['Air Programs']

['Air Emissions', 'Air Quality', 'Acid Rain']

05/13/2025

...

Authority: 42 U.S.C. 7401–7671q and 7651k note.

Subpart A - General

§75.1 Purpose and scope.

(a) Purpose. The purpose of this part is to establish requirements for the monitoring, recordkeeping, and reporting of sulfur dioxide (SO2), nitrogen oxides (NOX), and carbon dioxide (CO2) emissions, volumetric flow, and opacity data from affected units under the Acid Rain Program pursuant to sections 412 and 821 of the CAA, 42 U.S.C. 7401-7671q as amended by Public Law 101-549 (November 15, 1990) [the Act]. In addition, this part sets forth provisions for the monitoring, recordkeeping, and reporting of NOX mass emissions with which EPA, individual States, or groups of States may require sources to comply in order to demonstrate compliance with a NOX mass emission reduction program, to the extent these provisions are adopted as requirements under such a program.

(b) Scope. (1) The regulations established under this part include general requirements for the installation, certification, operation, and maintenance of continuous emission or opacity monitoring systems and specific requirements for the monitoring of SO2 emissions, volumetric flow, NOX emissions, opacity, CO2 emissions and SO2 emissions removal by qualifying Phase I technologies. Specifications for the installation and performance of continuous emission monitoring systems, certification tests and procedures, and quality assurance tests and procedures are included in appendices A and B to this part. Criteria for alternative monitoring systems and provisions to account for missing data from certified continuous emission monitoring systems or approved alternative monitoring systems are also included in the regulation.

(2) Statistical estimation procedures for missing data are included in appendix C to this part. Optional protocols for estimating SO2 mass emissions from gas-fired or oil-fired units and NOX emissions from gas-fired peaking or oil-fired peaking units are included in appendices D and E, respectively, to this part. Requirements for recording and recordkeeping of monitoring data and for quarterly electronic reporting also are specified. Procedures for conversion of monitoring data into units of the standard are included in appendix F to this part. Procedures for the monitoring and calculation of CO2 emissions are included in appendix G of this part.

[58 FR 3701, Jan. 11, 1993; 58 FR 34126, June 23, 1993; 58 FR 40747, July 30, 1993; 63 FR 57498, Oct. 27, 1999; 67 FR 40421, June 12, 2002]

§75.2 Applicability.

(a) Except as provided in paragraphs (b) and (c) of this section, the provisions of this part apply to each affected unit subject to Acid Rain emission limitations or reduction requirements for SO2 or NOX.

(b) The provisions of this part do not apply to:

(1) A new unit for which a written exemption has been issued under §72.7 of this chapter (any new unit that serves one or more generators with total nameplate capacity of 25 MWe or less and burns only fuels with a sulfur content of 0.05 percent or less by weight may apply to the Administrator for an exemption); or

(2) Any unit not subject to the requirements of the Acid Rain Program due to operation of any paragraph of §72.6(b) of this chapter; or

(3) An affected unit for which a written exemption has been issued under §72.8 of this chapter and an exception granted under §75.67 of this part.

(c) The provisions of this part apply to sources subject to a State or federal NOX mass emission reduction program, to the extent these provisions are adopted as requirements under such a program.

[58 FR 3701, Jan. 11, 1993, as amended at 58 FR 15716, Mar. 23, 1993; 60 FR 26516, May 17, 1995; 63 FR 57499, Oct. 27, 1998; 70 FR 28678, May 18, 2005; 76 FR 17306, Mar. 28, 2011]

§75.3 General Acid Rain Program provisions.

The provisions of part 72, including the following, shall apply to this part:

(a) §72.2 (Definitions);

(b) §72.3 (Measurements, Abbreviations, and Acronyms);

(c) §72.4 (Federal Authority);

(d) §72.5 (State Authority);

(e) §72.6 (Applicability);

(f) §72.7 (New Unit Exemption);

(g) §72.8 (Retired Units Exemption);

(h) §72.9 (Standard Requirements);

(i) §72.10 (Availability of Information); and

(j) §72.11 (Computation of Time).

In addition, the procedures for appeals of decisions of the Administrator under this part are contained in part 78 of this chapter.

§75.4 Compliance dates.

(a) The provisions of this part apply to each existing Phase I and Phase II unit on February 10, 1993. For substitution or compensating units that are so designated under the Acid Rain permit which governs that unit and contains the approved substitution or reduced utilization plan, pursuant to §72.41 or §72.43 of this chapter, the provisions of this part become applicable upon the issuance date of the Acid Rain permit. For combustion sources seeking to enter the Opt-in Program in accordance with part 74 of this chapter, the provisions of this part become applicable upon the submission of an opt-in permit application in accordance with §74.14 of this chapter. The provisions of this part for the monitoring, recording, and reporting of NOX mass emissions become applicable on the deadlines specified in the applicable State or federal NOX mass emission reduction program, to the extent these provisions are adopted as requirements under such a program. In accordance with §75.20, the owner or operator of each existing affected unit shall ensure that all monitoring systems required by this part for monitoring SO2, NOX, CO2, opacity, moisture and volumetric flow are installed and that all certification tests are completed no later than the following dates (except as provided in paragraphs (d) through (i) of this section):

(1) For a unit listed in table 1 of §73.10(a) of this chapter, November 15, 1993.

(2) For a substitution or a compensating unit that is designated under an approved substitution plan or reduced utilization plan pursuant to §72.41 or §72.43 of this chapter, or for a unit that is designated an early election unit under an approved NOX compliance plan pursuant to part 76 of this chapter, that is not conditionally approved and that is effective for 1995, the earlier of the following dates:

(i) January 1, 1995; or

(ii) 90 days after the issuance date of the Acid Rain permit (or date of approval of permit revision) that governs the unit and contains the approved substitution plan, reduced utilization plan, or NOX compliance plan.

(3) For either a Phase II unit, other than a gas-fired unit or an oil-fired unit, or a substitution or compensating unit that is not a substitution or compensating unit under paragraph (a)(2) of this section: January 1, 1995.

(4) For a gas-fired Phase II unit or an oil-fired Phase II unit, January 1, 1995, except that installation and certification tests for continuous emission monitoring systems for NOX and CO2 or excepted monitoring systems for NOX under appendix E or CO2 estimation under appendix G of this part shall be completed as follows:

(i) For an oil-fired Phase II unit or a gas-fired Phase II unit located in an ozone nonattainment area or the ozone transport region, not later than July 1, 1995; or

(ii) For an oil-fired Phase II unit or a gas-fired Phase II unit not located in an ozone nonattainment area or the ozone transport region, not later than January 1, 1996.

(5) For combustion sources seeking to enter the Opt-in Program in accordance with part 74 of this chapter, the expiration date of a combustion source's opt-in permit under §74.14(e) of this chapter.

