CSB video exposes chemical safety failures that sparked deadly blast

A mixture of flammable vapors and resin liquid escaped through the seal of a closed manway of an operating low-pressure vessel. Then, a flammable vapor cloud spread and within minutes it found an ignition source, causing an explosion and fire. One plant employee was killed and eight others suffered third-degree burns and crushed or broken bones.

Watch the incident unfold in the latest Chemical Safety and Hazard Investigation Board (CSB) animated video. The 18-minute video explains the conditions that led to the incident and highlights key safety issues. The vessel was covered by OSHA’s Process Safety Management standard.

What happened?

An operator was overseeing a batch operation in a vessel (called a kettle) at a resin plant. While he left the room briefly, the kettle agitator unexpectedly shut down. He returned shortly but did not realize the agitator was off. Soon, the employee pushed a button to begin cooling the kettle contents. Normally, the agitator would be running, but it remained stopped.

A half hour later, the operator began adding a flammable solvent into the kettle to further cool the contents. Once the solvent was added, he waited. Meanwhile, the solvent and the hot resin did not mix, leaving the resin settled at the bottom and the solvent floating on top. After another half hour, the operator noticed that the contents were much hotter than expected. He investigated and noticed the agitator was not spinning. Immediately, he turned the agitator on.

With the agitator on, the solvent began to vaporize, increasing the pressure inside the kettle in seconds. When the pressure reached 9 pounds per square inch gauge (psig), a mixture of hot resin and flammable solvent vapor began spewing out through the seal of the manway at the top of the kettle.

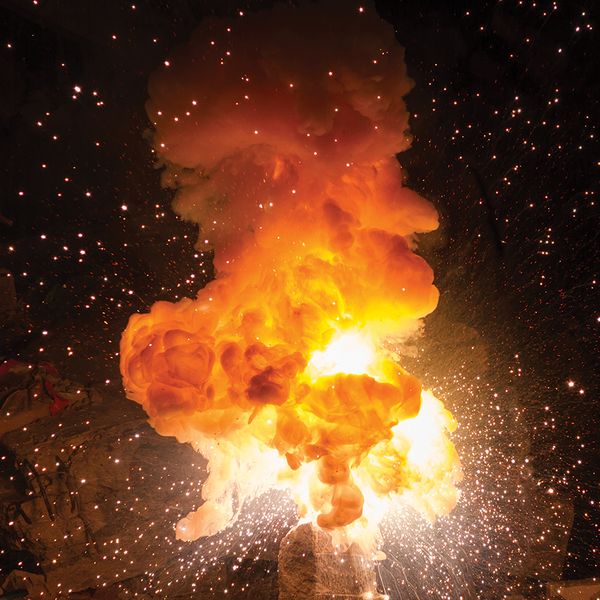

The operator had trouble seeing and breathing. Closing his eyes, he tried to find the emergency-stop button but failed. He then evacuated the kettle room 20 seconds later and escaped the plant only 30 seconds before the vapor reached an ignition source and triggered an explosion. The explosion ignited flammable materials, causing a large fire.

Some employees evacuated by running through flames. Eight were transported to area hospitals with injuries like burns and fractures. One required a leg amputation. Firefighters found one employee fatally injured by thermal injuries and inhalation of products of combustion.

Safety issues

CSB’s investigation report identified numerous safety issues:

- Lack of mechanical integrity of the new manway installed on the kettle three months before the incident. The kettle was known to potentially build pressure up to 15 psig, but the plant only leak checked it up to 4 psig. In other words, it did not adequately pressure test equipment after alterations.

- No interlocks installed or configured to prevent the addition of solvent when the agitator was off.

- Not equipping computer panel indicators with alarms to communicate the agitator status.

- Poor emergency preparedness. Some gas monitors detected the release and sent an email to an offsite employee but did not sound an audible alarm to notify onsite employees of the need to evacuate. Employees were also not trained to recognize and respond to the presence of a flammable vapor cloud and its associated hazards. (An employee approached the release to investigate instead of evacuating.)

- Lack of flame-resistant personal protective equipment (PPE). Some resin plant operators were allowed to wear cotton short-sleeved shirts while working in proximity to flammable materials. (Proper PPE may have reduced or prevented the burn injuries, CSB argues.)

Cause

CSB determined the cause of the fatal explosion and fire was the release of flammable solvent through the seal of the closed manway that was not properly designed, constructed, or pressure tested to a design pressure appropriate for the process. The absence of engineering controls, but also inadequate emergency preparedness and a lack of flame-resistant uniforms, were contributing factors.

Lessons for the chemical industry

A lot of facilities deal with flammable and other hazardous chemicals. CSB urges facilities to consider these key lessons:

- Ensure equipment can safely operate within the safe operating limits.

- After equipment alterations, assure quality for normal as well as abnormal conditions.

- Consider both mechanical and chemical risks when designing equipment.

- Use the hierarchy of controls and prevention-through-design principles.

- Install lower explosive limit (LEL) detectors that trigger automatic shutdowns of process equipment with audible and visible alarms, if the facility handles flammable materials.

- Train employees in what actions to take when alarms are activated.

- Know the hazard characteristics (e.g., dense vapor cloud formation) of the chemicals present.

- Train employees in how to identify and react to hazardous situations.

- Provide employees with PPE that is protective against the hazards they may encounter in an emergency.

Key to remember

CSB issued a video highlighting the key safety issues of a real-life incident. The video urges the chemical industry to learn from it.