EPA Final Rule: National Emission Standards for Hazardous Air Pollutants: Ethylene Oxide Emissions Standards for Sterilization Facilities Residual Risk and Technology Review

This action finalizes the residual risk and technology review (RTR) conducted for the Commercial Sterilization Facilities source category regulated under national emission standards for hazardous air pollutants (NESHAP) under the Clean Air Act. The EPA is finalizing decisions concerning the RTR, including definitions for affected sources, emission standards for previously unregulated sources, amendments pursuant to the risk review to address ethylene oxide (EtO) emissions from certain sterilization chamber vents (SCVs), aeration room vents (ARVs), chamber exhaust vents (CEVs), and room air emissions, and amendments pursuant to the technology review for certain SCVs and ARVs. In addition, we are taking final action to correct and clarify regulatory provisions related to emissions during periods of startup, shutdown, and malfunction (SSM), including removing exemptions for periods of SSM. We are also taking final action to require owners and operators to demonstrate compliance through the use of EtO continuous emissions monitoring systems (CEMS), with exceptions for very small users of EtO; add provisions for electronic reporting of performance test results and other reports; and include other technical revisions to improve consistency and clarity. We estimate that these final amendments will reduce EtO emissions from this source category by approximately 21 tons per year (tpy).

DATES: This final rule is effective on April 5, 2024, published in the Federal Register April 5, 2024, page 24090.

View final rule.

| Appendix B to Part 60—Performance Specifications | ||

| Performance Specification 19 | Added | View text |

| Appendix F to Part 60—Quality Assurance Procedures | ||

| Procedure 7 | Added | View text |

| §63.14 Incorporations by reference. | ||

| (a), (f), (i) introductory text | Revised | View text |

| (i)(88)-(120) | Redesignated | View text |

| Subpart O—Ethylene Oxide Emissions Standards for Sterilization Facilities | ||

| Entire subpart | Revised | View text |

Previous Text

§63.14 Incorporations by reference.

(a) The materials listed in this section are incorporated by reference into this part with the approval of the Director of the Federal Register under 5 U.S.C. 552(a) and 1 CFR part 51. To enforce any edition other than that specified in this section, a document must be published in the Federal Register and the material must be available to the public. All approved materials are available for inspection at the Air and Radiation Docket and Information Center (Air Docket) in the EPA Docket Center (EPA/DC) at Rm. 3334, EPA West Bldg., 1301 Constitution Ave. NW, Washington, DC. The EPA/DC Public Reading Room hours of operation are 8:30 a.m. to 4:30 p.m., Monday through Friday, excluding legal holidays. The telephone number of the EPA/DC Public Reading Room is (202) 566-1744, and the telephone number for the Air Docket is (202) 566-1742. These approved materials are also available for inspection at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, email fedreg.legal@nara.gov or go to www.archives.gov/federal-register/cfr/ibr-locations.html. In addition, these materials are available from the following sources:

* * * *

(f) American Society of Mechanical Engineers (ASME), Three Park Avenue, New York, NY 10016-5990, Telephone (800) 843-2763, http://www.asme.org; also available from HIS, Incorporated, 15 Inverness Way East, Englewood, CO 80112, Telephone (877) 413-5184, http://global.ihs.com.

(1) ANSI/ASME PTC 19.10-1981, Flue and Exhaust Gas Analyses [Part 10, Instruments and Apparatus], issued August 31, 1981, IBR approved for §§63.309(k), 63.457(k), 63.772(e) and (h), 63.865(b), 63.997(e), 63.1282(d) and (g), and 63.1625(b), table 5 to subpart EEEE, §§63.3166(a), 63.3360(e), 63.3545(a), 63.3555(a), 63.4166(a), 63.4362(a), 63.4766(a), 63.4965(a), and 63.5160(d), table 4 to subpart UUUU, table 3 to subpart YYYY, §§63.7822(b), 63.7824(e), 63.7825(b), 63.8000(d), 63.9307(c), 63.9323(a), 63.9621(b) and (c), 63.11148(e), 63.11155(e), 63.11162(f), 63.11163(g), 63.11410(j), 63.11551(a), 63.11646(a), and 63.11945, and table 4 to subpart AAAAA, table 5 to subpart DDDDD, table 4 to subpart JJJJJ, table 4 to subpart KKKKK, table 4 to subpart SSSSS, tables 4 and 5 of subpart UUUUU, table 1 to subpart ZZZZZ, and table 4 to subpart JJJJJJ.

(2) [Reserved]

* * * *

(i) ASTM International, 100 Barr Harbor Drive, Post Office Box C700, West Conshohocken, PA 19428-2959, Telephone (610) 832-9585, http://www.astm.org; also available from ProQuest, 789 East Eisenhower Parkway, Ann Arbor, MI 48106-1346, Telephone (734) 761-4700, http://www.proquest.com.

Subpart O—Ethylene Oxide Emissions Standards for Sterilization Facilities

§63.360 Applicability.

(a) All sterilization sources using 1 ton (see definition) in sterilization or fumigation operations are subject to the emissions standards in §63.362, except as specified in paragraphs (b) through (e) of this section. Owners or operators of sources using 1 ton (see definition) subject to the provisions of this subpart must comply with the requirements of subpart A, of this part according to the applicability of subpart A of this part to such sources in Table 1 of this section.

| Reference | Applies to sources using 10 tons in subpart O a | Applies to sources using 1 to 10 tons in subpart O a | Comment |

|---|---|---|---|

| a See definition. | |||

| 63.1(a)(1) | Yes | Additional terms defined in §63.361; when overlap between subparts A and O occurs, subpart O takes precedence. | |

| 63.1(a)(2) | Yes | ||

| 63.1(a)(3) | Yes | ||

| 63.1(a)(4) | Yes | Subpart O clarifies the applicability of each paragraph in subpart A to sources subject to subpart O. | |

| 63.1(a)(5) | No | Reserved. | |

| 63.1(a)(6) | Yes | ||

| 63.1(a)(7) | Yes | ||

| 63.1.1(a)(8) | Yes | ||

| 63.1(a)(9) | No | Reserved. | |

| 63.1(a)(10) | Yes | ||

| 63.1(a)(11) | Yes | §63.366(a) of subpart O also allows report submissions via fax and on electronic media. | |

| 63.1(a)(12)-(14) | Yes | ||

| 63.1(b)(1)-(2) | Yes | ||

| 63.1(b)(3) | No | §63.367 clarifies the applicability of recordkeeping requirements for sources that determine they are not subject to the emissions standards. | |

