['Air Programs']

['Air Quality']

11/20/2023

...

§60.280 Applicability and designation of affected facility.

(a) The provisions of this subpart are applicable to the following affected facilities in kraft pulp mills: Digester system, brown stock washer system, multiple-effect evaporator system, recovery furnace, smelt dissolving tank, lime kiln, and condensate stripper system. In pulp mills where kraft pulping is combined with neutral sulfite semichemical pulping, the provisions of this subpart are applicable when any portion of the material charged to an affected facility is produced by the kraft pulping operation.

(b) Except as noted in §60.283(a)(1)(iv), any facility under paragraph (a) of this section that commences construction, reconstruction, or modification after September 24, 1976, and on or before May 23, 2013 is subject to the requirements of this subpart. Any facility under paragraph (a) of this section that commences construction, reconstruction, or modification after May 23, 2013 is subject to the requirements of subpart BBa of this part.

[51 FR 18544, May 20, 1986, as amended at 79 FR 18966, Apr. 4, 2014]

§60.281 Definitions.

As used in this subpart, all terms not defined herein shall have the same meaning given them in the Act and in subpart A.

(a) Kraft pulp mill means any stationary source which produces pulp from wood by cooking (digesting) wood chips in a water solution of sodium hydroxide and sodium sulfide (white liquor) at high temperature and pressure. Regeneration of the cooking chemicals through a recovery process is also considered part of the kraft pulp mill.

(b) Neutral sulfite semichemical pulping operation means any operation in which pulp is produced from wood by cooking (digesting) wood chips in a solution of sodium sulfite and sodium bicarbonate, followed by mechanical defibrating (grinding).

(c) Total reduced sulfur (TRS) means the sum of the sulfur compounds hydrogen sulfide, methyl mercaptan, dimethyl sulfide, and dimethyl disulfide, that are released during the kraft pulping operation and measured by Method 16.

(d) Digester system means each continuous digester or each batch digester used for the cooking of wood in white liquor, and associated flash tank(s), blow tank(s), chip steamer(s), and condenser(s).

(e) Brown stock washer system means brown stock washers and associated knotters, vacuum pumps, and filtrate tanks used to wash the pulp following the digester system. Diffusion washers are excluded from this definition.

(f) Multiple-effect evaporator system means the multiple-effect evaporators and associated condenser(s) and hotwell(s) used to concentrate the spent cooking liquid that is separated from the pulp (black liquor).

(g) Black liquor oxidation system means the vessels used to oxidize, with air or oxygen, the black liquor, and associated storage tank(s).

(h) Recovery furnace means either a straight kraft recovery furnace or a cross recovery furnace, and includes the direct-contact evaporator for a direct-contact furnace.

(i) Straight kraft recovery furnace means a furnace used to recover chemicals consisting primarily of sodium and sulfur compounds by burning black liquor which on a quarterly basis contains 7 weight percent or less of the total pulp solids from the neutral sulfite semichemical process or has green liquor sulfidity of 28 percent or less.

(j) Cross recovery furnace means a furnace used to recover chemicals consisting primarily of sodium and sulfur compounds by burning black liquor which on a quarterly basis contains more than 7 weight percent of the total pulp solids from the neutral sulfite semichemical process and has a green liquor sulfidity of more than 28 percent.

(k) Black liquor solids means the dry weight of the solids which enter the recovery furnace in the black liquor.

(l) Green liquor sulfidity means the sulfidity of the liquor which leaves the smelt dissolving tank.

(m) Smelt dissolving tank means a vessel used for dissolving the smelt collected from the recovery furnace.

(n) Lime kiln means a unit used to calcine lime mud, which consists primarily of calcium carbonate, into quicklime, which is calcium oxide.

(o) Condensate stripper system means a column, and associated condensers, used to strip, with air or steam, TRS compounds from condensate streams from various processes within a kraft pulp mill.

[43 FR 7572, Feb. 23, 1978, as amended at 51 FR 18544, May 20, 1986; 65 FR 61758, Oct. 17, 2000]

§60.282 Standard for particulate matter.

(a) On and after the date on which the performance test required to be conducted by §60.8 is completed, no owner or operator subject to the provisions of this subpart shall cause to be discharged into the atmosphere:

(1) From any recovery furnace any gases which:

(i) Contain particulate matter in excess of 0.10 g/dscm (0.044 gr/dscf) corrected to 8 percent oxygen.

(ii) Exhibit 35 percent opacity or greater.

(2) From any smelt dissolving tank any gases which contain particulate matter in excess of 0.1 g/kg black liquor solids (dry weight)[0.2 lb/ton black liquor solids (dry weight)].

(3) From any lime kiln any gases which contain particulate matter in excess of:

(i) 0.15 g/dscm (0.066 gr/dscf) corrected to 10 percent oxygen, when gaseous fossil fuel is burned.

