['Air Programs']

['Air Emissions']

03/16/2023

...

Authority:42 U.S.C. 7401-7671q.

Subpart A — Applicability and General Provisions

§1065.1 Applicability.

(a) This part describes the procedures that apply to testing we require for the following engines or for vehicles using the following engines:

(1) Locomotives we regulate under 40 CFR part 1033.

(2) Heavy-duty highway engines we regulate under 40 CFR parts 86 and 1036.

(3) Nonroad compression-ignition engines we regulate under 40 CFR part 1039 and stationary diesel engines that are certified to the standards in 40 CFR part 1039 as specified in 40 CFR part 60, subpart IIII.

(4) Marine compression-ignition engines we regulate under 40 CFR part 1042.

(5) Marine spark-ignition engines we regulate under 40 CFR part 1045.

(6) Large nonroad spark-ignition engines we regulate under 40 CFR part 1048, and stationary engines that are certified to the standards in 40 CFR part 1048 or as otherwise specified in 40 CFR part 60, subpart JJJJ.

(7) Vehicles we regulate under 40 CFR part 1051 (such as snowmobiles and off-highway motorcycles) based on engine testing. See 40 CFR part 1051, subpart F, for standards and procedures that are based on vehicle testing.

(8) Small nonroad spark-ignition engines we regulate under 40 CFR part 1054 and stationary engines that are certified to the standards in 40 CFR part 1054 as specified in 40 CFR part 60, subpart JJJJ.

(b) The procedures of this part may apply to other types of engines, as described in this part and in the standard-setting part.

(c) The term “you” means anyone performing testing under this part other than EPA.

(1) This part is addressed primarily to manufacturers of engines, vehicles, equipment, and vessels, but it applies equally to anyone who does testing under this part for such manufacturers.

(2) This part applies to any manufacturer or supplier of test equipment, instruments, supplies, or any other goods or services related to the procedures, requirements, recommendations, or options in this part.

(d) Paragraph (a) of this section identifies the parts of the CFR that define emission standards and other requirements for particular types of engines. In this part, we refer to each of these other parts generically as the ”standard-setting part.” For example, 40 CFR part 1051 is always the standard-setting part for snowmobiles. Note that while 40 CFR part 86 is the standard-setting part for heavy-duty highway engines, this refers specifically to 40 CFR part 86, subpart A, and to certain portions of 40 CFR part 86, subpart N, as described in 40 CFR 86.1301.

(e) Unless we specify otherwise, the terms “procedures” and “test procedures” in this part include all aspects of engine testing, including the equipment specifications, calibrations, calculations, and other protocols and procedural specifications needed to measure emissions.

(f) For vehicles, equipment, or vessels subject to this part and regulated under vehicle-based, equipment-based, or vessel-based standards, use good engineering judgment to interpret the term “engine” in this part to include vehicles, equipment, or vessels, where appropriate.

(g) For additional information regarding the test procedures in this part, visit our website at www.epa.gov, and in particular https://www.epa.gov/vehicle-and-fuel-emissions-testing/engine-testing-regulations.

(h) This part describes procedures and specifications for measuring an engine's exhaust emissions. While the measurements are geared toward engine-based measurements (in units of g/kW · hr), many of these provisions apply equally to vehicle-based measurements (in units of g/mile or g/kilometer). 40 CFR part 1066 describes the analogous procedures for vehicle-based emission measurements, and in many cases states that specific provisions of this part 1065 also apply for those vehicle-based measurements. Where material from this part 1065 applies for vehicle-based measurements under 40 CFR part 1066, it is sometimes necessary to include parenthetical statements in this part 1065 to properly cite secondary references that are different for vehicle-based testing. See 40 CFR part 1066 and the standard-setting part for additional information.

(i) The following additional procedures apply as described in subpart L of this part:

(1) Measuring brake-specific emissions of semi-volatile organic compounds, which are not subject to separate emission standards.

(2) Identifying the threshold temperature for vanadium sublimation for SCR catalysts.

(3) Measuring the smoke opacity of engine exhaust.

(4) Aging aftertreatment devices in support of determining deterioration factors for certified compression-ignition engines.

[73 FR 37288, June 30, 2008, as amended at 73 FR 59321, Oct. 8, 2008; 75 FR 23028, Apr. 30, 2010; 76 FR 37977, June 28, 2011; 76 FR 57437, Sept. 15, 2011; 79 FR 23752, Apr. 28, 2014; 86 FR 34533, Jun. 29, 2021; 88 FR 4669, Jan. 24, 2023]

§1065.2 Submitting information to EPA under this part.

(a) You are responsible for statements and information in your applications for certification, requests for approved procedures, selective enforcement audits, laboratory audits, production-line test reports, field test reports, or any other statements you make to us related to this part 1065. If you provide statements or information to someone for submission to EPA, you are responsible for these statements and information as if you had submitted them to EPA yourself.

(b) In the standard-setting part and in 40 CFR 1068.101, we describe your obligation to report truthful and complete information and the consequences of failing to meet this obligation. See also 18 U.S.C. 1001 and 42 U.S.C. 7413(c)(2). This obligation applies whether you submit this information directly to EPA or through someone else.

(c) We may void any certificates or approvals associated with a submission of information if we find that you intentionally submitted false, incomplete, or misleading information. For example, if we find that you intentionally submitted incomplete information to mislead EPA when requesting approval to use alternate test procedures, we may void the certificates for all engine families certified based on emission data collected using the alternate procedures. This paragraph (c) would also apply if you ignore data from incomplete tests or from repeat tests with higher emission results.

(d) We may require an authorized representative of your company to approve and sign the submission, and to certify that all the information submitted is accurate and complete. This includes everyone who submits information, including manufacturers and others.

(e) See 40 CFR 1068.10 for provisions related to confidential information. Note however that under 40 CFR 2.301, emission data are generally not eligible for confidential treatment.

(f) Nothing in this part should be interpreted to limit our ability under Clean Air Act section 208 (42 U.S.C. 7542) to verify that engines conform to the regulations.

[73 FR 37289, June 30, 2008, as amended at 75 FR 23028, Apr. 30, 2010; 79 FR 23752, Apr. 28, 2014; 86 FR 34533, Jun. 29, 2021]

§1065.5 Overview of this part 1065 and its relationship to the standard-setting part.

(a) This part specifies procedures that apply generally to measuring brake-specific emissions from various categories of engines. See subpart L of this part for measurement procedures for testing related to standards other than brake-specific emission standards. See the standard-setting part for directions in applying specific provisions in this part for a particular type of engine. Before using this part's procedures, read the standard-setting part to answer at least the following questions:

(1) What duty cycles must I use for laboratory testing?

(2) Should I warm up the test engine before measuring emissions, or do I need to measure cold-start emissions during a warm-up segment of the duty cycle?

(3) Which exhaust constituents do I need to measure? Measure all exhaust constituents that are subject to emission standards, any other exhaust constituents needed for calculating emission rates, and any additional exhaust constituents as specified in the standard-setting part. Alternatively, you may omit the measurement of N2O and CH4 for an engine, provided it is not subject to an N2O or CH4 emission standard. If you omit the measurement of N2O and CH4, you must provide other information and/or data that will give us a reasonable basis for estimating the engine's emission rates.

(4) Do any unique specifications apply for test fuels?

(5) What maintenance steps may I take before or between tests on an emission-data engine?

(6) Do any unique requirements apply to stabilizing emission levels on a new engine?

(7) Do any unique requirements apply to test limits, such as ambient temperatures or pressures?

(8) Is field testing required or allowed, and are there different emission standards or procedures that apply to field testing?

(9) Are there any emission standards specified at particular engine-operating conditions or ambient conditions?

(10) Do any unique requirements apply for durability testing?

(b) The testing specifications in the standard-setting part may differ from the specifications in this part. In cases where it is not possible to comply with both the standard-setting part and this part, you must comply with the specifications in the standard-setting part. The standard-setting part may also allow you to deviate from the procedures of this part for other reasons.

(c) The following table shows how this part divides testing specifications into subparts:

| This subpart | Describes these specifications or procedures |

|---|---|

| Subpart A | Applicability and general provisions. |

| Subpart B | Equipment for testing. |

| Subpart C | Measurement instruments for testing. |

| Subpart D | Calibration and performance verifications for measurement systems. |

| Subpart E | How to prepare engines for testing, including service accumulation. |

| Subpart F | How to run an emission test over a predetermined duty cycle. |

| Subpart G | Test procedure calculations. |

| Subpart H | Fuels, engine fluids, analytical gases, and other calibration standards. |

| Subpart I | Special procedures related to oxygenated fuels. |

| Subpart J | How to test with portable emission measurement systems (PEMS). |

| Subpart L | How to test for unregulated and special pollutants and to perform additional measurements related to certification. |

[73 FR 37289, June 30, 2008, as amended at 74 FR 56511, Oct. 30, 2009; 88 FR 4669, Jan. 24, 2023]

§1065.10 Other procedures.

(a) Your testing. The procedures in this part apply for all testing you do to show compliance with emission standards, with certain exceptions noted in this section. In some other sections in this part, we allow you to use other procedures (such as less precise or less accurate procedures) if they do not affect your ability to show that your engines comply with the applicable emission standards. This generally requires emission levels to be far enough below the applicable emission standards so that any errors caused by greater imprecision or inaccuracy do not affect your ability to state unconditionally that the engines meet all applicable emission standards.

