- Each employer is required to develop an energy-control program consisting of energy-control procedures, employee training, and periodic inspections.

The Occupational Safety and Health Administration’s (OSHA’s) lockout/tagout standard lays out the minimum requirements for employers whose employees are exposed to hazardous energy during the servicing and maintenance of machinery and equipment. Each employer covered by the standard must develop, implement, and enforce an energy-control program to protect employees against injury from the unexpected release of hazardous energy. Among the most critical requirements of this program for employers are to:

- Develop, implement, and enforce documented energy-control procedures;

- Use lockout devices for all energy-isolating devices that can be locked out, unless an employer can demonstrate that a tagout program will provide a level of safety equivalent to the protection provided by a lockout program;

- Ensure that all new and overhauled machinery and equipment can be locked out;

- Develop, implement, and enforce an effective tagout program if machines or equipment cannot be locked out;

- Use only lockout/tagout devices authorized for the specific machines and equipment to which they are applied;

- Ensure that lockout/tagout devices are standardized, durable, and substantial;

- Ensure that lockout/tagout devices identify their individual users;

- Permit only the employee who applied a lockout/tagout device to remove it;

- Provide effective training for all authorized, affected, and other employees covered by the standard, and document certification of this training;

- Inspect energy-control procedures at least annually and document certification of these inspections; and

- Comply with the additional energy-control provisions when machines or equipment must be tested or repositioned during servicing and maintenance, when outside contractors work at the site, when lockout is performed by a group of employees, and when shifts or personnel change.

What are the parts of an energy-control program?

- An energy control program is made up of energy-control procedures, training for those procedures, and inspections of employees following those procedures.

- Each energy-control procedure specifies the necessary steps to control hazardous energy on a particular machine or piece of equipment.

The Occupational Safety and Health Administration’s (OSHA’s) lockout/tagout standard requires employers to establish an energy-control program tailored to the machinery and equipment in each workplace to protect employees from the unexpected release of hazardous energy during servicing and maintenance activities. An energy-control program includes:

- Energy-control procedures, which specify the steps employees must take to isolate machines and equipment from their energy sources and to render them safe for employees to perform servicing and maintenance;

- Employee training, which teaches authorized employees, affected employees, and other employees their responsibilities as laid out by the energy-control procedures; and

- Periodic inspections of employees performing the energy-control procedures, which ensure the procedures are followed and understood.

Lockout vs. tagout

At the core of an employer’s energy-control program are the protective tools that control hazardous energy: the energy-control devices. There are two types of energy-control device:

- Energy-isolation devices¸ which physically prevent the transmission and release of energy; and

- Lockout/tagout devices, which are applied to energy-isolation devices to prevent them from being operated during servicing and maintenance.

Together, when properly used, energy-isolation devices and lockout/tagout devices protect employees from the unexpected energization of machines and equipment.

There are two kinds of energy-isolation device:

- Energy-isolation devices that are capable of being locked out, and

- Energy-isolation devices that are incapable of being locked out cannot be locked out.

The specific lockout/tagout devices that employers must provide to employees depends in large part on whether the energy-isolation devices on machinery and equipment in their workplaces are of one kind or another.

These two kinds of energy-isolation device correspond to two kinds of lockout/tagout device:

- Lockout devices, which when fastened to energy-isolation devices that can be locked out physically hold them in place; and

- Tagout devices, which display prominent warnings against operating energy-isolation devices while the tagout devices are in place.

OSHA requires employers to use lockout devices on energy-isolation devices that are capable of being locked out. On energy-isolation devices that are incapable of being locked out, OSHA requires tagout devices to be fastened as close as possible to the energy-isolation device to communicate their warnings as clearly as possible.

There is one exception to the lockout device requirement:

- An employer may have employees use tagout devices on energy-isolation devices that are capable of being locked out only if that employer demonstrates that the tagout program provides full employee protection. Full employee protection requires the use of additional protective measures: ...

Stand-alone tagout system

If, due to equipment age or construction, a lockout device cannot be used, the employer’s energy-control program must use a tagout system. If an energy-isolating device is capable of being locked out, it must be locked out during service and maintenance operations unless the employer can demonstrate that a tagout system provides full employee protection.

When a tagout system is used instead of lockout, the employer must supplement tagout with additional means to ensure full employee protection. These additional means could include the removal of an isolating circuit element, blocking of a controlling switch, opening of an extra disconnecting device, or the removal of a valve handle to reduce the likelihood of inadvertent energization. Tagout alone does not physically prevent activation of the control, and it may give a false sense of security to the employee. Further training will be required if the employer must use a tagout system.

Whenever machines or equipment are installed, replaced, renovated, modified, or repaired, the energy-isolating devices on such machines and equipment must be designed to accept a lockout device.