| 63.1(c)(1) | Yes | Subpart O clarifies the applicability of each paragraph in subpart A to sources subject to subpart O in this table. | |

| 63.1(c)(2) | Yes | §63.360(f) exempts area sources subject to this subpart from the obligation to obtain Title V operating permits. | |

| 63.1(c)(3) | No | Reserved. | |

| 63.1(c)(4) | Yes | ||

| 63.1(c)(5) | No | §63.360 specifies applicability. | |

| 63.1(d) | No | Reserved. | |

| 63.1(e) | Yes | ||

| 63.2 | Yes | Additional terms defined in §63.361; when overlap between subparts A and O occurs, subpart O takes precedence. | |

| 63.3 | Yes | Other units used in subpart O are defined in the text of subpart O. | |

| 63.4(a)(1)-(3) | Yes | ||

| 63.4(a)(4) | No | Reserved. | |

| 63.4(a)(5) | Yes | ||

| 63.4(b) | Yes | ||

| 63.4(c) | Yes | ||

| 63.5(a) | No | §63.366(b)(1) contains applicability requirements for constructed or reconstructed sources. | |

| 63.5(b)(1) | Yes | No | |

| 63.5(b)(2) | No | Reserved. | |

| 63.5(b)(3) | No | See §63.366(b)(2). | |

| 63.5(b)(4) | Yes | No | |

| 63.5(b)(5) | Yes | No | |

| 63.5(b)(6) | Yes | No | |

| 63.5(c) | No | Reserved. | |

| 63.5(d)(1)-(2) | No | See §63.366(b)(3). | |

| 63.5(d)(3)-(4) | Yes | No | |

| 63.5(e) | Yes | No | |

| 63.5(f)(1)-(2) | No | See §63.366(b)(4). | |

| 63.6(a)(1) | Yes | ||

| 63.6(a)(2) | No | §63.360 specifies applicability. | |

| 63.6(b)-(c) | No | §63.360(g) specifies compliance dates for sources. | |

| 63.6(d) | No | Reserved. | |

| 63.6(e) | No | Subpart O does not contain any operation and maintenance plan requirements. | |

| 63.6(f)(1) | No | §63.362(b) specifies when the standards apply. | |

| 63.6(f)(2)(i) | Yes | ||

| 63.6(f)(2)(ii) | No | §63.363 specifies parameters for determining compliance. | |

| 63.6(f)(2)(iii)-(iv) | Yes | ||

| 63.6(f)(2)(v) | No | ||

| 63.6(f)(3) | Yes | ||

| 63.6(g) | Yes | ||

| 63.6(h) | No | Subpart O does not contain any opacity or visible emission standards. | |

| 63.6(i)(1)-(14) | Yes | ||

| 63.6(i)(15) | No | Reserved | |

| 63.6(i)(16) | Yes | ||

| 63.6(j) | Yes | ||

| 63.7(a)(1) | Yes | ||

| 63.7(a)(2) | Yes | ||

| 63.7(a)(3) | Yes | ||

| 63.7(b) | Yes | ||

| 63.7(c) | Yes | No | |

| 63.7(d) | Yes | No | |

| 63.7(e) | Yes | §63.365 also contains test methods specific to sources subject to the emissions standards. | |

| 63.7(f) | Yes | ||

| 63.7(g)(1) | Yes | ||

| 63.7(g)(2) | No | Reserved | |

| 63.7(g)(3) | Yes | ||

| 63.7(h) | Yes | ||

| 63.8(a)(1) | Yes | ||

| 63.8(a)(2) | Yes | ||

| 63.8(a)(3) | No | Reserved | |

| 63.8(a)(4) | Yes | ||

| 63.8(b)(1) | Yes | ||

| 63.8(b)(2) | Yes | ||

| 63.8(b)(3) | No | ||

| 63.8(c)(1) (i)-(ii) | No | A startup, shutdown, and malfunction plan is not required for these standards. | |

| 63.8(c)(1)(iii) | Yes | ||

| 63.8(c)(2)-(3) | Yes | ||

| 63.8(c)(4)-(5) | No | Frequency of monitoring measurements is provided in §63.364; opacity monitors are not required for these standards. | |

| 63.8(c)(6) | No | Performance specifications for gas chromatographs and temperature monitors are contained in §63.365. | |

| 63.8(c)(7)(i)(A)-(B) | No | Performance specifications for gas chromatographs and temperature monitors are contained in §63.365. | |

| 63.8(c)(7)(i)(C) | No | Opacity monitors are not required for these standards. | |

| 63.8(c)(7)(ii) | No | Performance specifications for gas chromatographs and temperature monitors are contained in §63.365. | |

| 63.8(c)(8) | No | ||

| 63.8(d) | Yes | No | |

| 63.8(e)(1) | Yes | ||

| 63.8(e)(2) | Yes | ||

| 63.8(e)(3) | Yes | No | |

| 63.8(e)(4) | Yes | ||

| 63.8(e)(5)(i) | Yes | ||

| 63.8(e)(5)(ii) | No | Opacity monitors are not required for these standards. | |

| 63.8(f)(1)-(5) | Yes | ||

| 63.8(f)(6) | No | ||

| 63.8(g)(1) | Yes | ||

| 63.8(g)(2) | No | ||

| 63.8(g)(3)-(5) | Yes | ||

| 63.9(a) | Yes | ||

| 63.9(b)(1)-(i) | Yes | ||

| 63.9(b)(1)(ii)-(iii) | No | §63.366(c)(1)(i) contains language for sources that increase usage such that the source becomes subject to the emissions standards. | |

| 63.9(b)(2)-(3) | Yes | §63.366(c)(3) contains additional information to be included in the initial report for existing and new sources. | |

| 63.9(b)(4)-(5) | No | §63.366(c)(1)(ii) and (iii) contains requirements for new or reconstructed sources subject to the emissions standards. | |

| 63.9(c) | Yes | ||

| 63.9(d) | No | ||

| 63.9(e) | Yes | ||

| 63.9(f) | No | Opacity monitors are not required for these standards. | |

| 63.9(g)(1) | Yes | ||

| 63.9(g)(2)-(3) | No | Opacity monitors and relative accuracy testing are not required for these standards. | |

| 63.9(h)(1)-(3) | Yes | ||

| 63.9(h)(4) | No | Reserved. | |

| 63.9(h)(5) | No | §63.366(c)(2) instructs sources to submit actual data. | |

| 63.9(h)(6) | Yes | ||

| 63.9(i) | Yes | ||

| 63.9(j) | Yes | ||

| 63.10(a) | Yes | ||

| 63.10(b)(1) | Yes | ||

| 63.10(b)(2)(i) | No | Not applicable due to batch nature of the industry. | |

| 63.10(b)(2)(ii) | Yes | ||

| 63.10(b)(2)(iii) | No | ||

| 63.10(b)(2)(iv)-(v) | No | A startup, shutdown, and malfunction plan is not required for these standards. | |

