EPA Final Rule: National Emission Standards for Hazardous Air Pollutants: Ethylene Production, Miscellaneous Organic Chemical Manufacturing, Organic Liquids Distribution (Non-Gasoline), and Petroleum Refineries Reconsideration

On July 6, 2020, the U.S. Environmental Protection Agency (EPA or the Agency) finalized the residual risk and technology review (RTR) conducted for the Ethylene Production source category, which is part of the Generic Maximum Achievable Control Technology Standards National Emission Standards for Hazardous Air Pollutants (NESHAP); on July 7, 2020, the EPA finalized the RTR conducted for the Organic Liquids Distribution (Non-Gasoline) NESHAP; and on August 12, 2020, the EPA finalized the RTR conducted for the Miscellaneous Organic Chemical Manufacturing NESHAP. Amendments to the Petroleum Refinery Sector NESHAP were most recently finalized on February 4, 2020. Subsequently, the EPA received and granted various petitions for reconsideration on these NESHAP for, among other things, the provisions related to the work practice standards for pressure relief devices (PRDs), emergency flaring, and degassing of floating roof storage vessels. This action finalizes proposed amendments to remove the force majeure exemption for PRDs and emergency flaring, incorporate clarifications for the degassing requirements for floating roof storage vessels, and address other corrections and clarifications.

DATES: This final action is effective on April 4, 2024, published in the Federal Register April 4, 2024, page 23840.

View final rule.

| §63.641 Definitions. | ||

| Definition of “Flare” | Revised | View text |

| §63.643 Miscellaneous process vent provisions. | ||

| (c)(1)-(2) | Revised | View text |

| §63.648 Equipment leak standards. | ||

| (j)(3)(iv), (j)(3)(v)(B) and (C), (j)(6) introductory text, and (j)(6)(ii) | Revised | View text |

| §63.655 Reporting and recordkeeping requirements. | ||

| (g) | Revised | View text |

| (i)(9)-(12) | Revised | View text |

| §63.670 Requirements for flare control devices. | ||

| (b), (d) introductory text, (e), (l)(5) introductory text, (o)(4)(iv), (o)(6), (o)(7)(ii) through (o)(7)(v) | Revised | View text |

| (d)(3) | Added | View text |

| §63.671 Requirements for flare monitoring systems. | ||

| (e) introductory text | Revised | View text |

| (e)(4), (f) | Added | View text |

| Appendix to Subpart CC of Part 63—Tables | ||

| Table 13 | Revised | View text |

| §63.1100 Applicability. | ||

| (b), (g)(7)(iii) | Revised | View text |

| §63.1102 Compliance schedule. | ||

| (c)(11), (d)(2)(ii), (e)(2)(iii) | Revised | View text |

| §63.1103 Source category-specific applicability, definitions, and requirements. | ||

| (e) | Revised | View text |

| §63.1107 Equipment leaks. | ||

| (h)(3)(iv), (h)(3)(v)(B) and (C), (h)(6) introductory text, and (h)(6)(ii) | Revised | View text |

| §63.1109 Recordkeeping requirements. | ||

| (f)(2), (3), and (5), and (i)(2) | Revised | View text |

| §63.1110 Reporting requirements. | ||

| (a)(10), (e)(4)(iii), (e)(4)(iv)(A) and (B), (e)(5)(iii), and (e)(8)(iii) | Revised | View text |

| §63.2346 What emission limitations, operating limits, and work practice standards must I meet? | ||

| (a)(6) introductory text, (e) | Revised | View text |

| (a)(6)(iv) | Added | View text |

| §63.2378 How do I demonstrate continuous compliance with the emission limitations, operating limits, and work practice standards? | ||

| (e) | Revised | View text |

| §63.2382 What notifications must I submit and when and what information should be submitted? | ||

| (d) | Revised | View text |

| §63.2386 What reports must I submit and when and what information is to be submitted in each? | ||

| (f), (g), and (h) | Revised | View text |

| (i)-(j) | Removed | View text |

| §63.2406 What definitions apply to this subpart? | ||

| Definition of ”Force majeure event” | Removed | View text |

| Table 12 to Subpart EEEE of Part 63—Applicability of General Provisions to Subpart EEEE | ||

| “63.9(k)” | Added | View text |

| ”63.7(a)(4)”“63.9(k)” | Revised | View text |

| §63.2450 What are my general requirements for complying with this subpart? | ||

| (e)(1), (e)(5)(iv), (e)(5)(viii)(B), (e)(6)(i), (e)(7) introductory text, (v)(1)(i), (v)(1)(ii), and (v)(2) | Revised | View text |

| §63.2460 What requirements must I meet for batch process vents? | ||

| (c)(9) introductory text | View text | |

| §63.2470 What requirements must I meet for storage tanks? | ||

| (f) | Revised | View text |

| §63.2480 What requirements must I meet for equipment leaks? | ||

| (a), (e)(2)(ii), (e)(2)(iii), (e)(3)(iv), (e)(3)(v)(B), (e)(3)(v)(C), (e)(6)(ii), (f)(18)(iii), (f)(18)(vi), (f)(18)(x), and (f)(18)(xiii) | Revised | View text |

| §63.2490 What requirements must I meet for heat exchange systems? | ||

| (a), (d) introductory text, and (d)(4)(iii) introductory text; | Revised | View text |

| (e) | Added | View text |

| §63.2492 How do I determine whether my process vent, storage tank, or equipment is in ethylene oxide service? | ||

| (b) | Revised | View text |

| §63.2493 What requirements must I meet for process vents, storage tanks, or equipment that are in ethylene oxide service? | ||

| (a)(2)(vi) introductory text, (a)(2)(vi)(C), (a)(2)(viii), (b)(2), (b)(4) introductory text, (b)(4)(iv), (b)(6), (d)(1)(iii), (d)(2)(iii), (d)(3), (d)(4)(v), and (e) introductory text | Revised | View text |

| §63.2515 What notifications must I submit and when? | ||

| (d) | Revised | View text |

| §63.2520 What reports must I submit and when? | ||

| (d) introductory text, (e) introductory text, (e)(2), (e)(14)(iii), (e)(16), (f) and (g) | Revised | View text |

| (d)(6) | Added | View text |

| (h)-(i) | Removed | View text |

| §63.2525 What records must I keep? | ||

| (o), (p)(2), (p)(3), (p)(5), (q)(2), (r)(1), (r)(4)(iv) introductory text, (r)(4)(iv)(B) and (r)(4)(iv)(C) | Revised | View text |

| (r)(4)(iv)(D) | Added | View text |

| §63.2550 What definitions apply to this subpart? | ||

| “In ethylene oxide service’” | Revised | View text |

| Table 10 to Subpart FFFF of Part 63—Work Practice Standards for Heat Exchange Systems | ||

| Entire table | Revised | View text |

| Table 12 to Subpart FFFF of Part 63—Applicability of General Provisions to Subpart FFFF | ||

| Entry ”63.9(k)” | Revised | View text |

Previous Text

§63.641 Definitions.

* * * *

Flare means a combustion device lacking an enclosed combustion chamber that uses an uncontrolled volume of ambient air to burn gases. For the purposes of this rule, the definition of flare includes, but is not necessarily limited to, air-assisted flares, steam-assisted flares and non-assisted flares.

§63.643 Miscellaneous process vent provisions.

* * * *

(c)(1) Prior to venting to the atmosphere, process liquids are removed from the equipment as much as practical and the equipment is depressured to a control device meeting requirements in paragraphs (a)(1) or (2) of this section, a fuel gas system, or back to the process until one of the following conditions, as applicable, is met.

(i) The vapor in the equipment served by the maintenance vent has a lower explosive limit (LEL) of less than 10 percent.

(ii) If there is no ability to measure the LEL of the vapor in the equipment based on the design of the equipment, the pressure in the equipment served by the maintenance vent is reduced to 5 pounds per square inch gauge (psig) or less. Upon opening the maintenance vent, active purging of the equipment cannot be used until the LEL of the vapors in the maintenance vent (or inside the equipment if the maintenance is a hatch or similar type of opening) is less than 10 percent.

