What are the parts of an energy-control program?

- An energy control program is made up of energy-control procedures, training for those procedures, and inspections of employees following those procedures.

- Each energy-control procedure specifies the necessary steps to control hazardous energy on a particular machine or piece of equipment.

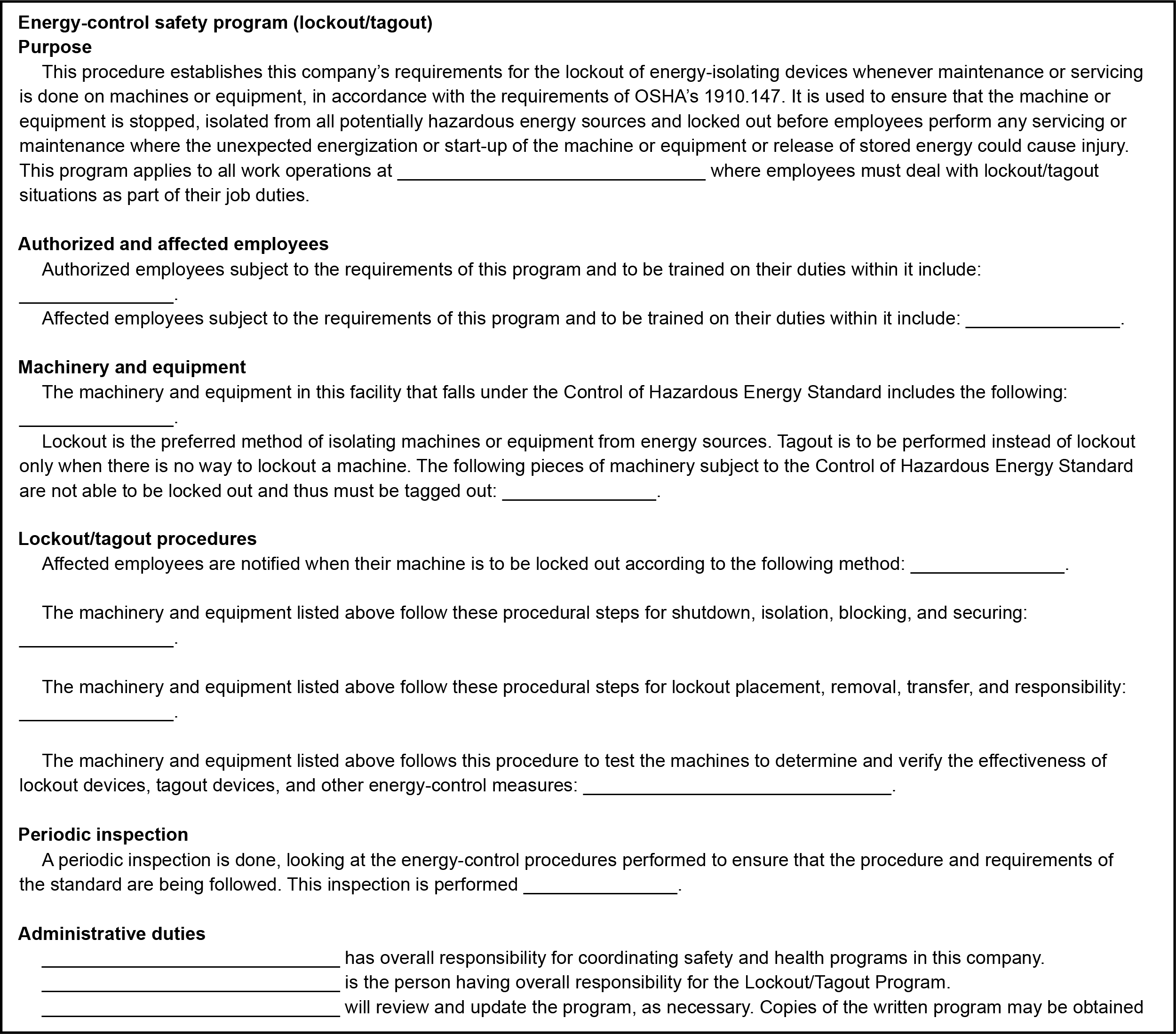

The Occupational Safety and Health Administration’s (OSHA’s) lockout/tagout standard requires employers to establish an energy-control program tailored to the machinery and equipment in each workplace to protect employees from the unexpected release of hazardous energy during servicing and maintenance activities. An energy-control program includes:

- Energy-control procedures, which specify the steps employees must take to isolate machines and equipment from their energy sources and to render them safe for employees to perform servicing and maintenance;

- Employee training, which teaches authorized employees, affected employees, and other employees their responsibilities as laid out by the energy-control procedures; and

- Periodic inspections of employees performing the energy-control procedures, which ensure the procedures are followed and understood.