(b) In accordance with §75.20, the owner or operator of each new affected unit shall ensure that all monitoring systems required under this part for monitoring of SO2, NOX, CO2, opacity, and volumetric flow are installed and all certification tests are completed on or before the later of the following dates:

(1) January 1, 1995, except that for a gas-fired unit or oil-fired unit located in an ozone nonattainment area or the ozone transport region, the date for installation and completion of all certification tests for NOX and CO2 monitoring systems shall be July 1, 1995 and for a gas-fired unit or an oil-fired unit not located in an ozone nonattainment area or the ozone transport region, the date for installation and completion of all certification tests for NOX and CO2 monitoring systems shall be January 1, 1996; or

(2) 180 calendar days after the date the unit commences commercial operation, notice of which date shall be provided under subpart G of this part.

(c) In accordance with §75.20, the owner or operator of any unit affected under any paragraph of §72.6(a)(3) (ii) through (vii) of this chapter shall ensure that all monitoring systems required under this part for monitoring of SO2, NOX, CO2, opacity, and volumetric flow are installed and all certification tests are completed on or before the later of the following dates:

(1) January 1, 1995, except that for a gas-fired unit or oil-fired unit located in an ozone nonattainment area or the ozone transport region, the date for installation and completion of all certification tests for NOX and CO2 monitoring systems shall be July 1, 1995 and for a gas-fired unit or an oil-fired unit not located in an ozone nonattainment area or the ozone transport region, the date for installation and completion of all certification tests for NOX and CO2 monitoring systems shall be January 1, 1996; or

(2) 180 calendar days after the date on which the unit becomes subject to the requirements of the Acid Rain Program, notice of which date shall be provided under subpart G of this part.

(d) This paragraph (d) applies to affected units under the Acid Rain Program and to units subject to a State or Federal pollutant mass emissions reduction program that adopts the emission monitoring and reporting provisions of this part. In accordance with §75.20, for an affected unit which, on the applicable compliance date, is either in long-term cold storage (as defined in §72.2 of this chapter) or is shut down as the result of a planned outage or a forced outage, thereby preventing the required continuous monitoring system certification tests from being completed by the compliance date, the owner or operator shall provide notice of such unit storage or outage in accordance with §75.61(a)(3) or §75.61(a)(7), as applicable. For the planned and unplanned unit outages described in this paragraph (d), the owner or operator shall ensure that all of the continuous monitoring systems for SO2, NOX, CO2, opacity, and volumetric flow rate required under this part (or under the applicable State or Federal mass emissions reduction program) are installed and that all required certification tests are completed no later than 90 unit operating days or 180 calendar days (whichever occurs first) after the date that the unit recommences commercial operation, notice of which date shall be provided under §75.61(a)(3) or §75.61(a)(7), as applicable. The owner or operator shall determine and report SO2 concentration, NOX emission rate, CO2 concentration, and flow rate data (as applicable) for all unit operating hours after the applicable compliance date until all of the required certification tests are successfully completed, using either:

(1) The maximum potential concentration of SO2 (as defined in section 2.1.1.1 of appendix A to this part), the maximum potential NOX emission rate, as defined in §72.2 of this chapter, the maximum potential flow rate, as defined in section 2.1.4.1 of appendix A to this part, or the maximum potential CO2 concentration, as defined in section 2.1.3.1 of appendix A to this part; or

(2) The conditional data validation provisions of §75.20(b)(3); or

(3) Reference methods under §75.22(b); or

(4) Another procedure approved by the Administrator pursuant to a petition under §75.66.

(e) In accordance with §75.20, if the owner or operator of an affected unit completes construction of a new stack or flue, or a flue gas desulfurization system or add-on NOX emission controls, after the applicable deadline in paragraph (a), (b), or (c) of this section:

(1) Except as otherwise provided in paragraph (e)(3) of this section, the owner or operator shall ensure that all required certification and/or recertification and/or diagnostic tests of the monitoring systems required under this part (i.e., the SO2, NOX, CO2, O2, opacity, volumetric flow rate, and moisture monitoring systems, as applicable) are completed not later than 90 unit operating days or 180 calendar days (whichever occurs first) after:

(i) For theevent of construction of a new stack or flue, the date that emissions first exit to the atmosphere through the new stack or flue, notice of which date shall be provided under subpart G of this part; or

(ii) For the event of installation of a flue gas desulfurization system or add-on NOX emission controls, the date that reagent is first injected into the flue gas desulfurization system or the add-on NOX emission controls, as applicable, notice of which date shall be provided under subpart G of this part.

(2) The owner or operator shall determine and report, as applicable, SO2 concentration, NOX concentration, NOX emission rate, CO2 concentration, O2 concentration, volumetric flow rate, and moisture data for all unit or stack operating hours after emissions first pass through the new stack or flue, or reagent is first injected into the flue gas desulfurization system or add-on NOX emission controls, as applicable, until all required certification and/or recertification and/or diagnostic tests are successfully completed, using:

(i) Quality-assured data recorded by a previously-certified monitoring system for which the event requires no additional testing;

(ii) The applicable missing data substitution procedures under §§75.31 through 75.37;

(iii) The conditional data validation procedures of §75.20(b)(3), except that conditional data validation may, if necessary, be used for the entire window of time provided under paragraph (e)(1) of this section in lieu of the periods specified in §75.20(b)(3)(iv);

(iv) Reference methods under §75.22(b);

(v) For the event of installation of a flue gas desulfurization system or add-on NOX emission controls, quality-assured data recorded on the high measurement scale of the monitor that measures the pollutant being removed by the add-on emission controls (i.e., SO2 or NOX, as applicable), if, pursuant to section 2 of appendix A to this part, two spans and ranges are required for that monitor and if the high measurement scale of the monitor has been certified according to §75.20(c), section 6 of appendix A to this part, and, if applicable, paragraph (e)(4)(i) of this section. Data recorded on the certified high scale that ordinarily would be required to be recorded on the low scale, pursuant to section 2.1.1.4(g) or 2.1.2.4(f) of appendix A to this part, may be reported as quality-assured for a period not to exceed 60 unit or stack operating days after the date and hour that reagent is first injected into the control device, after which one or more of the options provided in paragraphs (e)(2)(ii), (e)(2)(iii), (e)(2)(iv) and (e)(2)(vi) of this section must be used to report SO2 or NOX concentration data (as applicable) for each operating hour in which these low emissions occur, until certification testing of the low scale of the monitor is successfully completed; or

(vi) Another procedure approved by the Administrator pursuant to a petition under §75.66.

(3) If a particular project involves both the event of new stack or flue construction and the event of installation of a flue gas desulfurization system or add-on NOX emission controls, the owner or operator shall either:

(i) Complete all of the monitoring system certification and/or recertification and/or diagnostic testing requirements of bothevents within the window of time provided under paragraph (e)(1)(i) of this section; or

(ii) Complete all of the monitoring system certification and/or recertification and/or diagnostic testing requirements of each event within the separate window of time applicable to such event provided under paragraph (e)(1) of this section.