(b) Our testing. These procedures generally apply for testing that we do to determine if your engines comply with applicable emission standards. We may perform other testing as allowed by the Act.

(c) Exceptions. We may allow or require you to use procedures other than those specified in this part in the following cases, which may apply to laboratory testing, field testing, or both. We intend to publicly announce when we allow or require such exceptions. All of the test procedures noted here as exceptions to the specified procedures are considered generically as “other procedures.” Note that the terms “special procedures” and “alternate procedures” have specific meanings; “special procedures” are those allowed by §1065.10(c)(2) and “alternate procedures” are those allowed by §1065.10(c)(7).

(1) The objective of the procedures in this part is to produce emission measurements equivalent to those that would result from measuring emissions during in-use operation using the same engine configuration as installed in a vehicle, equipment, or vessel. However, in unusual circumstances where these procedures may result in measurements that do not represent in-use operation, you must notify us if good engineering judgment indicates that the specified procedures cause unrepresentative emission measurements for your engines. Note that you need not notify us of unrepresentative aspects of the test procedure if measured emissions are equivalent to in-use emissions. This provision does not obligate you to pursue new information regarding the different ways your engine might operate in use, nor does it obligate you to collect any other in-use information to verify whether or not these test procedures are representative of your engine's in-use operation. If you notify us of unrepresentative procedures under this paragraph (c)(1), we will cooperate with you to establish whether and how the procedures should be appropriately changed to result in more representative measurements. While the provisions of this paragraph (c)(1) allow us to be responsive to issues as they arise, we would generally work toward making these testing changes generally applicable through rulemaking. We will allow reasonable lead time for compliance with any resulting change in procedures. We will consider the following factors in determining the importance of pursuing changes to the procedures:

(i) Whether supplemental emission standards or other requirements in the standard-setting part address the type of operation of concern or otherwise prevent inappropriate design strategies.

(ii) Whether the unrepresentative aspect of the procedures affects your ability to show compliance with the applicable emission standards.

(iii) The extent to which the established procedures require the use of emission-control technologies or strategies that are expected to ensure a comparable degree of emission control under the in-use operation that differs from the specified procedures.

(2) You may request to use special procedures if your engine cannot be tested using the specified procedures. For example, this may apply if your engine cannot operate on the specified duty cycle. In this case, tell us in writing why you cannot satisfactorily test your engine using this part's procedures and ask to use a different approach. We will approve your request if we determine that it would produce emission measurements that represent in-use operation and we determine that it can be used to show compliance with the requirements of the standard-setting part. Where we approve special procedures that differ substantially from the specified procedures, we may preclude you from participating in averaging, banking, and trading with the affected engine families.

(3) In a given model year, you may use procedures required for later model year engines without request. If you upgrade your testing facility in stages, you may rely on a combination of procedures for current and later model year engines as long as you can ensure, using good engineering judgment, that the combination you use for testing does not affect your ability to show compliance with the applicable emission standards.

(4) In a given model year, you may ask to use procedures allowed for earlier model year engines. We will approve this only if you show us that using the procedures allowed for earlier model years does not affect your ability to show compliance with the applicable emission standards.

(5) You may ask to use emission data collected using other procedures, such as those of the California Air Resources Board or the International Organization for Standardization. We will approve this only if you show us that using these other procedures does not affect your ability to show compliance with the applicable emission standards.

(6) During the 12 months following the effective date of any change in the provisions of this part 1065 (and 40 CFR part 1066 for vehicle testing), you may use data collected using procedures specified in the previously applicable version of this part 1065 (and 40 CFR part 1066 for vehicle testing). This also applies for changes to test procedures specified in the standard-setting part to the extent that these changes do not correspond to new emission standards. This paragraph (c)(6) does not restrict the use of carryover certification data otherwise allowed by the standard-setting part.

(7) You may request to use alternate procedures that are equivalent to the specified procedures, or procedures that are more accurate or more precise than the specified procedures. We may perform tests with your engines using either the approved alternate procedures or the specified procedures. The following provisions apply to requests for alternate procedures:

(i) Applications. Follow the instructions in §1065.12.

(ii) Submission. Submit requests in writing to the EPA Program Officer.

(iii) Notification. We may approve your request by telling you directly, or we may issue guidance announcing our approval of a specific alternate procedure, which would make additional requests for approval unnecessary.

(d) Advance approval. If we require you to request approval to use other procedures under paragraph (c) of this section, you may not use them until we approve your request.

[70 FR 40516, July 13, 2005, as amended at 73 FR 37290, June 30, 2008; 75 FR 23028, Apr. 30, 2010; 79 FR 23752, Apr. 28, 2014; 80 FR 9118, Feb. 19, 2015; 81 FR 74162, Oct. 25, 2016; 88 FR 4670, Jan. 24, 2023]

§1065.12 Approval of alternate procedures.

(a) To get approval for an alternate procedure under §1065.10(c), send the EPA Program Officer an initial written request describing the alternate procedure and why you believe it is equivalent to the specified procedure. Anyone may request alternate procedure approval. This means that an individual engine manufacturer may request to use an alternate procedure. This also means that an instrument manufacturer may request to have an instrument, equipment, or procedure approved as an alternate procedure to those specified in this part. We may approve your request based on this information alone, whether or not it includes all the information specified in this section. Where we determine that your original submission does not include enough information for us to determine that the alternate procedure is equivalent to the specified procedure, we may ask you to submit supplemental information showing that your alternate procedure is consistently and reliably at least as accurate and repeatable as the specified procedure.

(b) We may make our approval under this section conditional upon meeting other requirements or specifications. We may limit our approval, for example, to certain time frames, specific duty cycles, or specific emission standards. Based upon any supplemental information we receive after our initial approval, we may amend a previously approved alternate procedure to extend, limit, or discontinue its use. We intend to publicly announce alternate procedures that we approve.

(c) Although we will make every effort to approve only alternate procedures that completely meet our requirements, we may revoke our approval of an alternate procedure if new information shows that it is significantly not equivalent to the specified procedure.

If we do this, we will grant time to switch to testing using an allowed procedure, considering the following factors:

(1) The cost, difficulty, and availability to switch to a procedure that we allow.

(2) The degree to which the alternate procedure affects your ability to show that your engines comply with all applicable emission standards.

(3) Any relevant factors considered in our initial approval.

(d) If we do not approve your proposed alternate procedure based on the information in your initial request, we may ask you to send additional information to fully evaluate your request. While we consider the information specified in this paragraph (d) and the statistical criteria of paragraph (e) of this section to be sufficient to demonstrate equivalence, it may not be necessary to include all the information or meet the specified statistical criteria. For example, systems that do not meet the statistical criteria in paragraph (e) of this section because they have a small bias toward high emission results could be approved since they would not adversely affect your ability to demonstrate compliance with applicable standards.

(1) Theoretical basis. Give a brief technical description explaining why you believe the proposed alternate procedure should result in emission measurements equivalent to those using the specified procedure. You may include equations, figures, and references. You should consider the full range of parameters that may affect equivalence. For example, for a request to use a different NOX measurement procedure, you should theoretically relate the alternate detection principle to the specified detection principle over the expected concentration ranges for NO, NO2, and interference gases. For a request to use a different PM measurement procedure, you should explain the principles by which the alternate procedure quantifies particulate mass similarly to the specified procedures.

(2) Technical description. Describe briefly any hardware or software needed to perform the alternate procedure. You may include dimensioned drawings, flowcharts, schematics, and component specifications. Explain any necessary calculations or other data manipulation.

(3) Procedure execution. Describe briefly how to perform the alternate procedure and recommend a level of training an operator should have to achieve acceptable results.

Summarize the installation, calibration, operation, and maintenance procedures in a step-by-step format. Describe how any calibration is performed using NIST-traceable standards or other similar standards we approve. Calibration must be specified by using known quantities and must not be specified as a comparison with other allowed procedures.

(4) Data-collection techniques. Compare measured emission results using the proposed alternate procedure and the specified procedure, as follows:

(i) Both procedures must be calibrated independently to NIST-traceable standards or to other similar standards we approve.

(ii) Include measured emission results from all applicable duty cycles. Measured emission results should show that the test engine meets all applicable emission standards according to specified procedures.

(iii) Use statistical methods to evaluate the emission measurements, such as those described in paragraph (e) of this section.