Energy-control procedures

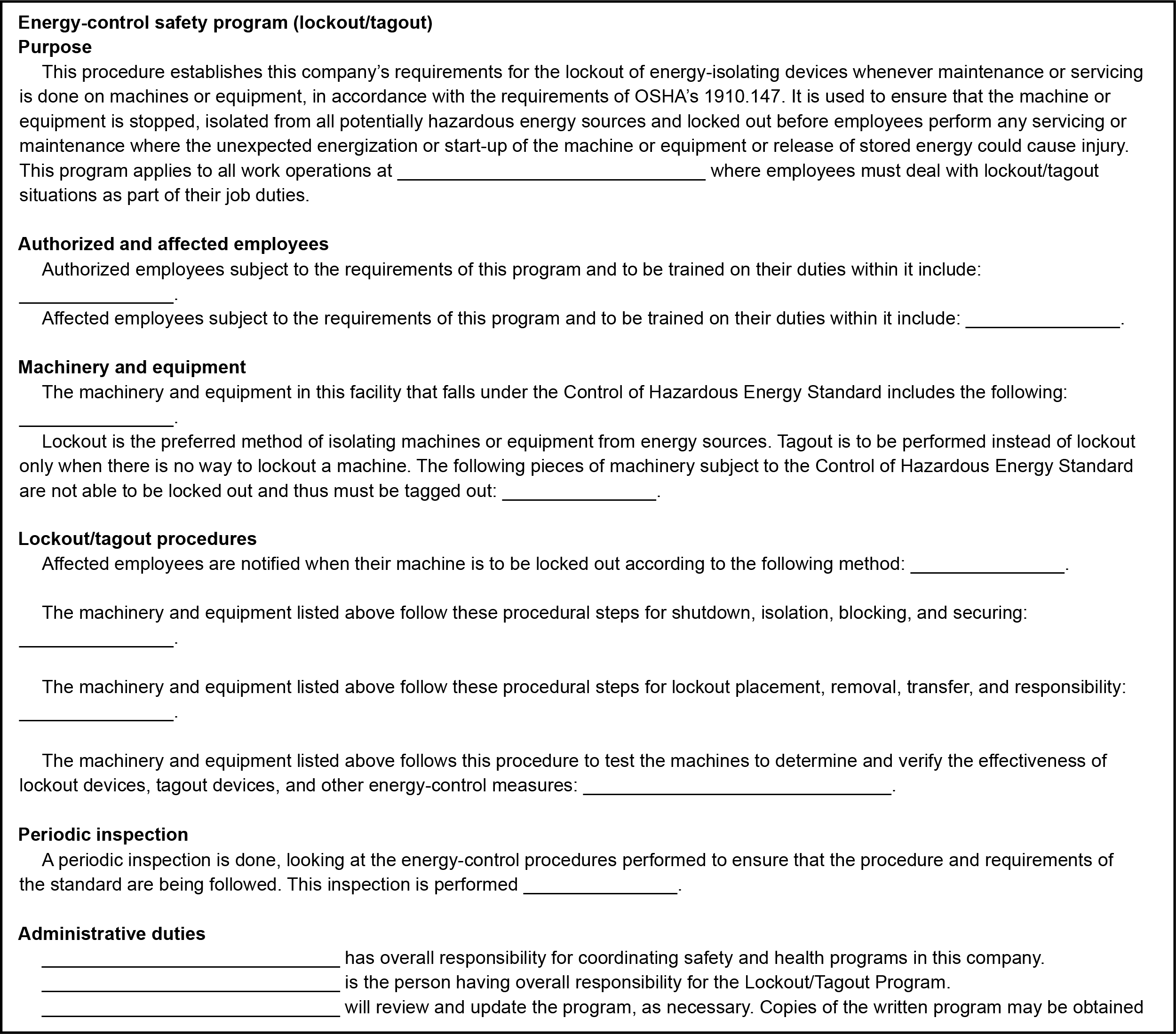

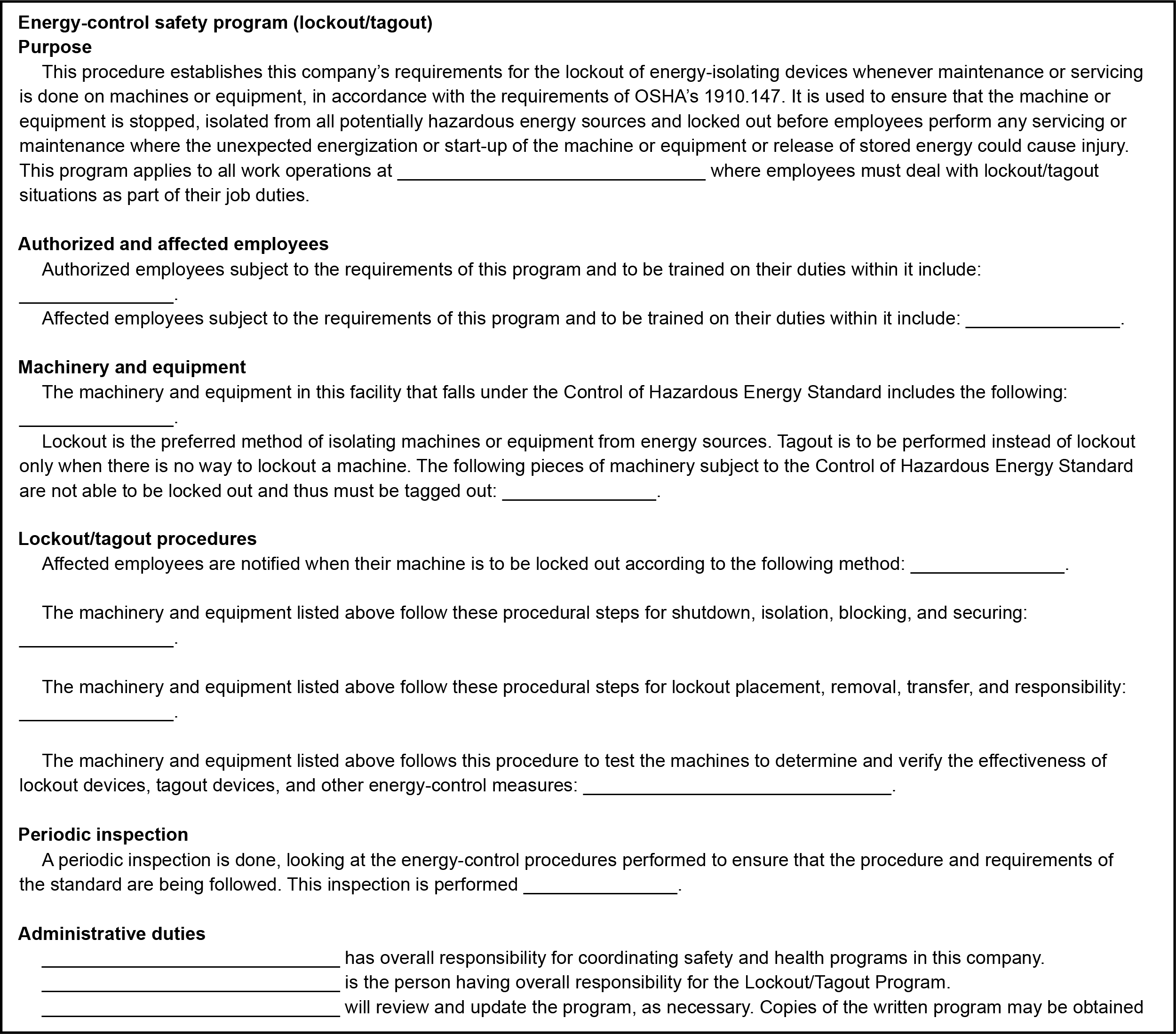

Each employer must develop and document energy-control procedures for isolating machines and equipment in the workplace from their energy sources before any employees may service or maintain them. An energy-control procedure serves to guide employees through the application of lockout or tagout devices to energy isolation devices to disable a machine or piece of equipment inoperative and safe to service.

At minimum, each of an employer’s energy-control procedures must clearly specify the scope, purpose, authorization, rules, and techniques that employees will use to control potentially hazardous energy. To guide employees effectively, each written energy-control procedure must provide them with at least the following information:

- A specific statement on how employees are intended to use the procedure;

- Which employees are authorized to perform the procedure;

- The employer’s means for enforcing compliance;

- Each specific step for shutting down, isolating, blocking, and securing a machine or piece of equipment;

- Each specific step for placing, removing, and transferring lockout or tagout devices;

- Each specific step for releasing, draining, or otherwise controlling stored energy; and

- Each specific requirement for testing a machine to verify that lockout devices, tagout devices, and any other energy-control methods are effective.

If the information employees need to control hazardous energy effectively is the same for multiple machines in the workplace, then a single written procedure may be used for all such similar machines. However, machines or equipment with, for example, different kinds of energy sources, different energy-isolating devices, or different procedural steps to follow require separate written energy-control procedures.

NOTE: Exception to documentation requirements

Employers are not required to document an energy-control procedure for a particular machine or piece of equipment only if each of the following eight conditions apply:

- The machine or equipment has no potential for stored or residual energy, or the re-accumulation of stored energy after shutdown;

- The machine or equipment has a single energy source which can be readily identified and isolated;

- The isolation and locking out of that energy source completely de-energizes and deactivates the machine or equipment;

- The machine or equipment is isolated from that energy source and locked out during servicing or maintenance;

- A single lockout device achieves a locked-out condition;

- The lockout device is exclusively controlled by the authorized employee performing the servicing or maintenance;