(4) For the project described in paragraph (e)(3) of this section, the emissions data from each CEMS installed on the new stack recorded in the interval of time starting on the date and hour on which emissions first exit to the atmosphere through the new stack and ending on the hour before the date and hour on which reagent is first injected into the control device may be reported as quality assured:

(i) For the CEMS that includes the monitor that measures the pollutant being removed by the add-on emission controls (i.e., SO2 or NOX, as applicable):

(A) Only if the relative accuracy test audit (RATA) of the high measurement scale of the monitor is successfully completed either prior to the date and hour of the first injection of reagent into the emission control device, or after that date and hour during a period when the control device is not operating, but still within the window of time provided under paragraph (e)(1)(i) of this section, and the rest of the certification tests required under §75.20(c) and section 6 of appendix A to this part for the high measurement scale of the monitor are successfully completed within the window of time provided under paragraph (e)(1)(i) of this section;

(B) Beginning with:

(1) The first unit or stack operating hour after successful completion of all of the certification tests in accordance with paragraph (e)(4)(i)(A) of this section; or

(2) The hour of the probationary calibration error test (see §75.20(b)(3)(ii)), if conditional data validation is used and all of the certification tests are successfully completed in accordance with paragraph (e)(4)(i)(A) of this section, with no test failures. If any required test is failed or aborted or is otherwise not in accordance with paragraph (e)(4)(i)(A) of this section, data validation shall be done according to §75.20(b)(3)(vii).

(ii) For a CEMS other than one addressed in paragraph (e)(4)(i) of this section:

(A) Only if the relative accuracy test audit (RATA) of the CEMS is successfully completed either prior to the date and hour of the first injection of reagent into the emission control device, or after that date and hour during a period when the control device is not operating, but still within the window of time provided under paragraph (e)(1)(i) of this section, and the rest of the certification tests required under §75.20(c) and section 6 of appendix A to this part for the CEMS are successfully completed within the window of time provided under paragraph (e)(1)(i) of this section;

(B) Beginning with:

(1) The first unit or stack operating hour after successful completion of all of the certification tests in accordance with paragraph (e)(4)(ii)(A) of this section; or

(2) The hour of the probationary calibration error test (see §75.20(b)(3)(ii)), if conditional data validation is used and all of the certification tests are successfully completed in accordance with paragraph (e)(4)(ii)(A) of this section, with no test failures. If any required test is failed or aborted or is otherwise not in accordance with paragraph (e)(4)(ii)(A) of this section, data validation shall be done according to §75.20(b)(3)(vii).

(f) In accordance with §75.20, the owner or operator of an affected gas-fired or oil-fired peaking unit, if planning to use appendix E of this part, shall ensure that the required certification tests for excepted monitoring systems under appendix E are completed for backup fuel, as defined in §72.2 of this chapter, no later than 90 unit operating days or 180 calendar days (whichever occurs first) after the date that the unit first combusts the backup fuel following the certification testing with the primary fuel. If the required testing is completed by this deadline, the appendix E correlation curve derived from the test results may be used for reporting data under this part beginning with the first date and hour that the backup fuel is combusted, provided that the fuel flowmeter for the backup fuel was certified as of that date and hour. If the required appendix E testing has not been successfully completed by the compliance date in this paragraph, then, until the testing is completed, the owner or operator shall report NOX emission rate data for all unit operating hours that the backup fuel is combusted using either:

(1) The fuel-specific maximum potential NOX emission rate, as defined in §72.2 of this chapter; or

(2) Reference methods under §75.22(b) of this part; or

(3) Another procedure approved by the Administrator pursuant to a petition under §75.66.

(g) The provisions of this paragraph shall apply unless an owner or operator is exempt from certifying a fuel flowmeter for use during combustion of emergency fuel under section 2.1.4.3 of appendix D to this part, in which circumstance the provisions of section 2.1.4.3 of appendix D shall apply. In accordance with §75.20, whenever the owner or operator of a gas-fired or oil-fired unit uses an excepted monitoring system under appendix D or E of this part and combusts emergency fuel as defined in §72.2 of this chapter, then the owner or operator shall ensure that a fuel flowmeter measuring emergency fuel is installed and the required certification tests for excepted monitoring systems are completed by no later than 30 unit operating days after the first date after January 1, 1995 that the unit combusts emergency fuel. For all unit operating hours that the unit combusts emergency fuel after January 1, 1995 until the owner or operator installs a flowmeter for emergency fuel and successfully completes all required certification tests, the owner or operator shall determine and report SO2 mass emission data using either:

(1) The maximum potential fuel flow rate, as described in appendix D of this part, and the maximum sulfur content of the fuel, as described in section 2.1.1.1 of appendix A of this part;

(2) Reference methods under §75.22(b) of this part; or

(3) Another procedure approved by the Administrator pursuant to a petition under §75.66.

(h) [Reserved]

(i) In accordance with §75.20, the owner or operator of each affected unit at which SO2 concentration is measured on a dry basis or at which moisture corrections are required to account for CO2 emissions, NOX emission rate in lb/mmBtu, heat input, or NOX mass emissions for units in a NOX mass reduction program, shall ensure that the continuous moisture monitoring system required by this part is installed and that all applicable initial certification tests required under §75.20(c)(5), (c)(6), or (c)(7) for the continuous moisture monitoring system are completed no later than the following dates:

(1) April 1, 2000, for a unit that is existing and has commenced commercial operation by January 2, 2000;

(2) For a new affected unit which has not commenced commercial operation by January 2, 2000, 90 unit operating days or 180 calendar days (whichever occurs first) after the date the unit commences commercial operation; or

(3) For an existing unit that is shutdown and is not yet operating by April 1, 2000, 90 unit operating days or 180 calendar days (whichever occurs first) after the date that the unit recommences commercial operation.

(j) If the certification tests required under paragraph (b) or (c) of this section have not been completed by the applicable compliance date, the owner or operator shall determine and report SO2 concentration, NOX emission rate, CO2 concentration, and flow rate data for all unit operating hours after the applicable compliance date in this paragraph until all required certification tests are successfully completed using either:

(1) The maximum potential concentration of SO2, as defined in section 2.1.1.1 of appendix A to this part, the maximum potential NOX emission rate, as defined in §72.2 of this chapter, the maximum potential flow rate, as defined in section 2.1.4.1 of appendix A to this part, or the maximum potential CO2 concentration, as defined in section 2.1.3.1 of appendix A to this part;

(2) Reference methods under §75.22(b); or

(3) Another procedure approved by the Administrator pursuant to a petition under §75.66.

[60 FR 17131, Apr. 4, 1995, as amended at 60 FR 26516, May 17, 1995; 63 FR 57499, Oct. 27, 1998; 64 FR 28588, May 26, 1999; 67 FR 40421, June 12, 2002; 73 FR 4340, Jan. 24, 2008; 76 FR 17306, Mar. 28, 2011; 76 FR 50132, Aug. 12, 2011]

§75.5 Prohibitions.