| 63.10(b)(2)(vi)-(xii) | Yes | ||

| 63.10(b)(2)(xiii) | No | ||

| 63.10(b)(2)(xiv) | Yes | ||

| 63.10(b)(3) | No | §63.367 (b) and (c) contains applicability determination requirements. | |

| 63.10(c)(1) | Yes | ||

| 63.10(c)(2)-(4) | No | Reserved. | |

| 63.10(c)(5) | Yes | ||

| 63.10(c)(6) | No | ||

| 63.10(c)(7) | No | Not applicable due to batch nature of the industry. | |

| 63.10(c)(8) | Yes | ||

| 63.10(c)(9) | No | ||

| 63.10(c)(10)-(13) | Yes | ||

| 63.10(c)(14) | Yes | No | |

| 63.10(c)(15) | No | A startup, shutdown, and malfunction plan is not required for these standards. | |

| 63.10(d)(1) | Yes | ||

| 63.10(d)(2) | Yes | ||

| 63.10(d)(3) | No | Subpart O does not contain opacity or visible emissions standards. | |

| 63.10(d)(4) | Yes | ||

| 63.10(d)(5) | No | A startup, shutdown, and malfunction plan is not required for these standards. | |

| 63.10(e)(1) | Yes | ||

| 63.10(e)(2)(i) | Yes | ||

| 63.10(e)(2)(ii) | No | Opacity monitors are not required for these standards. | |

| 63.10(e)(3)(i)-(iv) | Yes | ||

| 63.10(e)(3)(v) | No | §63.366(a)(3) specifies contents and submittal dates for excess emissions and monitoring system performance reports. | |

| 63.10(e)(3)(vi)-(viii) | Yes | ||

| 63.10(e)(4) | No | Opacity monitors are not required for these standards. | |

| 63.10(f) | Yes | ||

| 63.11 | Yes | ||

| 63.12-63.15 | Yes | ||

(b) Sterilization sources using less than 1 ton (see definition) are not subject to the emissions standards in §63.362. The recordkeeping requirements of §63.367(c) apply.

(c) This subpart does not apply to beehive fumigators.

(d) This subpart does not apply to research or laboratory facilities as defined in section 112(c)(7) of title III of the Clean Air Act Amendment of 1990.

(e) This subpart does not apply to ethylene oxide sterilization operations at stationary sources such as hospitals, doctors offices, clinics, or other facilities whose primary purpose is to provide medical services to humans or animals.

(f) If you are an owner or operator of an area source subject to this subpart, you are exempt from the obligation to obtain a permit under 40 CFR part 70 or 71, provided you are not required to obtain a permit under 40 CFR 70.3(a) or 71.3(a) for a reason other than your status as an area source under this subpart. Notwithstanding the previous sentence, you must continue to comply with the provisions of this subpart applicable to area sources.

(g) The owner or operator shall comply with the provisions of this subpart as follows:

(1) All sterilization chamber vents subject to the emissions standards in §63.362 with an initial startup date before December 6, 1998, no later than December 6, 1998.

(2) All sterilization chamber vents subject to the emissions standards in §63.362 with an initial startup date on or after December 6, 1998, immediately upon initial startup of the source.

(3) All sterilization chamber vents at sources using less than 1 ton of ethylene oxide that increase their ethylene oxide usage after December 6, 1998 such that the sterilization chamber vent becomes subject to the emissions standards in §63.362(c), immediately upon becoming subject to the emission standards.

(4) All aeration room vents subject to the emissions standards in §63.362 with an initial startup date before December 6, 2000, no later than December 6, 2000.

(5) All aeration room vents subject to the emissions standards in §63.362 with an initial startup date on or after December 6, 2000, immediately upon initial startup of the source.

(6) All aeration room vents at sources using less than 10 tons that increase their ethylene oxide usage after December 6, 2000, such that the aeration room vents become subject to the emissions standards in §63.362, immediately upon becoming subject to the emission standards.

(7)-(10) [Reserved]

§63.361 Definitions.

Terms and nomenclature used in this subpart are defined in the Clean Air Act (the Act) as amended in 1990, §§63.2 and 63.3 of subpart A of this part, or in this section. For the purposes of subpart O, if the same term is defined in subpart A and in this section, it shall have the meaning given in this section.

Aeration room means any vessel or room that is used to facilitate off-gassing of ethylene oxide at a sterilization facility.

Aeration room vent means the point(s) through which the evacuation of ethylene oxide-laden air from an aeration room occurs.

Baseline temperature means a minimum temperature at the outlet from the catalyst bed of a catalytic oxidation control device or at the exhaust point from the combustion chamber of a thermal oxidation control device.

Chamber exhaust vent means the point(s) through which ethylene oxide-laden air is removed from the sterilization chamber during chamber unloading following the completion of sterilization and associated air washes.

Compliance date means the date by which a source subject to the emissions standards in §63.362 is required to be in compliance with the standard.

Deviation means any instance in which an affected source, subject to this subpart, or an owner or operator of such a source:

(1) Fails to meet any requirement or obligation established by this subpart including, but not limited to, any emission limitation (including any operating limit) or work practice standard;

(2) Fails to meet any term or condition that is adopted to implement an applicable requirement in this subpart and that is included in the operating permit for any affected source required to obtain such a permit; or

(3) Fails to meet any emission limitation (including any operating limit) or work practice standard in this subpart during startup, shutdown, or malfunction, regardless of whether or not such failure is permitted by this subpart.

Effective date means the date of promulgation in the Federal Register notice.

Initial startup date means the date when a source subject to the emissions standards in §63.362 first begins operation of a sterilization process.

Manifolding emissions means combining ethylene oxide emissions from two or more different vent types for the purpose of controlling these emissions with a single control device.

Maximum ethylene glycol concentration means any concentration of ethylene glycol in the scrubber liquor of an acid-water scrubber control device established during a performance test when the scrubber achieves at least 99-percent control of ethylene oxide emissions.

Maximum liquor tank level means any level of scrubber liquor in the acid-water scrubber liquor recirculation tank established during a performance test when the scrubber achieves at least 99-percent control of ethylene oxide emissions.

Oxidation temperature means the temperature at the outlet point of a catalytic oxidation unit control device or at the exhaust point from the combustion chamber for a thermal oxidation unit control device.