- The servicing or maintenance does not create hazards for other employees; and

- The employer has had no accidents involving the unexpected activation or re-energization of the machine or equipment during servicing or maintenance.

What are required steps of an energy-control procedure?

Energy-control procedures guide employees through the necessary steps for safely controlling hazardous energy on machines specific and equipment. Each energy-control procedure must detail, in the proper order, the six procedural steps for applying lockout/tagout to a given machine or piece of equipment before servicing or maintenance begins and the five procedural steps for releasing that machine from lockout/tagout after servicing or maintenance is complete. The six steps for applying lockout/tagout are:

- Preparation for shutdown,

- Shutdown,

- Energy isolation,

- Application of lockout/tagout devices,

- Release of stored energy, and

- Verification of isolation.

Verification of isolation is critical and can never be overemphasized in training.

An energy-control procedure must also detail the steps for releasing a machine or piece of equipment from lockout/tagout once servicing and maintenance have been completed. The five steps for releasing machinery and equipment are:

- Inspection of system components,

- Checking for safe positioning,

- Removal of lockout/tagout devices,

- Notification of removal, and

- Safe re-energization.

Authorized employees

Importantly, the only employees who may perform energy-control procedures on machines and equipment are the employees who service and maintain them. It is essential that those employees who are exposed to hazardous energy during servicing and maintenance activities are the ones responsible for taking the procedural steps that protect against energization hazards.

Documenting LOTO events

The standard does not include any requirement to fill out or keep a log or other record of lockout/tagout events. If the employer keeps service or maintenance logs as a “best practice,” it would be up to that employer to establish whatever procedures and record retention times that best fit the need of the company.

What are the steps for applying controls?

Workers must follow their employer’s energy control plan while applying LOTO controls to avoid exposure to hazardous energy.

- Preparation for shutdown

The first step in an energy-control procedure is ensuring two conditions are met before a machine or piece of equipment is shut down. First, employers must ensure that each authorized employee who will perform servicing or maintenance knows the following information: - The types and magnitude of the energy to be controlled,

- The hazards this energy poses, and

- The devices and methods used to control this energy.

