['Air Programs']

['Air Quality']

11/20/2023

...

�60.100a Applicability, designation of affected facility, and reconstruction.

(a) The provisions of this subpart apply to the following affected facilities in petroleum refineries: fluid catalytic cracking units (FCCU), fluid coking units (FCU), delayed coking units, fuel gas combustion devices (including process heaters), flares and sulfur recovery plants. The sulfur recovery plant need not be physically located within the boundaries of a petroleum refinery to be an affected facility, provided it processes gases produced within a petroleum refinery.

(b) Except for flares and delayed coking units, the provisions of this subpart apply only to affected facilities under paragraph (a) of this section which either commence construction, modification or reconstruction after May 14, 2007, or elect to comply with the provisions of this subpart in lieu of complying with the provisions in subpart J of this part. For flares, the provisions of this subpart apply only to flares which commence construction, modification or reconstruction after June 24, 2008. For the purposes of this subpart, a modification to a flare commences when a project that includes any of the activities in paragraphs (c)(1) or (2) of this section is commenced. For delayed coking units, the provisions of this subpart apply to delayed coking units that commence construction, reconstruction or modification on the earliest of the following dates:

(1) May 14, 2007, for such activities that involve a �delayed coking unit� defined as follows: one or more refinery process units in which high molecular weight petroleum derivatives are thermally cracked and petroleum coke is produced in a series of closed, batch system reactors;

(2) December 22, 2008, for such activities that involve a �delayed coking unit� defined as follows: a refinery process unit in which high molecular weight petroleum derivatives are thermally cracked and petroleum coke is produced in a series of closed, batch system reactors. A delayed coking unit consists of the coke drums and associated fractionator;

(3) September 12, 2012, for such activities that involve a �delayed coking unit� as defined in �60.101a.

(c) For all affected facilities other than flares, the provisions in �60.14 regarding modification apply. As provided in �60.14(f), the special provisions set forth under this subpart shall supersede the provisions in �60.14 with respect to flares. For the purposes of this subpart, a modification to a flare occurs as provided in paragraphs (c)(1) or (2) of this section.

(1) Any new piping from a refinery process unit, including ancillary equipment, or a fuel gas system is physically connected to the flare (e.g., for direct emergency relief or some form of continuous or intermittent venting). However, the connections described in paragraphs (c)(1)(i) through (vii) of this section are not considered modifications of a flare.

(i) Connections made to install monitoring systems to the flare.

(ii) Connections made to install a flare gas recovery system or connections made to upgrade or enhance components of a flare gas recovery system (e.g., addition of compressors or recycle lines).

(iii) Connections made to replace or upgrade existing pressure relief or safety valves, provided the new pressure relief or safety valve has a set point opening pressure no lower and an internal diameter no greater than the existing equipment being replaced or upgraded.

(iv) Connections made for flare gas sulfur removal.

(v) Connections made to install back-up (redundant) equipment associated with the flare (such as a back-up compressor) that does not increase the capacity of the flare.

(vi) Replacing piping or moving an existing connection from a refinery process unit to a new location in the same flare, provided the new pipe diameter is less than or equal to the diameter of the pipe/connection being replaced/moved.

(vii) Connections that interconnect two or more flares.

(2) A flare is physically altered to increase the flow capacity of the flare.

(d) For purposes of this subpart, under �60.15, the �fixed capital cost of the new components� includes the fixed capital cost of all depreciable components which are or will be replaced pursuant to all continuous programs of component replacement which are commenced within any 2-year period following the relevant applicability date specified in paragraph (b) of this section.

[73 FR 35867, June 24, 2008, as amended at 77 FR 56464, Sep. 12, 2012; 80 FR 75230, Dec. 1, 2015]

�60.101a Definitions.

Terms used in this subpart are defined in the Clean Air Act (CAA), in �60.2 and in this section.

Air preheat means a device used to heat the air supplied to a process heater generally by use of a heat exchanger to recover the sensible heat of exhaust gas from the process heater.

Ancillary equipment means equipment used in conjunction with or that serve a refinery process unit. Ancillary equipment includes, but is not limited to, storage tanks, product loading operations, wastewater treatment systems, steam- or electricity-producing units (including coke gasification units), pressure relief valves, pumps, sampling vents and continuous analyzer vents.

Cascaded flare system means a series of flares connected to one flare gas header system arranged with increasing pressure set points so that discharges will be initially directed to the first flare in the series (i.e., the primary flare). If the discharge pressure exceeds a set point at which the flow to the primary flare would exceed the primary flare's capacity, flow will be diverted to the second flare in the series. Similarly, flow would be diverted to a third (or fourth) flare if the pressure in the flare gas header system exceeds a threshold where the flow to the first two (or three) flares would exceed their capacities.

Co-fired process heater means a process heater that employs burners that are designed to be supplied by both gaseous and liquid fuels on a routine basis. Process heaters that have gas burners with emergency oil back-up burners are not considered co-fired process heaters.

Coke burn-off means the coke removed from the surface of the FCCU catalyst by combustion in the catalyst regenerator. The rate of coke burn-off is calculated by the formula specified in �60.104a.

Contact material means any substance formulated to remove metals, sulfur, nitrogen, or any other contaminant from petroleum derivatives.

Corrective action means the design, operation and maintenance changes that one takes consistent with good engineering practice to reduce or eliminate the likelihood of the recurrence of the primary cause and any other contributing cause(s) of an event identified by a root cause analysis as having resulted in a discharge of gases from an affected facility in excess of specified thresholds.

Corrective action analysis means a description of all reasonable interim and long-term measures, if any, that are available, and an explanation of why the selected corrective action(s) is/are the best alternative(s), including, but not limited to, considerations of cost effectiveness, technical feasibility, safety and secondary impacts.

Delayed coking unit means a refinery process unit in which high molecular weight petroleum derivatives are thermally cracked and petroleum coke is produced in a series of closed, batch system reactors. A delayed coking unit includes, but is not limited to, all of the coke drums associated with a single fractionator; the fractionator, including the bottoms receiver and the overhead condenser; the coke drum cutting water and quench system, including the jet pump and coker quench water tank; and the coke drum blowdown recovery compressor system.

Emergency flare means a flare that combusts gas exclusively released as a result of malfunctions (and not startup, shutdown, routine operations or any other cause) on four or fewer occasions in a rolling 365-day period. For purposes of this rule, a flare cannot be categorized as an emergency flare unless it maintains a water seal.

Flare means a combustion device that uses an uncontrolled volume of air to burn gases. The flare includes the foundation, flare tip, structural support, burner, igniter, flare controls, including air injection or steam injection systems, flame arrestors and the flare gas header system. In the case of an interconnected flare gas header system, the flare includes each individual flare serviced by the interconnected flare gas header system and the interconnected flare gas header system.

Flare gas header system means all piping and knockout pots, including those in a subheader system, used to collect and transport gas to a flare either from a process unit or a pressure relief valve from the fuel gas system, regardless of whether or not a flare gas recovery system draws gas from the flare gas header system. The flare gas header system includes piping inside the battery limit of a process unit if the purpose of the piping is to transport gas to a flare or knockout pot that is part of the flare.

Flare gas recovery system means a system of one or more compressors, piping and the associated water seal, rupture disk or similar device used to divert gas from the flare and direct the gas to the fuel gas system or to a fuel gas combustion device.

Flexicoking unit means a refinery process unit in which high molecular weight petroleum derivatives are thermally cracked and petroleum coke is continuously produced and then gasified to produce a synthetic fuel gas.

Fluid catalytic cracking unit means a refinery process unit in which petroleum derivatives are continuously charged and hydrocarbon molecules in the presence of a catalyst suspended in a fluidized bed are fractured into smaller molecules, or react with a contact material suspended in a fluidized bed to improve feedstock quality for additional processing and the catalyst or contact material is continuously regenerated by burning off coke and other deposits. The unit includes the riser, reactor, regenerator, air blowers, spent catalyst or contact material stripper, catalyst or contact material recovery equipment, and regenerator equipment for controlling air pollutant emissions and for heat recovery. When fluid catalyst cracking unit regenerator exhaust from two separate fluid catalytic cracking units share a common exhaust treatment (e.g., CO boiler or wet scrubber), the fluid catalytic cracking unit is a single affected facility.

Fluid coking unit means a refinery process unit in which high molecular weight petroleum derivatives are thermally cracked and petroleum coke is continuously produced in a fluidized bed system. The fluid coking unit includes the coking reactor, the coking burner, and equipment for controlling air pollutant emissions and for heat recovery on the fluid coking burner exhaust vent.