(a) A violation of any applicable regulation in this part by the owners or operators or the designated representative of an affected source or an affected unit is a violation of the Act.

(b) No owner or operator of an affected unit shall operate the unit without complying with the requirements of §§75.2 through 75.75 and appendices A through G to this part.

(c) No owner or operator of an affected unit shall use any alternative monitoring system, alternative reference method, or any other alternative for the required continuous emission monitoring system without having obtained the Administrator's prior written approval in accordance with §§75.23, 75.48 and 75.66.

(d) No owner or operator of an affected unit shall operate the unit so as to discharge, or allow to be discharged, emissions of SO2, NOX or CO2 to the atmosphere without accounting for all such emissions in accordance with the provisions of §§75.10 through 75.19.

(e) No owner or operator of an affected unit shall disrupt the continuous emission monitoring system, any portion thereof, or any other approved emission monitoring method, and thereby avoid monitoring and recording SO2, NOX, or CO2 emissions discharged to the atmosphere, except for periods of recertification, or periods when calibration, quality assurance, or maintenance is performed pursuant to §75.21 and appendix B of this part.

(f) No owner or operator of an affected unit shall retire or permanently discontinue use of the continuous emission monitoring system, any component thereof, the continuous opacity monitoring system, or any other approved emission monitoring system under this part, except under any one of the following circumstances:

(1) During the period that the unit is covered by an approved retired unit exemption under §72.8 of this chapter that is in effect; or

(2) The owner or operator is monitoring emissions from the unit with another certified monitoring system or an excepted methodology approved by the Administrator for use at that unit that provides emissions data for the same pollutant or parameter as the retired or discontinued monitoring system; or

(3) The designated representative submits notification of the date of recertification testing of a replacement monitoring system in accordance with §§75.20 and 75.61, and the owner or operator recertifies thereafter a replacement monitoring system in accordance with §75.20.

[58 FR 3701, Jan. 11, 1993, as amended at 58 FR 40747, July 30, 1993; 60 FR 26517, May 17, 1995; 64 FR 28589, May 26, 1999]

§75.6 Incorporation by reference.

The materials listed in this section are incorporated by reference in the corresponding sections noted. These incorporations by reference were approved by the Director of the Federal Register in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. These materials are incorporated as they existed on the date of approval, and a notice of any change in these materials will be published in the Federal Register. The materials are available for purchase at the corresponding address noted below and are available for inspection at the Public Information Reference Unit of the U.S. EPA, 401 M St., SW., Washington, DC and at the Library (MD-35), U.S. EPA, Research Triangle Park, North Carolina or at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, call 202-741-6030, or go to: http://www.archives.gov/federal_register/code_of_federal_regulations/ibr_locations.html.

(a) The following materials are available for purchase from the following address: American Society for Testing and Material (ASTM) International, 100 Barr Harbor Drive, P.O. Box C700, West Conshohocken, Pennsylvania, 19428-2959, phone: 610-832-9585, http://www.astm.org/DIGITAL_LIBRARY/index.shtml.

(1) ASTM D129-00, Standard Test Method for Sulfur in Petroleum Products (General Bomb Method), for appendices A and D of this part.

(2) D240-00, Standard Test Method for Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter, for appendices A, D and F of this part.

(3) ASTM D287-92 (Reapproved 2000), Standard Test Method for API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method), for appendix D of this part.

(4) ASTM D388-99, Standard Classification of Coals by Rank, incorporation by reference for appendix F of this part.

(5) [Reserved]

(6) ASTM D1072-06, Standard Test Method for Total Sulfur in Fuel Gases by Combustion and Barium Chloride Titration, for appendix D of this part.

(7) ASTM D1217-993 (Reapproved 1998), Standard Test Method for Density and Relative Density (Specific Gravity) of Liquids by Bingham Pycnometer, for appendix D of this part.

(8) ASTM D1250-07 , Standard Guide for Use of the Petroleum Measurement Tables, for appendix D of this part.

(9) ASTM D1298-99, Standard Test Method for Density, Relative Density (Specific Gravity) or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method, for appendix D of this part.

(10) ASTM D1480-93 (Reapproved 1997), Standard Test Method for Density and Relative Density (Specific Gravity) of Viscous Materials by Bingham Pycnometer, for appendix D of this part.

(11) ASTM D1481-93 (Reapproved 1997), Standard Test Method for Density and Relative Density (Specific Gravity) of Viscous Materials by Lipkin Bicapillary Pycnometer, for appendix D of this part.

(12) ASTM D1552-01, Standard Test Method for Sulfur in Petroleum Products (High-Temperature Method), for appendices A and D of the part.

(13) ASTM D1826-94 (Reapproved 1998), Standard Test Method for Calorific (Heating) Value of Gases in Natural Gas Range by Continuous Recording Calorimeter, for appendices D and F to this part.

(14) ASTM D1945-96 (Reapproved 2001), Standard Test Method for Analysis of Natural Gas by Gas Chromatography, for appendices F and G of this part.

(15) ASTM D1946-90 (Reapproved 2006), Standard Practice for Analysis of Reformed Gas by Gas Chromatography, for appendices F and G of this part.

(16) [Reserved]

(17) ASTM D2013-01, Standard Practice for Preparing Coal Samples for Analysis, for appendix F of this part.

(18) [Reserved]

(19) ASTM D2234-00, Standard Practice for Collection of a Gross Sample of Coal, for appendix F of this part.

(20) [Reserved]

(21) ASTM D2502-92 (Reapproved 1996), Standard Test Method for Estimation of Molecular Weight (Relative Molecular Mass) of Petroleum Oils from Viscosity Measurements, for appendix G of this part.

(22) ASTM D2503-92 (Reapproved 1997), Standard Test Method for Relative Molecular Mass (Molecular Weight) of Hydrocarbons by Thermoelectric Measurement of Vapor Pressure, for appendix G of this part.

(23) ASTM D2622-98, Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry, for appendices A and D of this part.

(24) ASTM D3174-00, Standard Test Method for Ash in the Analysis Sample of Coal and Coke from Coal, for appendix G of this part.

(25) ASTM D3176-89 (Reapproved 2002), Standard Practice for Ultimate Analysis of Coal and Coke, for appendices A and F of this part.

(26) ASTM D3177-02 (Reapproved 2007), Standard Test Methods for Total Sulfur in the Analysis Sample of Coal and Coke, for appendix A of this part.

(27) ASTM D5373-02 (Reapproved 2007) Standard Test Methods for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Laboratory Samples of Coal and Coke, for appendix G of this part.

(28) ASTM D3238-95 (Reapproved 2000), Standard Test Method for Calculation of Carbon Distribution and Structural Group Analysis of Petroleum Oils by the n-d-M Method, for appendix G of this part.

(29) ASTM D3246-96, Standard Test Method for Sulfur in Petroleum Gas by Oxidative Microcoulometry, for appendix D of this part.

