415(a); 60.4900(b); 60.5220(b); tables 1 and 2 to subpart LLLL; tables 2 and 3 to subpart MMMM; §§60.5406(c); 60.5406a(c); 60.5407a(g); 60.5413(b); 60.5413a(b); 60.5413a(d).

* * * *

(h)(206) ASTM D7520-16, Standard Test Method for Determining the Opacity of a Plume in the Outdoor Ambient Atmosphere, approved April 1, 2016; IBR approved for §60.374a(d).

* * * *

(j)(2) EPA-454/R-98-015, Office of Air Quality Planning and Standards (OAQPS), Fabric Filter Bag Leak Detection Guidance, September 1997, https://nepis.epa.gov/Exe/ZyPDF.cgi?Dockey=2000D5T6.PDF; IBR approved for §§60.373a(b); 60.2145(r); 60.2710(r); 60.4905(b); 60.5225(b).

§60.270 Applicability and designation of affected facility.

* * * *

(b) The provisions of this subpart apply to each affected facility identified in paragraph (a) of this section that commenced construction, modification, or reconstruction after October 21, 1974, and on or before August 17, 1983.

§60.271 Definitions.

As used in this subpart, all terms not defined herein shall have the meaning given them in the Act and in subpart A of this part.

(a) Electric arc furnace (EAF) means a furnace that produces molten steel and heats the charge materials with electric arcs from carbon electrodes. Furnaces that continuously feed direct-reduced iron ore pellets as the primary source of iron are not affected facilities within the scope of this definition.

(b) Dust-handling equipment means any equipment used to handle particulate matter collected by the control device and located at or near the control device for an EAF subject to this subpart.

(c) Control device means the air pollution control equipment used to remove particulate matter generated by an EAF(s) from the effluent gas stream.

(d) Capture system means the equipment (including ducts, hoods, fans, dampers, etc.) used to capture or transport particulate matter generated by an EAF to the air pollution control device.

(e) Charge means the addition of iron and steel scrap or other materials into the top of an electric arc furnace.

(f) Charging period means the time period commencing at the moment an EAF starts to open and ending either three minutes after the EAF roof is returned to its closed position or six minutes after commencement of opening of the roof, whichever is longer.

(g) Tap means the pouring of molten steel from an EAF.

(h) Tapping period means the time period commencing at the moment an EAF begins to pour molten steel and ending either three minutes after steel ceases to flow from an EAF, or six minutes after steel begins to flow, whichever is longer.

(i) Meltdown and refining means that phase of the steel production cycle when charge material is melted and undesirable elements are removed from the metal.

(j) Meltdown and refining period means the time period commencing at the termination of the initial charging period and ending at the initiation of the tapping period, excluding any intermediate charging periods and times when power to the EAF is off.

(k) Shop opacity means the arithmetic average of 24 or more opacity observations of emissions from the shop taken in accordance with Method 9 of appendix A of this part for the applicable time periods.

(l) Heat time means the period commencing when scrap is charged to an empty EAF and terminating when the EAF tap is completed.

(m) Shop means the building which houses one or more EAF's.

(n) Direct shell evacuation system means any system that maintains a negative pressure within the EAF above the slag or metal and ducts these emissions to the control device.

(o) Bag leak detection system means a system that is capable of continuously monitoring relative particulate matter (dust) loadings in the exhaust of a baghouse to detect bag leaks and other conditions that result in increases in particulate loadings. A bag leak detection system includes, but is not limited to, an instrument that operates on triboelectric, electrodynamic, light scattering, light transmittance, or other effect to continuously monitor relative particulate matter loadings.

§60.272 Standard for particulate matter.

* * * *

(a)(2) Exit from a control device and exhibit three percent opacity or greater.

(a)(3) Exit from a shop and, due solely to operations of any EAF(s), exhibit 6 percent opacity or greater except:

* * * *

(b) On and after the date on which the performance test required to be conducted by §60.8 is completed, no owner or operator subject to the provisions of this subpart shall cause to be discharged into the atmosphere from dust-handling equipment any gases which exhibit 10 percent opacity or greater.

§60.273 Emission monitoring.

(a) A continuous monitoring system for the measurement of the opacity of emissions discharged into the atmosphere from the control device(s) shall be installed, calibrated, maintained, and operated by the owner or operator subject to the provisions of this subpart.

(b) For the purpose of reports under §60.7(c), all six-minute periods during which the average opacity is three percent or greater shall indicate a period of excess emission, and shall be reported to the Administrator semi-annually.