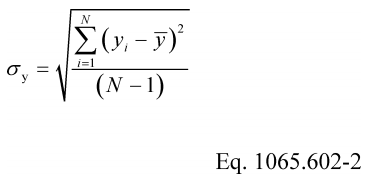

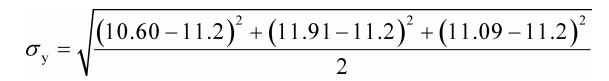

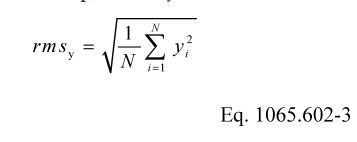

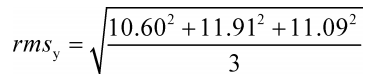

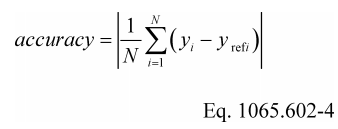

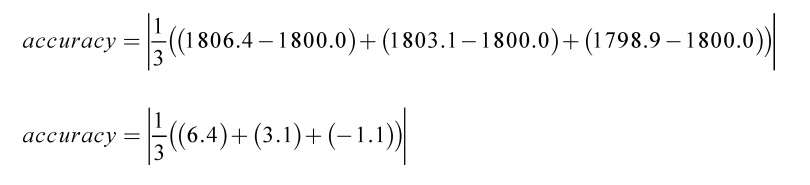

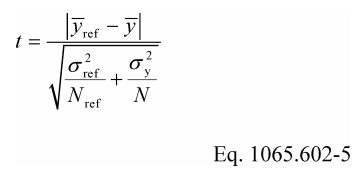

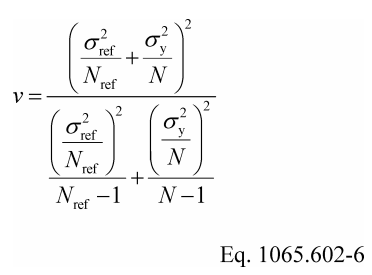

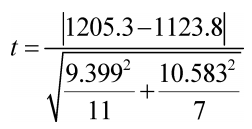

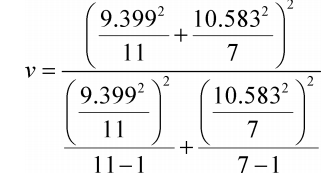

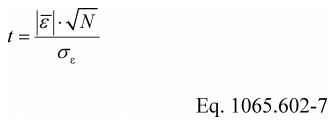

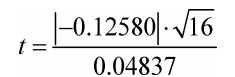

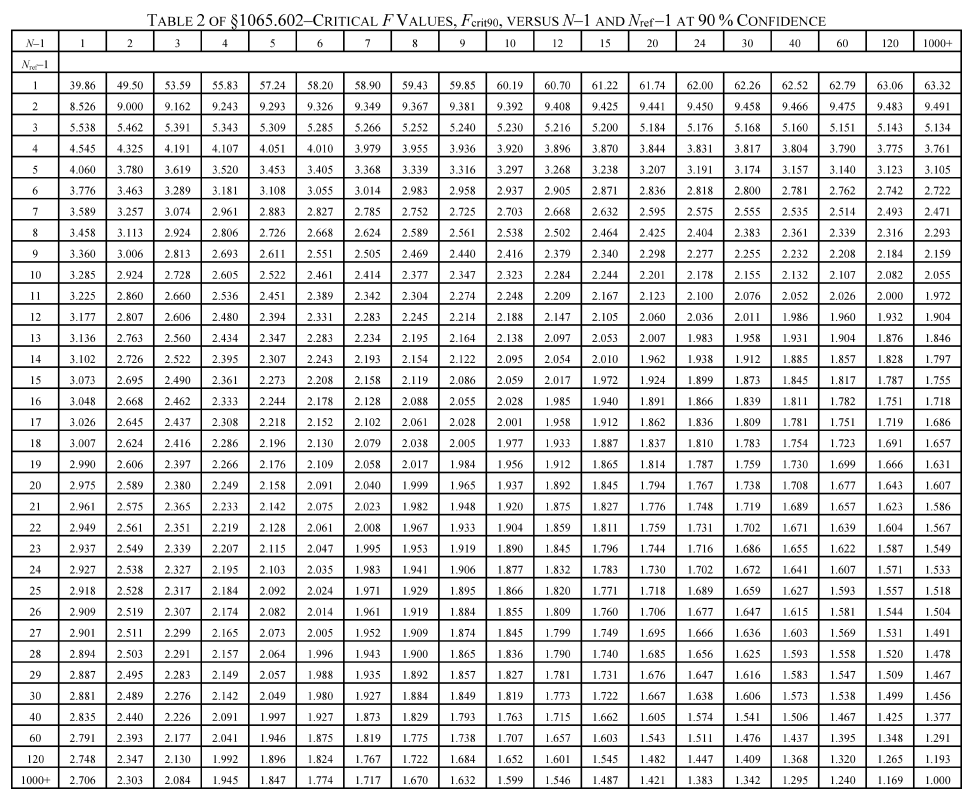

(e) Absent any other directions from us, use a t-test and an F-test calculated according to §1065.602 to evaluate whether your proposed alternate procedure is equivalent to the specified procedure. We may give you specific directions regarding methods for statistical analysis, or we may approve other methods that you propose. Such alternate methods may be more or less stringent than those specified in this paragraph (e). In determining the appropriate statistical criteria, we will consider the repeatability of measurements made with the reference procedure. For example, less stringent statistical criteria may be appropriate for measuring emission levels being so low that they adversely affect the repeatability of reference measurements. We recommend that you consult a statistician if you are unfamiliar with these statistical tests. Perform the tests as follows:

(1) Repeat measurements for all applicable duty cycles at least seven times for each procedure. You may use laboratory duty cycles to evaluate field-testing procedures.

Be sure to include all available results to evaluate the precision and accuracy of the proposed alternate procedure, as described in §1065.2.

(2) Demonstrate the accuracy of the proposed alternate procedure by showing that it passes a two-sided t-test. Use an unpaired t-test, unless you show that a paired t-test is appropriate under both of the following provisions:

(i) For paired data, the population of the paired differences from which you sampled paired differences must be independent. That is, the probability of any given value of one paired difference is unchanged by knowledge of the value of another paired difference. For example, your paired data would violate this requirement if your series of paired differences showed a distinct increase or decrease that was dependent on the time at which they were sampled.

(ii) For paired data, the population of paired differences from which you sampled the paired differences must have a normal (i.e., Gaussian) distribution. If the population of paired difference is not normally distributed, consult a statistician for a more appropriate statistical test, which may include transforming the data with a mathematical function or using some kind of non-parametric test.

(3) Show that t is less than the critical t value, tcrit, tabulated in §1065.602, for the following confidence intervals:

(i) 90% for a proposed alternate procedure for laboratory testing.

(ii) 95% for a proposed alternate procedure for field testing.

(4) Demonstrate the precision of the proposed alternate procedure by showing that it passes an F-test. Use a set of at least seven samples from the reference procedure and a set of at least seven samples from the alternate procedure to perform an F-test. The sets must meet the following requirements:

(i) Within each set, the values must be independent. That is, the probability of any given value in a set must be unchanged by knowledge of another value in that set. For example, your data would violate this requirement if a set showed a distinct increase or decrease that was dependent upon the time at which they were sampled.

(ii) For each set, the population of values from which you sampled must have a normal (i.e., Gaussian) distribution. If the population of values is not normally distributed, consult a statistician for a more appropriate statistical test, which may include transforming the data with a mathematical function or using some kind of non-parametric test.

(iii) The two sets must be independent of each other. That is, the probability of any given value in one set must be unchanged by knowledge of another value in the other set. For example, your data would violate this requirement if one value in a set showed a distinct increase or decrease that was dependent upon a value in the other set. Note that a trend of emission changes from an engine would not violate this requirement.

(iv) If you collect paired data for the paired t-test in paragraph (e)(2) in this section, use caution when selecting sets from paired data for the F-test. If you do this, select sets that do not mask the precision of the measurement procedure. We recommend selecting such sets only from data collected using the same engine, measurement instruments, and test cycle.

(5) Show that F is less than the critical F value, Fcrit, tabulated in §1065.602. If you have several F-test results from several sets of data, show that the mean F-test value is less than the mean critical F value for all the sets. Evaluate Fcrit, based on the following confidence intervals:

(i) 90% for a proposed alternate procedure for laboratory testing.

(ii) 95% for a proposed alternate procedure for field testing.

[70 FR 40516, July 13, 2005, as amended at 73 FR 37290, June 30, 2008; 79 FR 23752, Apr. 28, 2014; 88 FR 4670, Jan. 24, 2023]

§1065.15 Overview of procedures for laboratory and field testing.

This section outlines the procedures to test engines that are subject to emission standards.

(a) In the standard-setting part, we set brake-specific emission standards in g/(kW · hr) (or g/(hp · hr)), for the following constituents:

(1) Total oxides of nitrogen, NOX.

(2) Hydrocarbon, HC, which may be expressed in the following ways:

(i) Total hydrocarbon, THC.

(ii) Nonmethane hydrocarbon, NMHC, which results from subtracting methane, CH4, from THC.

(iii) Nonmethane-nonethane hydrocarbon, NMNEHC, which results from subtracting methane, CH4, and ethane, C2H6, from THC.

(iv) Total hydrocarbon-equivalent, THCE, which results from adjusting THC mathematically to be equivalent on a carbon-mass basis.

(v) Nonmethane hydrocarbon-equivalent, NMHCE, which results from adjusting NMHC mathematically to be equivalent on a carbon-mass basis.

(3) Particulate matter, PM.

(4) Carbon monoxide, CO.

(5) Carbon dioxide, CO2.

(6) Methane, CH4.

(7) Nitrous oxide, N2O.