(30) [Reserved]

(31) ASTM D3588-98, Standard Practice for Calculating Heat Value, Compressibility Factor, and Relative Density of Gaseous Fuels, for appendices D and F to this part.

(32) ASTM D4052-96 (Reapproved 2002), Standard Test Method for Density and Relative Density of Liquids by Digital Density Meter, for appendix D of this part.

(33) ASTM D4057-95 (Reapproved 2000), Standard Practice for Manual Sampling of Petroleum and Petroleum Products, for appendix D of this part.

(34) ASTM D4177-95 (Reapproved 2000), Standard Practice for Automatic Sampling of Petroleum and Petroleum Products, for appendix D of this part.

(35) ASTM D4239-02, Standard Test Methods for Sulfur in the Analysis Sample of Coal and Coke Using High-Temperature Tube Furnace Combustion Methods, for appendix A of this part.

(36) ASTM D4294-98, Standard Test Method for Sulfur in Petroleum and Petroleum Products by Energy-Dispersive X-ray Fluorescence Spectrometry, for appendices A and D of this part.

(37) ASTM D4468-85 (Reapproved 2006), Standard Test Method for Total Sulfur in Gaseous Fuels by Hydrogenolysis and Rateometric Colorimetry, for appendix D of this part.

(38) [Reserved]

(39) ASTM D4891-89 (Reapproved 2006), Standard Test Method for Heating Value of Gases in Natural Gas Range by Stoichiometric Combustion, for appendices D and F to this part.

(40) ASTM D5291-02, Standard Test Methods for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Petroleum Products and Lubricants, for appendices F and G to this part.

(41) ASTM D5373-02 (Reapproved 2007), “Standard Test Methods for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Laboratory Samples of Coal and Coke,” for appendix G to this part.

(42) ASTM D5504-01, Standard Test Method for Determination of Sulfur Compounds in Natural Gas and Gaseous Fuels by Gas Chromatography and Chemiluminescence, for appendix D of this part.

(43) [Reserved]

(44) [Reserved]

(45) ASTM D6667-04, Standard Test Method for Determination of Total Volatile Sulfur in Gaseous Hydrocarbons and Liquefied Petroleum Gases by Ultraviolet Fluorescence, for appendix D of this part.

(46) ASTM D4809-00, Standard Test Method for Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter (Precision Method), for appendices D and F of this part.

(47) ASTM D5865-01a, Standard Test Method for Gross Calorific Value of Coal and Coke, for appendices A, D, and F of this part.

(48) ASTM D7036-04, Standard Practice for Competence of Air Emission Testing Bodies, for §75.21, §75.59, and appendix A to this part.

(49) ASTM D5453-06, Standard Test Method for Determination of Total Sulfur in Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel Engine Fuel, and Engine Oil by Ultraviolet Fluorescence, for appendix D of this part.

(50) ASTM D5865-10 (Approved January 1, 2010), Standard Test Method for Gross Calorific Value of Coal and Coke, for appendices A, D, and F of this part.

(b) The following materials are available for purchase from the American Society of Mechanical Engineers (ASME), 22 Law Drive, P.O. Box 2900, Fairfield, New Jersey 07007-2900:

(1) ASME MFC-3M-2004 (Revision of ASME MFC-3M-1989 (R1995)), Measurement of Fluid Flow in Pipes Using Orifice, Nozzle, and Venturi, for appendix D of this part.

(2) ASME MFC-4M-1986 (Reaffirmed 1997), Measurement of Gas Flow by Turbine Meters, for appendix D of this part.

(3) ASME-MFC-5M-1985 (Reaffirmed 1994), Measurement of Liquid Flow in Closed Conduits Using Transit-Time Ultrasonic Flowmeters, for appendix D of this part.

(4) ASME MFC-6M-1998, Measurement of Fluid Flow in Pipes Using Vortex Flowmeters, for appendix D of this part.

(5) ASME MFC-7M-1987 (Reaffirmed 1992), Measurement of Gas Flow by Means of Critical Flow Venturi Nozzles, for appendix D of this part.

(6) ASME MFC-9M-1988 (Reaffirmed 2001), Measurement of Liquid Flow in Closed Conduits by Weighing Method, for appendix D of this part.

(c) The following materials are available for purchase from the American National Standards Institute (ANSI), 25 West 43rd Street, Fourth Floor, New York, New York 10036:

(1) ISO 8316: 1987(E) Measurement of Liquid Flow in closed Conduits-Method by Collection of the Liquid in a Volumetric Tank, for appendices D and E of this part.

(2) [Reserved]

(d) The following materials are available for purchase from the following address: Gas Processors Association (GPA), 6526 East 60th Street, Tulsa, Oklahoma 74143:

(1) GPA Standard 2172-96, Calculation of Gross Heating Value, Relative Density and Compressibility Factor for Natural Gas Mixtures from Compositional Analysis, for appendices D, E, and F of this part.

(2) GPA Standard 2261-00, Analysis for Natural Gas and Similar Gaseous Mixtures by Gas Chromatography, for appendices D, F, and G of this part.

(e) The following American Gas Association materials are available for purchase from the following address: ILI Infodisk, 610 Winters Avenue, Paramus, New Jersey 07652:

(1) American Gas Association Report No. 3: Orifice Metering of Natural Gas and Other Related Hydrocarbon Fluids, Part 1: General Equations and Uncertainty Guidelines (October 1990 Edition), Part 2: Specification and Installation Requirements (February 1991 Edition) and Part 3: Natural Gas Applications (August 1992 Edition), for appendices D and E of this part.

(2) American Gas Association Transmission Measurement Committee Report No. 7: Measurement of Gas by Turbine Meters (Second Revision, April, 1996), for appendix D to this part.

(f) The following materials are available for purchase from the following address: American Petroleum Institute, Publications Department, 1220 L Street NW, Washington, DC 20005-4070.

(1) American Petroleum Institute (API) Manual of Petroleum Measurement Standards, Chapter 3 - Tank Gauging, Section 1A, Standard Practice for the Manual Gauging of Petroleum and Petroleum Products, Second Edition, August 2005; Section 1B - Standard Practice for Level Measurement of Liquid Hydrocarbons in Stationary Tanks by Automatic Tank Gauging, Second Edition June 2001; Section 2 - Standard Practice for Gauging Petroleum and Petroleum Products in Tank Cars, First Edition, August 1995 (Reaffirmed March 2006); Section 3 - Standard Practice for Level Measurement of Liquid Hydrocarbons in Stationary Pressurized Storage Tanks by Automatic Tank Gauging, First Edition June 1996; Section 4 - Standard Practice for Level Measurement of Liquid Hydrocarbons on Marine Vessels by Automatic Tank Gauging, First Edition April 1995 (Reaffirmed, March 2006); and Section 5 - Standard Practice for Level Measurement of Light Hydrocarbon Liquids Onboard Marine Vessels by Automatic Tank Gauging, First Edition March 1997 (Reaffirmed, March 2003); for §75.19.