(iii) The equipment served by the maintenance vent contains less than 72 pounds of total volatile organic compounds (VOC).

(iv) If the maintenance vent is associated with equipment containing pyrophoric catalyst (e.g., hydrotreaters and hydrocrackers) and a pure hydrogen supply is not available at the equipment at the time of the startup, shutdown, maintenance, or inspection activity, the LEL of the vapor in the equipment must be less than 20 percent, except for one event per year not to exceed 35 percent.

(v) If, after applying best practices to isolate and purge equipment served by a maintenance vent, none of the applicable criterion in paragraphs (c)(1)(i) through (iv) of this section can be met prior to installing or removing a blind flange or similar equipment blind, the pressure in the equipment served by the maintenance vent is reduced to 2 psig or less. Active purging of the equipment may be used provided the equipment pressure at the location where purge gas is introduced remains at 2 psig or less.

(c)(2) Except for maintenance vents complying with the alternative in paragraph (c)(1)(iii) of this section, the owner or operator must determine the LEL or, if applicable, equipment pressure using process instrumentation or portable measurement devices and follow procedures for calibration and maintenance according to manufacturer's specifications.

§63.648 Equipment leak standards.

* * * *

(j)(3)(iv) The owner or operator shall determine the total number of release events occurred during the calendar year for each affected pressure relief device separately. The owner or operator shall also determine the total number of release events for each pressure relief device for which the root cause analysis concluded that the root cause was a force majeure event, as defined in this subpart.

* * * *

(j)(3)(v)(B) A second release event not including force majeure events from a single pressure relief device in a 3 calendar year period for the same root cause for the same equipment.

(j)(3)(v)(C) A third release event not including force majeure events from a single pressure relief device in a 3 calendar year period for any reason.

* * * *

(j)(6) Root cause analysis and corrective action analysis. A root cause analysis and corrective action analysis must be completed as soon as possible, but no later than 45 days after a release event. Special circumstances affecting the number of root cause analyses and/or corrective action analyses are provided in paragraphs (j)(6)(i) through (iv) of this section.

* * * *

(j)(6)(ii) You may conduct a single root cause analysis and corrective action analysis for a single emergency event that causes two or more pressure relief devices to release, regardless of the equipment served, if the root cause is reasonably expected to be a force majeure event, as defined in this subpart.

§63.655 Reporting and recordkeeping requirements.

* * * *

(g) The owner or operator of a source subject to this subpart shall submit Periodic Reports no later than 60 days after the end of each 6-month period when any of the information specified in paragraphs (g)(1) through (7) of this section or paragraphs (g)(9) through (14) of this section is collected. The first 6-month period shall begin on the date the Notification of Compliance Status report is required to be submitted. A Periodic Report is not required if none of the events identified in paragraphs (g)(1) through (7) of this section or paragraphs (g)(9) through (14) of this section occurred during the 6-month period unless emissions averaging is utilized. Quarterly reports must be submitted for emission points included in emission averages, as provided in paragraph (g)(8) of this section. An owner or operator may submit reports required by other regulations in place of or as part of the Periodic Report required by this paragraph (g) if the reports contain the information required by paragraphs (g)(1) through (14) of this section.

(1) For storage vessels, Periodic Reports shall include the information specified for Periodic Reports in paragraphs (g)(2) through (5) of this section. Information related to gaskets, slotted membranes, and sleeve seals is not required for storage vessels that are part of an existing source complying with §63.646.

(2) Internal floating roofs.(i) An owner or operator who elects to comply with §63.646 by using a fixed roof and an internal floating roof or by using an external floating roof converted to an internal floating roof shall submit the results of each inspection conducted in accordance with §63.120(a) of subpart G in which a failure is detected in the control equipment.

(A) For vessels for which annual inspections are required under §63.120(a)(2)(i) or (a)(3)(ii) of subpart G, the specifications and requirements listed in paragraphs (g)(2)(i)(A)(1) through (3) of this section apply.

(1) A failure is defined as any time in which the internal floating roof is not resting on the surface of the liquid inside the storage vessel and is not resting on the leg supports; or there is liquid on the floating roof; or the seal is detached from the internal floating roof; or there are holes, tears, or other openings in the seal or seal fabric; or there are visible gaps between the seal and the wall of the storage vessel.

(2) Except as provided in paragraph (g)(2)(i)(A)(3) of this section, each Periodic Report shall include the date of the inspection, identification of each storage vessel in which a failure was detected, and a description of the failure. The Periodic Report shall also describe the nature of and date the repair was made or the date the storage vessel was emptied.

(3) If an extension is utilized in accordance with §63.120(a)(4) of subpart G, the owner or operator shall, in the next Periodic Report, identify the vessel; include the documentation specified in §63.120(a)(4) of subpart G; and describe the date the storage vessel was emptied and the nature of and date the repair was made.

(B) For vessels for which inspections are required under §63.120(a)(2)(ii), (a)(3)(i), or (a)(3)(iii) of subpart G (i.e., internal inspections), the specifications and requirements listed in paragraphs (g)(2)(i)(B)(1) and (2) of this section apply.

(1) A failure is defined as any time in which the internal floating roof has defects; or the primary seal has holes, tears, or other openings in the seal or the seal fabric; or the secondary seal (if one has been installed) has holes, tears, or other openings in the seal or the seal fabric; or, for a storage vessel that is part of a new source, the gaskets no longer close off the liquid surface from the atmosphere; or, for a storage vessel that is part of a new source, the slotted membrane has more than a 10 percent open area.

(2) Each Periodic Report shall include the date of the inspection, identification of each storage vessel in which a failure was detected, and a description of the failure. The Periodic Report shall also describe the nature of and date the repair was made.

(ii) An owner or operator who elects to comply with §63.660 by using a fixed roof and an internal floating roof shall submit the results of each inspection conducted in accordance with §63.1063(c)(1), (d)(1), and (d)(2) of subpart WW in which a failure is detected in the control equipment. For vessels for which inspections are required under §63.1063(c) and (d), the specifications and requirements listed in paragraphs (g)(2)(ii)(A) through (C) of this section apply.

(A) A failure is defined in §63.1063(d)(1) of subpart WW.

(B) Each Periodic Report shall include a copy of the inspection record required by §63.1065(b) of subpart WW when a failure occurs.

(C) An owner or operator who elects to use an extension in accordance with §63.1063(e)(2) of subpart WW shall, in the next Periodic Report, submit the documentation required by §63.1063(e)(2).

(3) External floating roofs.(i) An owner or operator who elects to comply with §63.646 by using an external floating roof shall meet the periodic reporting requirements specified in paragraphs (g)(3)(i)(A) through (C) of this section.

(A) The owner or operator shall submit, as part of the Periodic Report, documentation of the results of each seal gap measurement made in accordance with §63.120(b) of subpart G in which the seal and seal gap requirements of §63.120(b)(3), (4), (5), or (6) of subpart G are not met. This documentation shall include the information specified in paragraphs (g)(3)(i)(A)(1) through (4) of this section.

(1) The date of the seal gap measurement.

(2) The raw data obtained in the seal gap measurement and the calculations described in §63.120(b)(3) and (4) of subpart G.

(3) A description of any seal condition specified in §63.120(b)(5) or (6) of subpart G that is not met.

(4) A description of the nature of and date the repair was made, or the date the storage vessel was emptied.

(B) If an extension is utilized in accordance with §63.120(b)(7)(ii) or (b)(8) of subpart G, the owner or operator shall, in the next Periodic Report, identify the vessel; include the documentation specified in §63.120(b)(7)(ii) or (b)(8) of subpart G, as applicable; and describe the date the vessel was emptied and the nature of and date the repair was made.

(C) The owner or operator shall submit, as part of the Periodic Report, documentation of any failures that are identified during visual inspections required by §63.120(b)(10) of subpart G. This documentation shall meet the specifications and requirements in paragraphs (g)(3)(i)(C)(1) and (2) of this section.