(b) Note that some engines are not subject to standards for all the emission constituents identified in paragraph (a) of this section. Note also that the standard-setting part may include standards for pollutants not listed in paragraph (a) of this section.

(c) We generally set brake-specific emission standards over test intervals and/or duty cycles, as follows:

(1) Engine operation. Testing may involve measuring emissions and work in a laboratory-type environment or in the field, as described in paragraph (f) of this section. For most laboratory testing, the engine is operated over one or more duty cycles specified in the standard-setting part. However, laboratory testing may also include non-duty cycle testing (such as simulation of field testing in a laboratory). For field testing, the engine is operated under normal in-use operation. The standard-setting part specifies how test intervals are defined for field testing. Refer to the definitions of “duty cycle” and “test interval” in §1065.1001. Note that a single duty cycle may have multiple test intervals and require weighting of results from multiple test intervals to calculate a composite brake-specific emissions value to compare to the standard.

(2) Constituent determination. Determine the total mass of each constituent over a test interval by selecting from the following methods:

(i) Continuous sampling. In continuous sampling, measure the constituent's concentration continuously from raw or dilute exhaust. Multiply this concentration by the continuous (raw or dilute) flow rate at the emission sampling location to determine the constituent's flow rate. Sum the constituent's flow rate continuously over the test interval. This sum is the total mass of the emitted constituent.

(ii) Batch sampling. In batch sampling, continuously extract and store a sample of raw or dilute exhaust for later measurement. Extract a sample proportional to the raw or dilute exhaust flow rate. You may extract and store a proportional sample of exhaust in an appropriate container, such as a bag, and then measure NOX, HC, CO, CO2, CH4, N2O, and CH2O concentrations in the container after the test interval. You may deposit PM from proportionally extracted exhaust onto an appropriate substrate, such as a filter. In this case, divide the PM by the amount of filtered exhaust to calculate the PM concentration. Multiply batch sampled concentrations by the total (raw or dilute) flow from which it was extracted during the test interval. This product is the total mass of the emitted constituent.

(iii) Combined sampling. You may use continuous and batch sampling simultaneously during a test interval, as follows:

(A) You may use continuous sampling for some constituents and batch sampling for others.

(B) You may use continuous and batch sampling for a single constituent, with one being a redundant measurement. See §1065.201 for more information on redundant measurements.

(3) Work determination. Determine work over a test interval by one of the following methods:

(i) Speed and torque. Synchronously multiply speed and brake torque to calculate instantaneous values for engine brake power. Sum engine brake power over a test interval to determine total work.

(ii) Fuel consumed and brake-specific fuel consumption. Directly measure fuel consumed or calculate it with chemical balances of the fuel, intake air, and exhaust. To calculate fuel consumed by a chemical balance, you must also measure either intake-air flow rate or exhaust flow rate. Divide the fuel consumed during a test interval by the brake-specific fuel consumption to determine work over the test interval. For laboratory testing, calculate the brake-specific fuel consumption using fuel consumed and speed and torque over a test interval. For field testing, refer to the standard-setting part and §1065.915 for selecting an appropriate value for brake-specific fuel consumption.

(d) Refer to §1065.650 for calculations to determine brake-specific emissions.

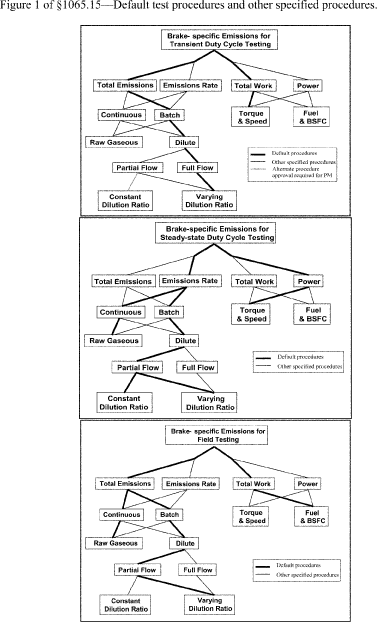

(e) The following figure illustrates the allowed measurement configurations described in this part 1065:

(f) This part 1065 describes how to test engines in a laboratory-type environment or in the field.

(1) This affects test intervals and duty cycles as follows:

(i) For laboratory testing, you generally determine brake-specific emissions for duty-cycle testing by using an engine dynamometer in a laboratory or other environment. This typically consists of one or more test intervals, each defined by a duty cycle, which is a sequence of modes, speeds, and/or torques (or powers) that an engine must follow. If the standard-setting part allows it, you may also simulate field testing with an engine dynamometer in a laboratory or other environment.

(ii) Field testing consists of normal in-use engine operation while an engine is installed in a vehicle, equipment, or vessel rather than following a specific engine duty cycle. The standard-setting part specifies how test intervals are defined for field testing.

(2) The type of testing may also affect what test equipment may be used. You may use “lab-grade” test equipment for any testing. The term “lab-grade” refers to equipment that fully conforms to the applicable specifications of this part. For some testing you may alternatively use “field-grade” equipment. The term “field-grade” refers to equipment that fully conforms to the applicable specifications of subpart J of this part, but does not fully conform to other specifications of this part. You may use “field-grade” equipment for field testing. We also specify in this part and in the standard-setting parts certain cases in which you may use “field-grade” equipment for testing in a laboratory-type environment. (Note: Although “field-grade” equipment is generally more portable than “lab-grade” test equipment, portability is not relevant to whether equipment is considered to be “field-grade” or “lab-grade”.)

[70 FR 40516, July 13, 2005, as amended at 73 FR 37290, June 30, 2008; 75 FR 23028, Apr. 30, 2010; 76 FR 57437, Sept. 15, 2011; 79 FR 23753, Apr. 28, 2014; 81 FR 74162, Oct. 25, 2016]

§1065.20 Units of measure and overview of calculations.

(a) System of units. The procedures in this part generally follow the International System of Units (SI), as detailed in NIST Special Publication 811, which we incorporate by reference in §1065.1010. The following exceptions apply:

(1) We designate angular speed, fn, of an engine's crankshaft in revolutions per minute (r/min), rather than the SI unit of radians per second (rad/s). This is based on the commonplace use of r/min in many engine dynamometer laboratories.

(2) We designate brake-specific emissions in grams per kilowatt-hour (g/(kW · hr)), rather than the SI unit of grams per megajoule (g/MJ). In addition, we use the symbol hr to identify hour, rather than the SI convention of using h. This is based on the fact that engines are generally subject to emission standards expressed in g/kW · hr. If we specify engine standards in grams per horsepower · hour (g/(hp · hr)) in the standard-setting part, convert units as specified in paragraph (d) of this section.

(3) We generally designate temperatures in units of degrees Celsius (°C) unless a calculation requires an absolute temperature. In that case, we designate temperatures in units of Kelvin (K). For conversion purposes throughout this part, 0°C equals 273.15 K. Unless specified otherwise, always use absolute temperature values for multiplying or dividing by temperature.

(b) Concentrations. This part does not rely on amounts expressed in parts per million. Rather, we express such amounts in the following SI units:

(1) For ideal gases, µmol/mol, formerly ppm (volume).

(2) For all substances, cm 3/m 3, formerly ppm (volume).

(3) For all substances, mg/kg, formerly ppm (mass).

(c) Absolute pressure. Measure absolute pressure directly or calculate it as the sum of atmospheric pressure plus a differential pressure that is referenced to atmospheric pressure. Always use absolute pressure values for multiplying or dividing by pressure.

(d) Units conversion. Use the following conventions to convert units:

(1) Testing. You may record values and perform calculations with other units. For testing with equipment that involves other units, use the conversion factors from NIST Special Publication 811, as described in paragraph (a) of this section.

(2) Humidity. In this part, we identify humidity levels by specifying dewpoint, which is the temperature at which pure water begins to condense out of air. Use humidity conversions as described in §1065.645.

(3) Emission standards. If your standard is in g/(hp · hr) units, convert kW to hp before any rounding by using the conversion factor of 1 hp (550 ft · lbf/s) = 0.7456999 kW. Round the final value for comparison to the applicable standard.

(e) Rounding. You are required to round certain final values, such as final emission values. You may round intermediate values when transferring data as long as you maintain at least six significant digits (which requires more than six decimal places for values less than 0.1), or all significant digits if fewer than six digits are available. Unless the standard-setting part specifies otherwise, do not round other intermediate values. Round values to the number of significant digits necessary to match the number of decimal places of the applicable standard or specification as described in this paragraph (e). Note that specifications expressed as percentages have infinite precision (as described in paragraph (e)(7) of this section). Use the following rounding convention, which is consistent with ASTM E29 and NIST SP 811:

(1) If the first (left-most) digit to be removed is less than five, remove all the appropriate digits without changing the digits that remain. For example, 3.141593 rounded to the second decimal place is 3.14.

(2) If the first digit to be removed is greater than five, remove all the appropriate digits and increase the lowest-value remaining digit by one. For example, 3.141593 rounded to the fourth decimal place is 3.1416.

(3) If the first digit to be removed is five with at least one additional non-zero digit following the five, remove all the appropriate digits and increase the lowest-value remaining digit by one. For example, 3.141593 rounded to the third decimal place is 3.142.

