Does OSHA require posting load limits for storage and working areas?

OSHA does not specifically require posting load limits on storage racks or walking-working surfaces. However, OSHA has issued General Duty Clause citations for overloading storage racks. Storage areas are treated a bit differently from employee working surfaces.

Walking-Working Surfaces

For many years, employers were required to post a plate on mezzanines, platforms, or similar work areas showing the weight capacity or load rating approved by a building official. OSHA removed that requirement in 2017, so these capacity plates are no longer required.

The current regulation at 1910.22(b) simply requires employers to ensure that each walking-working surface can support the maximum intended load. OSHA reasoned that builders consider maximum loads during design and construction.

Employers can certainly leave existing capacity plates in place and may want to check local building codes, which may still require a weight capacity posting.

Storage areas and racks

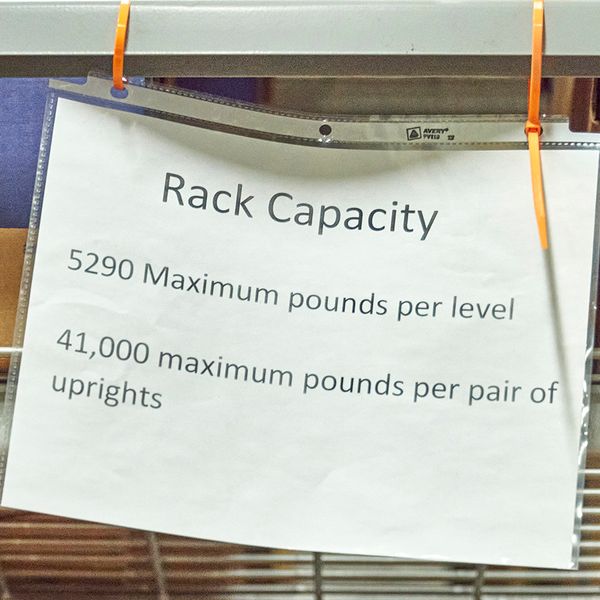

OSHA doesn’t explicitly require posting storage areas or shelves with weight capacities. Still, the agency has cited employers for unposted storage systems, particularly if a collapse occurred.

The weight of stored materials must not exceed the safe weight limits of shelving. Most industrial shelving is already labeled, helping identify capacities for each shelf or shelving unit. For shelving not labeled or built in-house, OSHA recommends determining capacity limits using sound engineering calculations, then clearly marking storage equipment with safe load capacities. Again, this isn’t technically required, but it can go a long way toward reducing human error and avoiding a possible General Duty Clause citation.

Other storage hazards

OSHA also looks to ANSI/RMI MH16.1 – Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks, which recommends securing storage racks of various types and heights. This increases their stability and decreases the potential for tipping over.

Damaged shelves or supports, improper installation, and unsafe modifications can all increase the risk of worker injury. Storage shelving must be installed appropriately, limited to a safe height, secured properly, and guarded to prevent damage.

Mitigating shelving hazards

Employers are responsible for identifying and mitigating shelving hazards in the workplace. Some effective ways of protecting workers include:

- Inspect shelving and racking regularly for damage or defects. Train workers to report any damage, loose bolts, or other concerns immediately.

- Remove any damaged shelving or immediately isolate the affected area until it can be repaired or replaced.

- Label shelving and storage racks with load capacities and do not exceed storage capacities.

- Install guards on shelving uprights to prevent damage from incidental vehicle or forklift contact.

- Ensure materials stored on shelving, racks, and other storage devices are stacked, blocked, interlocked, and limited in height so they remain stable and secure.

- Ensure that materials don’t protrude from storage areas, such as boards or other items extending into pedestrian or vehicle aisles.

- Train workers to store heavier loads on lower or middle shelves and lighter loads on higher shelves.

Every employer that maintains sales stock or manufacturing supplies needs a safe and secure way to store those items. Following these best practices helps ensure that the storage itself doesn’t create additional hazards to workers.

Key to remember: Although OSHA no longer requires posting load ratings on working surfaces, employers should have load ratings on storage areas to help prevent overloading.