Source(s) using less than 1 ton means source(s) using less than 907 kg (1 ton) of ethylene oxide within all consecutive 12-month periods after December 6, 1996.

Source(s) using 1 ton means source(s) using 907 kg (1 ton) or more of ethylene oxide within any consecutive 12-month period after December 6, 1996.

Source(s) using 1 to 10 tons means source(s) using 907 kg (1 ton) or more of ethylene oxide in any consecutive 12-month period but less than 9,070 kg (10 tons) of ethylene oxide in all consecutive 12-month periods after December 6, 1996.

Source(s) using less than 10 tons means source(s) using less than 9,070 kg (10 tons) of ethylene oxide in all consecutive 12-month periods after December 6, 1996.

Source(s) using 10 tons means source(s) using 9,070 kg (10 tons) or more of ethylene oxide in any consecutive 12-month period after December 6, 1996.

Sterilization chamber means any enclosed vessel or room that is filled with ethylene oxide gas, or an ethylene oxide/inert gas mixture, for the purpose of sterilizing and/or fumigating at a sterilization facility.

Sterilization chamber vent means the point (prior to the vacuum pump) through which the evacuation of ethylene oxide from the sterilization chamber occurs following sterilization or fumigation, including any subsequent air washes.

Sterilization facility means any stationary source where ethylene oxide is used in the sterilization or fumigation of materials.

Sterilization operation means any time when ethylene oxide is removed from the sterilization chamber through the sterilization chamber vent or the chamber exhaust vent or when ethylene oxide is removed from the aeration room through the aeration room vent.

Thermal oxidizer means all combustion devices except flares.

§63.362 Standards.

(a) Each owner or operator of a source subject to the provisions of this subpart shall comply with these requirements on and after the compliance date specified in §63.360(g). The standards of this section are summarized in Table 1 of this section.

| Existing and new sources | Source type | Sterilization chamber vent | Aeration room vent | Chamber exhaust vent |

|---|---|---|---|---|

| Source size | <907 kg (<1 ton) | No control required; minimal recordkeeping requirements apply (see §63.367(c)). | ||

| ≥907 kg and <9,070 kg (≥1 ton and <10 tons) | 99% emission reduction (see §63.362(c)) | No control | No control. | |

| ≥9,070 kg (≥10 tons) | 99% emission reduction (see §63.362(c)) | 1 ppm maximum outlet concentration or 99% emission reduction (see §63.362(d)) | No control. | |

(b) Applicability of emission limits. The emission limitations of paragraphs (c), (d), and (e) of this section apply during sterilization operation. The emission limitations do not apply during periods of malfunction.

(c) Sterilization chamber vent at sources using 1 ton. Each owner or operator of a sterilization source using 1 ton shall reduce ethylene oxide emissions to the atmosphere by at least 99 percent from each sterilization chamber vent.

(d) Aeration room vent at sources using 10 tons. Each owner or operator of a sterilization source using 10 tons shall reduce ethylene oxide emissions to the atmosphere from each aeration room vent to a maximum concentration of 1 ppmv or by at least 99 percent, whichever is less stringent, from each aeration room vent.

(e) [Reserved]

§63.363 Compliance and performance provisions.

(a)(1) The owner or operator of a source subject to emissions standards in §63.362 shall conduct an initial performance test using the procedures listed in §63.7 according to the applicability in Table 1 of §63.360, the procedures listed in this section, and the test methods listed in §63.365.

(2) The owner or operator of all sources subject to these emissions standards shall complete the performance test within 180 days after the compliance date for the specific source as determined in §63.360(g).

(b) The procedures in paragraphs (b)(1) through (3) of this section shall be used to determine initial compliance with the emission limits under §63.362(c), the sterilization chamber vent standard and to establish operating limits for the control devices:

(1) The owner or operator shall determine the efficiency of control devices used to comply with §63.362(c) using the test methods and procedures in §63.365(b).

(2) For facilities with acid-water scrubbers, the owner or operator shall establish as an operating limit either:

(i) The maximum ethylene glycol concentration using the procedures described in §63.365(e)(1); or

(ii) The maximum liquor tank level using the procedures described in §63.365(e)(2).

(3) For facilities with catalytic oxidizers or thermal oxidizers, the operating limit consists of the recommended minimum oxidation temperature provided by the oxidation unit manufacturer for an operating limit.

(4) Facilities with catalytic oxidizers shall comply with one of the following work practices:

(i) Once per year after the initial compliance test, conduct a performance test during routine operations, i.e., with product in the chamber using the procedures described in §63.365(b) or (d) as appropriate. If the percent efficiency is less than 99 percent, restore the catalyst as soon as practicable but no later than 180 days after conducting the performance test; or

(ii) Once per year after the initial compliance test, analyze ethylene oxide concentration data from §63.364(e) or a continuous emission monitoring system (CEMS) and restore the catalyst as soon as practicable but no later than 180 days after data analysis; or,

(iii) Every 5 years, beginning 5 years after the initial compliance test (or by December 6, 2002, whichever is later), replace the catalyst bed with new catalyst material.

(c) The procedures in paragraphs (c)(1) through (3) of this section shall be used to determine initial compliance with the emission limits under §63.362(d), the aeration room vent standard:

(1) The owner or operator shall comply with either paragraph (b)(2) or (3) of this section.

(2) Determine the concentration of ethylene oxide emitted from the aeration room into the atmosphere (after any control device used to comply with §63.362(d)) using the methods in §63.365(c)(1); or

(3) Determine the efficiency of the control device used to comply with §63.362(d) using the test methods and procedures in §63.365(d)(2).

(d) [Reserved]

(e) For facilities complying with the emissions limits under §63.362 with a control technology other than acid-water scrubbers or catalytic or thermal oxidizers, the owner or operator of the facility shall provide to the Administrator or delegated authority information describing the design and operation of the air pollution control system, including recommendations for the operating parameters to be monitored to demonstrate continuous compliance. Based on this information, the Administrator will determine the operating parameter(s) to be measured during the performance test. During the performance test required in paragraph (a) of this section, using the methods approved in §63.365(g), the owner or operator shall determine the site-specific operating limit(s)for the operating parameters approved by the Administrator.

(f) A facility must demonstrate continuous compliance with each operating limit and work practice standard required under this section, except during periods of startup, shutdown, and malfunction, according to the methods specified in §63.364.

§63.364 Monitoring requirements.

(a)(1) The owner or operator of a source subject to emissions standards in §63.362 shall comply with the monitoring requirements in §63.8 of subpart A of this part, according to the applicability in Table 1 of §63.360, and in this section.