(4) If the first digit to be removed is five with no additional non-zero digits following the five, remove all the appropriate digits, increase the lowest-value remaining digit by one if it is odd and leave it unchanged if it is even. For example, 1.75 and 1.750 rounded to the first decimal place are 1.8; while 1.85 and 1.850 rounded to the first decimal place are also 1.8. Note that this rounding procedure will always result in an even number for the lowest-value digit.

(5) This paragraph (e)(5) applies if the regulation specifies rounding to an increment other than decimal places or powers of ten (to the nearest 0.01, 0.1, 1, 10, 100, etc.). To round numbers for these special cases, divide the quantity by the specified rounding increment. Round the result to the nearest whole number as described in paragraphs (e)(1) through (4) of this section. Multiply the rounded number by the specified rounding increment. This value is the desired result. For example, to round 0.90 to the nearest 0.2, divide 0.90 by 0.2 to get a result of 4.5, which rounds to 4. Multiplying 4 by 0.2 gives 0.8, which is the result of rounding 0.90 to the nearest 0.2.

(6) The following tables further illustrate the rounding procedures specified in this paragraph (e):

| Quantity | Rounding increment | |||

|---|---|---|---|---|

| 10 | 1 | 0.1 | 0.01 | |

| 3.141593 | 0 | 3 | 3.1 | 3.14 |

| 123,456.789 | 123,460 | 123,457 | 123,456.8 | 123,456.79 |

| 5.500 | 10 | 6 | 5.5 | 5.50 |

| 4.500 | 0 | 4 | 4.5 | 4.50 |

| Quantity | Rounding increment | |||

|---|---|---|---|---|

| 25 | 3 | 0.5 | 0.02 | |

| 229.267 | 225 | 228 | 229.5 | 229.26 |

| 62.500 | 50 | 63 | 62.5 | 62.50 |

| 87.500 | 100 | 87 | 87.5 | 87.50 |

| 7.500 | 0 | 6 | 7.5 | 7.50 |

(7) This paragraph (e)(7) applies where we specify a limit or tolerance as some percentage of another value (such as ±2% of a maximum concentration). You may show compliance with such specifications either by applying the percentage to the total value to calculate an absolute limit, or by converting the absolute value to a percentage by dividing it by the total value.

(i) Do not round either value (the absolute limit or the calculated percentage), except as specified in paragraph (e)(7)(ii) of this section. For example, assume we specify that an analyzer must have a repeatability of ±1% of the maximum concentration or better, the maximum concentration is 1059 ppm, and you determine repeatability to be ±6.3 ppm. In this example, you could calculate an absolute limit of ±10.59 ppm (1059 ppm × 0.01) or calculate that the 6.3 ppm repeatability is equivalent to a repeatability of 0.5949008498584%.

(ii) Prior to July 1, 2013, you may treat tolerances (and equivalent specifications) specified in percentages as having fixed rather than infinite precision. For example, 2% would be equivalent to 1.51% to 2.50% and 2.0% would be equivalent to 1.951% to 2.050%. Note that this allowance applies whether or not the percentage is explicitly specified as a percentage of another value.

(8) You may use measurement devices that incorporate internal rounding, consistent with the provisions of this paragraph (e)(8). You may use devices that use any rounding convention if they report six or more significant digits. You may use devices that report fewer than six digits, consistent with good engineering judgment and the accuracy, repeatability, and noise specifications of this part. Note that this provision does not necessarily require you to perform engineering analysis or keep records.

(f) Interpretation of ranges. Interpret a range as a tolerance unless we explicitly identify it as an accuracy, repeatability, linearity, or noise specification. See §1065.1001 for the definition of tolerance. In this part, we specify two types of ranges:

(1) Whenever we specify a range by a single value and corresponding limit values above and below that value (such as X ±Y), target the associated control point to that single value (X). Examples of this type of range include “±10% of maximum pressure”, or “(30 ±10) kPa”. In these examples, you would target the maximum pressure or 30 kPa, respectively.

(2) Whenever we specify a range by the interval between two values, you may target any associated control point to any value within that range. An example of this type of range is “(40 to 50) kPa”.

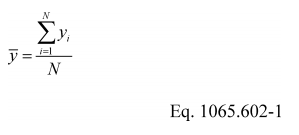

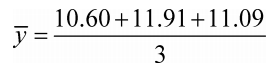

(g) Scaling of specifications with respect to an applicable standard. Because this part 1065 is applicable to a wide range of engines and emission standards, some of the specifications in this part are scaled with respect to an engine's applicable standard or maximum power. This ensures that the specification will be adequate to determine compliance, but not overly burdensome by requiring unnecessarily high-precision equipment. Many of these specifications are given with respect to a “flow-weighted mean” that is expected at the standard or during testing. Flow-weighted mean is the mean of a quantity after it is weighted proportional to a corresponding flow rate. For example, if a gas concentration is measured continuously from the raw exhaust of an engine, its flow-weighted mean concentration is the sum of the products (dry-to-wet corrected, if applicable) of each recorded concentration times its respective exhaust flow rate, divided by the sum of the recorded flow rates. As another example, the bag concentration from a CVS system is the same as the flow-weighted mean concentration, because the CVS system itself flow-weights the bag concentration. Refer to §1065.602 for information needed to estimate and calculate flow-weighted means. Wherever a specification is scaled to a value based upon an applicable standard, interpret the standard to be the family emission limit if the engine is certified under an emission credit program in the standard-setting part.

[70 FR 40516, July 13, 2005, as amended at 73 FR 37292, June 30, 2008; 76 FR 57438, Sept. 15, 2011; 79 FR 23753, Apr. 28, 2014]

§1065.25 Recordkeeping.

(a) The procedures in this part include various requirements to record data or other information. Refer to the standard-setting part and §1065.695 regarding specific recordkeeping requirements.

(b) You must promptly send us organized, written records in English if we ask for them. We may review them at any time.

(c) We may waive specific reporting or recordkeeping requirements we determine to be unnecessary for the purposes of this part and the standard-setting part. Note that while we will generally keep the records required by this part, we are not obligated to keep records we determine to be unnecessary for us to keep. For example, while we require you to keep records for invalid tests so that we may verify that your invalidation was appropriate, it is not necessary for us to keep records for our own invalid tests.

[79 FR 23753, Apr. 28, 2014]

Subpart B — Equipment Specifications

§1065.101 Overview.

(a) This subpart specifies equipment, other than measurement instruments, related to emission testing. The provisions of this subpart apply for all engine dynamometer testing where engine speeds and loads are controlled to follow a prescribed duty cycle. See subpart J of this part to determine which of the provisions of this subpart apply for field testing. This equipment includes three broad categories-dynamometers, engine fluid systems (such as fuel and intake-air systems), and emission-sampling hardware.

(b) Other related subparts in this part identify measurement instruments (subpart C), describe how to evaluate the performance of these instruments (subpart D), and specify engine fluids and analytical gases (subpart H).

(c) Subpart J of this part describes additional equipment that is specific to field testing.

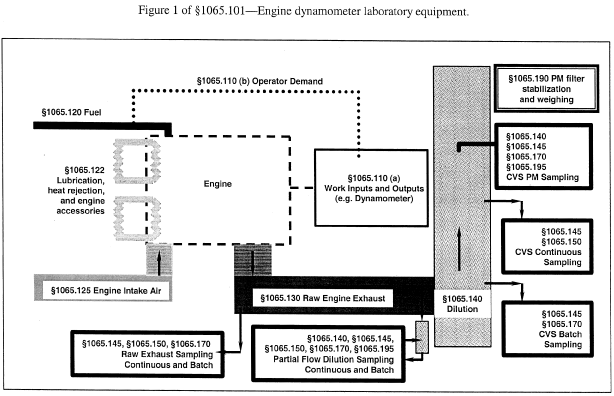

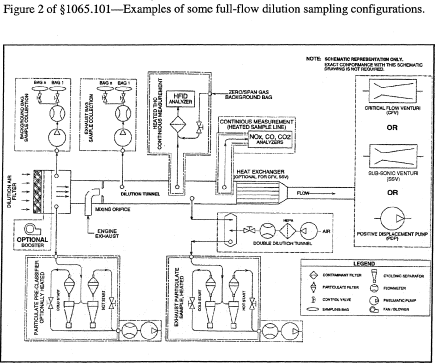

(d) Figures 1 and 2 of this section illustrate some of the possible configurations of laboratory equipment. These figures are schematics only; we do not require exact conformance to them. Figure 1 of this section illustrates the equipment specified in this subpart and gives some references to sections in this subpart. Figure 2 of this section illustrates some of the possible configurations of a full-flow dilution, constant-volume sampling (CVS) system. Not all possible CVS configurations are shown.

(e) Dynamometer testing involves engine operation over speeds and loads that are controlled to a prescribed duty cycle. Field testing involves measuring emissions over normal in-use operation of a vehicle or piece of equipment. Field testing does not involve operating an engine over a prescribed duty cycle.

[70 FR 40516, July 13, 2005, as amended at 73 FR 37292, June 30, 2008]

§1065.110 Work inputs and outputs, accessory work, and operator demand.