Second, an employer or authorized employee must notify all affected employees that lockout or tagout devices are about to be applied. Notifying affected employees before these devices are applied lets them know that the machine or piece of equipment will be off-limits for servicing and maintenance, which is essential for preventing employees from trying to operate locked out or tagged out machinery and equipment. - Shutdown

Once these conditions are satisfied, the machine or equipment must be turned off or shut down using the stop button or other normal stopping method. - This is the only step in an energy-control procedure that affected employees may perform as well as authorized employees. The limited involvement of affected employees serves to keep shutdown orderly and minimize additional hazards.

- Energy isolation

Once a machine or piece of equipment has been shut down, authorized employees must de-energize it by locating each energy-isolating device and setting each in the “safe” or “off” position. - Depending on the machine, operating energy-isolating devices may involve operating disconnect switches, closing valves, or other methods. Though different in structure, these all serve to physically separate or disconnect machines and equipment from their sources of energy.

- Because the number and layout of energy-isolating devices can be elaborate on complex machinery and equipment, an employer’s energy-control procedure needs to identify all energy-isolating devices for employees to locate.

- Application of lockout/tagout devices

Once all necessary energy-isolating devices are set to “safe” or “off,” authorized employees must apply to them the appropriate lockout devices (“locks”) or tagout devices (“tags”). - If the energy-isolating devices on a machine or piece of equipment can be locked out, then authorized employees must secure the appropriate locks to the energy-isolating devices so the latter are held in the “safe” or “off” position.

- If energy-isolating devices cannot be locked out or if a tagout program is used, authorized employees must secure tags as close as is safely possible to those energy-isolating devices so it is obvious that taking the latter out of the “safe” or “off” position is prohibited.

- Release of stored energy

After locks or tags are applied, authorized employee must relieve, disconnect, restrain, or render safe all potentially hazardous stored or residual energy in the machine or equipment. - Stored energy is potential energy that remains present in machines and equipment even after they are isolated from their energy sources. Each energy-control procedure must identify the types and sources of stored energy, such as capacitors, line pressure, and elevated parts, and explain what authorized employees must do to dissipate or strain it from these sources.

- If stored energy could reaccumulate in a machine or piece of equipment while employees perform servicing or maintenance service and maintain the machine or equipment, the employer must continually verify that the machine remains isolated to ensure no hazards arise. If hydraulic or pneumatic systems are present, bleed valves may be necessary to relieve built-up pressure.

- Verification of isolation

Finally, authorized employees must verify that energy isolation is complete and that the machinery or equipment is safe for servicing and maintenance. - Isolation can be verified by using test equipment, checking gauges, or by trying to restart the machinery or equipment.

- Authorized employees must always return all controls to the “off” or “stop” position following this verification step to ensure that no machine or piece of equipment starts automatically when power is restored. This is especially important for computerized machinery and equipment whose controls are programmed to remember and act on their last commands.

What are the steps for removing controls?

After servicing and maintenance is complete, authorized employees must follow the written procedural steps for reenergizing and starting up machinery and equipment.

- Inspection of system components

Authorized employees must first inspect a machine or piece of equipment to confirm that it has been returned to safe operating condition. Employees must check and ensure that:- All tools and other nonessential items have been removed,

- All safeguards removed during servicing or maintenance are reinstalled or replaced, and

- All controls at the control panel remain in the “off” or “stop” position.

This inspection is essential for worker safety: tools left behind in a machine or piece of equipment can damage it when it is reenergized, which can cause injury, downtime, and product loss; missing safeguards, meanwhile, leave employees exposed to hazardous areas when normal operations resume. For large, complex machinery and equipment, checklists or other administrative means may be necessary to ensure these inspections are sufficiently thorough. - Checking for safe positioning

Once they have completed the system inspection and reinstalled all guards, authorized employees must ensure that all affected and other employees in the area are positioned at a safe distance away from the machine or equipment before it is reenergized. - Alarms or other warning devices may be necessary for large machinery that blocks the sightlines of authorized employees.

- Removal of lockout/tagout devices

When the safe positioning of employees in the area is confirmed, each lockout or tagout device must be removed from its energy-isolating device by the authorized employee who applied it. The identity of this employee must be indicated on the device itself. - Notification of removal After authorized employees have removed lockout or tagout devices and before machinery or equipment is started up, the authorized employees or the employer must notify all affected employees that lockout or tagout devices have been removed.

- These notifications ensure that employees are safely positioned away from machines and equipment before they are reenergized.

- Restoration of energy

When these notifications are complete, an authorized employee can start the machine or equipment to confirm that it is functioning properly and is safe for normal operations to resume.

NOTE: Removal of a lockout device by others

Only the authorized employee who applies a lockout or tagout device may remove it. However, when this employee is unavailable, the employee’s device may be removed by another employee only if specific procedures documented in the employer’s lockout/tagout program are followed. The requirements of this specific procedure are that:

- The employer demonstrates that this specific procedure provides equivalent safety to that provided by the removal of the lockout or tagout device by the authorized employee who applied it,

- The employer verifies that the authorized employee who applied the device is absent from the facility,

- The employer makes all reasonable efforts to contact this authorized employee to report that the employee’s lockout/tagout device has been removed, and

- The authorized employee is informed that the device was removed before that employee resumes work at the facility.