(2) Each owner or operator of an ethylene oxide sterilization facility subject to these emissions standards shall monitor the parameters specified in this section. All monitoring equipment shall be installed such that representative measurements of emissions or process parameters from the source are obtained. For monitoring equipment purchased from a vendor, verification of the operational status of the monitoring equipment shall include completion of the manufacturer's written specifications or recommendations for installation, operation, and calibration of the system.

(b) For sterilization facilities complying with §63.363(b) or (d) through the use of an acid-water scrubber, the owner or operator shall either:

(1) Sample the scrubber liquor and analyze and record once per week the ethylene glycol concentration of the scrubber liquor using the test methods and procedures in §63.365(e)(1). Monitoring is required during a week only if the scrubber unit has been operated; or

(2) Measure and record once per week the level of the scrubber liquor in the recirculation tank. The owner or operator shall install, maintain, and use a liquid level indicator to measure the scrubber liquor tank level (i.e., a marker on the tank wall, a dipstick, a magnetic indicator, etc.). Monitoring is required during a week only if the scrubber unit has been operated.

(c) For sterilization facilities complying with §63.363(b) or (c) through the use of catalytic oxidation or thermal oxidation, the owner or operator shall either comply with §63.364(e) or continuously monitor and record the oxidation temperature at the outlet to the catalyst bed or at the exhaust point from the thermal combustion chamber using the temperature monitor described in paragraph (c)(4) of this section. Monitoring is required only when the oxidation unit is operated. From 15-minute or shorter period temperature values, a data acquisition system for the temperature monitor shall compute and record a daily average oxidation temperature. Strip chart data shall be converted to record a daily average oxidation temperature each day any instantaneous temperature recording falls below the minimum temperature.

(1)-(3) [Reserved]

(4) The owner or operator shall install, calibrate, operate, and maintain a temperature monitor accurate to within ±5.6°C (±10°F) to measure the oxidation temperature. The owner or operator shall verify the accuracy of the temperature monitor twice each calendar year with a reference temperature monitor (traceable to National Institute of Standards and Technology (NIST) standards or an independent temperature measurement device dedicated for this purpose). During accuracy checking, the probe of the reference device shall be at the same location as that of the temperature monitor being tested. As an alternative, the accuracy temperature monitor may be verified in a calibrated oven (traceable to NIST standards).

(d) For sterilization facilities complying with §63.363(b) or (c) through the use of a control device other than acid-water scrubbers or catalytic or thermal oxidizers, the owner or operator shall monitor the parameters as approved by the Administrator using the methods and procedures in §63.365(g).

(e) Measure and record once per hour the ethylene oxide concentration at the outlet to the atmosphere after any control device according to the procedures specified in §63.365(c)(1). The owner or operator shall compute and record a 24-hour average daily. The owner or operator will install, calibrate, operate, and maintain a monitor consistent with the requirements of performance specification (PS) 8 or 9 in 40 CFR part 60, appendix B, to measure ethylene oxide. The daily calibration requirements of section 7.2 of PS-9 or Section 13.1 of PS-8 are required only on days when ethylene oxide emissions are vented to the control device.

(f) [Reserved]

§63.365 Test methods and procedures.

(a) Performance testing. The owner or operator of a source subject to the emissions standards in §63.362 shall comply with the performance testing requirements in §63.7 of subpart A of this part, according to the applicability in Table 1 of §63.360, and in this section.

(b) Efficiency at the sterilization chamber vent. California Air Resources Board (CARB) Method 431 or the following procedures shall be used to determine the efficiency of all types of control devices used to comply with §63.362(c), sterilization chamber vent standard.

(1) First evacuation of the sterilization chamber. These procedures shall be performed on an empty sterilization chamber, charged with a typical amount of ethylene oxide, for the duration of the first evacuation under normal operating conditions (i.e., sterilization pressure and temperature).

(i) The amount of ethylene oxide loaded into the sterilizer (Wc) shall be determined by either:

(A) Weighing the ethylene oxide gas cylinder(s) used to charge the sterilizer before and after charging. Record these weights to the nearest 45 g (0.1 lb). Multiply the total mass of gas charged by the weight percent ethylene oxide present in the gas.

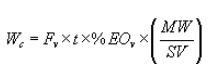

(B) Installing calibrated rotameters at the sterilizer inlet and measuring flow rate and duration of sterilizer charge. Use the following equation to convert flow rate to weight of ethylene oxide:

where:

Wc = weight of ethylene oxide charged, g (lb)

Fv = volumetric flow rate, liters per minute (L/min) corrected to 20°C and 101.325 kilopascals (kPa) (scf per minute (scfm) corrected to 68°F and 1 atmosphere of pressure (atm)); the flowrate must be constant during time (t)

t = time, min

%EOV = volume fraction ethylene oxide

SV = standard volume, 24.05 liters per mole (L/mole) = 22.414 L/mole ideal gas law constant corrected to 20°C and 101.325 kPa (385.32 scf per mole (scf/mole) = 359 scf/mole ideal gas law constant corrected to 68°F and 1 atm).

MW = molecular weight of ethylene oxide, 44.05 grams per gram-mole (g/g-mole) (44.05 pounds per pound-mole (lb/lb-mole)), or

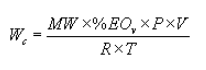

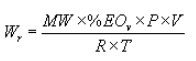

(C) Calculating the mass based on the conditions of the chamber immediately after it has been charged using the following equation:

where:

P = chamber pressure, kPa (psia)

V = chamber volume, liters (L) (ft 3)

R = gas constant, 8.313 L·kPa/g-mole·(10.73 psia·ft 3/mole°R)

T = temperature, K (°R)

Note:

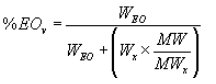

If the ethylene oxide concentration is in weight percent, use the following equation to calculate mole fraction:

where:

WEO = weight percent of ethylene oxide

Wx = weight percent of compound in the balance of the mixture

MWx = molecular weight of compound in the balance gas mixture

(ii) The residual mass of ethylene oxide in the sterilizer shall be determined by recording the chamber temperature, pressure, and volume after the completion of the first evacuation and using the following equation:

where:

Wr = weight of ethylene oxide remaining in chamber (after the first evacuation), in g (lb)

(iii) Calculate the total mass of ethylene oxide at the inlet to the control device (Wi) by subtracting the residual mass (Wr) calculated in paragraph (b)(1)(ii) of this section from the charged weight (Wc) calculated in paragraph (b)(1)(i) of this section.