Forced draft process heater means a process heater in which the combustion air is supplied under positive pressure produced by a fan at any location in the inlet air line prior to the point where the combustion air enters the process heater or air preheat. For the purposes of this subpart, a process heater that uses fans at both the inlet air side and the exhaust air side (i.e., balanced draft system) is considered to be a forced draft process heater.

Fuel gas means any gas which is generated at a petroleum refinery and which is combusted. Fuel gas includes natural gas when the natural gas is combined and combusted in any proportion with a gas generated at a refinery. Fuel gas does not include gases generated by catalytic cracking unit catalyst regenerators, coke calciners (used to make premium grade coke) and fluid coking burners, but does include gases from flexicoking unit gasifiers and other gasifiers. Fuel gas does not include vapors that are collected and combusted in a thermal oxidizer or flare installed to control emissions from wastewater treatment units other than those processing sour water, marine tank vessel loading operations or asphalt processing units (i.e., asphalt blowing stills).

Fuel gas combustion device means any equipment, such as process heaters and boilers, used to combust fuel gas. For the purposes of this subpart, fuel gas combustion device does not include flares or facilities in which gases are combusted to produce sulfur or sulfuric acid.

Fuel gas system means a system of compressors, piping, knock-out pots, mix drums, and units used to remove sulfur contaminants from the fuel gas (e.g., amine scrubbers) that collects refinery fuel gas from one or more sources for treatment as necessary prior to combusting in process heaters or boilers. A fuel gas system may have an overpressure vent to a flare but the primary purpose for a fuel gas system is to provide fuel to the refinery.

Natural draft process heater means any process heater in which the combustion air is supplied under ambient or negative pressure without the use of an inlet air (forced draft) fan. For the purposes of this subpart, a natural draft process heater is any process heater that is not a forced draft process heater, including induced draft systems.

Non-emergency flare means any flare that is not an emergency flare as defined in this subpart.

Oxidation control system means an emission control system which reduces emissions from sulfur recovery plants by converting these emissions to sulfur dioxide (SO2) and recycling the SO2 to the reactor furnace or the first-stage catalytic reactor of the Claus sulfur recovery plant or converting the SO2 to a sulfur product.

Petroleum means the crude oil removed from the earth and the oils derived from tar sands, shale, and coal.

Petroleum refinery means any facility engaged in producing gasoline, kerosene, distillate fuel oils, residual fuel oils, lubricants, asphalt (bitumen) or other products through distillation of petroleum or through redistillation, cracking or reforming of unfinished petroleum derivatives. A facility that produces only oil shale or tar sands-derived crude oil for further processing at a petroleum refinery using only solvent extraction and/or distillation to recover diluent is not a petroleum refinery.

Primary flare means the first flare in a cascaded flare system.

Process heater means an enclosed combustion device used to transfer heat indirectly to process stream materials (liquids, gases, or solids) or to a heat transfer material for use in a process unit instead of steam.

Process upset gas means any gas generated by a petroleum refinery process unit or by ancillary equipment as a result of startup, shutdown, upset or malfunction.

Purge gas means gas introduced between a flare's water seal and a flare's tip to prevent oxygen infiltration (backflow) into the flare tip. For flares with no water seals, the function of purge gas is performed by sweep gas (i.e., flares without water seals do not use purge gas).

Reduced sulfur compounds means hydrogen sulfide (H2S), carbonyl sulfide, and carbon disulfide.

Reduction control system means an emission control system which reduces emissions from sulfur recovery plants by converting these emissions to H2S and either recycling the H2S to the reactor furnace or the first-stage catalytic reactor of the Claus sulfur recovery plant or converting the H2S to a sulfur product.

Refinery process unit means any segment of the petroleum refinery in which a specific processing operation is conducted.

Root cause analysis means an assessment conducted through a process of investigation to determine the primary cause, and any other contributing cause(s), of a discharge of gases in excess of specified thresholds.

Secondary flare means a flare in a cascaded flare system that provides additional flare capacity and pressure relief to a flare gas system when the flare gas flow exceeds the capacity of the primary flare. For purposes of this subpart, a secondary flare is characterized by infrequent use and must maintain a water seal.

Sour water means water that contains sulfur compounds (usually H2S) at concentrations of 10 parts per million by weight or more.

Sulfur pit means the storage vessel in which sulfur that is condensed after each Claus catalytic reactor is initially accumulated and stored. A sulfur pit does not include secondary sulfur storage vessels downstream of the initial Claus reactor sulfur pits.

Sulfur recovery plant means all process units which recover sulfur from H2S and/or SO2 from a common source of sour gas produced at a petroleum refinery. The sulfur recovery plant also includes sulfur pits used to store the recovered sulfur product, but it does not include secondary sulfur storage vessels or loading facilities downstream of the sulfur pits. For example, a Claus sulfur recovery plant includes: Reactor furnace and waste heat boiler, catalytic reactors, sulfur pits and, if present, oxidation or reduction control systems or incinerator, thermal oxidizer or similar combustion device. Multiple sulfur recovery units are a single affected facility only when the units share the same source of sour gas. Sulfur recovery plants that receive source gas from completely segregated sour gas treatment systems are separate affected facilities.

Sweep gas means the gas introduced in a flare gas header system to maintain a constant flow of gas to prevent oxygen buildup in the flare header. For flares with no water seals, sweep gas also performs the function of preventing oxygen infiltration (backflow) into the flare tip.

[73 FR 35867, June 24, 2008, as amended at 77 FR 56464, Sep. 12, 2012; 78 FR 76756, Dec. 19, 2013; 80 FR 75230, Dec. 1, 2015]

�60.102a Emissions limitations.

(a) Each owner or operator that is subject to the requirements of this subpart shall comply with the emissions limitations in paragraphs (b) through (i) of this section on and after the date on which the initial performance test, required by �60.8, is completed, but not later than 60 days after achieving the maximum production rate at which the affected facility will be operated or 180 days after initial startup, whichever comes first.

(b) An owner or operator subject to the provisions of this subpart shall not discharge or cause the discharge into the atmosphere from any FCCU or FCU:

(1) Particulate matter (PM) in excess of the limits in paragraphs (b)(1)(i), (ii), or (iii) of this section.

(i) 1.0 gram per kilogram (g/kg) (1 pound (lb) per 1,000 lb) coke burn-off or, if a PM continuous emission monitoring system (CEMS) is used, 0.040 grain per dry standard cubic feet (gr/dscf) corrected to 0 percent excess air for each modified or reconstructed FCCU.

(ii) 0.5 gram per kilogram (g/kg) coke burn-off (0.5 lb PM/1,000 lb coke burn-off) or, if a PM CEMS is used, 0.020 gr/dscf corrected to 0 percent excess air for each newly constructed FCCU.

(iii) 1.0 g/kg (1 lb/1,000 lb) coke burn-off or, if a PM CEMS is used, 0.040 grain per dry standard cubic feet (gr/dscf) corrected to 0 percent excess air for each affected FCU.

(2) Nitrogen oxides (NOX) in excess of 80 parts per million by volume (ppmv), dry basis corrected to 0 percent excess air, on a 7-day rolling average basis.

(3) Sulfur dioxide (SO2) in excess of 50 ppmv dry basis corrected to 0 percent excess air, on a 7-day rolling average basis and 25 ppmv, dry basis corrected to 0 percent excess air, on a 365-day rolling average basis.

(4) Carbon monoxide (CO) in excess of 500 ppmv, dry basis corrected to 0 percent excess air, on an hourly average basis.

(c) The owner or operator of a FCCU or FCU that uses a continuous parameter monitoring system (CPMS) according to �60.105a(b)(1) shall comply with the applicable control device parameter operating limit in paragraph (c)(1) or (2) of this section.

(1) If the FCCU or FCU is controlled using an electrostatic precipitator:

(i) The 3-hour rolling average total power and secondary current to the entire system must not fall below the level established during the most recent performance test; and

(ii) The daily average exhaust coke burn-off rate must not exceed the level established during the most recent performance test.

(2) If the FCCU or FCU is controlled using a wet scrubber:

(i) The 3-hour rolling average pressure drop must not fall below the level established during the most recent performance test; and

(ii) The 3-hour rolling average liquid-to-gas ratio must not fall below the level established during the most recent performance test.

(d) If an FCCU or FCU uses a continuous opacity monitoring system (COMS) according to the alternative monitoring option in �60.105a(e), the 3-hour rolling average opacity of emissions from the FCCU or FCU as measured by the COMS must not exceed the site-specific opacity limit established during the most recent performance test.