(ii) 0.30 g/dscm (0.13 gr/dscf) corrected to 10 percent oxygen, when liquid fossil fuel is burned.

[43 FR 7572, Feb. 23, 1978, as amended at 65 FR 61758, Oct. 17, 2000]

§60.283 Standard for total reduced sulfur (TRS).

(a) On and after the date on which the performance test required to be conducted by §60.8 is completed, no owner or operator subject to the provisions of this subpart shall cause to be discharged into the atmosphere:

(1) From any digester system, brown stock washer system, multiple-effect evaporator system, or condensate stripper system any gases which contain TRS in excess of 5 ppm by volume on a dry basis, corrected to 10 percent oxygen, unless the following conditions are met:

(i) The gases are combusted in a lime kiln subject to the provisions of paragraph (a)(5) of this section; or

(ii) The gases are combusted in a recovery furnace subject to the provisions of paragraphs (a)(2) or (a)(3) of this section; or

(iii) The gases are combusted with other waste gases in an incinerator or other device, or combusted in a lime kiln or recovery furnace not subject to the provisions of this subpart, and are subjected to a minimum temperature of 650°C (1200°F) for at least 0.5 second; or

(iv) It has been demonstrated to the Administrator's satisfaction by the owner or operator that incinerating the exhaust gases from a new, modified, or reconstructed brown stock washer system is technologically or economically unfeasible. Any exempt system will become subject to the provisions of this subpart if the facility is changed so that the gases can be incinerated.

(v) The gases from the digester system, brown stock washer system, or condensate stripper system are controlled by a means other than combustion. In this case, this system shall not discharge any gases to the atmosphere which contain TRS in excess of 5 ppm by volume on a dry basis, uncorrected for oxygen content.

(vi) The uncontrolled exhaust gases from a new, modified, or reconstructed digester system contain TRS less than 0.005 g/kg air dried pulp (ADP) (0.01 lb/ton ADP).

(2) From any straight kraft recovery furnace any gases which contain TRS in excess of 5 ppm by volume on a dry basis, corrected to 8 percent oxygen.

(3) From any cross recovery furnace any gases which contain TRS in excess of 25 ppm by volume on a dry basis, corrected to 8 percent oxygen.

(4) From any smelt dissolving tank any gases which contain TRS in excess of 0.016 g/kg black liquor solids as H2S (0.033 lb/ton black liquor solids as H2S).

(5) From any lime kiln any gases which contain TRS in excess of 8 ppm by volume on a dry basis, corrected to 10 percent oxygen.

[43 FR 7572, Feb. 23, 1978, as amended at 50 FR 6317, Feb. 14, 1985; 51 FR 18544, May 20, 1986; 65 FR 61758, Oct. 17, 2000]

§60.284 Monitoring of emissions and operations.

(a) Any owner or operator subject to the provisions of this subpart shall install, calibrate, maintain, and operate the following continuous monitoring systems:

(1) A continuous monitoring system to monitor and record the opacity of the gases discharged into the atmosphere from any recovery furnace. The span of this system shall be set at 70 percent opacity.

(2) Continuous monitoring systems to monitor and record the concentration of TRS emissions on a dry basis and the percent of oxygen by volume on a dry basis in the gases discharged into the atmosphere from any lime kiln, recovery furnace, digester system, brown stock washer system, multiple-effect evaporator system, or condensate stripper system, except where the provisions of §60.283(a)(1)(iii) or (iv) apply. These systems shall be located downstream of the control device(s) and the spans of these continuous monitoring system(s) shall be set:

(i) At a TRS concentration of 30 ppm for the TRS continuous monitoring system, except that for any cross recovery furnace the span shall be set at 50 ppm.

(ii) At 25 percent oxygen for the continuous oxygen monitoring system.

(b) Any owner or operator subject to the provisions of this subpart shall install, calibrate, maintain, and operate the following continuous monitoring devices:

(1) For any incinerator, a monitoring device which measures and records the combustion temperature at the point of incineration of effluent gases which are emitted from any digester system, brown stock washer system, multiple-effect evaporator system, black liquor oxidation system, or condensate stripper system where the provisions of §60.283(a)(1)(iii) apply. The monitoring device is to be certified by the manufacturer to be accurate within ±1 percent of the temperature being measured.

(2) For any lime kiln or smelt dissolving tank using a scrubber emission control device:

(i) A monitoring device for the continuous measurement of the pressure loss of the gas stream through the control equipment. The monitoring device is to be certified by the manufacturer to be accurate to within a gage pressure of ±500 pascals (ca. ±2 inches water gage pressure).