(a) Work. Use good engineering judgment to simulate all engine work inputs and outputs as they typically would operate in use. Account for work inputs and outputs during an emission test by measuring them; or, if they are small, you may show by engineering analysis that disregarding them does not affect your ability to determine the net work output by more than ±0.5% of the net expected work output over the test interval. Use equipment to simulate the specific types of work, as follows:

(1) Shaft work. Use an engine dynamometer that is able to meet the cycle-validation criteria in §1065.514 over each applicable duty cycle.

(i) You may use eddy-current and water-brake dynamometers for any testing that does not involve engine motoring, which is identified by negative torque commands in a reference duty cycle. See the standard setting part for reference duty cycles that are applicable to your engine.

(ii) You may use alternating-current or direct-current motoring dynamometers for any type of testing.

(iii) You may use one or more dynamometers.

(iv) You may use any device that is already installed on a vehicle, equipment, or vessel to absorb work from the engine's output shaft(s). Examples of these types of devices include a vessel's propeller and a locomotive's generator.

(2) Electrical work. Use one or more of the following to simulate electrical work:

(i) Use storage batteries or capacitors that are of the type and capacity installed in use.

(ii) Use motors, generators, and alternators that are of the type and capacity installed in use.

(iii) Use a resistor load bank to simulate electrical loads.

(3) Pump, compressor, and turbine work. Use pumps, compressors, and turbines that are of the type and capacity installed in use. Use working fluids that are of the same type and thermodynamic state as normal in-use operation.

(b) Laboratory work inputs. You may supply any laboratory inputs of work to the engine. For example, you may supply electrical work to the engine to operate a fuel system, and as another example you may supply compressor work to the engine to actuate pneumatic valves. We may ask you to show by engineering analysis your accounting of laboratory work inputs to meet the criterion in paragraph (a) of this section.

(c) Engine accessories. You must either install or account for the work of engine accessories required to fuel, lubricate, or heat the engine, circulate coolant to the engine, or to operate aftertreatment devices. Operate the engine with these accessories installed or accounted for during all testing operations, including mapping. If these accessories are not powered by the engine during a test, account for the work required to perform these functions from the total work used in brake-specific emission calculations. For air-cooled engines only, subtract externally powered fan work from total work. We may ask you to show by engineering analysis your accounting of engine accessories to meet the criterion in paragraph (a) of this section.

(d) Engine starter. You may install a production-type starter.

(e) Operator demand for shaft work. Operator demand is defined in §1065.1001. Command the operator demand and the dynamometer(s) to follow a prescribed duty cycle with set points for engine speed and torque as specified in §1065.512. Refer to the standard-setting part to determine the specifications for your duty cycle(s). Use a mechanical or electronic input to control operator demand such that the engine is able to meet the validation criteria in §1065.514 over each applicable duty cycle. Record feedback values for engine speed and torque as specified in §1065.512. Using good engineering judgment, you may improve control of operator demand by altering on-engine speed and torque controls. However, if these changes result in unrepresentative testing, you must notify us and recommend other test procedures under §1065.10(c)(1).

(f) Other engine inputs. If your electronic control module requires specific input signals that are not available during dynamometer testing, such as vehicle speed or transmission signals, you may simulate the signals using good engineering judgment. Keep records that describe what signals you simulate and explain why these signals are necessary for representative testing.

[70 FR 40516, July 13, 2005, as amended at 73 FR 37292, June 30, 2008]

§1065.120 Fuel properties and fuel temperature and pressure.

(a) Use fuels as specified in the standard-setting part, or as specified in subpart H of this part if fuels are not specified in the standard-setting part.

(b) If the engine manufacturer specifies fuel temperature and pressure tolerances and the location where they are to be measured, then measure the fuel temperature and pressure at the specified location to show that you are within these tolerances throughout testing.

(c) If the engine manufacturer does not specify fuel temperature and pressure tolerances, use good engineering judgment to set and control fuel temperature and pressure in a way that represents typical in-use fuel temperatures and pressures.

[70 FR 40516, July 13, 2005, as amended at 73 FR 37293, June 30, 2008]

§1065.122 Engine cooling and lubrication.

(a) Engine cooling. Cool the engine during testing so its intake-air, oil, coolant, block, and head temperatures are within their expected ranges for normal operation. You may use auxiliary coolers and fans.

(1) For air-cooled engines only, if you use auxiliary fans you must account for work input to the fan(s) according to §1065.110.

(2) See §1065.125 for more information related to intake-air cooling.

(3) See §1065.127 for more information related to exhaust gas recirculation cooling.

(4) Measure temperatures at the manufacturer-specified locations. If the manufacturer does not specify temperature measurement locations, then use good engineering judgment to monitor intake-air, oil, coolant, block, and head temperatures to ensure that they are in their expected ranges for normal operation.

(b) Forced cooldown. You may install a forced cooldown system for an engine and an exhaust aftertreatment device according to §1065.530(a)(1).

(c) Lubricating oil. Use lubricating oils specified in §1065.740. For two-stroke engines that involve a specified mixture of fuel and lubricating oil, mix the lubricating oil with the fuel according to the manufacturer's specifications.

(d) Coolant. For liquid-cooled engines, use coolant as specified in §1065.745.

[70 FR 40516, July 13, 2005, as amended at 73 FR 37293, June 30, 2008]

§1065.125 Engine intake air.

(a) Use the intake-air system installed on the engine or one that represents a typical in-use configuration. This includes the charge-air cooling and exhaust gas recirculation systems.

(b) Measure temperature, humidity, and atmospheric pressure near the entrance of the furthest upstream engine or in-use intake system component. This would generally be near the engine's air filter, or near the inlet to the in-use air intake system for engines that have no air filter. For engines with multiple intakes, make measurements near the entrance of each intake.

(1) Pressure. You may use a single shared atmospheric pressure meter as long as your laboratory equipment for handling intake air maintains ambient pressure at all intakes within ±1 kPa of the shared atmospheric pressure. For engines with multiple intakes with separate atmospheric pressure measurements at each intake, use an average value for verifying compliance to §1065.520(b)(2).

(2) Humidity. You may use a single shared humidity measurement for intake air as long as your equipment for handling intake air maintains dewpoint at all intakes to within ±0.5°C of the shared humidity measurement. For engines with multiple intakes with separate humidity measurements at each intake, use a flow-weighted average humidity for NOX corrections. If individual flows of each intake are not measured, use good engineering judgment to estimate a flow-weighted average humidity.

(3) Temperature. Good engineering judgment may require that you shield the temperature sensors or move them upstream of an elbow in the laboratory intake system to prevent measurement errors due to radiant heating from hot engine surfaces or in-use intake system components. You must limit the distance between the temperature sensor and the entrance to the furthest upstream engine or in-use intake system component to no more than 12 times the outer hydraulic diameter of the entrance to the furthest upstream engine or in-use intake system component. However, you may exceed this limit if you use good engineering judgment to show that the temperature at the furthest upstream engine or in-use intake system component meets the specification in paragraph (c) of this section. For engines with multiple intakes, use a flow-weighted average value to verify compliance with the specification in paragraph (c) of this section. If individual flows of each intake are not measured, you may use good engineering judgment to estimate a flow-weighted average temperature. You may also verify that each individual intake complies with the specification in paragraph (c) of this section.

(c) Maintain the temperature of intake air to (25 ±5)°C, except as follows:

(1) Follow the standard-setting part if it specifies different temperatures.

(2) For engines above 560 kW, you may use 35°C as the upper bound of the tolerance. However, your system must be capable of controlling the temperature to the 25°C setpoint for any steady-state operation at >30% of maximum engine power.

(3) You may ask us to allow you to apply a different setpoint for intake air temperature if it is necessary to remain consistent with the provisions of §1065.10(c)(1) for testing during which ambient temperature will be outside this range.

(d) Use an intake-air restriction that represents production engines. Make sure the intake-air restriction is between the manufacturer's specified maximum for a clean filter and the manufacturer's specified maximum allowed. Measure the static differential pressure of the restriction at the location and at the speed and torque set points specified by the manufacturer. If the manufacturer does not specify a location, measure this pressure upstream of any turbocharger or exhaust gas recirculation system connection to the intake air system. If the manufacturer does not specify speed and torque points, measure this pressure while the engine outputs maximum power. As the manufacturer, you are liable for emission compliance for all values up to the maximum restriction you specify for a particular engine.

(e) This paragraph (e) includes provisions for simulating charge-air cooling in the laboratory. This approach is described in paragraph (e)(1) of this section. Limits on using this approach are described in paragraphs (e)(2) and (3) of this section.

(1) Use a charge-air cooling system with a total intake-air capacity that represents production engines' in-use installation. Design any laboratory charge-air cooling system to minimize accumulation of condensate. Drain any accumulated condensate. Before starting a duty cycle (or preconditioning for a duty cycle), completely close all drains that would normally be closed during in-use operation. Keep those drains closed during the emission test. Maintain coolant conditions as follows:

(i) Maintain a coolant temperature of at least 20°C at the inlet to the charge-air cooler throughout testing. We recommend maintaining a coolant temperature of 25 ±5°C at the inlet of the charge-air cooler.

(ii) At the engine conditions specified by the manufacturer, set the coolant flow rate to achieve an air temperature within ±5°C of the value specified by the manufacturer after the charge-air cooler's outlet. Measure the air-outlet temperature at the location specified by the manufacturer. Use this coolant flow rate set point throughout testing. If the engine manufacturer does not specify engine conditions or the corresponding charge-air cooler air outlet temperature, set the coolant flow rate at maximum engine power to achieve a charge-air cooler air outlet temperature that represents in-use operation.