(e) The owner or operator of a FCCU or FCU that is exempted from the requirement for a CO continuous emissions monitoring system under �60.105a(h)(3) shall comply with the parameter operating limits in paragraph (e)(1) or (2) of this section.

(1) For a FCCU or FCU with no post-combustion control device:

(i) The hourly average temperature of the exhaust gases exiting the FCCU or FCU must not fall below the level established during the most recent performance test.

(ii) The hourly average oxygen (O2) concentration of the exhaust gases exiting the FCCU or FCU must not fall below the level established during the most recent performance test.

(2) For a FCCU or FCU with a post-combustion control device:

(i) The hourly average temperature of the exhaust gas vent stream exiting the control device must not fall below the level established during the most recent performance test.

(ii) The hourly average O2 concentration of the exhaust gas vent stream exiting the control device must not fall below the level established during the most recent performance test.

(f) Except as provided in paragraph (f)(3) of this section, each owner or operator of an affected sulfur recovery plant shall comply with the applicable emission limits in paragraph (f)(1) or (2) of this section.

(1) For a sulfur recovery plant with a design production capacity greater than 20 long tons per day (LTD), the owner or operator shall comply with the applicable emission limit in paragraph (f)(1)(i) or (ii) of this section. If the sulfur recovery plant consists of multiple process trains or release points, the owner or operator shall comply with the applicable emission limit for each process train or release point individually or comply with the applicable emission limit in paragraph (f)(1)(i) or (ii) as a flow rate weighted average for a group of release points from the sulfur recovery plant provided that flow is monitored as specified in �60.106a(a)(7); if flow is not monitored as specified in �60.106a(a)(7), the owner or operator shall comply with the applicable emission limit in paragraph (f)(1)(i) or (ii) for each process train or release point individually. For a sulfur recovery plant with a design production capacity greater than 20 long LTD and a reduction control system not followed by incineration, the owner or operator shall also comply with the H2S emission limit in paragraph (f)(1)(iii) of this section for each individual release point.

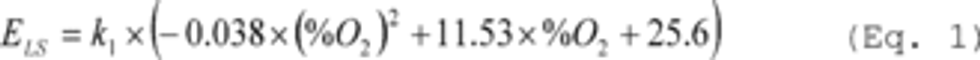

(i) For a sulfur recovery plant with an oxidation control system or a reduction control system followed by incineration, the owner or operator shall not discharge or cause the discharge of any gases containing SO2 into the atmosphere in excess of the emission limit calculated using Equation 1 of this section. For Claus units that use only ambient air in the Claus burner or that elect not to monitor O2 concentration of the air/oxygen mixture used in the Claus burner or for non-Claus sulfur recovery plants, this SO2 emissions limit is 250 ppmv (dry basis) at zero percent excess air.

Where:

ELS = Emission limit for large sulfur recovery plant, ppmv (as SO2, dry basis at zero percent excess air);

k1 = Constant factor for emission limit conversion: k1 = 1 for converting to the SO2 limit for a sulfur recovery plant with an oxidation control system or a reduction control system followed by incineration and k1 = 1.2 for converting to the reduced sulfur compounds limit for a sulfur recovery plant with a reduction control system not followed by incineration; and

%O2 = O2 concentration of the air/oxygen mixture supplied to the Claus burner, percent by volume (dry basis). If only ambient air is used for the Claus burner or if the owner or operator elects not to monitor O2 concentration of the air/oxygen mixture used in the Claus burner or for non-Claus sulfur recovery plants, use 20.9% for %O2.

(ii) For a sulfur recovery plant with a reduction control system not followed by incineration, the owner or operator shall not discharge or cause the discharge of any gases into the atmosphere containing reduced sulfur compounds in excess of the emission limit calculated using Equation 1 of this section. For Claus units that use only ambient air in the Claus burner or for non-Claus sulfur recovery plants, this reduced sulfur compounds emission limit is 300 ppmv calculated as ppmv SO2 (dry basis) at 0-percent excess air.

(iii) For a sulfur recovery plant with a reduction control system not followed by incineration, the owner or operator shall not discharge or cause the discharge of any gases into the atmosphere containing hydrogen sulfide (H2S) in excess of 10 ppmv calculated as ppmv SO2 (dry basis) at zero percent excess air.

(2) For a sulfur recovery plant with a design production capacity of 20 LTD or less, the owner or operator shall comply with the applicable emission limit in paragraph (f)(2)(i) or (ii) of this section. If the sulfur recovery plant consists of multiple process trains or release points, the owner or operator may comply with the applicable emission limit for each process train or release point individually or comply with the applicable emission limit in paragraph (f)(2)(i) or (ii) as a flow rate weighted average for a group of release points from the sulfur recovery plant provided that flow is monitored as specified in �60.106a(a)(7); if flow is not monitored as specified in �60.106a(a)(7), the owner or operator shall comply with the applicable emission limit in paragraph (f)(2)(i) or (ii) for each process train or release point individually. For a sulfur recovery plant with a design production capacity of 20 LTD or less and a reduction control system not followed by incineration, the owner or operator shall also comply with the H2S emission limit in paragraph (f)(2)(iii) of this section for each individual release point.

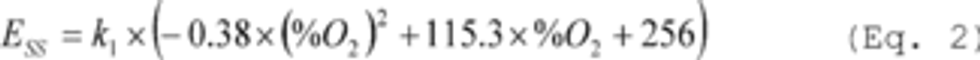

(i) For a sulfur recovery plant with an oxidation control system or a reduction control system followed by incineration, the owner or operator shall not discharge or cause the discharge of any gases into the atmosphere containing SO2 in excess of the emission limit calculated using Equation 2 of this section. For Claus units that use only ambient air in the Claus burner or that elect not to monitor O2 concentration of the air/oxygen mixture used in the Claus burner or for non-Claus sulfur recovery plants, this SO2 emission limit is 2,500 ppmv (dry basis) at zero percent excess air.

Where:

ESS = Emission limit for small sulfur recovery plant, ppmv (as SO2, dry basis at zero percent excess air);

k1 = Constant factor for emission limit conversion: k1 = 1 for converting to the SO2 limit for a sulfur recovery plant with an oxidation control system or a reduction control system followed by incineration and k1 = 1.2 for converting to the reduced sulfur compounds limit for a sulfur recovery plant with a reduction control system not followed by incineration; and

%O2 = O2 concentration of the air/oxygen mixture supplied to the Claus burner, percent by volume (dry basis). If only ambient air is used in the Claus burner or if the owner or operator elects not to monitor O2 concentration of the air/oxygen mixture used in the Claus burner or for non-Claus sulfur recovery plants, use 20.9% for %O2.

(ii) For a sulfur recovery plant with a reduction control system not followed by incineration, the owner or operator shall not discharge or cause the discharge of any gases into the atmosphere containing reduced sulfur compounds in excess of the emission limit calculated using Equation 2 of this section. For Claus units that use only ambient air in the Claus burner or for non-Claus sulfur recovery plants, this reduced sulfur compounds emission limit is 3,000 ppmv calculated as ppmv SO2 (dry basis) at zero percent excess air.

(iii) For a sulfur recovery plant with a reduction control system not followed by incineration, the owner or operator shall not discharge or cause the discharge of any gases into the atmosphere containing H2S in excess of 100 ppmv calculated as ppmv SO2 (dry basis) at zero percent excess air.

(3) The emission limits in paragraphs (f)(1) and (2) of this section shall not apply during periods of maintenance of the sulfur pit, which shall not exceed 240 hours per year. The owner or operator must document the time periods during which the sulfur pit vents were not controlled and measures taken to minimize emissions during these periods. Examples of these measures include not adding fresh sulfur or shutting off vent fans.

(g) Each owner or operator of an affected fuel gas combustion device shall comply with the emissions limits in paragraphs (g)(1) and (2) of this section.

(1) Except as provided in (g)(1)(iii) of this section, for each fuel gas combustion device, the owner or operator shall comply with either the emission limit in paragraph (g)(1)(i) of this section or the fuel gas concentration limit in paragraph (g)(1)(ii) of this section. For CO boilers or furnaces that are part of a fluid catalytic cracking unit or fluid coking unit affected facility, the owner or operator shall comply with the fuel gas concentration limit in paragraph (g)(1)(ii) for all fuel gas streams combusted in these units.