(iv) The mass of ethylene oxide emitted from the control device outlet (Wo) shall be calculated by continuously monitoring the flow rate and concentration using the following procedure.

(A) Measure the flow rate through the control device exhaust continuously during the first evacuation using the procedure found in 40 CFR part 60, appendix A, Test Methods 2, 2A, 2C, or 2D, as appropriate. (Method 2D (using orifice plates or Rootstype meters) is recommended for measuring flow rates from sterilizer control devices.) Record the flow rate at 1-minute intervals throughout the test cycle, taking the first reading within 15 seconds after time zero. Time zero is defined as the moment when the pressure in the sterilizer is released. Correct the flow to standard conditions (20°C and 101.325 kPa (68°F and 1 atm)) and determine the flow rate for the run as outlined in the test methods listed in paragraph (b) of this section.

(B) Test Method 18 or 25A, 40 CFR part 60, appendix A (hereafter referred to as Method 18 or 25A, respectively), shall be used to measure the concentration of ethylene oxide.

(1) Prepare a graph of volumetric flow rate versus time corresponding to the period of the run cycle. Integrate the area under the curve to determine the volume.

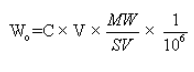

(2) Calculate the mass of ethylene oxide by using the following equation:

Where:

Wo = Mass of ethylene oxide, g (lb)

C = concentration of ethylene oxide in ppmv

V = volume of gas exiting the control device corrected to standard conditions, L (ft 3)

1/10 6 = correction factor LEO/10 6 LTOTAL GAS (ft 3EO/10 6 ft 3TOTAL GAS)

(3) Calculate the efficiency by the equation in paragraph (b)(1)(v) of this section.

(C) [Reserved]

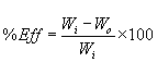

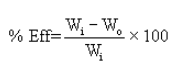

(v) Determine control device efficiency (% Eff) using the following equation:

where:

% Eff = percent efficiency

Wi = mass flow rate into the control device

Wo = mass flow rate out of the control device

(vi) Repeat the procedures in paragraphs (b)(1) (i) through (v) of this section three times. The arithmetic average percent efficiency of the three runs shall determine the overall efficiency of the control device.

(2) [Reserved]

(c) Concentration determination. The following procedures shall be used to determine the ethylene oxide concentration.

(1) Parameter monitoring. For determining the ethylene oxide concentration required in §63.364(e), follow the procedures in PS 8 or PS 9 in 40 CFR part 60, appendix B. Sources complying with PS 8 are exempt from the relative accuracy procedures in sections 2.4 and 3 of PS-8.

(2) Initial compliance. For determining the ethylene oxide concentration required in §63.363(c)(2), the procedures outlined in Method 18 or Method 25 A (40 CFR part 60, appendix A) shall be used. A Method 18 or Method 25A test consists of three 1-hour runs. If using Method 25A to determine concentration, calibrate and report Method 25A instrument results using ethylene oxide as the calibration gas. The arithmetic average of the ethylene oxide concentration of the three test runs shall determine the overall outlet ethylene oxide concentration from the control device.

(d) Efficiency determination at the aeration room vent (not manifolded). The following procedures shall be used to determine the efficiency of a control device used to comply with §63.362(d), the aeration room vent standard.

(1) Determine the concentration of ethylene oxide at the inlet and outlet of the control device using the procedures in Method 18 or 25A in 40 CFR part 60, appendix A. A test is comprised of three 1-hour runs.

(2) Determine control device efficiency (% Eff) using the following equation:

Where:

% Eff = percent efficiency

Wi = mass flow rate into the control device

WO = mass flow rate out of the control device

(3) Repeat the procedures in paragraphs (d)(1) and (2) of this section three times. The arithmetic average percent efficiency of the three runs shall determine the overall efficiency of the control device.

(e) Determination of baseline parameters for acid-water scrubbers. The procedures in this paragraph shall be used to determine the monitored parameters established in §63.363(b), (d), or (e) for acid-water scrubbers and to monitor the parameters as established in §63.364(b).

(1) Ethylene glycol concentration. For determining the ethylene glycol concentration, the facility owner or operator shall establish the maximum ethylene glycol concentration as the ethylene glycol concentration averaged over three test runs; the sampling and analysis procedures in ASTM D 3695-88, Standard Test Method for Volatile Alcohols in Water By Direct Aqueous-Injection Gas Chromatography, (incorporated by reference - see §63.14) shall be used to determine the ethylene glycol concentration.

(2) Scrubber liquor tank level. For determining the scrubber liquor tank level, the sterilization facility owner or operator shall establish the maximum liquor tank level based on a single measurement of the liquor tank level during one test run.

(f) [Reserved]

(g) An owner or operator of a sterilization facility seeking to demonstrate compliance with the standards found at §63.362(c), (d), or (e) with a control device other than an acid-water scrubber or catalytic or thermal oxidation unit shall provide to the Administrator the information requested under §63.363(f). The owner or operator shall submit: a description of the device; test results collected in accordance with §63.363(f) verifying the performance of the device for controlling ethylene oxide emissions to the atmosphere to the levels required by the applicable standards; the appropriate operating parameters that will be monitored; and the frequency of measuring and recording to establish continuous compliance with the standards. The monitoring plan submitted identifying the compliance monitoring is subject to the Administrator's approval. The owner or operator of the sterilization facility shall install, calibrate, operate, and maintain the monitor(s) approved by the Administrator based on the information submitted by the owner or operator. The owner or operator shall include in the information submitted to the Administrator proposed performance specifications and quality assurance procedures for their monitors. The Administrator may request further information and shall approve appropriate test methods and procedures.

(h) An owner or operator of a sterilization facility seeking to demonstrate compliance with the requirements of §63.363 or §">63.364, with a monitoring device or procedure other than a gas chromatograph or a flame ionization analyzer, shall provide to the Administrator information describing the operation of the monitoring device or procedure and the parameter(s) that would demonstrate continuous compliance with each operating limit. The Administrator may request further information and will specify appropriate test methods and procedures.

§63.366 Reporting requirements.

(a) The owner or operator of a source subject to the emissions standards in §63.362 shall fulfill all reporting requirements in §§63.10(a), (d), (e), and (f) of subpart A, according to the applicability in Table 1 of §63.360. These reports will be made to the Administrator at the appropriate address identified in §63.13 of subpart A of this part.

(1) Reports required by subpart A and this section may be sent by U.S. mail, fax, or by another courier.

(i) Submittals sent by U.S. mail shall be postmarked on or before the specified date.

(ii) Submittals sent by other methods shall be received by the Administrator on or before the specified date.