(c) A continuous monitoring system for the measurement of the opacity of emissions discharged into the atmosphere from the control device(s) is not required on any modular, multi-stack, negative-pressure or positive-pressure fabric filter if observations of the opacity of the visible emissions from the control device are performed by a certified visible emission observer; or on any single-stack fabric filter if visible emissions from the control device are performed by a certified visible emission observer and the owner installs and continuously operates a bag leak detection system according to paragraph (e) of this section. Visible emission observations shall be conducted at least once per day for at least three 6-minute periods when the furnace is operating in the melting and refining period. All visible emissions observations shall be conducted in accordance with Method 9 of appendix A to this part. If visible emissions occur from more than one point, the opacity shall be recorded for any points where visible emissions are observed. Where it is possible to determine that a number of visible emission sites relate to only one incident of the visible emission, only one set of three 6-minute observations will be required. In that case, the Method 9 observations must be made for the site of highest opacity that directly relates to the cause (or location) of visible emissions observed during a single incident. Records shall be maintained of any 6-minute average that is in excess of the emission limit specified in §60.272(a).

(d) A furnace static pressure monitoring device is not required on any EAF equipped with a DEC system if observations of shop opacity are performed by a certified visible emission observer as follows: Shop opacity observations shall be conducted at least once per day when the furnace is operating in the meltdown and refining period. Shop opacity shall be determined as the arithmetic average of 24 or more consecutive 15-second opacity observations of emissions from the shop taken in accordance with Method 9. Shop opacity shall be recorded for any point(s) where visible emissions are observed in proximity to an affected EAF. Where it is possible to determine that a number of visible emission sites relate to only one incident of visible emissions, only one observation of shop opacity will be required. In this case, the shop opacity observations must be made for the site of highest opacity that directly relates to the cause (or location) of visible emissions observed during a single incident.

(e) A bag leak detection system must be installed and continuously operated on all single-stack fabric filters if the owner or operator elects not to install and operate a continuous opacity monitoring system as provided for under paragraph (c) of this section. In addition, the owner or operator shall meet the visible emissions observation requirements in paragraph (c) of this section. The bag leak detection system must meet the specifications and requirements of paragraphs (e)(1) through (8) of this section.

(1) The bag leak detection system must be certified by the manufacturer to be capable of detecting particulate matter emissions at concentrations of 1 milligram per actual cubic meter (0.00044 grains per actual cubic foot) or less.

(2) The bag leak detection system sensor must provide output of relative particulate matter loadings and the owner or operator shall continuously record the output from the bag leak detection system using electronic or other means (e.g., using a strip chart recorder or a data logger.)

(3) The bag leak detection system must be equipped with an alarm system that will sound when an increase in relative particulate loading is detected over the alarm set point established according to paragraph (e)(4) of this section, and the alarm must be located such that it can be heard by the appropriate plant personnel.

(4) For each bag leak detection system required by paragraph (e) of this section, the owner or operator shall develop and submit to the Administrator or delegated authority, for approval, a site-specific monitoring plan that addresses the items identified in paragraphs (i) through (v) of this paragraph (e)(4). For each bag leak detection system that operates based on the triboelectric effect, the monitoring plan shall be consistent with the recommendations contained in the U.S. Environmental Protection Agency guidance document “Fabric Filter Bag Leak Detection Guidance” (EPA-454/R-98-015). The owner or operator shall operate and maintain the bag leak detection system according to the site-specific monitoring plan at all times. The plan shall describe:

(i) Installation of the bag leak detection system;

(ii) Initial and periodic adjustment of the bag leak detection system including how the alarm set-point will be established;

(iii) Operation of the bag leak detection system including quality assurance procedures;

(iv) How the bag leak detection system will be maintained including a routine maintenance schedule and spare parts inventory list; and

(v) How the bag leak detection system output shall be recorded and stored.

(5) The initial adjustment of the system shall, at a minimum, consist of establishing the baseline output by adjusting the sensitivity (range) and the averaging period of the device, and establishing the alarm set points and the alarm delay time (if applicable).

(6) Following initial adjustment, the owner or operator shall not adjust the averaging period, alarm set point, or alarm delay time without approval from the Administrator or delegated authority except as provided for in paragraphs (e)(6)(i) and (ii) of this section.

(i) Once per quarter, the owner or operator may adjust the sensitivity of the bag leak detection system to account for seasonal effects including temperature and humidity according to the procedures identified in the site-specific monitoring plan required under paragraphs (e)(4) of this section.

(ii) If opacities greater than zero percent are observed over four consecutive 15-second observations during the daily opacity observations required under paragraph (c) of this section and the alarm on the bag leak detection system does not sound, the owner or operator shall lower the alarm set point on the bag leak detection system to a point where the alarm would have sounded during the period when the opacity observations were made.

(7) For negative pressure, induced air baghouses, and positive pressure baghouses that are discharged to the atmosphere through a stack, the bag leak detection sensor must be installed downstream of the baghouse and upstream of any wet scrubber.

(8) Where multiple detectors are required, the system's instrumentation and alarm may be shared among detectors.

(f) For each bag leak detection system installed according to paragraph (e) of this section, the owner or operator shall initiate procedures to determine the cause of all alarms within 1 hour of an alarm. Except as provided for in paragraph (g) of this section, the cause of the alarm must be alleviated within 3 hours of the time the alarm occurred by taking whatever corrective action(s) are necessary. Corrective actions may include, but are not limited to the following:

(1) Inspecting the baghouse for air leaks, torn or broken bags or filter media, or any other condition that may cause an increase in particulate emissions;

(2) Sealing off defective bags or filter media;

(3) Replacing defective bags or filter media or otherwise repairing the control device;

(4) Sealing off a defective baghouse compartment;

(5) Cleaning the bag leak detection system probe or otherwise repairing the bag leak detection system; or

(6) Shutting down the process producing the particulate emissions.