(i) The owner or operator shall not discharge or cause the discharge of any gases into the atmosphere that contain SO2 in excess of 20 ppmv (dry basis, corrected to 0-percent excess air) determined hourly on a 3-hour rolling average basis and SO2 in excess of 8 ppmv (dry basis, corrected to 0-percent excess air), determined daily on a 365 successive calendar day rolling average basis; or

(ii) The owner or operator shall not burn in any fuel gas combustion device any fuel gas that contains H2S in excess of 162 ppmv determined hourly on a 3-hour rolling average basis and H2S in excess of 60 ppmv determined daily on a 365 successive calendar day rolling average basis.

(iii) The combustion in a portable generator of fuel gas released as a result of tank degassing and/or cleaning is exempt from the emissions limits in paragraphs (g)(1)(i) and (ii) of this section.

(2) For each process heater with a rated capacity of greater than 40 million British thermal units per hour (MMBtu/hr) on a higher heating value basis, the owner or operator shall not discharge to the atmosphere any emissions of NOX in excess of the applicable limits in paragraphs (g)(2)(i) through (iv) of this section.

(i) For each natural draft process heater, comply with the limit in either paragraph (g)(2)(i)(A) or (B) of this section. The owner or operator may comply with either limit at any time, provided that the appropriate parameters for each alternative are monitored as specified in �60.107a; if fuel gas composition is not monitored as specified in �60.107a(d), the owner or operator must comply with the concentration limits in paragraph (g)(2)(i)(A) of this section.

(A) 40 ppmv (dry basis, corrected to 0-percent excess air) determined daily on a 30-day rolling average basis; or

(B) 0.040 pounds per million British thermal units (lb/MMBtu) higher heating value basis determined daily on a 30-day rolling average basis.

(ii) For each forced draft process heater, comply with the limit in either paragraph (g)(2)(ii)(A) or (B) of this section. The owner or operator may comply with either limit at any time, provided that the appropriate parameters for each alternative are monitored as specified in �60.107a; if fuel gas composition is not monitored as specified in �60.107a(d), the owner or operator must comply with the concentration limits in paragraph (g)(2)(ii)(A) of this section.

(A) 60 ppmv (dry basis, corrected to 0-percent excess air) determined daily on a 30-day rolling average basis; or

(B) 0.060 lb/MMBtu higher heating value basis determined daily on a 30-day rolling average basis.

(iii) For each co-fired natural draft process heater, comply with the limit in either paragraph (g)(2)(iii)(A) or (B) of this section. The owner or operator must choose one of the emissions limits with which to comply at all times:

(A) 150 ppmv (dry basis, corrected to 0-percent excess air) determined daily on a 30 successive operating day rolling average basis; or

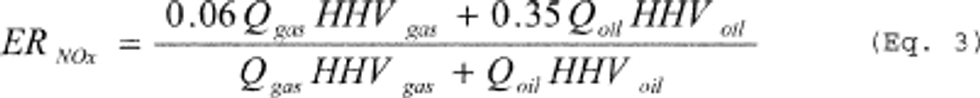

(B) The daily average emissions limit calculated using Equation 3 of this section:

Where:

ERNOx = Daily allowable average emission rate of NOX, lb/MMBtu (higher heating value basis);

Qgas = Daily average volumetric flow rate of fuel gas, standard cubic feet per day (scf/day);

Qoil = Daily average volumetric flow rate of fuel oil, scf/day;

HHVgas = Daily average higher heating value of gas fired to the process heater, MMBtu/scf; and

HHVoil = Daily average higher heating value of fuel oil fired to the process heater, MMBtu/scf.

(iv) For each co-fired forced draft process heater, comply with the limit in either paragraph (g)(2)(iv)(A) or (B) of this section. The owner or operator must choose one of the emissions limits with which to comply at all times:

(A) 150 ppmv (dry basis, corrected to 0-percent excess air) determined daily on a 30 successive operating day rolling average basis; or

(B) The daily average emissions limit calculated using Equation 4 of this section:

Where:

ERNOx = Daily allowable average emission rate of NOX, lb/MMBtu (higher heating value basis);

Qgas = Daily average volumetric flow rate of fuel gas, scf/day;

Qoil = Daily average volumetric flow rate of fuel oil, scf/day;

HHVgas = Daily average higher heating value of gas fired to the process heater, MMBtu/scf; and

HHVoil = Daily average higher heating value of fuel oil fired to the process heater, MMBtu/scf.

(h) [Reserved]

(i) For a process heater that meets any of the criteria of paragraphs (i)(1)(i) through (iv) of this section, an owner or operator may request approval from the Administrator for a NOX emissions limit which shall apply specifically to that affected facility. The request shall include information as described in paragraph (i)(2) of this section. The request shall be submitted and followed as described in paragraph (i)(3) of this section.

(1) A process heater that meets one of the criteria in paragraphs (i)(1)(i) through (iv) of this section may apply for a site-specific NOX emissions limit:

(i) A modified or reconstructed process heater that lacks sufficient space to accommodate installation and proper operation of combustion modification-based technology (e.g., ultra-low NOX burners); or

(ii) A modified or reconstructed process heater that has downwardly firing induced draft burners; or

(iii) A co-fired process heater; or

(iv) A process heater operating at reduced firing conditions for an extended period of time (i.e., operating in turndown mode). The site-specific NOX emissions limit will only apply for those operating conditions.

(2) The request shall include sufficient and appropriate data, as determined by the Administrator, to allow the Administrator to confirm that the process heater is unable to comply with the applicable NOX emissions limit in paragraph (g)(2) of this section. At a minimum, the request shall contain the information described in paragraphs (i)(2)(i) through (iv) of this section.

(i) The design and dimensions of the process heater, evaluation of available combustion modification-based technology, description of fuel gas and, if applicable, fuel oil characteristics, information regarding the combustion conditions (temperature, oxygen content, firing rates) and other information needed to demonstrate that the process heater meets one of the four classes of process heaters listed in paragraph (i)(1) of this section.

(ii) An explanation of how the data in paragraph (i)(2)(i) demonstrate that ultra-low NOX burners, flue gas recirculation, control of excess air or other combustion modification-based technology (including combinations of these combustion modification-based technologies) cannot be used to meet the applicable emissions limit in paragraph (g)(2) of this section.

(iii) Results of a performance test conducted under representative conditions using the applicable methods specified in �60.104a(i) to demonstrate the performance of the technology the owner or operator will use to minimize NOX emissions.

(iv) The means by which the owner or operator will document continuous compliance with the site-specific emissions limit.

(3) The request shall be submitted and followed as described in paragraphs (i)(3)(i) through (iii) of this section.

(i) The owner or operator of a process heater that meets one of the criteria in paragraphs (i)(1)(i) through (iv) of this section may request approval from the Administrator within 180 days after initial startup of the process heater for a NOX emissions limit which shall apply specifically to that affected facility.

(ii) The request must be submitted to the Administrator for approval. The owner or operator must comply with the request as submitted until it is approved.

(iii) The request shall also be submitted to the following address: U.S. Environmental Protection Agency, Office of Air Quality Planning and Standards, Sector Policies and Programs Division, U.S. EPA Mailroom (E143-01), Attention: Refinery Sector Lead, 109 T.W. Alexander Drive, Research Triangle Park, NC 27711. Electronic copies in lieu of hard copies may also be submitted to refinerynsps@epa.gov.

(4) The approval process for a request for a facility-specific NOX emissions limit is described in paragraphs (i)(4)(i) through (iii) of this section.

(i) Approval by the Administrator of a facility-specific NOX emissions limit request will be based on the completeness, accuracy and reasonableness of the request. Factors that the EPA will consider in reviewing the request for approval include, but are not limited to, the following:

(A) A demonstration that the process heater meets one of the four classes of process heaters outlined in paragraphs (i)(1) of this section;

(B) A description of the low-NOX burner designs and other combustion modifications considered for reducing NOX emissions;

(C) The combustion modification option selected; and

(D) The operating conditions (firing rate, heater box temperature and excess oxygen concentration) at which the NOX emission level was established.

(ii) If the request is approved by the Administrator, a facility-specific NOX emissions limit will be established at the NOX emission level demonstrated in the approved request.

(iii) If the Administrator finds any deficiencies in the request, the request must be revised to address the deficiencies and be re-submitted for approval.

[73 FR 35867, June 24, 2008, as amended at 77 FR 56466, Sep. 12, 2012; 80 FR 75230, Dec. 1, 2015; 81 FR 45240, July 13, 2016]

�60.103a Design, equipment, work practice or operational standards.

(a) Except as provided in paragraph (g) of this section, each owner or operator that operates a flare that is subject to this subpart shall develop and implement a written flare management plan no later than the date specified in paragraph (b) of this section. The flare management plan must include the information described in paragraphs (a)(1) through (7) of this section.