(ii) A monitoring device for the continuous measurement of the scrubbing liquid supply pressure to the control equipment. The monitoring device is to be certified by the manufacturer to be accurate within ±15 percent of design scrubbing liquid supply pressure. The pressure sensor or tap is to be located close to the scrubber liquid discharge point. The Administrator may be consulted for approval of alternative locations.

(c) Any owner or operator subject to the provisions of this subpart shall, except where the provisions of §60.283(a)(1)(iii) or (iv) apply, perform the following:

(1) Calculate and record on a daily basis 12-hour average TRS concentrations for the two consecutive periods of each operating day. Each 12-hour average shall be determined as the arithmetic mean of the appropriate 12 contiguous 1-hour average total reduced sulfur concentrations provided by each continuous monitoring system installed under paragraph (a)(2) of this section.

(2) Calculate and record on a daily basis 12-hour average oxygen concentrations for the two consecutive periods of each operating day for the recovery furnace and lime kiln. These 12-hour averages shall correspond to the 12-hour average TRS concentrations under paragraph (c)(1) of this section and shall be determined as an arithmetic mean of the appropriate 12 contiguous 1-hour average oxygen concentrations provided by each continuous monitoring system installed under paragraph (a)(2) of this section.

(3) Using the following equation, correct all 12-hour average TRS concentrations to 10 volume percent oxygen, except that all 12-hour average TRS concentrations from a recovery furnace shall be corrected to 8 volume percent oxygen instead of 10 percent, and all 12-hour average TRS concentrations from a facility to which the provisions of §60.283(a)(1)(v) apply shall not be corrected for oxygen content:

C corr = C meas × (21− X)/(21− Y)

where:

C corr = the concentration corrected for oxygen.

C meas = the concentration uncorrected for oxygen.

X = the volumetric oxygen concentration in percentage to be corrected to (8 percent for recovery furnaces and 10 percent for lime kilns, incinerators, or other devices).

Y = the measured 12-hour average volumetric oxygen concentration.

(4) Record once per shift measurements obtained from the continuous monitoring devices installed under paragraph (b)(2) of this section.

(d) For the purpose of reports required under §60.7(c), any owner or operator subject to the provisions of this subpart shall report semiannually periods of excess emissions as follows:

(1) For emissions from any recovery furnace periods of excess emissions are:

(i) All 12-hour averages of TRS concentrations above 5 ppm by volume for straight kraft recovery furnaces and above 25 ppm by volume for cross recovery furnaces.

(ii) All 6-minute average opacities that exceed 35 percent.

(2) For emissions from any lime kiln, periods of excess emissions are all 12-hour average TRS concentration above 8 ppm by volume.

(3) For emissions from any digester system, brown stock washer system, multiple-effect evaporator system, or condensate stripper system periods of excess emissions are:

(i) All 12-hour average TRS concentrations above 5 ppm by volume unless the provisions of §60.283(a)(1) (i), (ii), or (iv) apply; or

(ii) All periods in excess of 5 minutes and their duration during which the combustion temperature at the point of incineration is less than 650°C (1200°F), where the provisions of §60.283(a)(1)(iii) apply.

(e) The Administrator will not consider periods of excess emissions reported under paragraph (d) of this section to be indicative of a violation of §60.11(d) provided that:

(1) The percent of the total number of possible contiguous periods of excess emissions in a quarter (excluding periods of startup, shutdown, or malfunction and periods when the facility is not operating) during which excess emissions occur does not exceed:

(i) One percent for TRS emissions from recovery furnaces.

(ii) Six percent for average opacities from recovery furnaces.

(2) The Administrator determines that the affected facility, including air pollution control equipment, is maintained and operated in a manner which is consistent with good air pollution control practice for minimizing emissions during periods of excess emissions.

(f) The procedures under §60.13 shall be followed for installation, evaluation, and operation of the continuous monitoring systems required under this section. All continuous monitoring systems shall be operated in accordance with the applicable procedures under Performance Specifications 1, 3, and 5 of appendix B of this part.

[43 FR 7572, Feb. 23, 1978, as amended at 51 FR 18545, May 20, 1986; 65 FR 61759, Oct. 17, 2000; 71 FR 55127, Sept. 21, 2006; 79 FR 11250, Feb. 27, 2014]

§60.285 Test methods and procedures.

(a) In conducting the performance tests required in §60.8, the owner or operator shall use as reference methods and procedures the test methods in appendix A of this part or other methods and procedures in this section, except as provided in §60.8(b). Acceptable alternative methods and procedures are given in paragraph (f) of this section.

(b) The owner or operator shall determine compliance with the particulate matter standards in §60.282(a) (1) and (3) as follows:

(1) Method 5 shall be used to determine the particulate matter concentration. The sampling time and sample volume for each run shall be at least 60 minutes and 0.90 dscm (31.8 dscf). Water shall be used as the cleanup solvent instead of acetone in the sample recovery procedure. The particulate concentration shall be corrected to the appropriate oxygen concentration according to §60.284(c)(3).

