What are capacity and stability requirements?

- PIT operators must participate in stability training.

Perhaps the most critical operational element for Powered Industrial Trucks (PITs) is capacity and stability. In fact, it’s the basic reason most PITs exist. But it can be a hard concept to grasp and explain to workers.

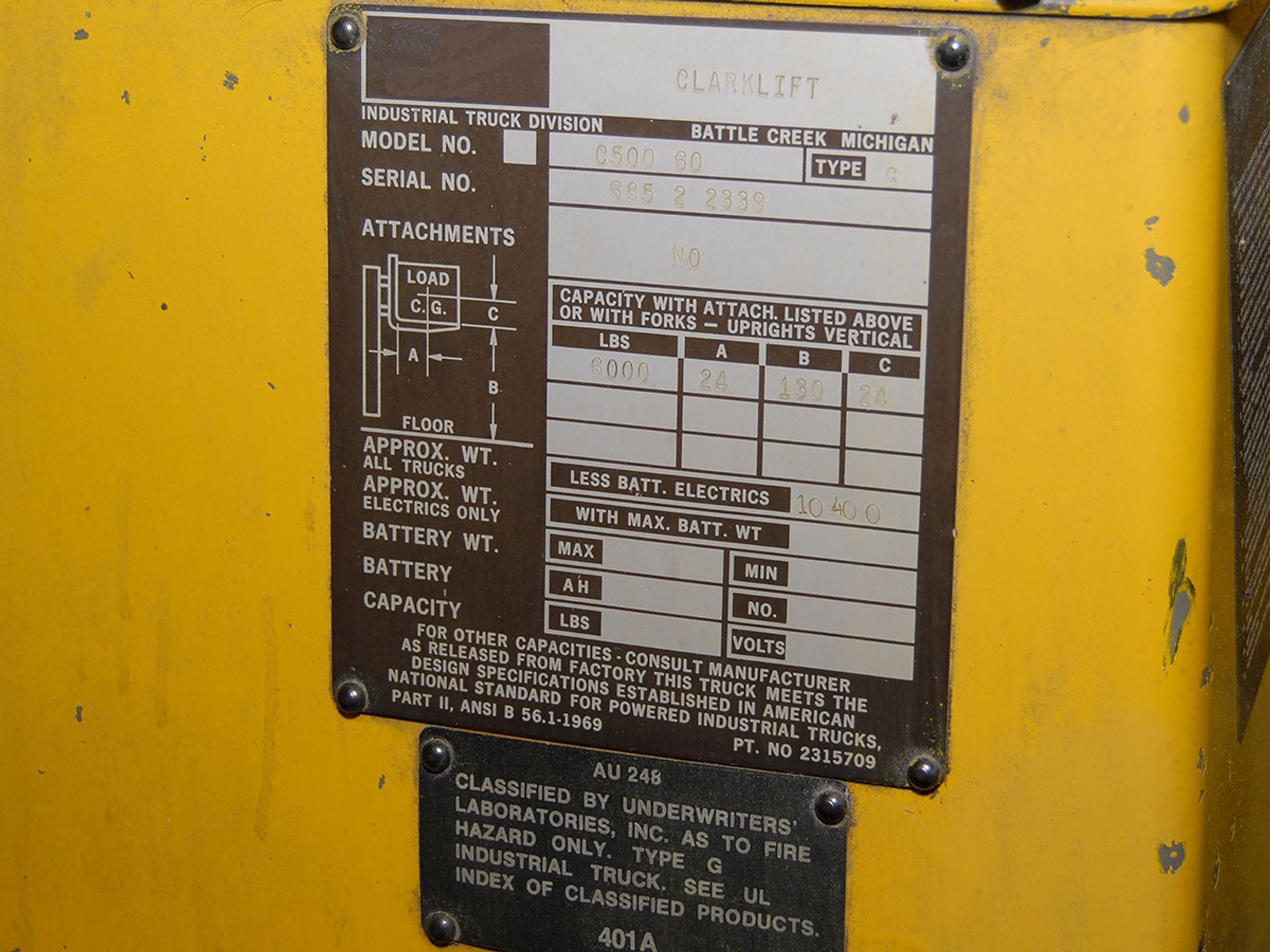

Most PITs work on essentially the same principle as a teeter-totter — the weight of the load on the forks must be counterbalanced by the weight of the truck body. The load weight that each lift can handle can be found on the nameplate, also known as a data plate, capacity plate, or ID plate. The nameplate will state the capacity of the lift — in other words, the manufacturer’s guideline for how much weight can be safely lifted.

The capacity data on the nameplate is critical information, but it was calculated using a load with a specific load center, commonly 24 inches. So, unless every load an operator lifts has a load center of 24 inches — or whatever load center the truck was rated at — and is placed perfectly on the forks, employers have to remember that the actual capacity will be reduced. The same thing goes for attachments — which also typically reduce capacity.

Stability training

Trainers need to have a thorough understanding of load composition and impart it to operators. Trainers must be thoroughly familiar with concepts such as:

- Center of gravity — The point on an object at which all of the object’s weight is concentrated. For symmetrical loads, the center of gravity is at the middle of the load.

- Counterweight — The weight that is built into the truck’s basic structure and used to offset the load’s weight and maximize the vehicle’s resistance to tipping over.

- Fulcrum — The truck’s axis of rotation when it tips over.

- Grade — The slope of a surface, which is usually measured as the number of feet of rise or fall over a 100-foot horizontal distance (the slope is expressed as a percent).

- Lateral stability — A truck’s resistance to overturning sideways.

- Line of action — An imaginary vertical line through an object’s center of gravity.

- Load center — The horizontal distance from the load’s edge (or the fork or other attachment’s vertical face) to the line of action through the load’s center of gravity.

- Longitudinal stability — The truck’s resistance to overturning forward or rearward.

- Moment — The product of the object’s weight times the distance from a fixed point (usually the fulcrum). In the case of a PIT, the distance is measured from the point at which the truck will tip over to the object’s line of action. The distance is always measured perpendicular to the line of action.

- Track — The distance between the wheels on the same axle of the truck.

- Wheelbase — The distance between the centerline of the vehicle’s front and rear wheels.