(2) Shop Testing of Automatic Liquid Level Gages, Bulletin 2509 B, December 1961 (Reaffirmed August 1987, October 1992), for §75.19.

(3) American Petroleum Institute (API) Manual of Petroleum Measurement Standards, Chapter 4 - Proving Systems, Section 2 - Pipe Provers (Provers Accumulating at Least 10,000 Pulses), Second Edition, March 2001, Section 3 - Small Volume Provers, First Edition, July 1988, Reaffirmed Oct 1993, and Section 5 - Master-Meter Provers, Second Edition, May 2000, for appendix D to this part.

(4) American Petroleum Institute (API) Manual of Petroleum Measurement Standards, Chapter 22 - Testing Protocol, Section 2 - Differential Pressure Flow Measurement Devices (First Edition, August 2005), for appendix D to this part.

(g) A copy of the following material is available from http://www.epa.gov/ttn/emc/news.html (see postings for Sections 1, 2, 3, 4, Appendices, Spreadsheets, and the “Read before downloading Section 2” revision posted August 27, 1999): EPA-600/R-97/121, EPA Traceability Protocol for Assay and Certification of Gaseous Calibration Standards, September 1997, as amended August 25, 1999, U.S. Environmental Protection Agency, for §75.21, and appendix A to this part.

Editorial Note: At 70 FR 28678, May 18, 2005, §75.6 was amended, however, certain amendments could not be incorporated due to inaccurate amendatory instruction.

[58 FR 3701, Jan. 11, 1993, as amended at 60 FR 26517, May 17, 1995; 61 FR 59157, Nov. 20, 1996; 63 FR 57499, Oct. 27, 1998; 64 FR 28589, May 26, 1999; 67 FR 40422, June 12, 2002; 70 FR 28678, May 18, 2005; 70 FR 51269, Aug. 30, 2005; 73 FR 4341, Jan. 24, 2008; 76 FR 17307, Mar. 28, 2011; 77 FR 2460, Jan. 18, 2012]

§§75.7-75.8 [Reserved]

Subpart B - Monitoring Provisions

§75.10 General operating requirements.

(a) Primary Measurement Requirement. The owner or operator shall measure opacity, and all SO2, NOX, and CO2 emissions for each affected unit as follows:

(1) To determine SO2 emissions, the owner or operator shall install, certify, operate, and maintain, in accordance with all the requirements of this part, a SO2 continuous emission monitoring system and a flow monitoring system with an automated data acquisition and handling system for measuring and recording SO2 concentration (in ppm), volumetric gas flow (in scfh), and SO2 mass emissions (in lb/hr) discharged to the atmosphere, except as provided in §§75.11 and 75.16 and subpart E of this part;

(2) To determine NOX emissions, the owner or operator shall install, certify, operate, and maintain, in accordance with all the requirements of this part, a NOX-diluent continuous emission monitoring system (consisting of a NOX pollutant concentration monitor and an O2 or CO2 diluent gas monitor) with an automated data acquisition and handling system for measuring and recording NOX concentration (in ppm), O2 or CO2 concentration (in percent O2 or CO2) and NOX emission rate (in lb/mmBtu) discharged to the atmosphere, except as provided in §§75.12 and 75.17 and subpart E of this part. The owner or operator shall account for total NOX emissions, both NO and NO2, either by monitoring for both NO and NO2 or by monitoring for NO only and adjusting the emissions data to account for NO2;

(3) The owner or operator shall determine CO2 emissions by using one of the following options, except as provided in §75.13 and subpart E of this part:

(i) The owner or operator shall install, certify, operate, and maintain, in accordance with all the requirements of this part, a CO2 continuous emission monitoring system and a flow monitoring system with an automated data acquisition and handling system for measuring and recording CO2 concentration (in ppm or percent), volumetric gas flow (in scfh), and CO2 mass emissions (in tons/hr) discharged to the atmosphere;

(ii) The owner or operator shall determine CO2 emissions based on the measured carbon content of the fuel and the procedures in appendix G of this part to estimate CO2 emissions (in ton/day) discharged to the atmosphere; or

(iii) The owner or operator shall install, certify, operate, and maintain, in accordance with all the requirements of this part, a flow monitoring system and a CO2 continuous emission monitoring system that uses an O2 concentration monitor to determine CO2 emissions (according to the procedures in appendix F of this part) with an automated data acquisition and handling system for measuring and recording O2 concentration (in percent), CO2 concentration (in percent), volumetric gas flow (in scfh), and CO2 mass emissions (in tons/hr) discharged to the atmosphere;

(4) The owner or operator shall install, certify, operate, and maintain, in accordance with all the requirements in this part, a continuous opacity monitoring system with the automated data acquisition and handling system for measuring and recording the opacity of emissions (in percent opacity) discharged to the atmosphere, except as provided in §§75.14 and 75.18; and

(5) A single certified flow monitoring system may be used to meet the requirements of paragraphs (a)(1) and (a)(3) of this section. A single certified diluent monitor may be used to meet the requirements of paragraphs (a)(2) and (a)(3) of this section. A single automated data acquisition and handling system may be used to meet the requirements of paragraphs (a)(1) through (a)(4) of this section.

(b) Primary Equipment Performance Requirements. The owner or operator shall ensure that each continuous emission monitoring system required by this part meets the equipment, installation, and performance specifications in appendix A to this part; and is maintained according to the quality assurance and quality control procedures in appendix B to this part; and shall record SO2 and NOX emissions in the appropriate units of measurement (i.e., lb/hr for SO2 and lb/mmBtu for NOX).

(c) Heat Input Rate Measurement Requirement. The owner or operator shall determine and record the heat input rate, in units of mmBtu/hr, to each affected unit for every hour or part of an hour any fuel is combusted following the procedures in appendix F to this part.

(d) Primary equipment hourly operating requirements. The owner or operator shall ensure that all continuous emission and opacity monitoring systems required by this part are in operation and monitoring unit emissions or opacity at all times that the affected unit combusts any fuel except as provided in §75.11(e) and during periods of calibration, quality assurance, or preventive maintenance, performed pursuant to §75.21 and appendix B of this part, periods of repair, periods of backups of data from the data acquisition and handling system, or recertification performed pursuant to §75.20. The owner or operator shall also ensure, subject to the exceptions above in this paragraph, that all continuous opacity monitoring systems required by this part are in operation and monitoring opacity during the time following combustion when fans are still operating, unless fan operation is not required to be included under any other applicable Federal, State, or local regulation, or permit. The owner or operator shall ensure that the following requirements are met:

(1) The owner or operator shall ensure that each continuous emission monitoring system is capable of completing a minimum of one cycle of operation (sampling, analyzing, and data recording) for each successive 15-min interval. The owner or operator shall reduce all SO2 concentrations, volumetric flow, SO2 mass emissions, CO2 concentration, O2 concentration, CO2 mass emissions (if applicable), NOX concentration, and NOX emission rate data collected by the monitors to hourly averages. Hourly averages shall be computed using at least one data point in each fifteen minute quadrant of an hour, where the unit combusted fuel during that quadrant of an hour. Notwithstanding this requirement, an hourly average may be computed from at least two data points separated by a minimum of 15 minutes (where the unit operates for more than one quadrant of an hour) if data are unavailable as a result of the performance of calibration, quality assurance, or preventive maintenance activities pursuant to §75.21 and appendix B of this part, or backups of data from the data acquisition and handling system, or recertification, pursuant to §75.20. The owner or operator shall use all valid measurements or data points collected during an hour to calculate the hourly averages. All data points collected during an hour shall be, to the extent practicable, evenly spaced over the hour.