(1) A listing of all refinery process units, ancillary equipment, and fuel gas systems connected to the flare for each affected flare.

(2) An assessment of whether discharges to affected flares from these process units, ancillary equipment and fuel gas systems can be minimized. The flare minimization assessment must (at a minimum) consider the items in paragraphs (a)(2)(i) through (iv) of this section. The assessment must provide clear rationale in terms of costs (capital and annual operating), natural gas offset credits (if applicable), technical feasibility, secondary environmental impacts and safety considerations for the selected minimization alternative(s) or a statement, with justifications, that flow reduction could not be achieved. Based upon the assessment, each owner or operator of an affected flare shall identify the minimization alternatives that it has implemented by the due date of the flare management plan and shall include a schedule for the prompt implementation of any selected measures that cannot reasonably be completed as of that date.

(i) Elimination of process gas discharge to the flare through process operating changes or gas recovery at the source.

(ii) Reduction of the volume of process gas to the flare through process operating changes.

(iii) Installation of a flare gas recovery system or, for facilities that are fuel gas rich, a flare gas recovery system and a co-generation unit or combined heat and power unit.

(iv) Minimization of sweep gas flow rates and, for flares with water seals, purge gas flow rates.

(3) A description of each affected flare containing the information in paragraphs (a)(3)(i) through (vii) of this section.

(i) A general description of the flare, including the information in paragraphs (a)(3)(i)(A) through (G) of this section.

(A) Whether it is a ground flare or elevated (including height).

(B) The type of assist system (e.g., air, steam, pressure, non-assisted).

(C) Whether it is simple or complex flare tip (e.g., staged, sequential).

(D) Whether the flare is part of a cascaded flare system (and if so, whether the flare is primary or secondary).

(E) Whether the flare serves as a backup to another flare.

(F) Whether the flare is an emergency flare or a non-emergency flare.

(G) Whether the flare is equipped with a flare gas recovery system.

(ii) Description and simple process flow diagram showing the interconnection of the following components of the flare: flare tip (date installed, manufacturer, nominal and effective tip diameter, tip drawing); knockout or surge drum(s) or pot(s) (including dimensions and design capacities); flare header(s) and subheader(s); assist system; and ignition system.

(iii) Flare design parameters, including the maximum vent gas flow rate; minimum sweep gas flow rate; minimum purge gas flow rate (if any); maximum supplemental gas flow rate; maximum pilot gas flow rate; and, if the flare is steam-assisted, minimum total steam rate.

(iv) Description and simple process flow diagram showing all gas lines (including flare, purge (if applicable), sweep, supplemental and pilot gas) that are associated with the flare. For purge, sweep, supplemental and pilot gas, identify the type of gas used. Designate which lines are exempt from sulfur, H2S or flow monitoring and why (e.g., natural gas, inherently low sulfur, pilot gas). Designate which lines are monitored and identify on the process flow diagram the location and type of each monitor.

(v) For each flow rate, H2S, sulfur content, pressure or water seal monitor identified in paragraph (a)(3)(iv) of this section, provide a detailed description of the manufacturer's specifications, including, but not limited to, make, model, type, range, precision, accuracy, calibration, maintenance and quality assurance procedures.

(vi) For emergency flares, secondary flares and flares equipped with a flare gas recovery system designed, sized and operated to capture all flows except those resulting from startup, shutdown or malfunction:

(A) Description of the water seal, including the operating range for the liquid level.

(B) Designation of the monitoring option elected (flow and sulfur monitoring or pressure and water seal liquid level monitoring).

(vii) For flares equipped with a flare gas recovery system:

(A) A description of the flare gas recovery system, including number of compressors and capacity of each compressor.

(B) A description of the monitoring parameters used to quantify the amount of flare gas recovered.

(C) For systems with staged compressors, the maximum time period required to begin gas recovery with the secondary compressor(s), the monitoring parameters and procedures used to minimize the duration of releases during compressor staging and a justification for why the maximum time period cannot be further reduced.

(4) An evaluation of the baseline flow to the flare. The baseline flow to the flare must be determined after implementing the minimization assessment in paragraph (a)(2) of this section. Baseline flows do not include pilot gas flow or purge gas flow (i.e., gas introduced after the flare's water seal) provided these gas flows remain reasonably constant (i.e., separate flow monitors for these streams are not required). Separate baseline flow rates may be established for different operating conditions provided that the management plan includes:

(i) A primary baseline flow rate that will be used as the default baseline for all conditions except those specifically delineated in the plan;

(ii) A description of each special condition for which an alternate baseline is established, including the rationale for each alternate baseline, the daily flow for each alternate baseline and the expected duration of the special conditions for each alternate baseline; and

(iii) Procedures to minimize discharges to the affected flare during each special condition described in paragraph (a)(4)(ii) of this section, unless procedures are already developed for these cases under paragraph (a)(5) through (7) of this section, as applicable.

(5) Procedures to minimize or eliminate discharges to the flare during the planned startup and shutdown of the refinery process units and ancillary equipment that are connected to the affected flare, together with a schedule for the prompt implementation of any procedures that cannot reasonably be implemented as of the date of the submission of the flare management plan.

(6) Procedures to reduce flaring in cases of fuel gas imbalance (i.e., excess fuel gas for the refinery's energy needs), together with a schedule for the prompt implementation of any procedures that cannot reasonably be implemented as of the date of the submission of the flare management plan.

(7) For flares equipped with flare gas recovery systems, procedures to minimize the frequency and duration of outages of the flare gas recovery system and procedures to minimize the volume of gas flared during such outages, together with a schedule for the prompt implementation of any procedures that cannot reasonably be implemented as of the date of the submission of the flare management plan.

(b) Except as provided in paragraph (g) of this section, each owner or operator required to develop and implement a written flare management plan as described in paragraph (a) of this section must submit the plan to the Administrator as described in paragraphs (b)(1) through (3) of this section.

(1) The owner or operator of a newly constructed or reconstructed flare must develop and implement the flare management plan by no later than the date that the flare becomes an affected facility subject to this subpart, except for the selected minimization alternatives in paragraph (a)(2) and/or the procedures in paragraphs (a)(5) though (a)(7) of this section that cannot reasonably be implemented by that date, which the owner or operator must implement in accordance with the schedule in the flare management plan. The owner or operator of a modified flare must develop and implement the flare management plan by no later than November 11, 2015 or upon startup of the modified flare, whichever is later.

(2) The owner or operator must comply with the plan as submitted by the date specified in paragraph (b)(1) of this section. The plan should be updated periodically to account for changes in the operation of the flare, such as new connections to the flare or the installation of a flare gas recovery system, but the plan need be re-submitted to the Administrator only if the owner or operator adds an alternative baseline flow rate, revises an existing baseline as described in paragraph (a)(4) of this section, installs a flare gas recovery system or is required to change flare designations and monitoring methods as described in �60.107a(g). The owner or operator must comply with the updated plan as submitted.

(3) All versions of the plan submitted to the Administrator shall also be submitted to the following address: U.S. Environmental Protection Agency, Office of Air Quality Planning and Standards, Sector Policies and Programs Division, U.S. EPA Mailroom (E143-01), Attention: Refinery Sector Lead, 109 T.W. Alexander Drive, Research Triangle Park, NC 27711. Electronic copies in lieu of hard copies may also be submitted to refinerynsps@epa.gov.

(c) Except as provided in paragraphs (f) and (g) of this section, each owner or operator that operates a fuel gas combustion device, flare or sulfur recovery plant subject to this subpart shall conduct a root cause analysis and a corrective action analysis for each of the conditions specified in paragraphs (c)(1) through (3) of this section.

(1) For a flare:

(i) Any time the SO2 emissions exceed 227 kilograms (kg) (500 lb) in any 24-hour period; or

(ii) Any discharge to the flare in excess of 14,160 standard cubic meters (m 3) (500,000 standard cubic feet (scf)) above the baseline, determined in paragraph (a)(4) of this section, in any 24-hour period; or

(iii) If the monitoring alternative in �60.107a(g) is elected, any period when the flare gas line pressure exceeds the water seal liquid depth, except for periods attributable to compressor staging that do not exceed the staging time specified in paragraph (a)(3)(vii)(C) of this section.

(2) For a fuel gas combustion device, each exceedance of an applicable short-term emissions limit in �60.102a(g)(1) if the SO2 discharge to the atmosphere is 227 kg (500 lb) greater than the amount that would have been emitted if the emissions limits had been met during one or more consecutive periods of excess emissions or any 24-hour period, whichever is shorter.