(g) In approving the site-specific monitoring plan required in paragraph (e)(4) of this section, the Administrator or delegated authority may allow owners or operators more than 3 hours to alleviate specific conditions that cause an alarm if the owner or operator identifies the condition that could lead to an alarm in the monitoring plan, adequately explains why it is not feasible to alleviate the condition within 3 hours of the time the alarm occurred, and demonstrates that the requested additional time will ensure alleviation of the condition as expeditiously as practicable.

§60.274 Monitoring of operations.

* * * *

(b) Except as provided under paragraph (d) of this section, the owner or operator subject to the provisions of this subpart shall check and record on a once-per-shift basis furnace static pressure (if a DEC system is in use, and a furnace static pressure gauge is installed according to paragraph (f) of this section) and either: check and record the control system fan motor amperes and damper positions on a once-per-shift basis; install, calibrate, and maintain a monitoring device that continuously records the volumetric flow rate through each separately ducted hood; or install, calibrate, and maintain a monitoring device that continuously records the volumetric flow rate at the control device inlet and check and record damper positions on a once-per-shift basis. The monitoring device(s) may be installed in any appropriate location in the exhaust duct such that reproducible flow rate monitoring will result. The flow rate monitoring device(s) shall have an accuracy of ±10 percent over its normal operating range and shall be calibrated according to the manufacturer's instructions. The Administrator may require the owner or operator to demonstrate the accuracy of the monitoring device(s) relative to Methods 1 and 2 of appendix A of this part.

(c) When the owner or operator of an affected facility is required to demonstrate compliance with the standards under §60.272(a)(3) and at any other time that the Administrator may require (under section 114 of the CAA, as amended) either: the control system fan motor amperes and all damper positions, the volumetric flow rate through each separately ducted hood, or the volumetric flow rate at the control device inlet and all damper positions shall be determined during all periods in which a hood is operated for the purpose of capturing emissions from the affected facility subject to paragraph (b) of this section. The owner or operator may petition the Administrator for reestablishment of these parameters whenever the owner or operator can demonstrate to the Administrator's satisfaction that the EAF operating conditions upon which the parameters were previously established are no longer applicable. The values of these parameters as determined during the most recent demonstration of compliance shall be maintained at the appropriate level for each applicable period. Operation at other than baseline values may be subject to the requirements of §60.276(a).

(d) The owner or operator may petition the Administrator to approve any alternative method that will provide a continuous record of operation of each emission capture system.

(e) The owner or operator shall perform monthly operational status inspections of the equipment that is important to the performance of the total capture system (i.e., pressure sensors, dampers, and damper switches). This inspection shall include observations of the physical appearance of the equipment (e.g., presence of hole in ductwork or hoods, flow constrictions caused by dents or accumulated dust in ductwork, and fan erosion). Any deficiencies shall be noted and proper maintenance performed.

(f) Except as provided for under §60.273(d), where emissions during any phase of the heat time are controlled by use of a direct shell evacuation system, the owner or operator shall install, calibrate, and maintain a monitoring device that continuously records the pressure in the free space inside the EAF. The pressure shall be recorded as 15-minute integrated averages. The monitoring device may be installed in any appropriate location in the EAF or DEC duct prior to the introduction of ambient air such that reproducible results will be obtained. The pressure monitoring device shall have an accuracy of ±5 mm of water gauge over its normal operating range and shall be calibrated according to the manufacturer's instructions.

(g) Except as provided for under §60.273(d), when the owner or operator of an EAF is required to demonstrate compliance with the standard under §60.272(a)(3) and at any other time the Administrator may require (under section 114 of the Act, as amended), the pressure in the free space inside the furnace shall be determined during the meltdown and refining period(s) using the monitoring device under paragraph (f) of this section. The owner or operator may petition the Administrator for reestablishment of the 15-minute integrated average pressure whenever the owner or operator can demonstrate to the Administrator's satisfaction that the EAF operating conditions upon which the pressures were previously established are no longer applicable. The pressure determined during the most recent demonstration of compliance shall be maintained at all times the EAF is operating in a meltdown and refining period. Operation at higher pressures may be considered by the Administrator to be unacceptable operation and maintenance of the affected facility.

* * * *

(i) During any performance test required under §60.8, and for any report thereof required by §60.276(c) of this subpart or to determine compliance with §60.272(a)(3) of this subpart, the owner or operator shall monitor the following information for all heats covered by the test:

§60.275 Test methods and procedures.

(a) During performance tests required in §60.8, the owner or operator shall not add gaseous diluent to the effluent gas after the fabric in any pressurized fabric collector, unless the amount of dilution is separately determined and considered in the determination of emissions.