The employer should not remove a lock without speaking to the employee who applied it. Whenever someone other than the employee who applied a lock or tag removes it, the machine or piece of equipment must be fully inspected by a qualified person to ensure that servicing or maintenance is complete and that it is safe to operate. If the authorized employee left the lock or tag in place out of negligence, the employer should strongly consider retraining or disciplinary action.

While bolt cutters or other device-destructive methods are permissible means to remove a lockout device, an employer’s specific procedure may use non-destructive methods if the employer demonstrates that it provides a degree of safety that is equivalent to the removal of the device by the authorized employee who first affixed it. A master key procedure, under which an employer has access to a key capable of opening multiple lockout devices, complies with the standard only if it includes a reliable method to ensure that access to the master key is carefully controlled by the employer. Safety is ensured through effective procedures that respect the sanctity of another employee’s lockout or tagout device.

What are the requirements for lockout/tagout devices?

- Lockout and tagout devices must be standardized, durable, substantial, and properly labeled.

All employers must provide authorized employees with lockout and tagout devices that meet the requirements of the lockout/tagout standard. These are the only devices that may be used with energy-isolating devices to control hazardous energy during servicing or maintenance, and neither type of energy-control device may be used for any other purpose.

While it’s easier to speak of “locks and tags” than always of “lockout and tagout devices,” different energy-isolating devices will need different protective hardware. To ensure that all such lockout and tagout devices remain easily noticeable and securely attached throughout servicing and maintenance, the Occupational Safety and Health Administration (OSHA) requires all lockout and tagout devices to be:

- Standardized

- Durable

- Substantial

- Labeled

Because lockout and tagout devices must be easily recognized by employees and contractors, all lockout and tagout devices in a facility must be standardized in one or more of the following ways:

For tagout devices, it is also a requirement that all text be standardized in both print and format.

Non-standardized devices make it difficult to distinguish what is locked out for servicing and maintenance from what is simply locked up. If the same kind of locks an employer assigns as lockout devices are also found on toolboxes or lockers in the employer’s facility, that employer is out of compliance with the standard.

Durable

All lockout and tagout devices must be resistant to wear and capable of withstanding the environment they are exposed to for the maximum period that exposure is expected. Tagout devices must be made and printed so that neither exposure to weather conditions, wet and damp locations, nor corrosive environments would cause tags to deteriorate or their messages to become illegible.

Substantial

Lockout devices must be substantial enough to be irremovable without the use of excessive force or unusual techniques, such as bolt cutters or other metal-cutting tools. For example, a simple little brass luggage lock is neither durable nor substantial enough to be used as an acceptable lockout device.

Tagout devices and their means of attachment must be substantial enough to prevent unintentional removal. The means of attachment for a tag must be:

- Attachable by hand,

- Self-locking,

- Non-releasable,

- Made with a minimum unlocking strength of 50 pounds,

- Designed with basic characteristics at least equivalent to a one-piece, all environment-tolerant nylon cable tie, and

- Made of non-reusable material.

- NOTE: Many employers mistake this to mean that the tags cannot be reused — the tags can be reused, but the attachment mechanism cannot.

Labeled

Each lockout device and tagout device must identify the authorized employee who applies it, using, for example, a warning tag attached to a lock’s hasp or an engraving. This identifies the person to ask about the status of the machine or equipment to which the lock or tag is applied and ensures that, after servicing or maintenance is complete, the employer can readily determine who is missing if a lock or tag is still in place.

These tags must warn employees that the machine or equipment is not to be energized and be properly labeled to accomplish this, with warnings such as “Do Not Start” or “Do Not Open.”

What training do employees need for lockout/tagout?

All employees working in areas where energy-control procedures are used must be trained in their duties under lockout/tagout. At minimum, an employer’s training program must cover:

- A review of the employer’s energy-control program,

- The elements of each energy-control procedure that relate to the employees’ duties, and

- The relevant requirements of the lockout/tagout standard (29 CFR 1910.147).

The specific training an employee receives depends on whether that employee is an authorized employee, affected employee, or other employee.

Authorized employees

Authorized employees must be trained:

- To recognize sources of hazardous energy,

- To understand the types and magnitudes of energy available to machinery and equipment and in the workplace,

- To know which lockout/tagout devices are used with which energy-isolation devices,

- To locate the energy-isolating devices on each machine and piece of equipment,

- To use the proper sequence for applying lockout/tagout devices to and removing them from the energy-isolating devices; and

- To only remove one’s personal lockout/tagout devices from energy-isolation devices.

Affected employees

Affected employees must be trained:

- On the purpose and use of energy-control procedures.

- To be alert and responsive to notifications about lockout/tagout activities in their areas,

- To stay clear of machinery and equipment when notified that lockout/tagout devices are going to be applied, and

- To position themselves a safe distance away when notified that lockout/ tagout devices have been removed.

Other employees

Other employees must be trained.

All employees working in areas where energy-control procedures may be used must be instructed about those procedures and must understand that they are prohibited from tampering with lockout/tagout devices and from restarting or reenergizing locked or tagged out machinery and equipment.

Employees not authorized to operate machinery must always stay clear of machinery and equipment when it is locked out for repairs. For instance, administrative employees delivering messages to employees in the work area must be able to identify and avoid contacting lockout devices, even if another employee asks for assistance.

This training does not have to be drawn out. Training is sufficient so long as it covers what lockout/tagout devices look like and that only trained, authorized employees can handle them.