(iii) If the engine manufacturer specifies pressure-drop limits across the charge-air cooling system, ensure that the pressure drop across the charge-air cooling system at engine conditions specified by the manufacturer is within the manufacturer's specified limit(s). Measure the pressure drop at the manufacturer's specified locations.

(2) Using a constant flow rate as described in paragraph (e)(1) of this section may result in unrepresentative overcooling of the intake air. The provisions of this paragraph (e)(2) apply instead of the provisions of §1065.10(c)(1) for this simulation. Our allowance to cool intake air as specified in this paragraph (e) does not affect your liability for field testing or for laboratory testing that is done in a way that better represents in-use operation. Where we determine that this allowance adversely affects your ability to demonstrate that your engines would comply with emission standards under in-use conditions, we may require you to use more sophisticated setpoints and controls of charge-air pressure drop, coolant temperature, and flow rate to achieve more representative results.

(3) This approach does not apply for field testing. You may not correct measured emission levels from field testing to account for any differences caused by the simulated cooling in the laboratory.

[70 FR 40516, July 13, 2005, as amended at 73 FR 37293, June 30, 2008; 73 FR 59321, Oct. 8, 2008; 75 FR 23029, Apr. 30, 2010; 76 FR 57440, Sept. 15, 2011]

§1065.127 Exhaust gas recirculation.

Use the exhaust gas recirculation (EGR) system installed with the engine or one that represents a typical in-use configuration. This includes any applicable EGR cooling devices.

§1065.130 Engine exhaust.

(a) General. Use the exhaust system installed with the engine or one that represents a typical in-use configuration. This includes any applicable aftertreatment devices. We refer to exhaust piping as an exhaust stack; this is equivalent to a tailpipe for vehicle configurations.

(b) Aftertreatment configuration. If you do not use the exhaust system installed with the engine, configure any aftertreatment devices as follows:

(1) Position any aftertreatment device so its distance from the nearest exhaust manifold flange or turbocharger outlet is within the range specified by the engine manufacturer in the application for certification. If this distance is not specified, position aftertreatment devices to represent typical in-use vehicle configurations.

(2) You may use exhaust tubing that is not from the in-use exhaust system upstream of any aftertreatment device that is of diameter(s) typical of in-use configurations. If you use exhaust tubing that is not from the in-use exhaust system upstream of any aftertreatment device, position each aftertreatment device according to paragraph (b)(1) of this section.

(c) Sampling system connections. Connect an engine's exhaust system to any raw sampling location or dilution stage, as follows:

(1) Minimize laboratory exhaust tubing lengths and use a total length of laboratory tubing of no more than 10 m or 50 outside diameters, whichever is greater. The start of laboratory exhaust tubing should be specified as the exit of the exhaust manifold, turbocharger outlet, last aftertreatment device, or the in-use exhaust system, whichever is furthest downstream. The end of laboratory exhaust tubing should be specified as the sample point, or first point of dilution. If laboratory exhaust tubing consists of several different outside tubing diameters, count the number of diameters of length of each individual diameter, then sum all the diameters to determine the total length of exhaust tubing in diameters. Use the mean outside diameter of any converging or diverging sections of tubing. Use outside hydraulic diameters of any noncircular sections. For multiple stack configurations where all the exhaust stacks are combined, the start of the laboratory exhaust tubing may be taken at the last joint of where all the stacks are combined.

(2) You may install short sections of flexible laboratory exhaust tubing at any location in the engine or laboratory exhaust systems. You may use up to a combined total of 2 m or 10 outside diameters of flexible exhaust tubing.

(3) Insulate any laboratory exhaust tubing downstream of the first 25 outside diameters of length.

(4) Use laboratory exhaust tubing materials that are smooth-walled, electrically conductive, and not reactive with exhaust constituents. Stainless steel is an acceptable material.

(5) We recommend that you use laboratory exhaust tubing that has either a wall thickness of less than 2 mm or is air gap-insulated to minimize temperature differences between the wall and the exhaust.

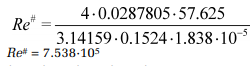

(6) We recommend that you connect multiple exhaust stacks from a single engine into one stack upstream of any emission sampling. For raw or dilute partial-flow emission sampling, to ensure mixing of the multiple exhaust streams before emission sampling, we recommend a minimum Reynolds number, Re #, of 4000 for the combined exhaust stream, where Re # is based on the inside diameter of the combined flow at the first sampling point. You may configure the exhaust system with turbulence generators, such as orifice plates or fins, to achieve good mixing; inclusion of turbulence generators may be required for Re # less than 4000 to ensure good mixing. Re # is defined in §1065.640. For dilute full-flow (CVS) emission sampling, you may configure the exhaust system without regard to mixing in the laboratory section of the raw exhaust. For example you may size the laboratory section to reduce its pressure drop even if the Re #, in the laboratory section of the raw exhaust is less than 4000.

(d) In-line instruments. You may insert instruments into the laboratory exhaust tubing, such as an in-line smoke meter. If you do this, you may leave a length of up to 5 outside diameters of laboratory exhaust tubing uninsulated on each side of each instrument, but you must leave a length of no more than 25 outside diameters of laboratory exhaust tubing uninsulated in total, including any lengths adjacent to in-line instruments.

(e) Leaks. Minimize leaks sufficiently to ensure your ability to demonstrate compliance with the applicable standards in this chapter. We recommend performing carbon balance error verification as described in §1065.543 to verify exhaust system integrity.

(f) Grounding. Electrically ground the entire exhaust system.

(g) Forced cooldown. You may install a forced cooldown system for an exhaust aftertreatment device according to §1065.530(a)(1)(i).

(h) Exhaust restriction. As the manufacturer, you are liable for emission compliance for all values up to the maximum restriction(s) you specify for a particular engine. Measure and set exhaust restriction(s) at the location(s) and at the engine speed and torque values specified by the manufacturer. Also, for variable-restriction aftertreatment devices, measure and set exhaust restriction(s) at the aftertreatment condition (degreening/aging and regeneration/loading level) specified by the manufacturer. If the manufacturer does not specify a location, measure this pressure downstream of any turbocharger. If the manufacturer does not specify speed and torque points, measure pressure while the engine produces maximum power. Use an exhaust-restriction setpoint that represents a typical in-use value, if available. If a typical in-use value for exhaust restriction is not available, set the exhaust restriction at (80 to 100)% of the maximum exhaust restriction specified by the manufacturer, or if the maximum is 5 kPa or less, the set point must be no less than 1.0 kPa from the maximum. For example, if the maximum back pressure is 4.5 kPa, do not use an exhaust restriction set point that is less than 3.5 kPa.

(i) Open crankcase emissions. If the standard-setting part requires measuring open crankcase emissions, you may either measure open crankcase emissions separately using a method that we approve in advance, or route open crankcase emissions directly into the exhaust system for emission measurement. If the engine is not already configured to route open crankcase emissions for emission measurement, route open crankcase emissions as follows:

(1) Use laboratory tubing materials that are smooth-walled, electrically conductive, and not reactive with crankcase emissions. Stainless steel is an acceptable material. Minimize tube lengths. We also recommend using heated or thin-walled or air gap-insulated tubing to minimize temperature differences between the wall and the crankcase emission constituents.

(2) Minimize the number of bends in the laboratory crankcase tubing and maximize the radius of any unavoidable bend.

(3) Use laboratory crankcase exhaust tubing that meets the engine manufacturer's specifications for crankcase back pressure.

(4) Connect the crankcase exhaust tubing into the raw exhaust downstream of any aftertreatment system, downstream of any installed exhaust restriction, and sufficiently upstream of any sample probes to ensure complete mixing with the engine's exhaust before sampling. Extend the crankcase exhaust tube into the free stream of exhaust to avoid boundary-layer effects and to promote mixing. You may orient the crankcase exhaust tube's outlet in any direction relative to the raw exhaust flow.

[73 FR 37293, June 30, 2008, as amended at 79 FR 23754, Apr. 28, 2014; 86 FR 34534, Jun. 29, 2021]

§1065.140 Dilution for gaseous and PM constituents.

(a) General. You may dilute exhaust with ambient air, purified air, or nitrogen. References in this part to “dilution air” may include any of these. For gaseous emission measurement, the dilution air must be at least 15°C. Note that the composition of the dilution air affects some gaseous emission measurement instruments' response to emissions. We recommend diluting exhaust at a location as close as possible to the location where ambient air dilution would occur in use. Dilution may occur in a single stage or in multiple stages. For dilution in multiple stages, the first stage is considered primary dilution and later stages are considered secondary dilution.

(b) Dilution-air conditions and background concentrations. Before dilution air is mixed with exhaust, you may precondition it by increasing or decreasing its temperature or humidity. You may also remove constituents to reduce their background concentrations. The following provisions apply to removing constituents or accounting for background concentrations:

(1) You may measure constituent concentrations in the dilution air and compensate for background effects on test results. See §1065.650 for calculations that compensate for background concentrations (40 CFR 1066.610 for vehicle testing).