(1) A failure is defined as any time in which the external floating roof has defects; or the primary seal has holes or other openings in the seal or the seal fabric; or the secondary seal has holes, tears, or other openings in the seal or the seal fabric; or, for a storage vessel that is part of a new source, the gaskets no longer close off the liquid surface from the atmosphere; or, for a storage vessel that is part of a new source, the slotted membrane has more than 10 percent open area.

(2) Each Periodic Report shall include the date of the inspection, identification of each storage vessel in which a failure was detected, and a description of the failure. The Periodic Report shall also describe the nature of and date the repair was made.

(ii) An owner or operator who elects to comply with §63.660 by using an external floating roof shall meet the periodic reporting requirements specified in paragraphs (g)(3)(ii)(A) and (B) of this section.

(A) For vessels for which inspections are required under §63.1063(c)(2), (d)(1), and (d)(3) of subpart WW, the owner or operator shall submit, as part of the Periodic Report, a copy of the inspection record required by §63.1065(b) of subpart WW when a failure occurs. A failure is defined in §63.1063(d)(1).

(B) An owner or operator who elects to use an extension in accordance with §63.1063(e)(2) or (c)(2)(iv)(B) of subpart WW shall, in the next Periodic Report, submit the documentation required by those paragraphs.

(4) [Reserved]

(5) An owner or operator who elects to comply with §63.646 or §63.660 by installing a closed vent system and control device shall submit, as part of the next Periodic Report, the information specified in paragraphs (g)(5)(i) through (v) of this section, as applicable.

(i) The Periodic Report shall include the information specified in paragraphs (g)(5)(i)(A) and (B) of this section for those planned routine maintenance operations that would require the control device not to meet the requirements of either §63.119(e)(1) or (2) of subpart G, §63.985(a) and (b) of subpart SS or §63.670, as applicable.

(A) A description of the planned routine maintenance that is anticipated to be performed for the control device during the next 6 months. This description shall include the type of maintenance necessary, planned frequency of maintenance, and lengths of maintenance periods.

(B) A description of the planned routine maintenance that was performed for the control device during the previous 6 months. This description shall include the type of maintenance performed and the total number of hours during those 6 months that the control device did not meet the requirements of either §63.119(e)(1) or (2) of subpart G, §63.985(a) and (b) of subpart SS or §63.670, as applicable, due to planned routine maintenance.

(ii) If a control device other than a flare is used, the Periodic Report shall describe each occurrence when the monitored parameters were outside of the parameter ranges documented in the Notification of Compliance Status report. The description shall include: Identification of the control device for which the measured parameters were outside of the established ranges, and causes for the measured parameters to be outside of the established ranges.

(iii) If a flare is used prior to January 30, 2019 and prior to electing to comply with the requirements in §63.670, the Periodic Report shall describe each occurrence when the flare does not meet the general control device requirements specified in §63.11(b) of subpart A and shall include: Identification of the flare that does not meet the general requirements specified in §63.11(b) of subpart A, and reasons the flare did not meet the general requirements specified in §63.11(b) of subpart A.

(iv) If a flare is used on or after the date for which compliance with the requirements in §63.670 is elected, which can be no later than January 30, 2019, the Periodic Report shall include the items specified in paragraph (g)(11) of this section.

(v) An owner or operator who elects to comply with §63.660 by installing an alternate control device as described in §63.1064 of subpart WW shall submit, as part of the next Periodic Report, a written application as described in §63.1066(b)(3) of subpart WW.

(6) For miscellaneous process vents for which continuous parameter monitors are required by this subpart, periods of excess emissions shall be identified in the Periodic Reports and shall be used to determine compliance with the emission standards.

(i) Period of excess emission means any of the following conditions:

(A) An operating day when the daily average value of a monitored parameter, except presence of a flare pilot flame, is outside the range specified in the Notification of Compliance Status report. Monitoring data recorded during periods of monitoring system breakdown, repairs, calibration checks and zero (low-level) and high-level adjustments shall not be used in computing daily average values of monitored parameters.

(B) An operating day when all pilot flames of a flare are absent.

(C) An operating day when monitoring data required to be recorded in paragraphs (i)(3) (i) and (ii) of this section are available for less than 75 percent of the operating hours.

(D) For data compression systems under paragraph (h)(5)(iii) of this section, an operating day when the monitor operated for less than 75 percent of the operating hours or a day when less than 18 monitoring values were recorded.

(ii) For miscellaneous process vents, excess emissions shall be reported for the operating parameters specified in table 10 of this subpart unless other site-specific parameter(s) have been approved by the operating permit authority.

(iii) For periods in closed vent systems when a Group 1 miscellaneous process vent stream was detected in the bypass line or diverted from the control device and either directly to the atmosphere or to a control device that does not comply with the requirements in §63.643(a), report the date, time, duration, estimate of the volume of gas, the concentration of organic HAP in the gas and the resulting mass emissions of organic HAP that bypassed the control device. For periods when the flow indicator is not operating, report the date, time, and duration.

(7) If a performance test for determination of compliance for a new emission point subject to this subpart or for an emission point that has changed from Group 2 to Group 1 is conducted during the period covered by a Periodic Report, the results of the performance test shall be included in the Periodic Report.

(i) Results of the performance test shall include the identification of the source tested, the date of the test, the percentage of emissions reduction or outlet pollutant concentration reduction (whichever is needed to determine compliance) for each run and for the average of all runs, and the values of the monitored operating parameters.

(ii) The complete test report shall be maintained onsite.

(8) The owner or operator of a source shall submit quarterly reports for all emission points included in an emissions average.

(i) The quarterly reports shall be submitted no later than 60 calendar days after the end of each quarter. The first report shall be submitted with the Notification of Compliance Status report no later than 150 days after the compliance date specified in §63.640.

(ii) The quarterly reports shall include:

(A) The information specified in this paragraph and in paragraphs (g)(2) through (g)(7) of this section for all storage vessels and miscellaneous process vents included in an emissions average;

(B) The information required to be reported by §63.428 (h)(1), (h)(2), and (h)(3) for each gasoline loading rack included in an emissions average, unless this information has already been submitted in a separate report;

(C) The information required to be reported by §63.567(e)(4) and (j)(3) of subpart Y for each marine tank vessel loading operation included in an emissions average, unless the information has already been submitted in a separate report;

(D) Any information pertaining to each wastewater stream included in an emissions average that the source is required to report under the Implementation Plan for the source;

(E) The credits and debits calculated each month during the quarter;

(F) A demonstration that debits calculated for the quarter are not more than 1.30 times the credits calculated for the quarter, as required under §§63.652(e)(4);

(G) The values of any inputs to the credit and debit equations in §63.652 (g) and (h) that change from month to month during the quarter or that have changed since the previous quarter; and

(H) Any other information the source is required to report under the Implementation Plan for the source.

(iii) Every fourth quarterly report shall include the following:

(A) A demonstration that annual credits are greater than or equal to annual debits as required by §63.652(e)(3); and

(B) A certification of compliance with all the emissions averaging provisions in §63.652 of this subpart.

(9) For heat exchange systems, Periodic Reports must include the following information:

(i) The number of heat exchange systems at the plant site subject to the monitoring requirements in §63.654.

(ii) The number of heat exchange systems at the plant site found to be leaking.

(iii) For each monitoring location where the total strippable hydrocarbon concentration was determined to be equal to or greater than the applicable leak definitions specified in §63.654(c)(6), identification of the monitoring location (e.g., unique monitoring location or heat exchange system ID number), the measured total strippable hydrocarbon concentration, the date the leak was first identified, and, if applicable, the date the source of the leak was identified;

(iv) For leaks that were repaired during the reporting period (including delayed repairs), identification of the monitoring location associated with the repaired leak, the total strippable hydrocarbon concentration measured during re-monitoring to verify repair, and the re-monitoring date (i.e., the effective date of repair); and

(v) For each delayed repair, identification of the monitoring location associated with the leak for which repair is delayed, the date when the delay of repair began, the date the repair is expected to be completed (if the leak is not repaired during the reporting period), the total strippable hydrocarbon concentration and date of each monitoring event conducted on the delayed repair during the reporting period, and an estimate of the potential strippable hydrocarbon emissions over the reporting period associated with the delayed repair.