(2) The emission rate correction factor, integrated sampling and analysis procedure of Method 3B shall be used to determine the oxygen concentration. The gas sample shall be taken at the same time and at the same traverse points as the particulate sample.

(3) Method 9 and the procedures in §60.11 shall be used to determine opacity.

(c) The owner or operator shall determine compliance with the particular matter standard in §60.282(a)(2) as follows:

(1) The emission rate (E) of particulate matter shall be computed for each run using the following equation:

E = cs Qsd / BLS

where:

E = emission rate of particulate matter, g/kg (lb/ton) of BLS.

cs = Concentration of particulate matter, g/dscm (lb/dscf).

Qsd = volumetric flow rate of effluent gas, dscm/hr (dscf/hr).

BLS = black liquor solids (dry weight) feed rate, kg/hr (ton/hr).

(2) Method 5 shall be used to determine the particulate matter concentration (cs) and the volumetric flow rate (Qsd) of the effluent gas. The sampling time and sample volume shall be at least 60 minutes and 0.90 dscm (31.8 dscf). Water shall be used instead of acetone in the sample recovery.

(3) Process data shall be used to determine the black liquor solids (BLS) feed rate on a dry weight basis.

(d) The owner or operator shall determine compliance with the TRS standards in §60.283, except §60.283(a)(1)(vi) and (4), as follows:

(1) Method 16 shall be used to determine the TRS concentration. The TRS concentration shall be corrected to the appropriate oxygen concentration using the procedure in §60.284(c)(3). The sampling time shall be at least 3 hours, but no longer than 6 hours.

(2) The emission rate correction factor, integrated sampling and analysis procedure of Method 3B shall be used to determine the oxygen concentration. The sample shall be taken over the same time period as the TRS samples.

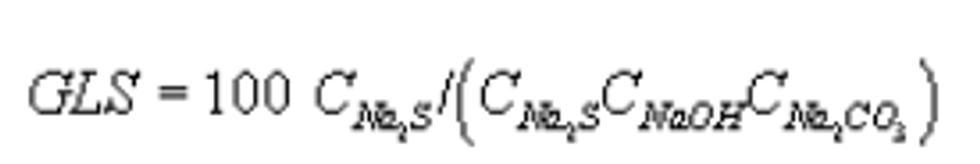

(3) When determining whether a furnace is a straight kraft recovery furnace or a cross recovery furnace, TAPPI Method T.624 (incorporated by reference - see §60.17) shall be used to determine sodium sulfide, sodium hydroxide, and sodium carbonate. These determinations shall be made 3 times daily from the green liquor, and the daily average values shall be converted to sodium oxide (Na20) and substituted into the following equation to determine the green liquor sulfidity:

Where:

GLS = green liquor sulfidity, percent.

CNa2S = concentration of Na2S as Na2O, mg/liter (gr/gal).

CNaOH = concentration of NaOH as Na2O, mg/liter (gr/gal).

CNa2CO3 = concentration of Na2CO3 as Na2O, mg/liter (gr/gal).

(e) The owner or operator shall determine compliance with the TRS standards in §60.283(a)(1)(vi) and (4) as follows:

(1) The emission rate (E) of TRS shall be computed for each run using the following equation:

E = CTRS F Qsd/P

where:

E = emission rate of TRS, g/kg (lb/ton) of BLS or ADP.

CTRS = average combined concentration of TRS, ppm.

F = conversion factor, 0.001417 g H2S/m 3-ppm (8.846 × 10−8 lb H2S/ft 3-ppm).

Qsd = volumetric flow rate of stack gas, dscm/hr (dscf/hr).

P = black liquor solids feed or pulp production rate, kg/hr (ton/hr).

(2) Method 16 shall be used to determine the TRS concentration (CTRS).

(3) Method 2 shall be used to determine the volumetric flow rate (Qsd) of the effluent gas.

(4) Process data shall be used to determine the black liquor feed rate or the pulp production rate (P).

(f) The owner or operator may use the following as alternatives to the reference methods and procedures specified in this section:

(1) For Method 5, Method 17 may be used if a constant value of 0.009 g/dscm (0.004 gr/dscf) is added to the results of Method 17 and the stack temperature is no greater than 204°C (400°F).

(2) In place of Method 16, Method 16A or 16B may be used.

[54 FR 6673, Feb. 14, 1989; 54 FR 21344, May 17, 1989, as amended at 55 FR 5212, Feb. 14, 1990; 65 FR 61759, Oct. 17, 2000]

['Air Programs']

['Air Quality']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.