What are the requirements for periodic inspections?

- Employers must conduct inspections of employees following energy-control procedures at least annually.

To ensure that employees perform the steps of each energy-control procedures correctly, inspections of authorized employees following each of an employer’s energy-control procedures must be conducted at least annually. Each of these periodic inspections is to be administered by an authorized employee other than the employee(s) using the energy-control procedure being inspected.

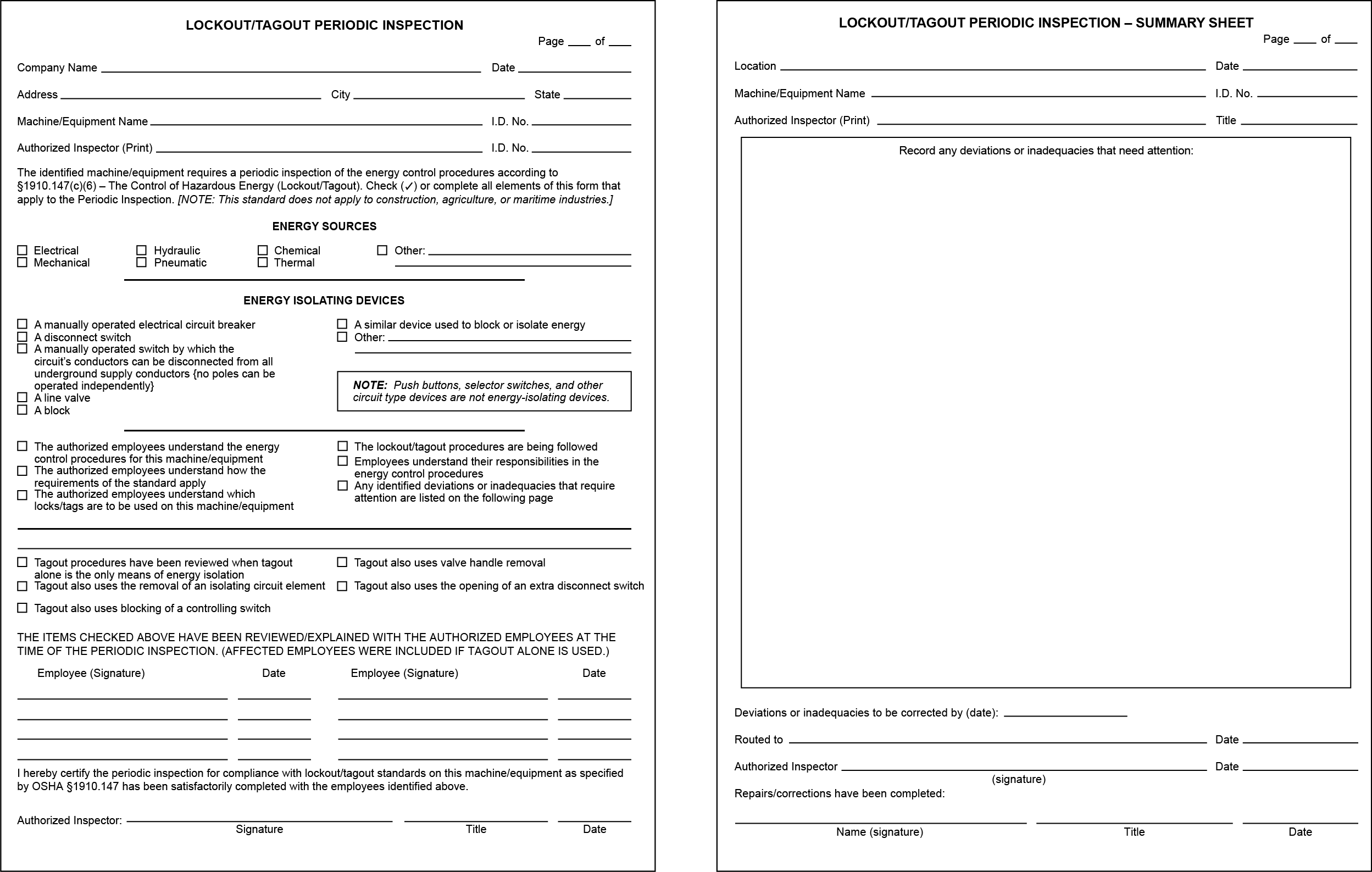

The periodic inspection is oriented around identifying deviations from procedure so they can be corrected. During an inspection, the inspector must observe how employees implement the steps of the procedure and talk with them to determine that all requirements are understood and followed. After the inspection, the inspector must prepare a certification statement that specifies:

- The machine or equipment inspected,

- The date of inspection,

- The names of employees included in the inspection, and

- The name of the inspector.

The format and recordkeeping method for documenting these certifications is up to the employer. The format for the inspections themselves is also reasonably flexible. So long as they meet the requirements listed here, periodic inspections may be accomplished through random audits, plant safety tours, or planned visual observations.

If the inspector identifies any deviations or inadequacies, employers must ensure that appropriate corrective action is taken, including retraining or disciplining any employees who failed to follow procedures.

- For any procedure using lockout devices, an inspector will speak with each authorized employee implementing it about that employee’s responsibilities under the procedure.

- For any procedure using tagout devices, an inspector will speak with each authorized employee and each affected employee both about that employees’ responsibilities under the procedure and about the limitations of tagout devices.

The periodic inspection must include a review of the responsibilities of each authorized employee implementing the lockout procedure. Group meetings between the inspector and authorized employees would constitute compliance with this requirement. When a tagout system is used, each affected employee is to be included in the review as well.

Two qualifications

Procedures used less often than once a year are exempt from the once-yearly requirement, and only need to be inspected when used.

For inspection purposes, the Occupational Safety and Health Administration (OSHA) allows employers to group lockout/tagout procedures for similar machines and conduct one inspection for the group. This approach is acceptable so long as the inspection sampling reasonably reflects plant servicing and maintenance operations and hazardous energy-control practices for the procedures being inspected.

The machines or equipment in the group must have the same or similar types of control measures.

For purposes of procedure grouping, machines and equipment may be grouped together as one procedure if they all are listed or identified in the scope of the energy-control procedure and if they all have the same or similar:

- Procedural steps for shutting down, isolating, blocking, securing, and dissipating stored energy in machines or equipment;

- Procedural steps for the placement, removal, and transfer of the lockout or tagout devices and the responsibility for them; and

- Requirements for testing a machine or equipment to verify that lockout or tagout devices and other control measures are effective.

For example, a single procedure intended to cover a group of machines and that part of the energy-control procedure requires using a start/stop button for both shutdown and energy-isolation verification. However, one of the machines does not have a start/stop button because it is wired directly to an electronic on-demand signal. In this scenario, the single procedure will not provide adequate instructions for the machine without a start/stop button because the single procedure will not provide sufficient employee guidance on how to effectively shut down the machine and verify energy isolation. The energy-control procedure for this machine may not be included in the group.

Employers who develop specific energy-control procedures for individual machines and pieces of equipment may still to group similar procedures for inspections if the procedures meet these criteria.