(10) For pressure relief devices subject to the requirements §63.648(j), Periodic Reports must include the information specified in paragraphs (g)(10)(i) through (iv) of this section.

(i) For pressure relief devices in organic HAP gas or vapor service, pursuant to §63.648(j)(1), report any instrument reading of 500 ppm or greater.

(ii) For pressure relief devices in organic HAP gas or vapor service subject to §63.648(j)(2), report confirmation that any monitoring required to be done during the reporting period to show compliance was conducted.

(iii) For pilot-operated pressure relief devices in organic HAP service, report each pressure release to the atmosphere through the pilot vent that equals or exceeds 72 pounds of VOC per day, including duration of the pressure release through the pilot vent and estimate of the mass quantity of each organic HAP released.

(iv) For pressure relief devices in organic HAP service subject to §63.648(j)(3), report each pressure release to the atmosphere, including duration of the pressure release and estimate of the mass quantity of each organic HAP released, and the results of any root cause analysis and corrective action analysis completed during the reporting period, including the corrective actions implemented during the reporting period and, if applicable, the implementation schedule for planned corrective actions to be implemented subsequent to the reporting period.

(11) For flares subject to §63.670, Periodic Reports must include the information specified in paragraphs (g)(11)(i) through (iv) of this section.

(i) Records as specified in paragraph (i)(9)(i) of this section for each 15-minute block during which there was at least one minute when regulated material is routed to a flare and no pilot flame is present.

(ii) Visible emission records as specified in paragraph (i)(9)(ii)(C) of this section for each period of 2 consecutive hours during which visible emissions exceeded a total of 5 minutes.

(iii) The 15-minute block periods for which the applicable operating limits specified in §63.670(d) through (f) are not met. Indicate the date and time for the period, the net heating value operating parameter(s) determined following the methods in §63.670(k) through (n) as applicable.

(iv) For flaring events meeting the criteria in §63.670(o)(3):

(A) The start and stop time and date of the flaring event.

(B) The length of time for which emissions were visible from the flare during the event.

(C) The periods of time that the flare tip velocity exceeds the maximum flare tip velocity determined using the methods in §63.670(d)(2) and the maximum 15-minute block average flare tip velocity recorded during the event.

(D) Results of the root cause and corrective actions analysis completed during the reporting period, including the corrective actions implemented during the reporting period and, if applicable, the implementation schedule for planned corrective actions to be implemented subsequent to the reporting period.

(12) For delayed coking units, the Periodic Report must include the information specified in paragraphs (g)(12)(i) through (iv) of this section.

(i) For existing source delayed coking units, any 60-cycle average exceeding the applicable limit in §63.657(a)(1).

(ii) For new source delayed coking units, any direct venting event exceeding the applicable limit in §63.657(a)(2).

(iii) The total number of double quenching events performed during the reporting period.

(iv) For each double quenching draining event when the drain water temperature exceeded 210°F, report the drum, date, time, the coke drum vessel pressure or temperature, as applicable, when pre-vent draining was initiated, and the maximum drain water temperature during the pre-vent draining period.

(13) For maintenance vents subject to the requirements in §63.643(c), Periodic Reports must include the information specified in paragraphs (g)(13)(i) through (iv) of this section for any release exceeding the applicable limits in §63.643(c)(1). For the purposes of this reporting requirement, owners or operators complying with §63.643(c)(1)(iv) must report each venting event for which the lower explosive limit is 20 percent or greater; owners or operators complying with §63.643(c)(1)(v) must report each venting event conducted under those provisions and include an explanation for each event as to why utilization of this alternative was required.

(i) Identification of the maintenance vent and the equipment served by the maintenance vent.

(ii) The date and time the maintenance vent was opened to the atmosphere.

(iii) The lower explosive limit, vessel pressure, or mass of VOC in the equipment, as applicable, at the start of atmospheric venting. If the 5 psig vessel pressure option in §63.643(c)(1)(ii) was used and active purging was initiated while the lower explosive limit was 10 percent or greater, also include the lower explosive limit of the vapors at the time active purging was initiated.

(iv) An estimate of the mass of organic HAP released during the entire atmospheric venting event.

(14) Any changes in the information provided in a previous Notification of Compliance Status report.

* * * *

(i)(9) For each flare subject to §63.670, each owner or operator shall keep the records specified in paragraphs (i)(9)(i) through (xii) of this section up-to-date and readily accessible, as applicable.

(i) Retain records of the output of the monitoring device used to detect the presence of a pilot flame as required in §63.670(b) for a minimum of 2 years. Retain records of each 15-minute block during which there was at least one minute that no pilot flame is present when regulated material is routed to a flare for a minimum of 5 years.

(ii) Retain records of daily visible emissions observations or video surveillance images required in §63.670(h) as specified in the paragraphs (i)(9)(ii)(A) through (C), as applicable, for a minimum of 3 years.

(A) If visible emissions observations are performed using Method 22 at 40 CFR part 60, appendix A-7, the record must identify whether the visible emissions observation was performed, the results of each observation, total duration of observed visible emissions, and whether it was a 5-minute or 2-hour observation. If the owner or operator performs visible emissions observations more than one time during a day, the record must also identify the date and time of day each visible emissions observation was performed.

(B) If video surveillance camera is used, the record must include all video surveillance images recorded, with time and date stamps.

(C) For each 2 hour period for which visible emissions are observed for more than 5 minutes in 2 consecutive hours, the record must include the date and time of the 2 hour period and an estimate of the cumulative number of minutes in the 2 hour period for which emissions were visible.

(iii) The 15-minute block average cumulative flows for flare vent gas and, if applicable, total steam, perimeter assist air, and premix assist air specified to be monitored under §63.670(i), along with the date and time interval for the 15-minute block. If multiple monitoring locations are used to determine cumulative vent gas flow, total steam, perimeter assist air, and premix assist air, retain records of the 15-minute block average flows for each monitoring location for a minimum of 2 years, and retain the 15-minute block average cumulative flows that are used in subsequent calculations for a minimum of 5 years. If pressure and temperature monitoring is used, retain records of the 15-minute block average temperature, pressure and molecular weight of the flare vent gas or assist gas stream for each measurement location used to determine the 15-minute block average cumulative flows for a minimum of 2 years, and retain the 15-minute block average cumulative flows that are used in subsequent calculations for a minimum of 5 years.

(iv) The flare vent gas compositions specified to be monitored under §63.670(j). Retain records of individual component concentrations from each compositional analyses for a minimum of 2 years. If NHVvg analyzer is used, retain records of the 15-minute block average values for a minimum of 5 years.

(v) Each 15-minute block average operating parameter calculated following the methods specified in §63.670(k) through (n), as applicable.

(vi) [Reserved]

(vii) All periods during which operating values are outside of the applicable operating limits specified in §63.670(d) through (f) when regulated material is being routed to the flare.

(viii) All periods during which the owner or operator does not perform flare monitoring according to the procedures in §63.670(g) through (j).

(ix) Records of periods when there is flow of vent gas to the flare, but when there is no flow of regulated material to the flare, including the start and stop time and dates of periods of no regulated material flow.

(x) Records when the flow of vent gas exceeds the smokeless capacity of the flare, including start and stop time and dates of the flaring event.

(xi) Records of the root cause analysis and corrective action analysis conducted as required in §63.670(o)(3), including an identification of the affected facility, the date and duration of the event, a statement noting whether the event resulted from the same root cause(s) identified in a previous analysis and either a description of the recommended corrective action(s) or an explanation of why corrective action is not necessary under §63.670(o)(5)(i).

(xii) For any corrective action analysis for which implementation of corrective actions are required in §63.670(o)(5), a description of the corrective action(s) completed within the first 45 days following the discharge and, for action(s) not already completed, a schedule for implementation, including proposed commencement and completion dates.

(10) [Reserved]

(11) For each pressure relief device subject to the pressure release management work practice standards in §63.648(j)(3), the owner or operator shall keep the records specified in paragraphs (i)(11)(i) through (iii) of this section. For each pilot-operated pressure relief device subject to the requirements at §63.648(j)(3), the owner or operator shall keep the records specified in paragraph (i)(11)(iv) of this section.

