Five ways your jobsite can prevent a costly OSHA citation

An OSHA inspection may not be avoidable, but your company can do things to avoid OSHA citations.

The best ways to do this is by:

- Ensuring regulatory compliance.

- Conducting hazard assessments, safety audits, and correcting any hazards found.

- Developing and implementing a written safety and health program.

- Training workers to protect them from safety hazards.

- Keeping accurate records.

1. Regulatory compliance

An inspector’s primary task during an inspection is straightforward: To find non-compliance issues. If they don’t find any, they won’t issue a citation. And if they do find violations, the officer can choose to expand the scope of the inspection. Therefore, it’s paramount your company identifies the requirements that apply to its jobsites. Also, stay abreast of regulatory changes. Complying now doesn’t mean a company will always comply. Regulations and policies change, and new ones are issued.

2. Hazard assessment

Conducting routine hazard assessments is an excellent way to find hazards before OSHA does. Focus on the Big Four: Falls, electrocutions, caught-in or between, and struck by. OSHA continues to place an increased focus on these hazards, which are the leading causes of fatalities.

In the past, OSHA focused on these hazards only in the construction industry, but now it targets these four hazards in the general industry too. So, if you have a project that follows two different OSHA industry standards (like in the new construction area and inside existing facilities), make sure to perform a thorough assessment in each work area. If an OSHA compliance officer finds that an employer has an otherwise good safety and health program, the officer will focus mainly on these four hazard areas.

3. Safety and health program

The benefits of developing and implementing a safety and health program are varied, and many, but perhaps the greatest benefit is reducing injuries and illnesses.

OSHA says that businesses spend approximately $170 billion annually on costs associated with occupational injuries and illnesses, which comes straight out of profits. But workplaces that establish a safety and health program can reduce their injury and illness costs by about 20 to 40 percent. Better yet, they reduce their likelihood of being inspected by OSHA.

If not done already, establish a written injury and illness prevention program that outlines the job’s hazards and how they are controlled. This is another way to “find and fix” hazards before OSHA finds them. And it’s also an eligibility requirement for receiving the “good faith” penalty reduction if cited by OSHA. This reduction can be between 10 and 60 percent, depending on the size of your company. No penalty reduction will be offered to employers with more than 251 workers.

4. Training

Ensure your workers are trained for the tasks that they perform. OSHA compliance officers verify that the required training has been conducted. Training must be provided in a format that workers could understand in terms of both the language and vocabulary used.

OSHA says that employers are expected to realize that if they customarily need to communicate work instructions or other workplace information to workers at a certain vocabulary level, or in a language other than English, they will also need to provide safety and health training to their workers in the same manner.

OSHA says that if a reasonable person would conclude that necessary training had not been conveyed to workers in a manner they could understand, the violation may be cited as serious.

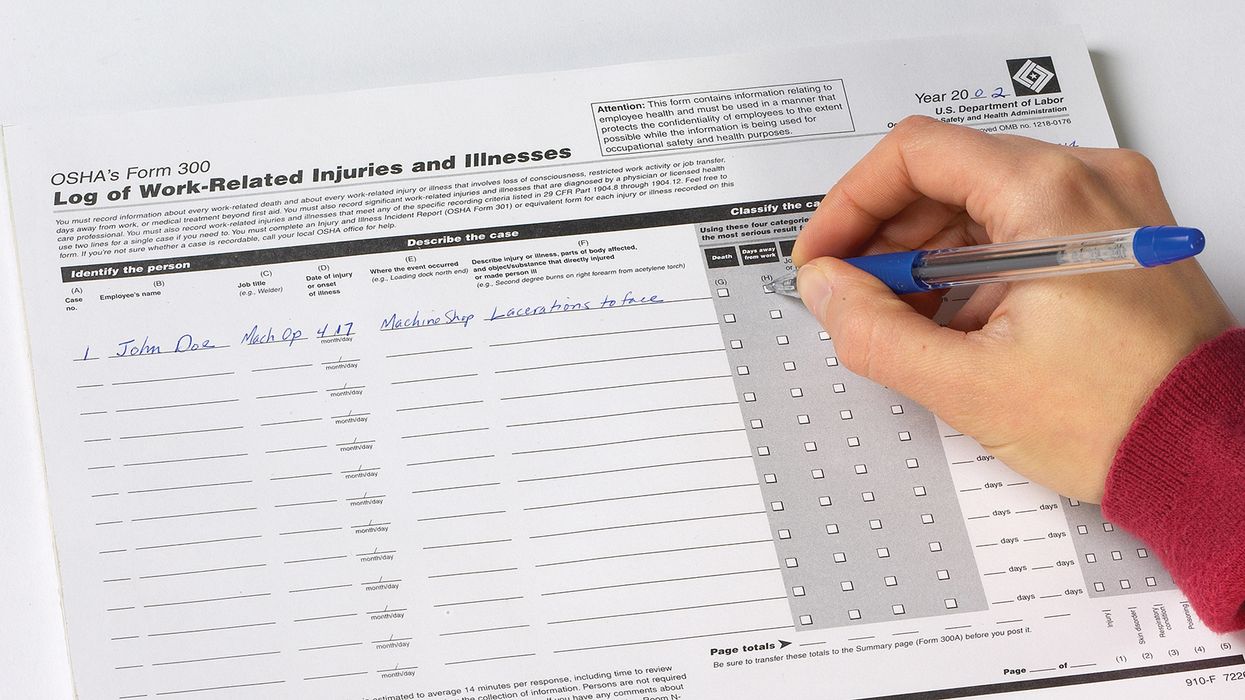

5. Records

One of the first things an OSHA compliance officer will do during an inspection is review records. Keeping accurate records is another way to avoid an OSHA citation. Focus on injury and illness records. OSHA is sincere about ensuring jobsites are not underreporting injuries and routinely issue citations specifically related to improperly recording injuries and illnesses. The term of art used in the field for this is “cooking the books.”

Perform self-inspections as an essential last line of defense. They provide a clear and concentrated focus on potential problems and will help you with these five ways to avoid an OSHA citation.

Key to remember: An inspector’s primary task during an inspection is straightforward: To find non-compliance issues. If they don’t find any, they won’t issue a citation.