Training for tagout programs

If a tagout program is used instead of a lockout program, further training is required for employees. Tagout training must ensure that all employees understand the limitations of tags: tags are warning devices that do not provide the same level of protection as lockout devices, which physically restrain the position of energy-isolation devices. Employees using tagout devices must be trained to understand that tagout devices might evoke a false sense of security.

As with lockout devices, a tagout device may only be removed by the authorized employee who attached it. Further, tagout devices should never be bypassed, ignored, or otherwise defeated, and must always be positioned so that their warnings against the hazards of energization, such as “Do Not Start,” are clearly visible and easily legible.

Retraining

The employer must retrain all authorized and affected employees whenever there is:

- A change in their job assignments;

- A change in machines, equipment, or processes that present a new hazard; or

- A change in the energy-control procedures.

Additional retraining is required whenever an inspection reveals or an employer reasonably suspect that an employee fails to understand or comply with the steps of an energy-control procedure.

For example, if an inspection reveals that an employee uses a lock other than the employee’s personal lockout device, that employee must be retrained. The retraining, along with the initial training, must establish employee proficiency and introduce new or revised control methods and procedures, as necessary.

Certification of training

The employer is required to certify that each trained employee has the knowledge, skills, and understanding to work safely. The certification must contain each employee’s name and the training date. Authorized employees and affected employees must be retrained whenever they have a change in job assignments or whenever a change in equipment, process, or energy-control procedures could expose them to a new hazard. Inspections that reveal inadequacies also trigger retraining.

The employer is required to certify that employee training has been accomplished and is being kept up to date. This certification must include the employee’s name and the dates of the training. Certifications must be updated after any refresher training.