(i) Records of the prevention measures implemented as required in §63.648(j)(3)(ii), if applicable.

(ii) Records of the number of releases during each calendar year and the number of those releases for which the root cause was determined to be a force majeure event. Keep these records for the current calendar year and the past five calendar years.

(iii) For each release to the atmosphere, the owner or operator shall keep the records specified in paragraphs (i)(11)(iii)(A) through (D) of this section.

(A) The start and end time and date of each pressure release to the atmosphere.

(B) Records of any data, assumptions, and calculations used to estimate of the mass quantity of each organic HAP released during the event.

(C) Records of the root cause analysis and corrective action analysis conducted as required in §63.648(j)(3)(iii), including an identification of the affected facility, the date and duration of the event, a statement noting whether the event resulted from the same root cause(s) identified in a previous analysis and either a description of the recommended corrective action(s) or an explanation of why corrective action is not necessary under §63.648(j)(7)(i).

(D) For any corrective action analysis for which implementation of corrective actions are required in §63.648(j)(7), a description of the corrective action(s) completed within the first 45 days following the discharge and, for action(s) not already completed, a schedule for implementation, including proposed commencement and completion dates.

(iv) For pilot-operated pressure relief devices, general or release-specific records for estimating the quantity of VOC released from the pilot vent during a release event, and records of calculations used to determine the quantity of specific HAP released for any event or series of events in which 72 or more pounds of VOC are released in a day.

(12) For each maintenance vent opening subject to the requirements in §63.643(c), the owner or operator shall keep the applicable records specified in paragraphs (i)(12)(i) through (vi) of this section.

(i) The owner or operator shall maintain standard site procedures used to deinventory equipment for safety purposes (e.g., hot work or vessel entry procedures) to document the procedures used to meet the requirements in §63.643(c). The current copy of the procedures shall be retained and available on-site at all times. Previous versions of the standard site procedures, is applicable, shall be retained for five years.

(ii) If complying with the requirements of §63.643(c)(1)(i) and the lower explosive limit at the time of the vessel opening exceeds 10 percent, identification of the maintenance vent, the process units or equipment associated with the maintenance vent, the date of maintenance vent opening, and the lower explosive limit at the time of the vessel opening.

(iii) If complying with the requirements of §63.643(c)(1)(ii) and either the vessel pressure at the time of the vessel opening exceeds 5 psig or the lower explosive limit at the time of the active purging was initiated exceeds 10 percent, identification of the maintenance vent, the process units or equipment associated with the maintenance vent, the date of maintenance vent opening, the pressure of the vessel or equipment at the time of discharge to the atmosphere and, if applicable, the lower explosive limit of the vapors in the equipment when active purging was initiated.

(iv) If complying with the requirements of §63.643(c)(1)(iii), records used to estimate the total quantity of VOC in the equipment and the type and size limits of equipment that contain less than 72 pounds of VOC at the time of maintenance vent opening. For each maintenance vent opening for which the deinventory procedures specified in paragraph (i)(12)(i) of this section are not followed or for which the equipment opened exceeds the type and size limits established in the records specified in this paragraph, identification of the maintenance vent, the process units or equipment associated with the maintenance vent, the date of maintenance vent opening, and records used to estimate the total quantity of VOC in the equipment at the time the maintenance vent was opened to the atmosphere.

(v) If complying with the requirements of §63.643(c)(1)(iv), identification of the maintenance vent, the process units or equipment associated with the maintenance vent, records documenting the lack of a pure hydrogen supply, the date of maintenance vent opening, and the lower explosive limit of the vapors in the equipment at the time of discharge to the atmosphere for each applicable maintenance vent opening.

(vi) If complying with the requirements of §63.643(c)(1)(v), identification of the maintenance vent, the process units or equipment associated with the maintenance vent, records documenting actions taken to comply with other applicable alternatives and why utilization of this alternative was required, the date of maintenance vent opening, the equipment pressure and lower explosive limit of the vapors in the equipment at the time of discharge, an indication of whether active purging was performed and the pressure of the equipment during the installation or removal of the blind if active purging was used, the duration the maintenance vent was open during the blind installation or removal process, and records used to estimate the total quantity of VOC in the equipment at the time the maintenance vent was opened to the atmosphere for each applicable maintenance vent opening.

§63.670 Requirements for flare control devices.

* * * *

(b) Pilot flame presence. The owner or operator shall operate each flare with a pilot flame present at all times when regulated material is routed to the flare. Each 15-minute block during which there is at least one minute where no pilot flame is present when regulated material is routed to the flare is a deviation of the standard. Deviations in different 15-minute blocks from the same event are considered separate deviations. The owner or operator shall monitor for the presence of a pilot flame as specified in paragraph (g) of this section.

* * * *

(d) Flare tip velocity. For each flare, the owner or operator shall comply with either paragraph (d)(1) or (2) of this section, provided the appropriate monitoring systems are in-place, whenever regulated material is routed to the flare for at least 15-minutes and the flare vent gas flow rate is less than the smokeless design capacity of the flare.

* * * *

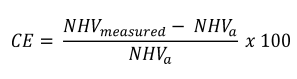

(e) Combustion zone operating limits. For each flare, the owner or operator shall operate the flare to maintain the net heating value of flare combustion zone gas (NHVcz) at or above 270 British thermal units per standard cubic feet (Btu/scf) determined on a 15-minute block period basis when regulated material is routed to the flare for at least 15-minutes. The owner or operator shall monitor and calculate NHVcz as specified in paragraph (m) of this section.

* * * *

(5) When a continuous monitoring system is used as provided in paragraph (j)(1) or (3) of this section and, if applicable, paragraph (j)(4) of this section, the owner or operator may elect to determine the 15-minute block average NHVvg using either the calculation methods in paragraph (l)(5)(i) of this section or the calculation methods in paragraph (l)(5)(ii) of this section. The owner or operator may choose to comply using the calculation methods in paragraph (l)(5)(i) of this section for some flares at the petroleum refinery and comply using the calculation methods (l)(5)(ii) of this section for other flares. However, for each flare, the owner or operator must elect one calculation method that will apply at all times, and use that method for all continuously monitored flare vent streams associated with that flare. If the owner or operator intends to change the calculation method that applies to a flare, the owner or operator must notify the Administrator 30 days in advance of such a change.

(i) Feed-forward calculation method. When calculating NHVvg for a specific 15-minute block:

(A) Use the results from the first sample collected during an event, (for periodic flare vent gas flow events) for the first 15-minute block associated with that event.

(B) If the results from the first sample collected during an event (for periodic flare vent gas flow events) are not available until after the second 15-minute block starts, use the results from the first sample collected during an event for the second 15-minute block associated with that event.

(C) For all other cases, use the results that are available from the most recent sample prior to the 15-minute block period for that 15-minute block period for all flare vent gas steams. For the purpose of this requirement, use the time that the results become available rather than the time the sample was collected. For example, if a sample is collected at 12:25 a.m. and the analysis is completed at 12:38 a.m., the results are available at 12:38 a.m. and these results would be used to determine compliance during the 15-minute block period from 12:45 a.m. to 1:00 a.m.

(ii) Direct calculation method. When calculating NHVvg for a specific 15-minute block:

(A) If the results from the first sample collected during an event (for periodic flare vent gas flow events) are not available until after the second 15-minute block starts, use the results from the first sample collected during an event for the first 15-minute block associated with that event.

(B) For all other cases, use the arithmetic average of all NHVvg measurement data results that become available during a 15-minute block to calculate the 15-minute block average for that period. For the purpose of this requirement, use the time that the results become available rather than the time the sample was collected. For example, if a sample is collected at 12:25 a.m. and the analysis is completed at 12:38 a.m., the results are available at 12:38 a.m. and these results would be used to determine compliance during the 15-minute block period from 12:30 a.m. to 12:45 a.m.