(2) Measure these background concentrations the same way you measure diluted exhaust constituents, or measure them in a way that does not affect your ability to demonstrate compliance with the applicable standards in this chapter. For example, you may use the following simplifications for background sampling:

(i) You may disregard any proportional sampling requirements.

(ii) You may use unheated gaseous sampling systems.

(iii) You may use unheated PM sampling systems.

(iv) You may use continuous sampling if you use batch sampling for diluted emissions.

(v) You may use batch sampling if you use continuous sampling for diluted emissions.

(3) For removing background PM, we recommend that you filter all dilution air, including primary full-flow dilution air, with high-efficiency particulate air (HEPA) filters that have an initial minimum collection efficiency specification of 99.97% (see §1065.1001 for procedures related to HEPA-filtration efficiencies). Ensure that HEPA filters are installed properly so that background PM does not leak past the HEPA filters. If you choose to correct for background PM without using HEPA filtration, demonstrate that the background PM in the dilution air contributes less than 50% to the net PM collected on the sample filter. You may correct net PM without restriction if you use HEPA filtration.

(c) Full-flow dilution; constant-volume sampling (CVS). You may dilute the full flow of raw exhaust in a dilution tunnel that maintains a nominally constant volume flow rate, molar flow rate or mass flow rate of diluted exhaust, as follows:

(1) Construction. Use a tunnel with inside surfaces of 300 series stainless steel. Electrically ground the entire dilution tunnel. We recommend a thin-walled and insulated dilution tunnel to minimize temperature differences between the wall and the exhaust gases. You may not use any flexible tubing in the dilution tunnel upstream of the PM sample probe. You may use nonconductive flexible tubing downstream of the PM sample probe and upstream of the CVS flow meter; use good engineering judgment to select a tubing material that is not prone to leaks, and configure the tubing to ensure smooth flow at the CVS flow meter.

(2) Pressure control. Maintain static pressure at the location where raw exhaust is introduced into the tunnel within ±1.2 kPa of atmospheric pressure. You may use a booster blower to control this pressure. If you test using more careful pressure control and you show by engineering analysis or by test data that you require this level of control to demonstrate compliance at the applicable standards in this chapter, we will maintain the same level of static pressure control when we test.

(3) Mixing. Introduce raw exhaust into the tunnel by directing it downstream along the centerline of the tunnel. If you dilute directly from the exhaust stack, the end of the exhaust stack is considered to be the start of the dilution tunnel. You may introduce a fraction of dilution air radially from the tunnel's inner surface to minimize exhaust interaction with the tunnel walls. You may configure the system with turbulence generators such as orifice plates or fins to achieve good mixing. We recommend a minimum Reynolds number, Re #, of 4000 for the diluted exhaust stream, where Re # is based on the inside diameter of the dilution tunnel. Re # is defined in §1065.640.

(4) Flow measurement preconditioning. You may condition the diluted exhaust before measuring its flow rate, as long as this conditioning takes place downstream of any heated HC or PM sample probes, as follows:

(i) You may use flow straighteners, pulsation dampeners, or both of these.

(ii) You may use a filter.

(iii) You may use a heat exchanger to control the temperature upstream of any flow meter, but you must take steps to prevent aqueous condensation as described in paragraph (c)(6) of this section.

(5) Flow measurement. Section 1065.240 describes measurement instruments for diluted exhaust flow.

(6) Aqueous condensation. You must address aqueous condensation in the CVS as described in this paragraph (c)(6). You may meet these requirements by preventing or limiting aqueous condensation in the CVS from the exhaust inlet to the last emission sample probe. See paragraph (c)(6)(2)(B) of this section for provisions related to the CVS between the last emission sample probe and the CVS flow meter. You may heat and/or insulate the dilution tunnel walls, as well as the bulk stream tubing downstream of the tunnel to prevent or limit aqueous condensation. Where we allow aqueous condensation to occur, use good engineering judgment to ensure that the condensation does not affect your ability to demonstrate that your engines comply with the applicable standards in this chapter (see §1065.10(a)).

(i) Preventing aqueous condensation. To prevent condensation, you must keep the temperature of internal surfaces, excluding any sample probes, above the dewpoint of the dilute exhaust passing through the CVS tunnel. Use good engineering judgment to monitor temperatures in the CVS. For the purposes of this paragraph (c)(6), assume that aqueous condensation is pure water condensate only, even though the definition of “aqueous condensation” in §1065.1001 includes condensation of any constituents that contain water. No specific verification check is required under this paragraph (c)(6)(i), but we may ask you to show how you comply with this requirement. You may use engineering analysis, CVS tunnel design, alarm systems, measurements of wall temperatures, and calculation of water dewpoint to demonstrate compliance with this requirement. For optional CVS heat exchangers, you may use the lowest water temperature at the inlet(s) and outlet(s) to determine the minimum internal surface temperature.

(ii) Limiting aqueous condensation. This paragraph (c)(6)(ii) specifies limits of allowable condensation and requires you to verify that the amount of condensation that occurs during each test interval does not exceed the specified limits.

(A) Use chemical balance equations in §1065.655 to calculate the mole fraction of water in the dilute exhaust continuously during testing. Alternatively, you may continuously measure the mole fraction of water in the dilute exhaust prior to any condensation during testing. Use good engineering judgment to select, calibrate and verify water analyzers/detectors. The linearity verification requirements of §1065.307 do not apply to water analyzers/detectors used to correct for the water content in exhaust samples.

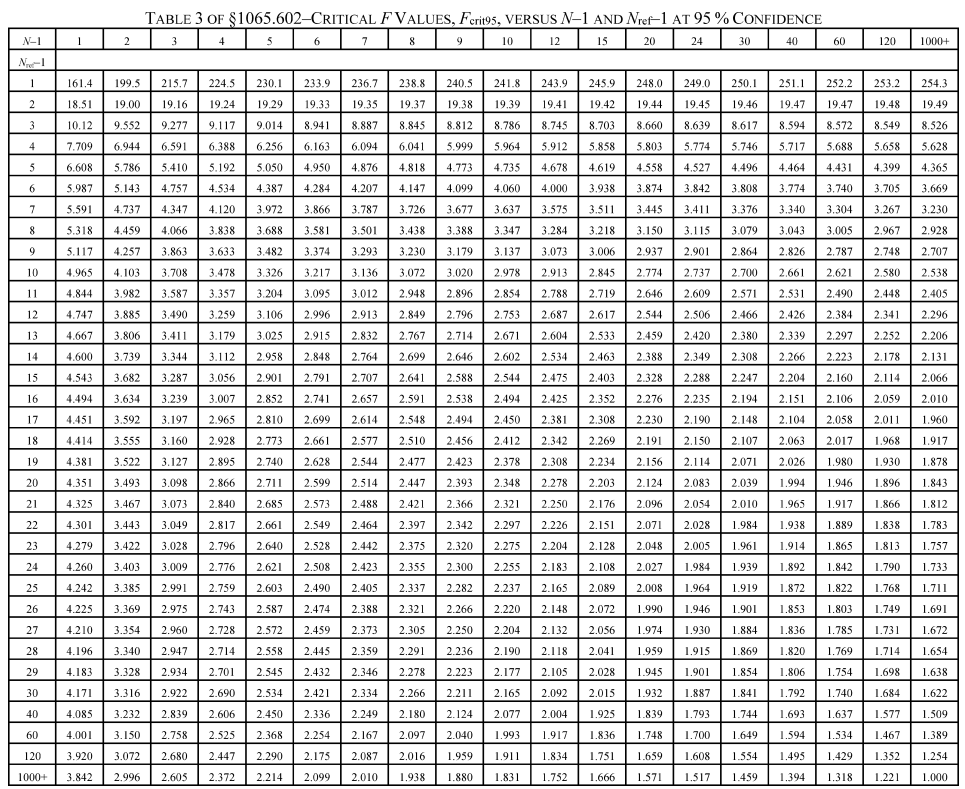

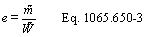

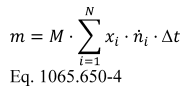

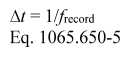

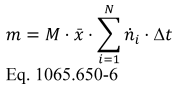

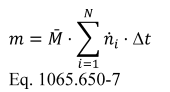

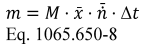

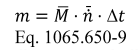

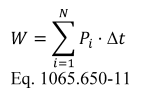

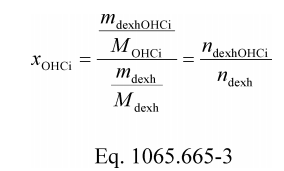

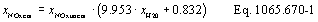

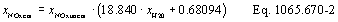

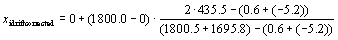

(B) Use good engineering judgment to select and monitor locations on the CVS tunnel walls prior to the last emission sample probe. If you are also verifying limited condensation from the last emission sample probe to the CVS flow meter, use good engineering judgment to select and monitor locations on the CVS tunnel walls, optional CVS heat exchanger, and CVS flow meter. For optional CVS heat exchangers, you may use the lowest water temperature at the inlet(s) and outlet(s) to determine the minimum internal surface temperature. Identify the minimum surface temperature on a continuous basis.