(2) If acceptable to both the Administrator and the owner or operator of a source, reports may be submitted on electronic media.

(3) Content and submittal dates for deviations and monitoring system performance reports. All deviations and monitoring system performance reports and all summary reports, if required per §63.10(e)(3)(vii) and (viii), shall be delivered or postmarked within 30 days following the end of each calendar half or quarter as appropriate (see §63.10(e)(3)(i) through (iv) for applicability). Written reports of deviations from an operating limit shall include all information required in §63.10(c)(5) through (13), as applicable in Table 1 of §63.360, and information from any calibration tests in which the monitoring equipment is not in compliance with PS 9 or the method used for temperature calibration. The written report shall also include the name, title, and signature of the responsible official who is certifying the accuracy of the report. When no deviations have occurred or monitoring equipment has not been inoperative, repaired, or adjusted, such information shall be stated in the report.

(b) Construction and reconstruction. The owner or operator of each source using 10 tons shall fulfill all requirements for construction or reconstruction of a source in §63.5 of subpart A of this part, according to the applicability in Table 1 of §63.360, and in this paragraph.

(1) Applicability.(i) This paragraph and §63.5 of subpart A of this part implement the preconstruction review requirements of section 112(i)(1) for sources subject to these emissions standards. In addition, this paragraph and §63.5 of subpart A of this part include other requirements for constructed and reconstructed sources that are or become subject to these emissions standards.

(ii) After the effective date, the requirements in this section and in §63.5 of subpart A of this part apply to owners or operators who construct a new source or reconstruct a source subject to these emissions standards after December 6, 1994. New or reconstructed sources subject to these emissions standards with an initial startup date before the effective date are not subject to the preconstruction review requirements specified in paragraphs (b) (2) and (3) of this section and §63.5(d) (3) and (4) and (e) of subpart A of this part.

(2) After the effective date, whether or not an approved permit program is effective in the State in which a source is (or would be) located, no person may construct a new source or reconstruct a source subject to these emissions standards, or reconstruct a source such that the source becomes a source subject to these emissions standards, without obtaining advance written approval from the Administrator in accordance with the procedures specified in paragraph (b)(3) of this section and §63.5(d) (3) and (4) and (e) of subpart A of this part.

(3) Application for approval of construction or reconstruction. The provisions of paragraph (b)(3) of this section and §63.5(d) (3) and (4) of subpart A of this part implement section 112(i)(1) of the Act.

(i) General application requirements.(A) An owner or operator who is subject to the requirements of paragraph (b)(2) of this section shall submit to the Administrator an application for approval of the construction of a new source subject to these emissions standards, the reconstruction of a source subject to these emissions standards, or the reconstruction of a source such that the source becomes a source subject to these emissions standards. The application shall be submitted as soon as practicable before the construction or reconstruction is planned to commence (but not sooner than the effective date) if the construction or reconstruction commences after the effective date. The application shall be submitted as soon as practicable before the initial startup date but no later than 60 days after the effective date if the construction or reconstruction had commenced and the initial startup date had not occurred before the effective date. The application for approval of construction or reconstruction may be used to fulfill the initial notification requirements of paragraph (c)(1)(iii) of this section. The owner or operator may submit the application for approval well in advance of the date construction or reconstruction is planned to commence in order to ensure a timely review by the Administrator and that the planned commencement date will not be delayed.

(B) A separate application shall be submitted for each construction or reconstruction. Each application for approval of construction or reconstruction shall include at a minimum:

(1) The applicant's name and address.

(2) A notification of intention to construct a new source subject to these emissions standards or make any physical or operational change to a source subject to these emissions standards that may meet or has been determined to meet the criteria for a reconstruction, as defined in §63.2 of subpart A of this part.

(3) The address (i.e., physical location) or proposed address of the source.

(4) An identification of the relevant standard that is the basis of the application.

(5) The expected commencement date of the construction or reconstruction.

(6) The expected completion date of the construction or reconstruction.

(7) The anticipated date of (initial) startup of the source.

(8) The type and quantity of hazardous air pollutants emitted by the source, reported in units and averaging times and in accordance with the test methods specified in the standard, or if actual emissions data are not yet available, an estimate of the type and quantity of hazardous air pollutants expected to be emitted by the source reported in units and averaging times specified. The owner or operator may submit percent reduction information, if the standard is established in terms of percent reduction. However, operating parameters, such as flow rate, shall be included in the submission to the extent that they demonstrate performance and compliance.

(9) Other information as specified in paragraph (b)(3)(ii) of this section and §63.5(d)(3) of subpart A of this part.

(C) An owner or operator who submits estimates or preliminary information in place of the actual emissions data and analysis required in paragraphs (b)(3)(i)(B)(8) and (ii) of this section shall submit the actual, measured emissions data and other correct information as soon as available but no later than with the notification of compliance status required in paragraph (c)(2) of this section.

(ii) Application for approval of construction. Each application for approval of construction shall include, in addition to the information required in paragraph (b)(3)(i)(B) of this section, technical information describing the proposed nature, size, design, operating design capacity, and method of operation of the source subject to these emissions standards, including an identification of each point of emission for each hazardous air pollutant that is emitted (or could be emitted) and a description of the planned air pollution control system (equipment or method) for each emission point. The description of the equipment to be used for the control of emissions shall include each control device for each hazardous air pollutant and the estimated control efficiency (percent) for each control device. The description of the method to be used for the control of emissions shall include an estimated control efficiency (percent) for that method. Such technical information shall include calculations of emission estimates in sufficient detail to permit assessment of the validity of the calculations. An owner or operator who submits approximations of control efficiencies under paragraph (b)(3) of this section shall submit the actual control efficiencies as specified in paragraph (b)(3)(i)(C) of this section.

(4) Approval of construction or reconstruction based on prior State preconstruction review. (i) The Administrator may approve an application for construction or reconstruction specified in paragraphs (b)(2) and (3) of this section and §63.5(d)(3) and (4) of subpart A of this part if the owner or operator of a new or reconstructed source who is subject to such requirement demonstrates to the Administrator's satisfaction that the following conditions have been (or will be) met:

(A) The owner or operator of the new or reconstructed source subject to these emissions standards has undergone a preconstruction review and approval process in the State in which the source is (or would be) located before the effective date and has received a federally enforceable construction permit that contains a finding that the source will meet these emissions standards as proposed, if the source is properly built and operated;

(B) In making its finding, the State has considered factors substantially equivalent to those specified in §63.5(e)(1) of subpart A of this part.