Lockout vs. tagout

At the core of an employer’s energy-control program are the protective tools that control hazardous energy: the energy-control devices. There are two types of energy-control device:

- Energy-isolation devices¸ which physically prevent the transmission and release of energy; and

- Lockout/tagout devices, which are applied to energy-isolation devices to prevent them from being operated during servicing and maintenance.

Together, when properly used, energy-isolation devices and lockout/tagout devices protect employees from the unexpected energization of machines and equipment.

There are two kinds of energy-isolation device:

- Energy-isolation devices that are capable of being locked out, and

- Energy-isolation devices that are incapable of being locked out cannot be locked out.

The specific lockout/tagout devices that employers must provide to employees depends in large part on whether the energy-isolation devices on machinery and equipment in their workplaces are of one kind or another.

These two kinds of energy-isolation device correspond to two kinds of lockout/tagout device:

- Lockout devices, which when fastened to energy-isolation devices that can be locked out physically hold them in place; and

- Tagout devices, which display prominent warnings against operating energy-isolation devices while the tagout devices are in place.

OSHA requires employers to use lockout devices on energy-isolation devices that are capable of being locked out. On energy-isolation devices that are incapable of being locked out, OSHA requires tagout devices to be fastened as close as possible to the energy-isolation device to communicate their warnings as clearly as possible.

There is one exception to the lockout device requirement:

- An employer may have employees use tagout devices on energy-isolation devices that are capable of being locked out only if that employer demonstrates that the tagout program provides full employee protection. Full employee protection requires the use of additional protective measures: ...

Stand-alone tagout system

If, due to equipment age or construction, a lockout device cannot be used, the employer’s energy-control program must use a tagout system. If an energy-isolating device is capable of being locked out, it must be locked out during service and maintenance operations unless the employer can demonstrate that a tagout system provides full employee protection.

When a tagout system is used instead of lockout, the employer must supplement tagout with additional means to ensure full employee protection. These additional means could include the removal of an isolating circuit element, blocking of a controlling switch, opening of an extra disconnecting device, or the removal of a valve handle to reduce the likelihood of inadvertent energization. Tagout alone does not physically prevent activation of the control, and it may give a false sense of security to the employee. Further training will be required if the employer must use a tagout system.

Whenever machines or equipment are installed, replaced, renovated, modified, or repaired, the energy-isolating devices on such machines and equipment must be designed to accept a lockout device.

Energy-control procedures

Each employer must develop and document energy-control procedures for isolating machines and equipment in the workplace from their energy sources before any employees may service or maintain them. An energy-control procedure serves to guide employees through the application of lockout or tagout devices to energy isolation devices to disable a machine or piece of equipment inoperative and safe to service.

At minimum, each of an employer’s energy-control procedures must clearly specify the scope, purpose, authorization, rules, and techniques that employees will use to control potentially hazardous energy. To guide employees effectively, each written energy-control procedure must provide them with at least the following information:

- A specific statement on how employees are intended to use the procedure;

- Which employees are authorized to perform the procedure;

- The employer’s means for enforcing compliance;

- Each specific step for shutting down, isolating, blocking, and securing a machine or piece of equipment;

- Each specific step for placing, removing, and transferring lockout or tagout devices;

- Each specific step for releasing, draining, or otherwise controlling stored energy; and

- Each specific requirement for testing a machine to verify that lockout devices, tagout devices, and any other energy-control methods are effective.

If the information employees need to control hazardous energy effectively is the same for multiple machines in the workplace, then a single written procedure may be used for all such similar machines. However, machines or equipment with, for example, different kinds of energy sources, different energy-isolating devices, or different procedural steps to follow require separate written energy-control procedures.

NOTE: Exception to documentation requirements

Employers are not required to document an energy-control procedure for a particular machine or piece of equipment only if each of the following eight conditions apply:

- The machine or equipment has no potential for stored or residual energy, or the re-accumulation of stored energy after shutdown;

- The machine or equipment has a single energy source which can be readily identified and isolated;

- The isolation and locking out of that energy source completely de-energizes and deactivates the machine or equipment;

- The machine or equipment is isolated from that energy source and locked out during servicing or maintenance;

- A single lockout device achieves a locked-out condition;

- The lockout device is exclusively controlled by the authorized employee performing the servicing or maintenance;

- The servicing or maintenance does not create hazards for other employees; and

- The employer has had no accidents involving the unexpected activation or re-energization of the machine or equipment during servicing or maintenance.