* * * *

(o)(4)(iv) You may conduct a single root cause analysis and corrective action analysis for a single event that causes two or more flares to have a flow event meeting the criteria in paragraph (o)(3)(i) or (ii) of this section, regardless of the configuration of the flares, if the root cause is reasonably expected to be a force majeure event, as defined in this subpart.

* * * *

(o)(6) The owner or operator shall determine the total number of events for which a root cause and corrective action analyses was required during the calendar year for each affected flare separately for events meeting the criteria in paragraph (o)(3)(i) of this section and those meeting the criteria in paragraph (o)(3)(ii) of this section. For the purpose of this requirement, a single root cause analysis conducted for an event that met both of the criteria in paragraphs (o)(3)(i) and (ii) of this section would be counted as an event under each of the separate criteria counts for that flare. Additionally, if a single root cause analysis was conducted for an event that caused multiple flares to meet the criteria in paragraph (o)(3)(i) or (ii) of this section, that event would count as an event for each of the flares for each criteria in paragraph (o)(3) of this section that was met during that event. The owner or operator shall also determine the total number of events for which a root cause and correct action analyses was required and the analyses concluded that the root cause was a force majeure event, as defined in this subpart.

* * * *

(o)(7)(ii) Two visible emissions exceedance events meeting the criteria in paragraph (o)(3)(i) of this section that were not caused by a force majeure event from a single flare in a 3 calendar year period for the same root cause for the same equipment.

(iii) Two flare tip velocity exceedance events meeting the criteria in paragraph (o)(3)(ii) of this section that were not caused by a force majeure event from a single flare in a 3 calendar year period for the same root cause for the same equipment.

(iv) Three visible emissions exceedance events meeting the criteria in paragraph (o)(3)(i) of this section that were not caused by a force majeure event from a single flare in a 3 calendar year period for any reason.

(v) Three flare tip velocity exceedance events meeting the criteria in paragraph (o)(3)(ii) of this section that were not caused by a force majeure event from a single flare in a 3 calendar year period for any reason.

§63.671 Requirements for flare monitoring systems.

* * * *

(e) Additional requirements for gas chromatographs. For monitors used to determine compositional analysis for net heating value per §63.670(j)(1), the gas chromatograph must also meet the requirements of paragraphs (e)(1) through (3) of this section.

Appendix to Subpart CC of Part 63—Tables

* * * *

| Parameter | Minimum accuracy requirements | Calibration requirements |

|---|---|---|

| Temperature | ±1 percent over the normal range of temperature measured, expressed in degrees Celsius (C), or 2.8 degrees C, whichever is greater | Conduct calibration checks at least annually; conduct calibration checks following any period of more than 24 hours throughout which the temperature exceeded the manufacturer's specified maximum rated temperature or install a new temperature sensor. At least quarterly, inspect all components for integrity and all electrical connections for continuity, oxidation, and galvanic corrosion, unless the CPMS has a redundant temperature sensor. |

| Record the results of each calibration check and inspection. | ||

| Locate the temperature sensor in a position that provides a representative temperature; shield the temperature sensor system from electromagnetic interference and chemical contaminants. | ||

| Flow Rate for All Flows Other Than Flare Vent Gas | ±5 percent over the normal range of flow measured or 1.9 liters per minute (0.5 gallons per minute), whichever is greater, for liquid flow | Conduct a flow sensor calibration check at least biennially (every two years); conduct a calibration check following any period of more than 24 hours throughout which the flow rate exceeded the manufacturer's specified maximum rated flow rate or install a new flow sensor. |

| ±5 percent over the normal range of flow measured or 280 liters per minute (10 cubic feet per minute), whichever is greater, for gas flow | At least quarterly, inspect all components for leakage, unless the CPMS has a redundant flow sensor. | |

| ±5 percent over the normal range measured for mass flow | Record the results of each calibration check and inspection. Locate the flow sensor(s) and other necessary equipment (such as straightening vanes) in a position that provides representative flow; reduce swirling flow or abnormal velocity distributions due to upstream and downstream disturbances. | |

| Flare Vent Gas Flow Rate | ±20 percent of flow rate at velocities ranging from 0.03 to 0.3 meters per second (0.1 to 1 feet per second) ±5 percent of flow rate at velocities greater than 0.3 meters per second (1 feet per second) | Conduct a flow sensor calibration check at least biennially (every two years); conduct a calibration check following any period of more than 24 hours throughout which the flow rate exceeded the manufacturer's specified maximum rated flow rate or install a new flow sensor. At least quarterly, inspect all components for leakage, unless the CPMS has a redundant flow sensor. |

| Record the results of each calibration check and inspection. | ||

| Locate the flow sensor(s) and other necessary equipment (such as straightening vanes) in a position that provides representative flow; reduce swirling flow or abnormal velocity distributions due to upstream and downstream disturbances. | ||

| Pressure | ±5 percent over the normal operating range or 0.12 kilopascals (0.5 inches of water column), whichever is greater | Review pressure sensor readings at least once a week for straightline (unchanging) pressure and perform corrective action to ensure proper pressure sensor operation if blockage is indicated. Using an instrument recommended by the sensor's manufacturer, check gauge calibration and transducer calibration annually; conduct calibration checks following any period of more than 24 hours throughout which the pressure exceeded the manufacturer's specified maximum rated pressure or install a new pressure sensor. |

| At least quarterly, inspect all components for integrity, all electrical connections for continuity, and all mechanical connections for leakage, unless the CPMS has a redundant pressure sensor. | ||

| Record the results of each calibration check and inspection. | ||

| Locate the pressure sensor(s) in a position that provides a representative measurement of the pressure and minimizes or eliminates pulsating pressure, vibration, and internal and external corrosion. | ||

| Net Heating Value by Calorimeter | ±2 percent of span | Specify calibration requirements in your site specific CPMS monitoring plan. Calibration requirements should follow manufacturer's recommendations at a minimum. Temperature control (heated and/or cooled as necessary) the sampling system to ensure proper year-round operation. |

| Where feasible, select a sampling location at least two equivalent diameters downstream from and 0.5 equivalent diameters upstream from the nearest disturbance. Select the sampling location at least two equivalent duct diameters from the nearest control device, point of pollutant generation, air in-leakages, or other point at which a change in the pollutant concentration or emission rate occurs. | ||

| Net Heating Value by Gas Chromatograph | As specified in Performance Specification 9 of 40 CFR part 60, appendix B | Follow the procedure in Performance Specification 9 of 40 CFR part 60,appendix B, except that a single daily mid-level calibration check can be used (rather than triplicate analysis), the multi-point calibration can be conducted quarterly (rather than monthly), and the sampling line temperature must be maintained at a minimum temperature of 60°C (rather than 120°C). |

| Hydrogen analyzer | ±2 percent over the concentration measured or 0.1 volume percent, whichever is greater | Specify calibration requirements in your site specific CPMS monitoring plan. Calibration requirements should follow manufacturer's recommendations at a minimum. |

| Where feasible, select the sampling location at least two equivalent duct diameters from the nearest control device, point of pollutant generation, air in-leakages, or other point at which a change in the pollutant concentration occurs. |

§63.1100 Applicability.

* * * *

(b) Subpart A requirements. The following provisions of subpart A of this part (General Provisions), §§63.1 through 63.5, and §§63.12 through 63.15, apply to owners or operators of affected sources subject to this subpart. For sources that reclassify from major source to area source status, the applicable provisions of §63.9(j) and (k) apply. Beginning no later than the compliance dates specified in §63.1102(c), for ethylene production affected sources, §§63.7(a)(4), (c), (e)(4), and (g)(2) and 63.10(b)(2)(vi) also apply.

* * * *

(iii) Beginning no later than the compliance dates specified in §63.1102(c), flares subject to the requirements in 40 CFR part 63, subpart CC and used as a control device for an emission point subject to the requirements in Table 7 to §63.1103(e) are only required to comply with the flare requirements in 40 CFR part 63, subpart CC. This paragraph does not apply to multi-point pressure assisted flares.

§63.1102 Compliance schedule.

* * * *

(c)(11) The requirements in §63.1108(a)(4)(i), (b)(1)(ii), (b)(2), and (b)(4)(ii)(B).