(3) For a sulfur recovery plant, each time the SO2 emissions are more than 227 kg (500 lb) greater than the amount that would have been emitted if the SO2 or reduced sulfur concentration was equal to the applicable emissions limit in �60.102a(f)(1) or (2) during one or more consecutive periods of excess emissions or any 24-hour period, whichever is shorter.

(d) Except as provided in paragraphs (f) and (g) of this section, a root cause analysis and corrective action analysis must be completed as soon as possible, but no later than 45 days after a discharge meeting one of the conditions specified in paragraphs (c)(1) through (3) of this section. Special circumstances affecting the number of root cause analyses and/or corrective action analyses are provided in paragraphs (d)(1) through (5) of this section.

(1) If a single continuous discharge meets any of the conditions specified in paragraphs (c)(1) through (3) of this section for 2 or more consecutive 24-hour periods, a single root cause analysis and corrective action analysis may be conducted.

(2) If a single discharge from a flare triggers a root cause analysis based on more than one of the conditions specified in paragraphs (c)(1)(i) through (iii) of this section, a single root cause analysis and corrective action analysis may be conducted.

(3) If the discharge from a flare is the result of a planned startup or shutdown of a refinery process unit or ancillary equipment connected to the affected flare and the procedures in paragraph (a)(5) of this section were followed, a root cause analysis and corrective action analysis is not required; however, the discharge must be recorded as described in �60.108a(c)(6) and reported as described in �60.108a(d)(5).

(4) If both the primary and secondary flare in a cascaded flare system meet any of the conditions specified in paragraphs (c)(1)(i) through (iii) of this section in the same 24-hour period, a single root cause analysis and corrective action analysis may be conducted.

(5) Except as provided in paragraph (d)(4) of this section, if discharges occur that meet any of the conditions specified in paragraphs (c)(1) through (3) of this section for more than one affected facility in the same 24-hour period, initial root cause analyses shall be conducted for each affected facility. If the initial root cause analyses indicate that the discharges have the same root cause(s), the initial root cause analyses can be recorded as a single root cause analysis and a single corrective action analysis may be conducted.

(e) Except as provided in paragraphs (f) and (g) of this section, each owner or operator of a fuel gas combustion device, flare or sulfur recovery plant subject to this subpart shall implement the corrective action(s) identified in the corrective action analysis conducted pursuant to paragraph (d) of this section in accordance with the applicable requirements in paragraphs (e)(1) through (3) of this section.

(1) All corrective action(s) must be implemented within 45 days of the discharge for which the root cause and corrective action analyses were required or as soon thereafter as practicable. If an owner or operator concludes that corrective action should not be conducted, the owner or operator shall record and explain the basis for that conclusion no later than 45 days following the discharge as specified in �60.108a(c)(6)(ix).

(2) For corrective actions that cannot be fully implemented within 45 days following the discharge for which the root cause and corrective action analyses were required, the owner or operator shall develop an implementation schedule to complete the corrective action(s) as soon as practicable.

(3) No later than 45 days following the discharge for which a root cause and corrective action analyses were required, the owner or operator shall record the corrective action(s) completed to date, and, for action(s) not already completed, a schedule for implementation, including proposed commencement and completion dates as specified in �60.108a(c)(6)(x).

(f) Modified flares shall comply with the requirements of paragraphs (c) through (e) of this section by November 11, 2015 or at startup of the modified flare, whichever is later. Modified flares that were not affected facilities subject to subpart J of this part prior to becoming affected facilities under �60.100a shall comply with the requirements of paragraph (h) of this section and the requirements of �60.107a(a)(2) by November 11, 2015 or at startup of the modified flare, whichever is later. Modified flares that were affected facilities subject to subpart J of this part prior to becoming affected facilities under �60.100a shall comply with the requirements of paragraph (h) of this section and the requirements of �60.107a(a)(2) by November 13, 2012 or at startup of the modified flare, whichever is later, except that modified flares that have accepted applicability of subpart J under a federal consent decree shall comply with the subpart J requirements as specified in the consent decree, but shall comply with the requirements of paragraph (h) of this section and the requirements of �60.107a(a)(2) by no later than November 11, 2015.

(g) An affected flare subject to this subpart located in the Bay Area Air Quality Management District (BAAQMD) may elect to comply with both BAAQMD Regulation 12, Rule 11 and BAAQMD Regulation 12, Rule 12 as an alternative to complying with the requirements of paragraphs (a) through (e) of this section. An affected flare subject to this subpart located in the South Coast Air Quality Management District (SCAQMD) may elect to comply with SCAQMD Rule 1118 as an alternative to complying with the requirements of paragraphs (a) through (e) of this section. The owner or operator of an affected flare must notify the Administrator that the flare is in compliance with BAAQMD Regulation 12, Rule 11 and BAAQMD Regulation 12, Rule 12 or SCAQMD Rule 1118. The owner or operator of an affected flare shall also submit the existing flare management plan to the following address: U.S. Environmental Protection Agency, Office of Air Quality Planning and Standards, Sector Policies and Programs Division, U.S. EPA Mailroom (E143-01), Attention: Refinery Sector Lead, 109 T.W. Alexander Drive, Research Triangle Park, NC 27711. Electronic copies in lieu of hard copies may also be submitted to refinerynsps@epa.gov.

(h) Each owner or operator shall not burn in any affected flare any fuel gas that contains H2S in excess of 162 ppmv determined hourly on a 3-hour rolling average basis. The combustion in a flare of process upset gases or fuel gas that is released to the flare as a result of relief valve leakage or other emergency malfunctions is exempt from this limit.

(i) Each owner or operator of a delayed coking unit shall depressure each coke drum to 5 lb per square inch gauge (psig) or less prior to discharging the coke drum steam exhaust to the atmosphere. Until the coke drum pressure reaches 5 psig, the coke drum steam exhaust must be managed in an enclosed blowdown system and the uncondensed vapor must either be recovered (e.g., sent to the delayed coking unit fractionators) or vented to the fuel gas system, a fuel gas combustion device or a flare.

(j) Alternative means of emission limitation. (1) Each owner or operator subject to the provisions of this section may apply to the Administrator for a determination of equivalence for any means of emission limitation that achieves a reduction in emissions of a specified pollutant at least equivalent to the reduction in emissions of that pollutant achieved by the controls required in this section.

(2) Determination of equivalence to the design, equipment, work practice or operational requirements of this section will be evaluated by the following guidelines:

(i) Each owner or operator applying for a determination of equivalence shall be responsible for collecting and verifying test data to demonstrate the equivalence of the alternative means of emission limitation.

(ii) For each affected facility for which a determination of equivalence is requested, the emission reduction achieved by the design, equipment, work practice or operational requirements shall be demonstrated.

(iii) For each affected facility for which a determination of equivalence is requested, the emission reduction achieved by the alternative means of emission limitation shall be demonstrated.

(iv) Each owner or operator applying for a determination of equivalence to a work practice standard shall commit in writing to work practice(s) that provide for emission reductions equal to or greater than the emission reductions achieved by the required work practice.

(v) The Administrator will compare the demonstrated emission reduction for the alternative means of emission limitation to the demonstrated emission reduction for the design, equipment, work practice or operational requirements and, if applicable, will consider the commitment in paragraph (j)(2)(iv) of this section.

(vi) The Administrator may condition the approval of the alternative means of emission limitation on requirements that may be necessary to ensure operation and maintenance to achieve the same emissions reduction as the design, equipment, work practice or operational requirements.

(3) An owner or operator may offer a unique approach to demonstrate the equivalence of any equivalent means of emission limitation.

(4) Approval of the application for equivalence to the design, equipment, work practice or operational requirements of this section will be evaluated by the following guidelines:

(i) After a request for determination of equivalence is received, the Administrator will publish a notice in the Federal Register and provide the opportunity for public hearing if the Administrator judges that the request may be approved.

(ii) After notice and opportunity for public hearing, the Administrator will determine the equivalence of a means of emission limitation and will publish the determination in the Federal Register.

(iii) Any equivalent means of emission limitations approved under this section shall constitute a required work practice, equipment, design or operational standard within the meaning of section 111(h)(1) of the CAA.

(5) Manufacturers of equipment used to control emissions may apply to the Administrator for determination of equivalence for any alternative means of emission limitation that achieves a reduction in emissions achieved by the equipment, design and operational requirements of this section. The Administrator will make an equivalence determination according to the provisions of paragraphs (j)(2) through (4) of this section.

[77 FR 56467, Sep. 12, 2012]

�60.104a Performance tests.

