Don’t compress gas safety while welding

Welding, cutting, and brazing are common procedures in many industries. Whenever welding, cutting, or brazing occurs, everyone involved in the operations must take precautions to prevent fires, explosions, or personal injuries from welding hazards.

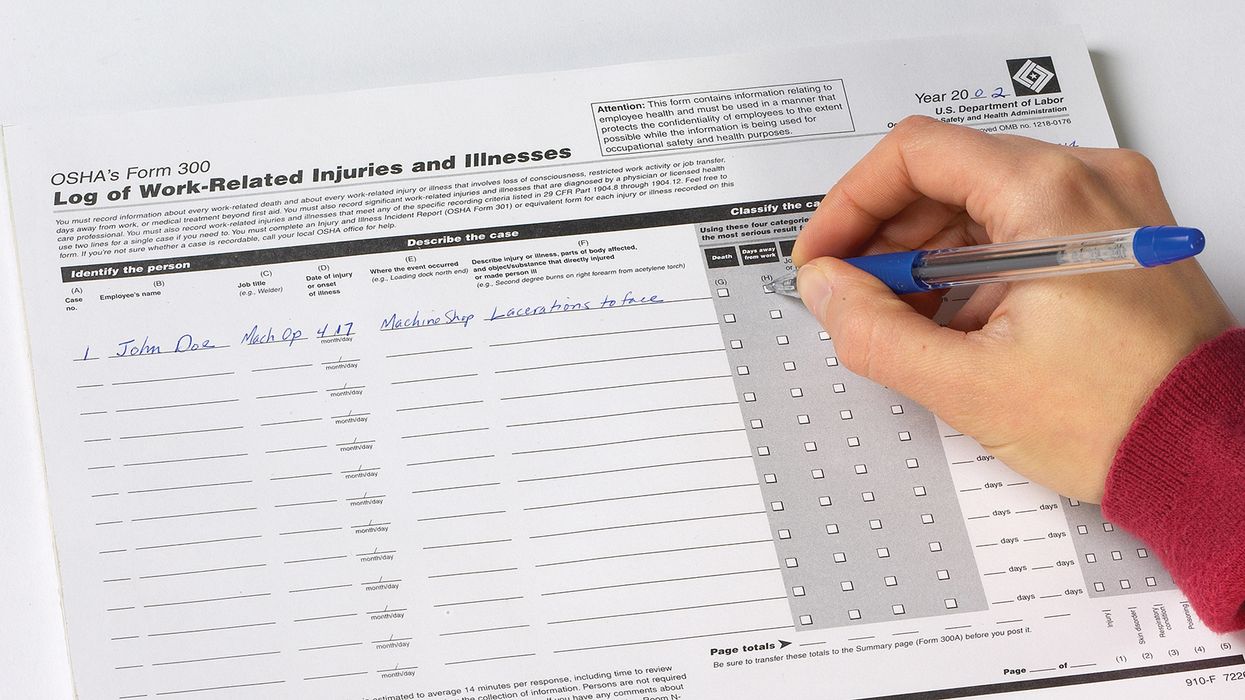

Welding hazards

Employers must review the company welding safety program with their welders. Whenever welding or working around welding and other hot work, you should know the following:

- The name and job title of the person responsible for safety in welding operations.

- The job hazards associated with welding such as: hazards from fumes and gases, radiation hazards, fire hazards, noise hazards, and electrical hazards.

- Any special procedures for the equipment being used, such as: care of compressed gas cylinders, the use of ventilation, and fire prevention methods.

- The use of engineering controls, such as flash screens and fire blankets.

- Any necessary personal protective equipment is required for the work being done.

How can I protect myself and others?

Here are a few practices for working safely that apply in welding situations.

- When working above ground or floor level, use a platform with toeboards and standard railings or a safety belt and lifeline. Also, protect workers from stray sparks or slag in areas below an elevated surface where welding occurs.

- Aim the welding torch away from cement or stone surfaces. Moisture within these materials could cause them to explode when they reach a certain temperature.

- When finished welding or cutting, warn other workers of hot metal by marking or putting up a sign. Keep floors clean by putting electrodes or rod stubs in an appropriate container. Keep floors clear of tripping hazards; store tools safely.

- Never use bare conductors, damaged regulators, torches, electrode holders, or other defective equipment.

- Do not arc or resistance weld while standing on damp surfaces.

Safely working with compressed gas cylinders

If employees properly handle compressed gas cylinders (CGCs), they can safely perform many welding tasks. The following procedures will reduce the hazards of handling CGCs:

- Minimize banging and clanking of CGCs. When in storage, keep the steel protective cap screwed on. This step reduces the chance that a blow to the valve will allow gas to escape.

- Don’t let cylinders fall or have things fall on them.

- Keep CGCs secured and upright. (But never secure CGCs to conduit carrying electrical wiring.)

- When accepting an acetylene delivery, make sure it arrives upright. Don’t accept CGCs of acetylene that arrives in a horizontal position. Such CGCs may be unstable.

- Ensure valves, hoses, connectors, and regulators are in good condition. Don’t use cylinders without them or without them being in good working order.

- Check whether regulators, hoses, and gauges can be used with different gases. Assume they cannot.

- Never open valves until regulators are drained of gas, and pressure-adjusting devices are released. When opening CGCs, point outlets away from people and sources of ignition, such as sparks or flames. Open valves slowly. On valves without hand wheels, use only supplier-recommended wrenches. On valves with hand wheels, never use wrenches. Never hammer a hand wheel to open or close a valve.

- When empty, close and return CGCs. Empty CGCs must be marked “MT” or “Empty.” Empty acetylene CGCs must be so labeled.

Here are several things to ensure your employees remember when moving CGCs:

- Don’t drop or bang CGCs.

- Don’t roll, drag, or slide CGCs.

- You may roll CGCs along the bottom rim.

- Don’t lift CGCs by their cap unless using hand trucks so designed.

- Ropes and chains should only be used if a CGC has special lugs to accommodate this.

- Some CGCs may require special hand trucks.

Employees must identify gas and its dangers before they use it. They can find this information on labels, SDSs, and cylinder markings. Instruct employees not to use it if they don’t know what’s in a cylinder.

Key to remember

Whenever welding, cutting, or brazing occurs, everyone involved in the operations must take precautions to prevent fires, explosions, or personal injuries from welding hazards.