* * * *

(d)(2)(ii) The compliance requirements specified in §63.1108(a)(4)(i), (b)(1)(ii), (b)(2), and (b)(4)(ii)(B).

* * * *

(e)(2)(iii) The compliance requirements specified in §63.1108(a)(4)(i), (b)(1)(ii), (b)(2), and (b)(4)(ii)(B).

§63.1103 Source category-specific applicability, definitions, and requirements.

* * * *

(e) Ethylene production applicability, definitions, and requirements- (1) Applicability- (i) Affected source. For the ethylene production (as defined in paragraph (e)(2) of this section) source category, the affected source comprises all emission points listed in paragraphs (e)(1)(i)(A) through (G) of this section that are associated with an ethylene production unit that is located at a major source, as defined in section 112(a) of the Act.

(A) All storage vessels (as defined in §63.1101) that store liquids containing organic HAP.

(B) All ethylene process vents (as defined in paragraph (e)(2) of this section) from continuous unit operations.

(C) All transfer racks (as defined in paragraph (e)(2) of this section) that load HAP-containing material.

(D) Equipment (as defined in §63.1101) that contains or contacts organic HAP.

(E) All waste streams (as defined in paragraph (e)(2) of this section) associated with an ethylene production unit.

(F) All heat exchange systems (as defined in §63.1082(b)) associated with an ethylene production unit.

(G) All ethylene cracking furnaces and associated decoking operations.

(ii) Exceptions. The emission points listed in paragraphs (e)(1)(ii) (A) through (L) of this section are in the ethylene production source category but are not subject to the requirements of paragraph (e)(3) of this section.

(A) Equipment that is located within an ethylene production unit that is subject to this subpart but does not contain organic HAP.

(B) Stormwater from segregated sewers.

(C) Water from fire-fighting and deluge systems in segregated sewers.

(D) Spills.

(E) Water from safety showers.

(F) Water from testing of fire-fighting and deluge systems.

(G) Vessels storing organic liquids that contain organic HAP as impurities.

(H) Transfer racks, loading arms, or loading hoses that only transfer liquids containing organic HAP as impurities.

(I) Transfer racks, loading arms, or loading hoses that vapor balance during all transfer operations.

(J) Air emissions from all ethylene cracking furnaces.

(K) Pressure vessels designed to operate in excess of 204.9 kilopascals and without emissions to the atmosphere.

(L) Vessels permanently attached to motor vehicles such as trucks, railcars, barges, or ships.

(iii) Exclusions. The provisions of this subpart do not apply to process units and emission points subject to subparts F, G, H, I and CC of this part.

(iv) Compliance schedule. The compliance schedule for the ethylene production source category is specified in §63.1102.

(2) Definitions. Ethylene process vent means a gas stream with a flow rate greater than 0.005 standard cubic meters per minute containing greater than 20 parts per million by volume HAP that is continuously discharged during operation of an ethylene production unit, as defined in this section. Ethylene process vents are gas streams that are discharged to the atmosphere (or the point of entry into a control device, if any) either directly or after passing through one or more recovery devices. Ethylene process vents do not include relief valve discharges; gaseous streams routed to a fuel gas system; leaks from equipment regulated under this subpart; episodic or nonroutine releases such as those associated with startup, shutdown, and malfunction; and in situ sampling systems (online analyzers).

Decoking operation means the coke combustion activity that occurs inside the radiant tube(s) in the ethylene cracking furnace firebox. Coke combustion activities during decoking can also occur in other downstream equipment such as the process gas outlet piping and transfer line exchangers or quench points.

Ethylene process vent means a gas stream with a flow rate greater than 0.005 standard cubic meters per minute containing greater than 20 parts per million by volume HAP that is continuously discharged during operation of an ethylene production unit. On and after July 6, 2023, ethylene process vent means a gas stream with a flow rate greater than 0.005 standard cubic meters per minute containing greater than 20 parts per million by volume HAP that is continuously or periodically discharged during operation of an ethylene production unit. Ethylene process vents are gas streams that are discharged to the atmosphere (or the point of entry into a control device, if any) either directly or after passing through one or more recovery devices. Ethylene process vents do not include:

(A) Pressure relief device discharges;

(B) Gaseous streams routed to a fuel gas system, including any flares using fuel gas, of which less than 50 percent of the fuel gas is derived from an ethylene production unit;

(C) Gaseous streams routed to a fuel gas system whereby any flares using fuel gas, of which 50 percent or more of the fuel gas is derived from an ethylene production unit, comply with §63.1103(e)(4) beginning no later than the compliance dates specified in §63.1102(c);

(D) Leaks from equipment regulated under this subpart;

(E) Episodic or nonroutine releases such as those associated with startup, shutdown, and malfunction until July 6, 2023;

(F) In situ sampling systems (online analyzers) until July 6, 2023; and

(G) Coke combustion emissions from decoking operations beginning no later than the compliance dates specified in §63.1102(c).

Ethylene production or production unit means a chemical manufacturing process unit in which ethylene and/or propylene are produced by separation from petroleum refining process streams or by subjecting hydrocarbons to high temperatures in the presence of steam. The ethylene production unit includes the separation of ethylene and/or propylene from associated streams such as a C4 product, pyrolysis gasoline, and pyrolysis fuel oil. Ethylene production does not include the manufacture of SOCMI chemicals such as the production of butadiene from the C4 stream and aromatics from pyrolysis gasoline.

Force majeure event means a release of HAP, either directly to the atmosphere from a pressure relief device or discharged via a flare, that is demonstrated to the satisfaction of the Administrator to result from an event beyond the owner or operator's control, such as natural disasters; acts of war or terrorism; loss of a utility external to the ethylene production unit (e.g., external power curtailment), excluding power curtailment due to an interruptible service agreement; and fire or explosion originating at a near or adjoining facility outside of the ethylene production unit that impacts the ethylene production unit's ability to operate.Force majeure event means a release of HAP, either directly to the atmosphere from a pressure relief device or discharged via a flare, that is demonstrated to the satisfaction of the Administrator to result from an event beyond the owner or operator's control, such as natural disasters; acts of war or terrorism; loss of a utility external to the ethylene production unit (e.g., external power curtailment), excluding power curtailment due to an interruptible service agreement; and fire or explosion originating at a near or adjoining facility outside of the ethylene production unit that impacts the ethylene production unit's ability to operate.

Heat exchange system means any cooling tower system or once-through cooling water system (e.g., river or pond water). A heat exchange system can include an entire recirculating or once-through cooling system.

Organic HAP means the compounds listed in Table 1 to subpart XX of this part.

Pressure-assisted multi-point flare means a flare system consisting of multiple flare burners in staged arrays whereby the vent stream pressure is used to promote mixing and smokeless operation at the flare burner tips. Pressure-assisted multi-point flares are designed for smokeless operation at velocities up to Mach = 1 conditions (i.e., sonic conditions), can be elevated or at ground level, and typically use cross-lighting for flame propagation to combust any flare vent gases sent to a particular stage of flare burners.

Pressure relief device means a valve, rupture disk, or similar device used only to release an unplanned, nonroutine discharge of gas from process equipment in order to avoid safety hazards or equipment damage. A pressure relief device discharge can result from an operator error, a malfunction such as a power failure or equipment failure, or other unexpected cause. Such devices include conventional, spring-actuated relief valves, balanced bellows relief valves, pilot-operated relief valves, rupture disks, and breaking, buckling, or shearing pin devices. Devices that are actuated either by a pressure of less than or equal to 2.5 pounds per square inch gauge or by a vacuum are not pressure relief devices.

Periodically dischargedmeans gas stream discharges that are intermittent for which the total organic HAP concentration is greater than 20 parts per million by volume and total volatile organic compound emissions are 50 pounds per day or more. These intermittent discharges are associated with routine operations, maintenance activities, startups, shutdowns, malfunctions, or process upsets and do not include pressure relief device discharges or discharges classified as maintenance vents.