(a) The owner or operator shall conduct a performance test for each FCCU, FCU, sulfur recovery plant and fuel gas combustion device to demonstrate initial compliance with each applicable emissions limit in �60.102a and conduct a performance test for each flare to demonstrate initial compliance with the H2S concentration requirement in �60.103a(h) according to the requirements of �60.8. The notification requirements of �60.8(d) apply to the initial performance test and to subsequent performance tests required by paragraph (b) of this section (or as required by the Administrator), but does not apply to performance tests conducted for the purpose of obtaining supplemental data because of continuous monitoring system breakdowns, repairs, calibration checks and zero and span adjustments.

(b) The owner or operator of a FCCU or FCU that elects to monitor control device operating parameters according to the requirements in �60.105a(b), to use bag leak detectors according to the requirements in �60.105a(c), or to use COMS according to the requirements in �60.105a(e) shall conduct a PM performance test at least annually (i.e., once per calendar year, with an interval of at least 8 months but no more than 16 months between annual tests) and furnish the Administrator a written report of the results of each test.

(c) In conducting the performance tests required by this subpart (or as requested by the Administrator), the owner or operator shall use the test methods in 40 CFR part 60, Appendices A-1 through A-8 or other methods as specified in this section, except as provided in �60.8(b).

(d) The owner or operator shall determine compliance with the PM, NOX, SO2, and CO emissions limits in �60.102a(b) for FCCU and FCU using the following methods and procedures:

(1) Method 1 of appendix A-1 to part 60 for sample and velocity traverses.

(2) Method 2 of appendix A-1 to part 60 for velocity and volumetric flow rate.

(3) Method 3, 3A, or 3B of appendix A-2 to part 60 for gas analysis. The method ANSI/ASME PTC 19.10-1981, �Flue and Exhaust Gas Analyses,� (incorporated by reference - see �60.17) is an acceptable alternative to EPA Method 3B of appendix A-2 to part 60.

(4) Method 5, 5B, or 5F of appendix A-3 to part 60 for determining PM emissions and associated moisture content from a FCCU or FCU without a wet scrubber subject to the emissions limit in �63.102a(b)(1). Use Method 5 or 5B of appendix A-3 to part 60 for determining PM emissions and associated moisture content from a FCCU or FCU with a wet scrubber subject to the emissions limit in �63.102a(b)(1).

(i) The PM performance test consists of 3 valid test runs; the duration of each test run must be no less than 60 minutes.

(ii) The emissions rate of PM (EPM) is computed for each run using Equation 5 of this section:

Where:

E = Emission rate of PM, g/kg (lb/1,000 lb) of coke burn-off;

cs = Concentration of total PM, grams per dry standard cubic meter (g/dscm) (gr/dscf);

Qsd = Volumetric flow rate of effluent gas, dry standard cubic meters per hour (dry standard cubic feet per hour);

Rc = Coke burn-off rate, kilograms per hour (kg/hr) [lb per hour (lb/hr)] coke; and

K = Conversion factor, 1.0 grams per gram (7,000 grains per lb).

(iii) The coke burn-off rate (Rc) is computed for each run using Equation 6 of this section:

Where:

Rc = Coke burn-off rate, kg/hr (lb/hr);

Qr = Volumetric flow rate of exhaust gas from FCCU regenerator or fluid coking burner before any emissions control or energy recovery system that burns auxiliary fuel, dry standard cubic meters per minute (dscm/min) [dry standard cubic feet per minute (dscf/min)];

Qa = Volumetric flow rate of air to FCCU regenerator or fluid coking burner, as determined from the unit's control room instrumentation, dscm/min (dscf/min);

Qoxy = Volumetric flow rate of O2 enriched air to FCCU regenerator or fluid coking unit, as determined from the unit's control room instrumentation, dscm/min (dscf/min);

%CO2 = Carbon dioxide (CO2) concentration in FCCU regenerator or fluid coking burner exhaust, percent by volume (dry basis);

%CO = CO concentration in FCCU regenerator or fluid coking burner exhaust, percent by volume (dry basis);

%O2 = O2 concentration in FCCU regenerator or fluid coking burner exhaust, percent by volume (dry basis);

%Ooxy = O2 concentration in O2 enriched air stream inlet to the FCCU regenerator or fluid coking burner, percent by volume (dry basis);

K1 = Material balance and conversion factor, 0.2982 (kg-min)/(hr-dscm-%) [0.0186 (lb-min)/(hr-dscf-%)];

K2 = Material balance and conversion factor, 2.088 (kg-min)/(hr-dscm) [0.1303 (lb-min)/(hr-dscf)]; and

K3 = Material balance and conversion factor, 0.0994 (kg-min)/(hr-dscm-%) [0.00624 (lb-min)/(hr-dscf-%)].

(iv) During the performance test, the volumetric flow rate of exhaust gas from catalyst regenerator (Qr) before any emission control or energy recovery system that burns auxiliary fuel is measured using Method 2 of appendix A-1 to part 60.

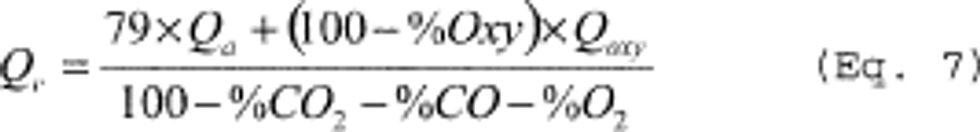

(v) For subsequent calculations of coke burn-off rates or exhaust gas flow rates, the volumetric flow rate of Qr is calculated using average exhaust gas concentrations as measured by the monitors required in �60.105a(b)(2), if applicable, using Equation 7 of this section:

Where:

Qr = Volumetric flow rate of exhaust gas from FCCU regenerator or fluid coking burner before any emission control or energy recovery system that burns auxiliary fuel, dscm/min (dscf/min);

Qa = Volumetric flow rate of air to FCCU regenerator or fluid coking burner, as determined from the unit's control room instrumentation, dscm/min (dscf/min);

Qoxy = Volumetric flow rate of O2 enriched air to FCCU regenerator or fluid coking unit, as determined from the unit's control room instrumentation, dscm/min (dscf/min);

%CO2 = Carbon dioxide concentration in FCCU regenerator or fluid coking burner exhaust, percent by volume (dry basis);

%CO = CO concentration FCCU regenerator or fluid coking burner exhaust, percent by volume (dry basis). When no auxiliary fuel is burned and a continuous CO monitor is not required in accordance with �60.105a(h)(3), assume %CO to be zero;

%O2 = O2 concentration in FCCU regenerator or fluid coking burner exhaust, percent by volume (dry basis); and

%Ooxy = O2 concentration in O2 enriched air stream inlet to the FCCU regenerator or fluid coking burner, percent by volume (dry basis).

(5) Method 6, 6A, or 6C of appendix A-4 to part 60 for moisture content and for the concentration of SO2; the duration of each test run must be no less than 4 hours. The method ANSI/ASME PTC 19.10-1981, �Flue and Exhaust Gas Analyses,� (incorporated by reference - see �60.17) is an acceptable alternative to EPA Method 6 or 6A of appendix A-4 to part 60.

(6) Method 7, 7A, 7C, 7D, or 7E of appendix A-4 to part 60 for moisture content and for the concentration of NOX calculated as nitrogen dioxide (NO2); the duration of each test run must be no less than 4 hours. The method ANSI/ASME PTC 19.10-1981, �Flue and Exhaust Gas Analyses,� (incorporated by reference - see �60.17) is an acceptable alternative to EPA Method 7 or 7C of appendix A-4 to part 60.

(7) Method 10, 10A, or 10B of appendix A-4 to part 60 for moisture content and for the concentration of CO. The sampling time for each run must be 60 minutes.

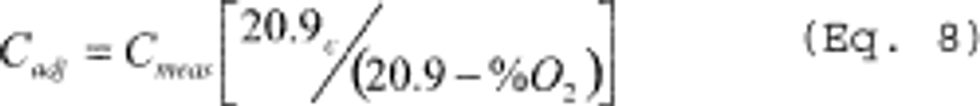

(8) The owner or operator shall adjust PM, NOX, SO2 and CO pollutant concentrations to 0-percent excess air or 0-percent O2 using Equation 8 of this section:

Where:

Cadj = pollutant concentration adjusted to 0-percent excess air or O2, parts per million (ppm) or g/dscm;

Cmeas = pollutant concentration measured on a dry basis, ppm or g/dscm;

20.9c = 20.9 percent O2?0.0 percent O2 (defined O2 correction basis), percent;

20.9 = O2 concentration in air, percent; and

%O2 = O2 concentration measured on a dry basis, percent.

