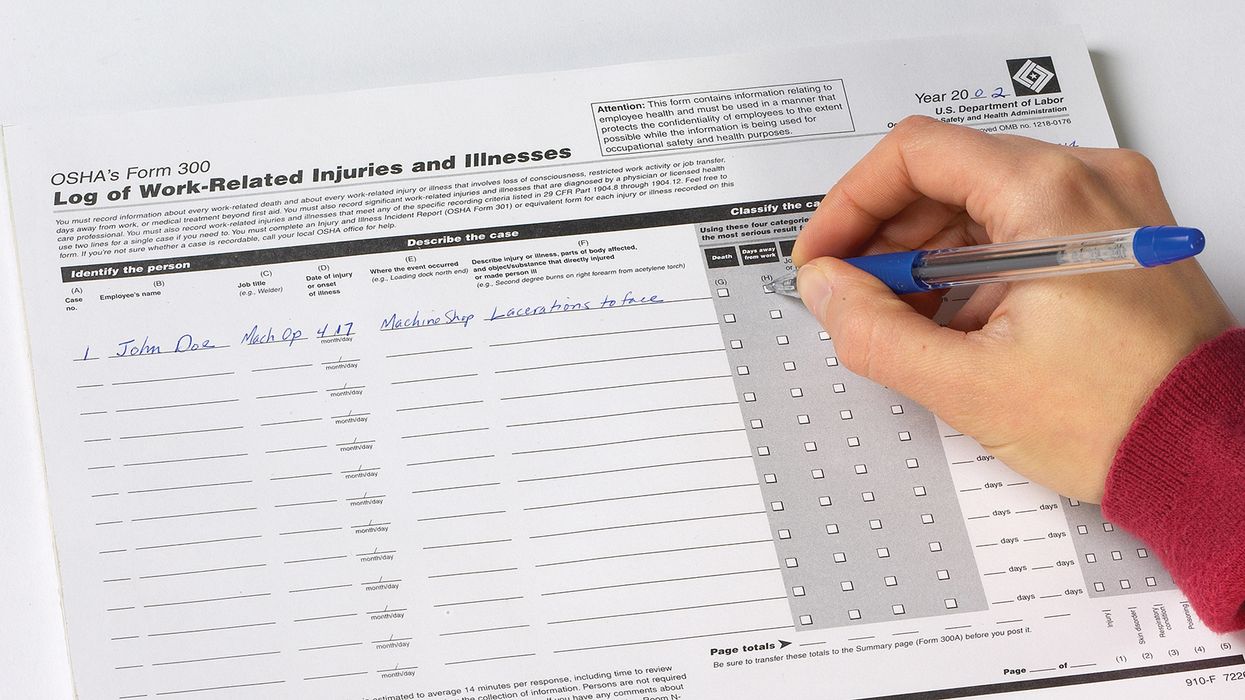

Are you as focused on combustible dusts as OSHA?

If you think you may have combustible dusts lurking in your facilities, you’ll want to know about recent updates to OSHA’s Combustible Dust National Emphasis Program (NEP). Have you been added to the list of higher-likelihood industries?

What are combustible dusts?

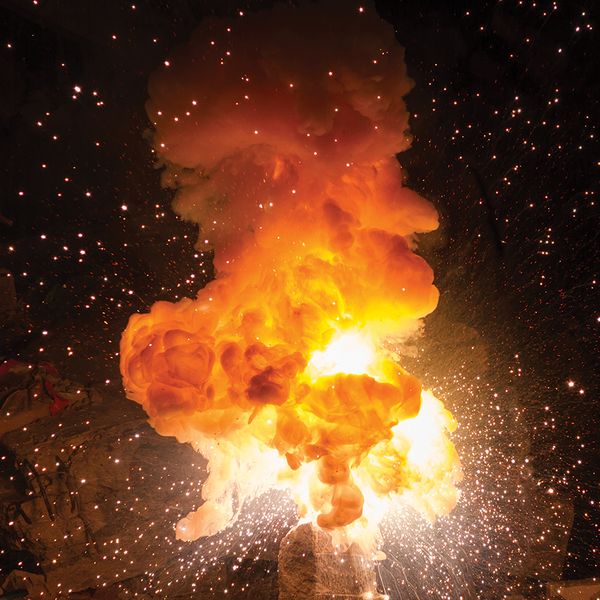

Employers are required to inspect their facilities for processes that generate or use combustible dusts and address associated fire, deflagration, and explosion hazards. So, what constitutes combustible dust? Combustible dusts are fine particles that present an explosion hazard when suspended in air under certain conditions.

The following combustible dusts can cause catastrophic loss of life, severe injuries, and building destruction:

- Metal dust such as aluminum, magnesium, and some forms of iron dusts;

- Wood dust;

- Coal and other carbon dusts, including carbon black;

- Plastic dust, phenolic resins, and additives;

- Rubber dust;

- Biosolids;

- Some textile materials;

- Organic dust such as sugar, flour, paper, and soap; and

- Dried blood.

Protecting workers from combustible dusts

Many combustible dust incidents occur without the employer or workers realizing they are in danger. They were either unaware of the potential for dust explosions or failed to recognize the serious nature of dust explosion hazards.

Hazard assessments must be performed to identify all physical and health hazards associated with combustible dusts and ensure Safety Data Sheets (SDSs) list potential exposures and controls. Employers must anticipate types of operations, material use, or downstream material processing that can generate or potentially generate combustible dusts. Operations and uses include:

- Abrasive blasting;

- Cutting, grinding, polishing, or crushing of materials;

- Conveying, mixing, sifting, or screening dry materials; and

- Building up dried residue from processing wet materials.

How easily particles ignite, or cause explosions, is dependent upon the particle size, shape, moisture content or humidity, and available oxygen. These physical characteristics can change during manufacturing, use, or while the material is being processed. The regulation at 1910.272(j)(2)(ii) requires the removal of any fugitive grain dust accumulations whenever they exceed ⅛ inch (0.32 cm) at priority housekeeping areas or to demonstrate and assure, through the development and implementation of the housekeeping program, that equivalent protection is provided. The thickness of dust must be no more than the thickness of a dime. Essentially, if a footprint can be made in the dust, there’s too much.

What changed with the NEP?

OSHA replaced its March 2008 directive with a revised NEP on January 30, 2023. The NEP added several industries with a higher likelihood of having combustible dust hazards or that have experienced combustible dust-related fatalities/catastrophes. Industries added include:

- 311812 – Commercial Bakeries

- 325910 – Printing Ink Manufacturing

- 321912 – Cut Stock, Resawing Lumber, and Planning

- 316110 – Leather and Hide Tanning and Finishing

- 321214 – Truss Manufacturing

- 424510 – Grain and Field Bean Merchant Wholesalers

Keys to remember

Too often, employers and workers were unaware of the potential for dust explosions or failed to recognize the serious nature of dust explosion hazards. OSHA has added some industries with a higher likelihood of having combustible dust hazards to the Combustible Dust NEP.