Radiant tube(s) means any portion of the tube coil assembly located within the ethylene cracking furnace firebox whereby a thermal cracking reaction of hydrocarbons (in the presence of steam) occurs. Hydrocarbons and steam pass through the radiant tube(s) of the ethylene cracking furnace during normal operation and coke is removed from the inside of the radiant tube(s) during decoking operation.

Relief valvemeans a type of pressure relief device that is designed to re-close after the pressure relief.

Transfer rack means the collection of loading arms and loading hoses at a single loading rack that is used to fill tank trucks and/or railcars with organic HAP. Transfer rack includes the associated pumps, meters, shutoff valves, relief valves, and other piping and valves. Transfer rack does not include racks, arms, or hoses that contain organic HAP only as impurities; or racks, arms, or hoses that vapor balance during all loading operations.

Waste means any material resulting from industrial, commercial, mining, or agricultural operations, or from community activities, that is discarded or is being accumulated, stored, or physically, chemically, thermally, or biologically treated prior to being discarded, recycled, or discharged.

Waste stream means the waste generated by a particular process unit, product tank, or waste management unit. The characteristics of the waste stream (e.g., flow rate, HAP concentration, water content) are determined at the point of waste generation. Examples of a waste stream include process wastewater, product tank drawdown, sludge and slop oil removed from waste management units, and landfill leachate.

(3) Requirements. The owner or operator must control organic HAP emissions from each affected source emission point by meeting the applicable requirements specified in Table 7 to this section. An owner or operator must perform the applicability assessment procedures and methods for process vents specified in §63.1104, except for paragraphs (d), (g), (h) through (j), (l)(1), and (n). An owner or operator must perform the applicability assessment procedures and methods for equipment leaks specified in §63.1107. General compliance, recordkeeping, and reporting requirements are specified in §§63.1108 through 63.1112. Before July 6, 2023, minimization of emissions from startup, shutdown, and malfunctions must be addressed in the startup, shutdown, and malfunction plan required by §63.1111; the plan must also establish reporting and recordkeeping of such events. A startup, shutdown, and malfunction plan is not required on and after July 6, 2023 and the requirements specified in §63.1111 no longer apply; however, for historical compliance purposes, a copy of the plan must be retained and available on-site for five years after July 6, 2023. Except as specified in paragraph (e)(4)(i) of this section, procedures for approval of alternate means of emission limitations are specified in §63.1113.

(4) Flares. Beginning no later than the compliance dates specified in §63.1102(c), if a steam-assisted, air-assisted, non-assisted, or pressure-assisted multi-point flare is used as a control device for an emission point subject to the requirements in Table 7 to this section, then the owner or operator must meet the applicable requirements for flares as specified in §§63.670 and 63.671 of subpart CC, including the provisions in Tables 12 and 13 to subpart CC of this part, except as specified in paragraphs (e)(4)(i) through (xiv) of this section. This requirement also applies to any flare using fuel gas from a fuel gas system, of which 50 percent or more of the fuel gas is derived from an ethylene production unit, being used to control an emission point subject to the requirements in Table 7 of this section. For purposes of compliance with this paragraph, the following terms are defined in §63.641 of subpart CC: Assist air, assist steam, center steam, combustion zone, combustion zone gas, flare, flare purge gas, flare supplemental gas, flare sweep gas, flare vent gas, lower steam, net heating value, perimeter assist air, pilot gas, premix assist air, total steam, and upper steam.

(i) The owner or operator may elect to comply with the alternative means of emissions limitation requirements specified in of §63.670(r) of subpart CC in lieu of the requirements in §63.670(d) through (f) of subpart CC, as applicable. However, instead of complying with §63.670(r)(3) of subpart CC, the owner or operator must submit the alternative means of emissions limitation request following the requirements in §63.1113.

(ii) Instead of complying with §63.670(o)(2)(i) of subpart CC, the owner or operator must develop and implement the flare management plan no later than the compliance dates specified in §63.1102(c).

(iii) Instead of complying with §63.670(o)(2)(iii) of subpart CC, if required to develop a flare management plan and submit it to the Administrator, then the owner or operator must also submit all versions of the plan in portable document format (PDF) to the EPA via the Compliance and Emissions Data Reporting Interface (CEDRI), which can be accessed through the EPA's Central Data Exchange (CDX) (https://cdx.epa.gov/). If you claim some of the information in your flare management plan is confidential business information (CBI), submit a version with the CBI omitted via CEDRI. A complete plan, including information claimed to be CBI and clearly marked as CBI, must be mailed to the following address: U.S. Environmental Protection Agency, Office of Air Quality Planning and Standards, Sector Policies and Programs Division, U.S. EPA Mailroom (E143-01), Attention: Ethylene Production Sector Lead, 109 T.W. Alexander Drive, Research Triangle Park, NC 27711.

(iv) Section 63.670(o)(3)(ii) of subpart CC and all references to §63.670(o)(3)(ii) of subpart CC do not apply. Instead, the owner or operator must comply with the maximum flare tip velocity operating limit at all times.

(v) Substitute “ethylene production unit” for each occurrence of “petroleum refinery.”

(vi) Each occurrence of “refinery” does not apply.

(vii) Except as specified in paragraph (e)(4)(vii)(G) of this section, if a pressure-assisted multi-point flare is used as a control device for an emission point subject to the requirements in Table 7 to this section, then the owner or operator must comply with the requirements specified in paragraphs (e)(4)(vii)(A) through (F) of this section.

(A) The owner or operator is not required to comply with the flare tip velocity requirements in §63.670(d) and (k) of subpart CC;

(B) The owner or operator must substitute “800” for each occurrence of “270” in §63.670(e) of subpart CC;

(C) The owner or operator must determine the 15-minute block average NHVvg using only the direct calculation method specified in §63.670(l)(5)(ii) of subpart CC;

(D) Instead of complying with §63.670(b) and (g) of subpart CC, if a pressure-assisted multi-point flare uses cross-lighting on a stage of burners rather than having an individual pilot flame on each burner, the owner or operator must operate each stage of the pressure-assisted multi-point flare with a flame present at all times when regulated material is routed to that stage of burners. Each stage of burners that cross-lights in the pressure-assisted multi-point flare must have at least two pilots with at least one continuously lit and capable of igniting all regulated material that is routed to that stage of burners. Each 15-minute block during which there is at least one minute where no pilot flame is present on a stage of burners when regulated material is routed to that stage is a deviation of the standard. Deviations in different 15-minute blocks from the same event are considered separate deviations. The pilot flame(s) on each stage of burners that use cross-lighting must be continuously monitored by a thermocouple or any other equivalent device used to detect the presence of a flame;

(E) Unless the owner or operator of a pressure-assisted multi-point flare chooses to conduct a cross-light performance demonstration as specified in this paragraph, the owner or operator must ensure that if a stage of burners on the flare uses cross-lighting, that the distance between any two burners in series on that stage is no more than 6 feet when measured from the center of one burner to the next burner. A distance greater than 6 feet between any two burners in series may be used provided the owner or operator conducts a performance demonstration that confirms the pressure-assisted multi-point flare will cross-light a minimum of three burners and the spacing between the burners and location of the pilot flame must be representative of the projected installation. The compliance demonstration must be approved by the permitting authority and a copy of this approval must be maintained onsite. The compliance demonstration report must include: A protocol describing the test methodology used, associated test method QA/QC parameters, the waste gas composition and NHVcz of the gas tested, the velocity of the waste gas tested, the pressure-assisted multi-point flare burner tip pressure, the time, length, and duration of the test, records of whether a successful cross-light was observed over all of the burners and the length of time it took for the burners to cross-light, records of maintaining a stable flame after a successful cross-light and the duration for which this was observed, records of any smoking events during the cross-light, waste gas temperature, meteorological conditions (e.g., ambient temperature, barometric pressure, wind speed and direction, and relative humidity), and whether there were any observed flare flameouts; and

(F) The owner or operator of a pressure-assisted multi-point flare must install and operate pressure monitor(s) on the main flare header, as well as a valve position indicator monitoring system for each staging valve to ensure that the flare operates within the proper range of conditions as specified by the manufacturer. The pressure monitor must meet the requirements in Table 13 to subpart CC of this part.