(ii) The owner or operator shall submit to the Administrator the request for approval of construction or reconstruction no later than the application deadline specified in paragraph (b)(3)(i) of this section. The owner or operator shall include in the request information sufficient for the Administrator's determination. The Administrator will evaluate the owner or operator's request in accordance with the procedures specified in §63.5 of subpart A of this part. The Administrator may request additional relevant information after the submittal of a request for approval of construction or reconstruction.

(c) Notification requirements. The owner or operator of each source subject to the emissions standards in §63.362 shall fulfill all notification requirements in §63.9 of subpart A of this part, according to the applicability in Table 1 of §63.360, and in this paragraph.

(1) Initial notifications. (i)(A) If a source that otherwise would be subject to these emissions standards subsequently increases its use of ethylene oxide within any consecutive 12-month period after December 6, 1996, such that the source becomes subject to these emissions standards or other requirements, such source shall be subject to the notification requirements of §63.9 of subpart A of this part.

(B) Sources subject to these emissions standards may use the application for approval of construction or reconstruction under paragraph (b)(3)(ii) of this section and §63.5(d) (3) of subpart A of this part, respectively, if relevant to fulfill the initial notification requirements.

(ii) The owner or operator of a new or reconstructed source subject to these emissions standards that has an initial startup date after the effective date and for which an application for approval of construction or reconstruction is required under paragraph (b)(3) of this section and §63.5(d) (3) and (4) of subpart A of this part shall provide the following information in writing to the Administrator:

(A) A notification of intention to construct a new source subject to these emissions standards, reconstruct a source subject to these emissions standards, or reconstruct a source such that the source becomes a source subject to these emissions standards with the application for approval of construction or reconstruction as specified in paragraph (b)(3)(i)(A) of this section;

(B) A notification of the date when construction or reconstruction was commenced, submitted simultaneously with the application for approval of construction or reconstruction, if construction or reconstruction was commenced before the effective date of these standards;

(C) A notification of the date when construction or reconstruction was commenced, delivered or postmarked not later than 30 days after such date, if construction or reconstruction was commenced after the effective date of these standards;

(D) A notification of the anticipated date of startup of the source, delivered or postmarked not more than 60 days nor less than 30 days before such date; and

(E) A notification of the actual date of initial startup of the source, delivered or postmarked within 15 calendar days after that date.

(iii) After the effective date, whether or not an approved permit program is effective in the State in which a source subject to these emissions standards is (or would be) located, an owner or operator who intends to construct a new source subject to these emissions standards or reconstruct a source subject to these emissions standards, or reconstruct a source such that it becomes a source subject to these emissions standards, shall notify the Administrator in writing of the intended construction or reconstruction. The notification shall be submitted as soon as practicable before the construction or reconstruction is planned to commence (but no sooner than the effective date of these standards) if the construction or reconstruction commences after the effective date of the standard. The notification shall be submitted as soon as practicable before the initial startup date but no later than 60 days after the effective date of this standard if the construction or reconstruction had commenced and the initial startup date has not occurred before the standard's effective date. The notification shall include all the information required for an application for approval of construction or reconstruction as specified in paragraph (b)(3) of this section and §63.5(d)(3) and (4) of subpart A of this part. For sources subject to these emissions standards, the application for approval of construction or reconstruction may be used to fulfill the initial notification requirements of §63.9 of subpart A of this part.

(2) If an owner or operator of a source subject to these emissions standards submits estimates or preliminary information in the application for approval of construction or reconstruction required in paragraph (b)(3)(ii) of this section and §63.5(d)(3) of subpart A of this part, respectively, in place of the actual emissions data or control efficiencies required in paragraphs (b)(3)(i)(B)(8) and (ii) of this section, the owner or operator shall submit the actual emissions data and other correct information as soon as available but no later than with the initial notification of compliance status.

(3) The owner or operator of any existing sterilization facility subject to this subpart shall also include the amount of ethylene oxide used during the previous consecutive 12-month period in the initial notification report required by §63.9(b)(2) and (3) of subpart A of this part. For new sterilization facilities subject to this subpart, the amount of ethylene oxide used shall be an estimate of expected use during the first consecutive 12-month period of operation.

§63.367 Recordkeeping requirements.

(a) The owner or operator of a source subject to §63.362 shall comply with the recordkeeping requirements in §63.10(b) and (c), according to the applicability in Table 1 of §63.360, and in this section. All records required to be maintained by this subpart or a subpart referenced by this subpart shall be maintained in such a manner that they can be readily accessed and are suitable for inspection. The most recent 2 years of records shall be retained onsite or shall be accessible to an inspector while onsite. The records of the preceding 3 years, where required, may be retained offsite. Records may be maintained in hard copy or computer-readable form including, but not limited to, on paper, microfilm, computer, computer disk, magnetic tape, or microfiche.

(b) The owners or operators of a source using 1 to 10 tons not subject to §63.362 shall maintain records of ethylene oxide use on a 12-month rolling average basis (until the source changes its operations to become a source subject to §63.362).

(c) The owners or operators of a source using less than 1 ton shall maintain records of ethylene oxide use on a 12-month rolling average basis (until the source changes its operations to become a source subject to §63.362).

(d) The owners or operators complying with §63.363(b) (4) shall maintain records of the compliance test, data analysis, and if catalyst is replaced, proof of replacement.

§63.368 Implementation and enforcement.

(a) This subpart can be implemented and enforced by the U.S. EPA, or a delegated authority such as the applicable State, local, or Tribal agency. If the U.S. EPA Administrator has delegated authority to a State, local, or Tribal agency, then that agency, in addition to the U.S. EPA, has the authority to implement and enforce this subpart. Contact the applicable U.S. EPA Regional Office to find out if implementation and enforcement of this subpart is delegated to a State, local, or Tribal agency.

(b) In delegating implementation and enforcement authority of this subpart to a State, local, or Tribal agency under subpart E of this part, the authorities contained in paragraph (c) of this section are retained by the Administrator of U.S. EPA and cannot be transferred to the State, local, or Tribal agency.

(c) The authorities that cannot be delegated to State, local, or Tribal agencies are as specified in paragraphs (c)(1) through (4) of this section.

(1) Approval of alternatives to the requirements in §§63.360 and 63.362.

(2) Approval of major alternatives to test methods under §63.7(e)(2)(ii) and (f), as defined in §63.90, and as required in this subpart.

(3) Approval of major alternatives to monitoring under §63.8(f), as defined in §63.90, and as required in this subpart.

(4) Approval of major alternatives to recordkeeping and reporting under §63.10(f), as defined in §63.90, and as required in this subpart.