(e) The owner or operator of a FCCU or FCU that is controlled by an electrostatic precipitator or wet scrubber and that is subject to control device operating parameter limits in �60.102a(c) shall establish the limits based on the performance test results according to the following procedures:

(1) Reduce the parameter monitoring data to hourly averages for each test run;

(2) Determine the hourly average operating limit for each required parameter as the average of the three test runs.

(f) The owner or operator of an FCCU or FCU that uses cyclones to comply with the PM per coke burn-off emissions limit in �60.102a(b)(1) shall establish a site-specific opacity operating limit according to the procedures in paragraphs (f)(1) through (3) of this section.

(1) Collect COMS data every 10 seconds during the entire period of the PM performance test and reduce the data to 6-minute averages.

(2) Determine and record the hourly average opacity from all the 6-minute averages.

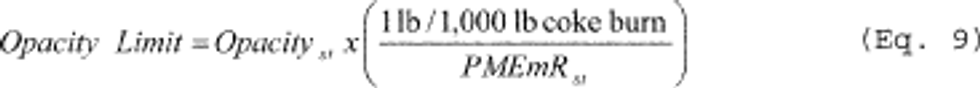

(3) Compute the site-specific limit using Equation 9 of this section:

Where:

Opacity limit = Maximum permissible 3-hour average opacity, percent, or 10 percent, whichever is greater;

Opacityst = Hourly average opacity measured during the source test, percent; and

PMEmRst = PM emission rate measured during the source test, lb/1,000 lb coke burn.

(g) The owner or operator of a FCCU or FCU that is exempt from the requirement to install and operate a CO CEMS pursuant to �60.105a(h)(3) and that is subject to control device operating parameter limits in �60.102a(c) shall establish the limits based on the performance test results using the procedures in paragraphs (g)(1) and (2) of this section.

(1) Reduce the temperature and O2 concentrations from the parameter monitoring systems to hourly averages for each test run.

(2) Determine the operating limit for temperature and O2 concentrations as the average of the average temperature and O2 concentration for the three test runs.

(h) The owner or operator shall determine compliance with the SO2 emissions limits for sulfur recovery plants in �60.102a(f)(1)(i) and (f)(2)(i) and the reduced sulfur compounds and H2S emissions limits for sulfur recovery plants in �60.102a(f)(1)(ii), (f)(1)(iii), (f)(2)(ii), and (f)(2)(iii) using the following methods and procedures:

(1) Method 1 of appendix A-1 to part 60 for sample and velocity traverses.

(2) Method 2 of appendix A-1 to part 60 for velocity and volumetric flow rate.

(3) Method 3, 3A, or 3B of appendix A-2 to part 60 for gas analysis. The method ANSI/ASME PTC 19.10-1981, �Flue and Exhaust Gas Analyses,� (incorporated by reference - see �60.17) is an acceptable alternative to EPA Method 3B of appendix A-2 to part 60.

(4) Method 6, 6A, or 6C of appendix A-4 to part 60 to determine the SO2 concentration. The method ANSI/ASME PTC 19.10-1981, �Flue and Exhaust Gas Analyses,� (incorporated by reference - see �60.17) is an acceptable alternative to EPA Method 6 or 6A of appendix A-4 to part 60.

(5) Method 15 or 15A of appendix A-5 to part 60 or Method 16 of appendix A-6 to part 60 to determine the reduced sulfur compounds and H2S concentrations. The method ANSI/ASME PTC 19.10-1981, �Flue and Exhaust Gas Analyses,� (incorporated by reference - see �60.17) is an acceptable alternative to EPA Method 15A of appendix A-5 to part 60.

(i) Each run consists of 16 samples taken over a minimum of 3 hours.

(ii) The owner or operator shall calculate the average H2S concentration after correcting for moisture and O2 as the arithmetic average of the H2S concentration for each sample during the run (ppmv, dry basis, corrected to 0 percent excess air).

(iii) The owner or operator shall calculate the SO2 equivalent for each run after correcting for moisture and O2 as the arithmetic average of the SO2 equivalent of reduced sulfur compounds for each sample during the run (ppmv, dry basis, corrected to 0 percent excess air).

(iv) The owner or operator shall use Equation 8 of this section to adjust pollutant concentrations to 0-percent O2 or 0- percent excess air.

(6) If oxygen or oxygen-enriched air is used in the Claus burner and either Equation 1 or 2 of this subpart is used to determine the applicable emissions limit, determine the average O2 concentration of the air/oxygen mixture supplied to the Claus burner, in percent by volume (dry basis), for the performance test using all hourly average O2 concentrations determined during the test runs using the procedures in �60.106a(a)(5) or (6).

(i) The owner or operator shall determine compliance with the SO2 and NOX emissions limits in �60.102a(g) for a fuel gas combustion device according to the following test methods and procedures:

(1) Method 1 of appendix A-1 to part 60 for sample and velocity traverses;

(2) Method 2 of appendix A-1 to part 60 for velocity and volumetric flow rate;

(3) Method 3, 3A, or 3B of appendix A-2 to part 60 for gas analysis. The method ANSI/ASME PTC 19.10-1981, �Flue and Exhaust Gas Analyses,� (incorporated by reference - see �60.17) is an acceptable alternative to EPA Method 3B of appendix A-2 to part 60;

(4) Method 6, 6A, or 6C of appendix A-4 to part 60 to determine the SO2 concentration. The method ANSI/ASME PTC 19.10-1981, �Flue and Exhaust Gas Analyses,� (incorporated by reference - see �60.17) is an acceptable alternative to EPA Method 6 or 6A of appendix A-4 to part 60.

(i) The performance test consists of 3 valid test runs; the duration of each test run must be no less than 1 hour.

(ii) If a single fuel gas combustion device having a common source of fuel gas is monitored as allowed under �60.107a(a)(1)(v), only one performance test is required. That is, performance tests are not required when a new affected fuel gas combustion device is added to a common source of fuel gas that previously demonstrated compliance.

(5) Method 7, 7A, 7C, 7D, or 7E of appendix A-4 to part 60 for moisture content and for the concentration of NOX calculated as NO2; the duration of each test run must be no less than 4 hours. The method ANSI/ASME PTC 19.10-1981, �Flue and Exhaust Gas Analyses,� (incorporated by reference - see �60.17) is an acceptable alternative to EPA Method 7 or 7C of appendix A-4 to part 60.

(6) For process heaters with a rated heat capacity between 40 and 100 MMBtu/hr that elect to demonstrate continuous compliance with a maximum excess oxygen limit as provided in �60.107a(c)(6) or (d)(8), the owner or operator shall establish the O2 operating limit or O2 operating curve based on the performance test results according to the requirements in paragraph (i)(6)(i) or (ii) of this section, respectively.

(i) If a single O2 operating limit will be used:

(A) Conduct the performance test following the methods provided in paragraphs (i)(1), (2), (3) and (5) of this section when the process heater is firing at no less than 70 percent of the rated heat capacity. For co-fired process heaters, conduct at least one of the test runs while the process heater is being supplied by both fuel gas and fuel oil and conduct at least one of the test runs while the process heater is being supplied solely by fuel gas.

(B) Each test will consist of three test runs. Calculate the NOX concentration for the performance test as the average of the NOX concentrations from each of the three test runs. If the NOX concentration for the performance test is less than or equal to the numerical value of the applicable NOX emissions limit (regardless of averaging time), then the test is considered to be a valid test.

(C) Determine the average O2 concentration for each test run of a valid test.

(D) Calculate the O2 operating limit as the average O2 concentration of the three test runs from a valid test.

(ii) If an O2 operating curve will be used:

(A) Conduct a performance test following the methods provided in paragraphs (i)(1), (2), (3) and (5) of this section at a representative condition for each operating range for which different O2 operating limits will be established. Different operating conditions may be defined as different firing rates (e.g., above 50 percent of rated heat capacity and at or below 50 percent of rated heat capacity) and/or, for co-fired process heaters, different fuel mixtures (e.g., primarily gas fired, primarily oil fired, and equally co-fired, i.e., approximately 50 percent of the input heating value is from fuel gas and approximately 50 percent of the input heating value is from fuel oil). Performance tests for different operating ranges may be conducted at different times.

(B) Each test will consist of three test runs. Calculate the NOX concentration for the performance test as the average of the NOX concentrations from each of the three test runs. If the NOX concentration for the performance test is less than or equal to the numerical value of the applicable NOX emissions limit (regardless of averaging time), then the test is considered to be a valid test.