Optimizing safety: The importance of understanding aisle width in your facility

In the fast-paced world of facility management, the importance of understanding aisle width cannot be overstated. Whether you’re overseeing a small mom-and-pop shop or a multi-million dollar warehousing and manufacturing operation, questions about aisle-width requirements often arise. The confusion only deepens when pedestrian aisles are shared with material handling equipment or serve as egress routes.

Complying with the regulations

According to 29 CFR 1910.22(c), employers must provide and ensure workers use a safe means of access and egress to and from surfaces they walk on, work on, or use to gain access to a work area. The width of aisles and passageways is generally not specified in the OSHA standard, other than in specific instances, including:

- Exit access (1910.36(g)(2)-(3)): A minimum exit access width must be 28 inches at all points.

- Flammables and combustibles (1910.106): Aisles in inside storage rooms holding flammable and combustible liquids must be 3 feet wide.

- Use of mechanical equipment (1910.176(a)): Where mechanical handling equipment is used, sufficient safe clearances must be allowed for aisles … and wherever turns or passage must be made. Aisles and passageways must be kept clear and in good repair, with no obstruction across or in aisles that could create a hazard.

Considering aisle width needs

The width of an aisle will vary depending on how the aisle or passage is used in the workplace. When determining the appropriate width, employers must prioritize safety, efficiency, and compliance by considering several key factors:

- Accessibility and egress: Aisles designated as egress routes or that provide access to emergency exits must follow specific criteria to ensure prompt and safe evacuation during emergencies.

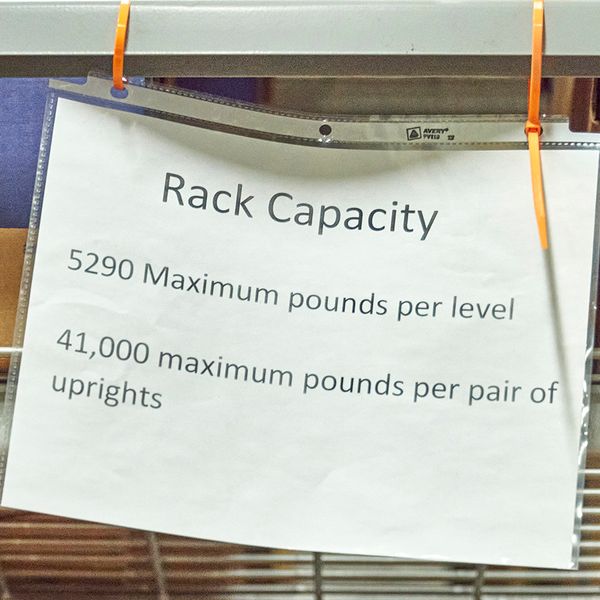

- Equipment type: Material handling equipment, such as forklifts and pallet jacks, comes in varying sizes and levels of maneuverability. Consider the different turning radius and clearance requirements of the equipment.

- Load size and storage method: Bulky or irregular-shaped items being stored and transported may require wider aisles to ensure safe handling and storage.

- Regulatory standards: Compliance with OSHA standards is crucial. Also, remember that state and local fire and building codes may be more stringent than OSHA.

- Traffic flow: The quantity and flow of pedestrian and vehicle traffic within the facility will influence aisle width. Areas with heavy traffic may necessitate broader aisles to facilitate safe movement and reduce the likelihood of incidents.

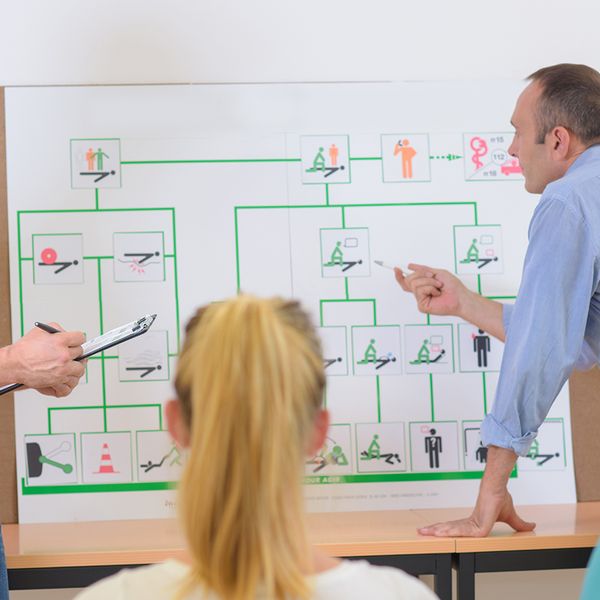

Marking aisles appropriately

OSHA regulations say permanent aisles and passageways must be marked (1910.176(a)). The agency also explains that one way employers can provide safe access and egress to and from walking-working surfaces per 1910.22(c) is by “appropriately marking” passageways and permanent aisles as a means of identifying safe access and egress. Neither regulation defines how aisle marking should be done.

A common marking method is using painted lines or strips of floor-marking tape. These methods are convenient and inexpensive and may hold up for several years without maintenance. The color yellow is popular, possibly because OSHA designates yellow as the “caution” color to be used for marking physical hazards, such as stumbling, falling, or tripping (1910.144(a)(3)).

The American National Standards Institute (ANSI) Z535.1-1998, Safety Color Code, recommends black, white, yellow, or a combination of black and yellow for traffic markings. Note: ANSI Z535.1-2002, Safety Color Code, and later editions no longer have safety color meanings, which appeared in the 1998 and earlier editions.

Accounting for material handling equipment

The current Materials Handling and Storage regulations at 1910.176 refer to “sufficient safe clearances…for aisles.” In a now archived 1972 OSHA letter of interpretation, the agency stipulated that aisles for mechanical equipment such as forklifts should be at least three feet wider than the equipment or a minimum of four feet. While specific measurements for aisles are no longer used, employers should use their best judgment and weigh the hazards of the workplace when determining how wide material handling equipment aisles should be.

OSHA’s general requirement for aisles and passageways is that sufficient safe clearances must be provided where mechanical equipment will be in use. The width of an aisle or passageway will vary depending on how the aisle or passage is used in the workplace. Aisles that must accommodate forklift trucks or other machinery will need to be wider than aisles for pedestrian traffic. Aisles for pedestrians can be narrower than aisles through which equipment or supplies will be transported. It’s always a good idea to make aisles wide enough for two lanes of traffic, whether it’s pedestrians or forklift trucks.

Key to remember

Understanding aisle width is crucial in facility management, as it impacts operations of all sizes, especially when shared with material handling equipment or serving as egress routes.