(2) The owner or operator shall ensure that each continuous opacity monitoring system is capable of completing a minimum of one cycle of sampling and analyzing for each successive 10-sec period and one cycle of data recording for each successive 6-min period. The owner or operator shall reduce all opacity data to 6-min averages calculated in accordance with the provisions of part 51, appendix M of this chapter, except where the applicable State implementation plan or operating permit requires a different averaging period, in which case the State requirement shall satisfy this Acid Rain Program requirement.

(3) Failure of an SO2, CO2, or O2 emissions concentration monitor, NOX concentration monitor, flow monitor, moisture monitor, or NOX-diluent continuous emission monitoring system to acquire the minimum number of data points for calculation of an hourly average in paragraph (d)(1) of this section shall result in the failure to obtain a valid hour of data and the loss of such component data for the entire hour. For a NOX-diluent monitoring system, an hourly average NOX emission rate in lb/mmBtu is valid only if the minimum number of data points is acquired by both the NOX pollutant concentration monitor and the diluent monitor (O2 or CO2). For a moisture monitoring system consisting of one or more oxygen analyzers capable of measuring O2 on a wet-basis and a dry-basis, an hourly average percent moisture value is valid only if the minimum number of data points is acquired for both the wet-and dry-basis measurements. If a valid hour of data is not obtained, the owner or operator shall estimate and record emissions, moisture, or flow data for the missing hour by means of the automated data acquisition and handling system, in accordance with the applicable procedure for missing data substitution in subpart D of this part.

(e) Optional backup monitor requirements. If the owner or operator chooses to use two or more continuous emission monitoring systems, each of which is capable of monitoring the same stack or duct at a specific affected unit, or group of units using a common stack, then the owner or operator shall designate one monitoring system as the primary monitoring system, and shall record this information in the monitoring plan, as provided for in §75.53. The owner or operator shall designate the other monitoring system(s) as backup monitoring system(s) in the monitoring plan. The backup monitoring system(s) shall be designated as redundant backup monitoring system(s), non-redundant backup monitoring system(s), or reference method backup system(s), as described in §75.20(d). When the certified primary monitoring system is operating and not out-of-control as defined in §75.24, only data from the certified primary monitoring system shall be reported as valid, quality-assured data. Thus, data from the backup monitoring system may be reported as valid, quality-assured data only when the backup is operating and not out-of-control as defined in §75.24 (or in the applicable reference method in appendix A of part 60 of this chapter) and when the certified primary monitoring system is not operating (or is operating but out-of-control). A particular monitor may be designated both as a certified primary monitor for one unit and as a certified redundant backup monitor for another unit.

(f) Minimum measurement capability requirement. The owner or operator shall ensure that each continuous emission monitoring system is capable of accurately measuring, recording, and reporting data, and shall not incur an exceedance of the full scale range, except as provided in sections 2.1.1.5, 2.1.2.5, and 2.1.4.3 of appendix A to this part.

(g) Minimum recording and recordkeeping requirements. The owner or operator shall record and the designated representative shall report the hourly, daily, quarterly, and annual information collected under the requirements of this part as specified in subparts F and G of this part.

[58 FR 3701, Jan. 11, 1993, as amended at 60 FR 26519, May 17, 1995; 64 FR 28590, May 26, 1999; 67 FR 40422, June 12, 2002; 70 FR 28678, May 18, 2005; 76 FR 17308, Mar. 28, 2011]

§75.11 Specific provisions for monitoring SO2 emissions.

(a) Coal-fired units. The owner or operator shall meet the general operating requirements in §75.10 for an SO2 continuous emission monitoring system and a flow monitoring system for each affected coal-fired unit while the unit is combusting coal and/or any other fuel, except as provided in paragraph (e) of this section, in §75.16, and in subpart E of this part. During hours in which only gaseous fuel is combusted in the unit, the owner or operator shall comply with the applicable provisions of paragraph (e)(1), (e)(2), or (e)(3) of this section.

(b) Moisture correction. Where SO2 concentration is measured on a dry basis, the owner or operator shall either:

(1) Report the appropriate fuel-specific default moisture value for each unit operating hour, selected from among the following: 3.0%, for anthracite coal; 6.0% for bituminous coal; 8.0% for sub-bituminous coal; 11.0% for lignite coal; 13.0% for wood and 14.0% for natural gas (boilers, only); or

(2) Install, operate, maintain, and quality assure a continuous moisture monitoring system for measuring and recording the moisture content of the flue gases, in order to correct the measured hourly volumetric flow rates for moisture when calculating SO2 mass emissions (in lb/hr) using the procedures in appendix F to this part. The following continuous moisture monitoring systems are acceptable: a continuous moisture sensor; an oxygen analyzer (or analyzers) capable of measuring O2 both on a wet basis and on a dry basis; or a stack temperature sensor and a moisture look-up table, i.e., a psychrometric chart (for saturated gas streams following wet scrubbers or other demonstrably saturated gas streams, only). The moisture monitoring system shall include as a component the automated data acquisition and handling system (DAHS) for recording and reporting both the raw data (e.g., hourly average wet-and dry-basis O2 values) and the hourly average values of the stack gas moisture content derived from those data. When a moisture look-up table is used, the moisture monitoring system shall be represented as a single component, the certified DAHS, in the monitoring plan for the unit or common stack.

(c) Unit with no location for a flow monitor meeting siting requirements. Where no location exists that satisfies the minimum physical siting criteria in appendix A to this part for installation of a flow monitor in either the stack or the ducts serving an affected unit or installation of a flow monitor in either the stack or ducts is demonstrated to the satisfaction of the Administrator to be technically infeasible, either:

(1) The designated representative shall petition the Administrator for an alternative method for monitoring volumetric flow in accordance with §75.66; or

(2) The owner or operator shall construct a new stack or modify existing ductwork to accommodate the installation of a flow monitor, and the designated representative shall petition the Administrator for an extension of the required certification date given in §75.4 and approval of an interim alternative flow monitoring methodology in accordance with §75.66. The Administrator may grant existing Phase I affected units an extension to January 1, 1995, and existing Phase II affected units an extension to January 1, 1996 for the submission of the certification application for the purpose of constructing a new stack or making substantial modifications to ductwork for installation of a flow monitor; or

(3) The owner or operator shall install a flow monitor in any existing location in the stack or ducts serving the affected unit at which the monitor can achieve the performance specifications of this part.