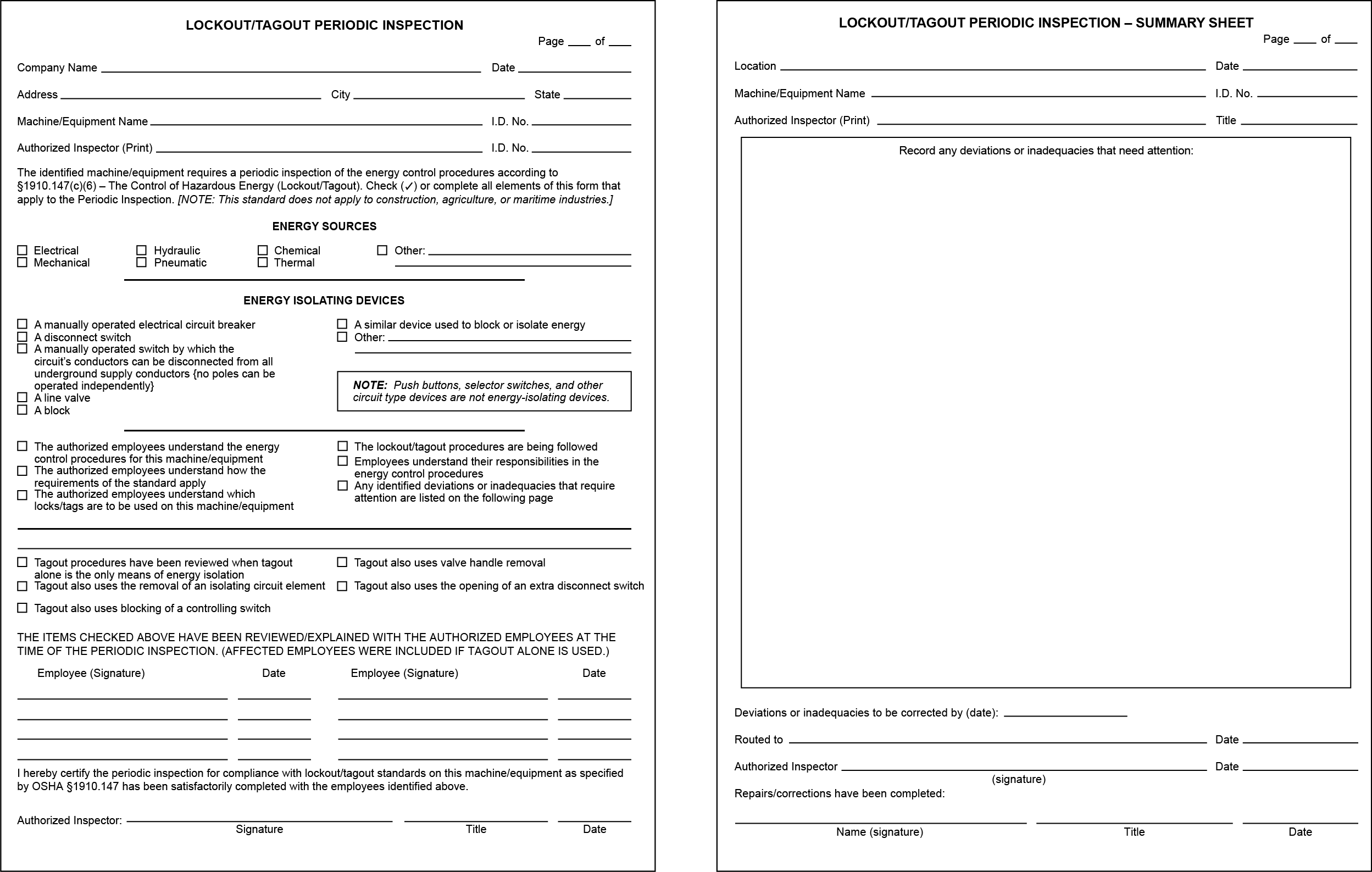

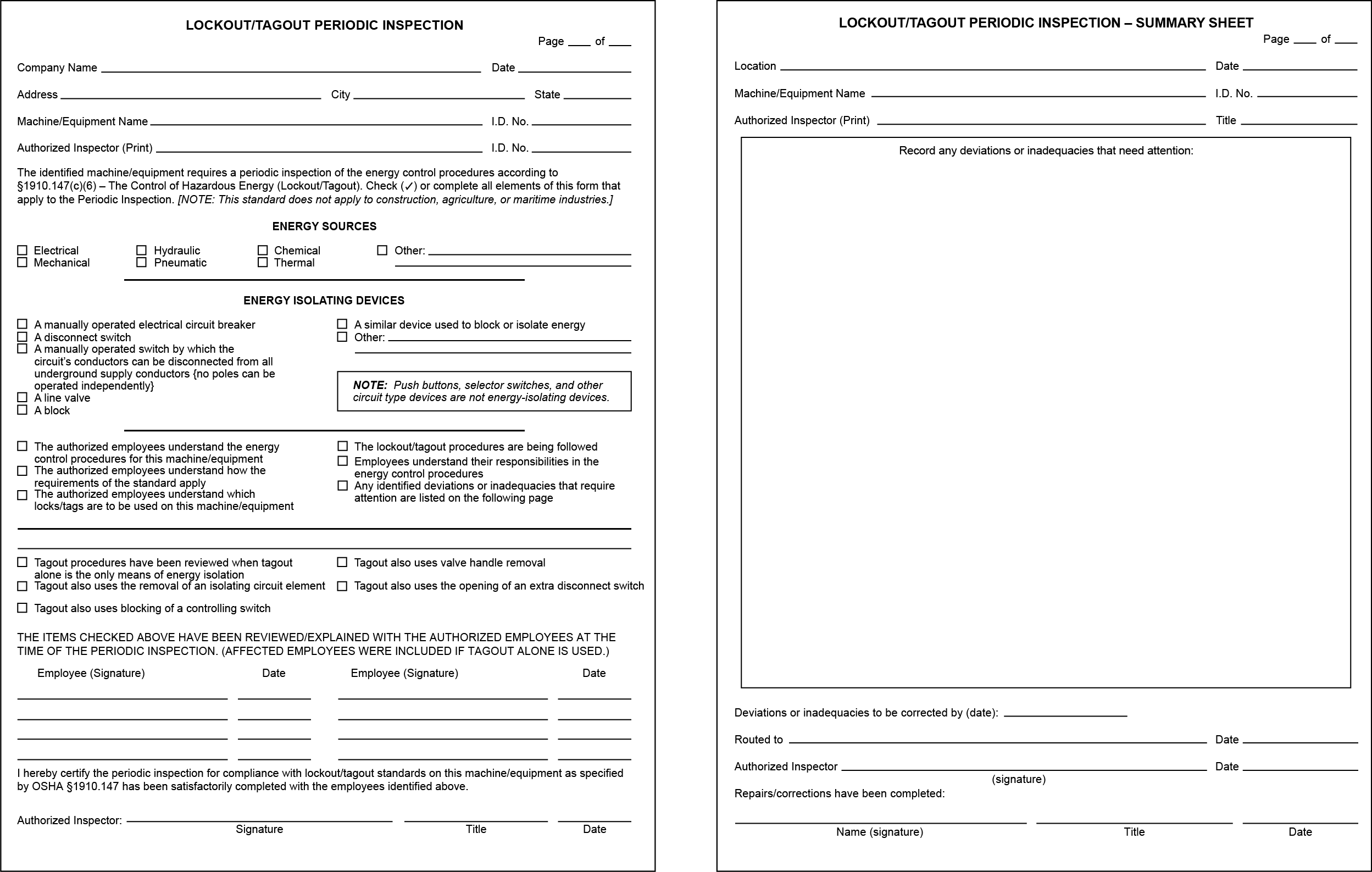

What are the requirements for periodic inspections?

- Employers must conduct inspections of employees following energy-control procedures at least annually.

To ensure that employees perform the steps of each energy-control procedures correctly, inspections of authorized employees following each of an employer’s energy-control procedures must be conducted at least annually. Each of these periodic inspections is to be administered by an authorized employee other than the employee(s) using the energy-control procedure being inspected.

The periodic inspection is oriented around identifying deviations from procedure so they can be corrected. During an inspection, the inspector must observe how employees implement the steps of the procedure and talk with them to determine that all requirements are understood and followed. After the inspection, the inspector must prepare a certification statement that specifies:

- The machine or equipment inspected,

- The date of inspection,

- The names of employees included in the inspection, and

- The name of the inspector.

The format and recordkeeping method for documenting these certifications is up to the employer. The format for the inspections themselves is also reasonably flexible. So long as they meet the requirements listed here, periodic inspections may be accomplished through random audits, plant safety tours, or planned visual observations.

If the inspector identifies any deviations or inadequacies, employers must ensure that appropriate corrective action is taken, including retraining or disciplining any employees who failed to follow procedures.

- For any procedure using lockout devices, an inspector will speak with each authorized employee implementing it about that employee’s responsibilities under the procedure.

- For any procedure using tagout devices, an inspector will speak with each authorized employee and each affected employee both about that employees’ responsibilities under the procedure and about the limitations of tagout devices.

The periodic inspection must include a review of the responsibilities of each authorized employee implementing the lockout procedure. Group meetings between the inspector and authorized employees would constitute compliance with this requirement. When a tagout system is used, each affected employee is to be included in the review as well.

Two qualifications

Procedures used less often than once a year are exempt from the once-yearly requirement, and only need to be inspected when used.

For inspection purposes, the Occupational Safety and Health Administration (OSHA) allows employers to group lockout/tagout procedures for similar machines and conduct one inspection for the group. This approach is acceptable so long as the inspection sampling reasonably reflects plant servicing and maintenance operations and hazardous energy-control practices for the procedures being inspected.

The machines or equipment in the group must have the same or similar types of control measures.

For purposes of procedure grouping, machines and equipment may be grouped together as one procedure if they all are listed or identified in the scope of the energy-control procedure and if they all have the same or similar:

- Procedural steps for shutting down, isolating, blocking, securing, and dissipating stored energy in machines or equipment;

- Procedural steps for the placement, removal, and transfer of the lockout or tagout devices and the responsibility for them; and

- Requirements for testing a machine or equipment to verify that lockout or tagout devices and other control measures are effective.

For example, a single procedure intended to cover a group of machines and that part of the energy-control procedure requires using a start/stop button for both shutdown and energy-isolation verification. However, one of the machines does not have a start/stop button because it is wired directly to an electronic on-demand signal. In this scenario, the single procedure will not provide adequate instructions for the machine without a start/stop button because the single procedure will not provide sufficient employee guidance on how to effectively shut down the machine and verify energy isolation. The energy-control procedure for this machine may not be included in the group.

Employers who develop specific energy-control procedures for individual machines and pieces of equipment may still to group similar procedures for inspections if the procedures meet these criteria.

Working on energized equipment

It may be necessary to energize equipment to perform tests or reposition parts during servicing. The procedures for the testing or positioning of machines, equipment, or components in situations where lockout/tagout devices must be temporarily removed must follow this specific sequence:

- Clear the machine of tools and materials and remove all employees in the danger area.

- Have the authorized employee remove the lockout/tagout devices.

- Energize the equipment for the test.

- Test the equipment.

- De-energize the equipment after testing and reapply the lockout/tagout devices.

OSHA allows the temporary removal of lockout or tagout devices and the re-energization of the machine or equipment ONLY during the limited time necessary for the testing or positioning of machines, equipment, or components. Note that OSHA does not specifically require the reinstallation of machine guards during these procedures, but it is very important for employees to be safely positioned while the machine or equipment is energized. After the completion of the temporary re-energization, the authorized employees shall again de-energize the equipment and resume lockout/tagout procedures.

Group lockout

When more than one authorized employee services or maintains a machine, the group must use an energy-control procedure that protects each employee to the equivalent extent of a personal lockout or tagout device. Each authorized employee must affix a personal lockout or tagout device to a group lockout device, group lockbox, or comparable mechanism upon beginning work and must remove that personal device upon stopping. working on the machine or equipment being serviced or maintained.”

For example, if a single lockout device or set of lockbox devices (often referred to as “operations locks”) are used to isolate the machine or equipment from its energy sources, all authorized employees must be able to use their personal lockout or tagout devices so that no single employee can remove the group device while other employees are still servicing or maintaining the machine or equipment. This can be accomplished using a lockbox or other similar appliance.

Once the machine or equipment is locked out, the keys to the operations locks that were applied to the machine’s energy-isolating devices are placed into the lockbox. Then all authorized employees place their lockout or tagout devices on the box. When employees complete their individual portions of the work, they remove their individual lockout or tagout devices from the lockbox. Once all personal lockout or tagout devices have been removed, the keys for the operations locks can be used to remove the locks from the machine. This method provides individual protection for all employees working under the protection of a particular lockout or tagout device.

However group lockout is performed, the employer needs to ensure that employees are protected. Further, the employer should note that when more than one craft is involved in the group lockout, the different craft personnel must coordinate work to ensure continuity of protection.

Shift changes

The continuity of lockout or tagout protection during shift changes requires that a procedure for orderly transferring lockout or tagout devices between outgoing and incoming employees be included in the written energy-control procedures. A multiple-lock hasp may be used so incoming employees can apply their locks before outgoing employees remove their locks.

Following a shift change and before starting work, each group of incoming authorized employees must reverify that a locked or tagged out machine remains isolated and de-energized.

In situations where outgoing employees remove lockout or tagout devices before the incoming employees arrive, such as a change from second-shift to first-shift employees, this procedure could allow for outgoing employees to apply a tagout device to indicate that the lock had been removed but the machine or equipment had not been reenergized. Any incoming employee would verify that the system was still de-energized, would remove the interim tag, and would replace it with a personal lockout device. This would ensure that continuous protection is maintained from one shift to another.

Contractors

- The host employer has specific responsibilities for contractors that come on-site.

Host employers must assess contractors’ safety policies to ensure that the contractors’ employees are properly trained and that contractors have the appropriate written programs in place.

Before the contractor starts work, the host employer and the contractor employer are required to inform each other of their respective lockout/tagout procedures and the hazards involved in the task at hand. The host employer then must inform employees about the contractor relationship and how to safely interact with the contractor’s employees. The contractor must also communicate this information with the contractor’s employees.

Both employers must comply with the minimum standards. If the host employer takes a direct supervisory role over the contract employees (telling the contract employees what to do when they are on-site), then the host employer becomes responsible for training the contract employees. Typically, temporary employees who are hired through an agency would fall into this category. Supervising host employers could be cited when an on-site contractor does not comply with the Occupational Safety and Health Administration standards.