(d) Gas-fired and oil-fired units. The owner or operator of an affected unit that qualifies as a gas-fired or oil-fired unit, as defined in §72.2 of this chapter, based on information submitted by the designated representative in the monitoring plan, shall measure and record SO2 emissions:

(1) By meeting the general operating requirements in §75.10 for an SO2 continuous emission monitoring system and flow monitoring system. If this option is selected, the owner or operator shall comply with the applicable provisions in paragraph (e)(1), (e)(2), or (e)(3) of this section during hours in which the unit combusts only gaseous fuel;

(2) By providing other information satisfactory to the Administrator using the applicable procedures specified in appendix D to this part for estimating hourly SO2 mass emissions; or

(3) By using the low mass emissions excepted methodology in §75.19(c) for estimating hourly SO2 mass emissions if the affected unit qualifies as a low mass emissions unit under §75.19(a) and (b). If this option is selected for SO2, the LME methodology must also be used for NOX and CO2 when these parameters are required to be monitored by applicable program(s).

(e) Special considerations during the combustion of gaseous fuels. The owner or operator of an affected unit that uses a certified flow monitor and a certified diluent gas (O2 or CO2) monitor to measure the unit heat input rate shall, during any hours in which the unit combusts only gaseous fuel, determine SO2 emissions in accordance with paragraph (e)(1) or (e)(3) of this section, as applicable.

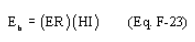

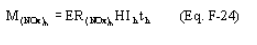

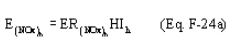

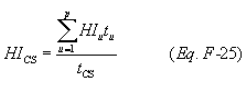

(1) If the gaseous fuel qualifies for a default SO2 emission rate under Section 2.3.1.1, 2.3.2.1.1, or 2.3.6(b) of appendix D to this part, the owner or operator may determine SO2 emissions by using Equation F-23 in appendix F to this part. Substitute into Equation F-23 the hourly heat input, calculated using the certified flow monitoring system and the certified diluent monitor (according to the applicable equation in section 5.2 of appendix F to this part), in conjunction with the appropriate default SO2 emission rate from section 2.3.1.1, 2.3.2.1.1, or 2.3.6(b) of appendix D to this part. When this option is chosen, the owner or operator shall perform the necessary data acquisition and handling system tests under §75.20(c), and shall meet all quality control and quality assurance requirements in appendix B to this part for the flow monitor and the diluent monitor; or

(2) [Reserved]

(3) The owner or operator may determine SO2 mass emissions by using a certified SO2 continuous monitoring system, in conjunction with the certified flow rate monitoring system. However, if the gaseous fuel is very low sulfur fuel (as defined in §72.2 of this chapter), the SO2 monitoring system shall meet the following quality assurance provisions when the very low sulfur fuel is combusted:

(i) When conducting the daily calibration error tests of the SO2 monitoring system, as required by section 2.1.1 in appendix B of this part, the zero-level calibration gas shall have an SO2 concentration of 0.0 percent of span. This restriction does not apply if gaseous fuel is burned in the affected unit only during unit startup.

(ii) EPA recommends that the calibration response of the SO2 monitoring system be adjusted, either automatically or manually, in accordance with the procedures for routine calibration adjustments in section 2.1.3 of appendix B to this part, whenever the zero-level calibration response during a required daily calibration error test exceeds the applicable performance specification of the instrument in section 3.1 of appendix A to this part (i.e., ±2.5 percent of the span value or ±5 ppm, whichever is less restrictive).

(iii) Any bias-adjusted hourly average SO2 concentration of less than 2.0 ppm recorded by the SO2 monitoring system shall be adjusted to a default value of 2.0 ppm, for reporting purposes. Such adjusted hourly averages shall be considered to be quality-assured data, provided that the monitoring system is operating and is not out-of-control with respect to any of the quality assurance tests required by appendix B of this part (i.e., daily calibration error, linearity and relative accuracy test audit).

(iv) In accordance with the requirements of section 2.1.1.2 of appendix A to this part, for units that sometimes burn gaseous fuel that is very low sulfur fuel (as defined in §72.2 of this chapter) and at other times burn higher sulfur fuel(s) such as coal or oil, a second low-scale SO2 measurement range is not required when the very low sulfur gaseous fuel is combusted. For units that burn only gaseous fuel that is very low sulfur fuel and burn no other type(s) of fuel(s), the owner or operator shall set the span of the SO2 monitoring system to a value no greater than 200 ppm.

(4) The provisions in paragraph (e)(1) of this section, may also be used for the combustion of a solid or liquid fuel that meets the definition of very low sulfur fuel in §72.2 of this chapter, mixtures of such fuels, or combinations of such fuels with gaseous fuel, if the owner or operator submits a petition under §75.66 for a default SO2 emission rate for each fuel, mixture or combination, and if the Administrator approves the petition.

(f) Other units. The owner or operator of an affected unit that combusts wood, refuse, or other material in addition to oil or gas shall comply with the monitoring provisions for coal-fired units specified in paragraph (a) of this section, except where the owner or operator has an approved petition to use the provisions of paragraph (e)(1) of this section.

[58 FR 3701, Jan. 11, 1993, as amended at 60 FR 26520, 26566, May 17, 1995; 61 FR 59157, Nov. 20, 1996; 63 FR 57499, Oct. 27, 1998; 64 FR 28590, May 26, 1999; 67 FR 40423, June 12, 2002; 73 FR 4342, Jan. 24, 2008]

§75.12 Specific provisions for monitoring NOX emission rate.

(a) Coal-fired units, gas-fired nonpeaking units or oil-fired nonpeaking units. The owner or operator shall meet the general operating requirements in §75.10 of this part for a NOX continuous emission monitoring system (CEMS) for each affected coal-fired unit, gas-fired nonpeaking unit, or oil-fired nonpeaking unit, except as provided in paragraph (d) of this section, §75.17, and subpart E of this part. The diluent gas monitor in the NOX-diluent CEMS may measure either O2 or CO2 concentration in the flue gases.

(b) Moisture correction. If a correction for the stack gas moisture content is needed to properly calculate the NOX emission rate in lb/mmBtu, e.g., if the NOX pollutant concentration monitor measures on a different moisture basis from the diluent monitor, the owner or operator shall either report a fuel-specific default moisture value for each unit operating hour, as provided in §75.11(b)(1), or shall install, operate, maintain, and quality assure a continuous moisture monitoring system, as defined in §75.11(b)(2). Notwithstanding this requirement, if Equation 19-3, 19-4 or 19-8 in Method 19 in appendix A to part 60 of this chapter is used to measure NOX emission rate, the following fuel-specific default moisture percentages shall be used in lieu of the default values specified in §75.11(b)(1): 5.0%, for anthracite coal; 8.0% for bituminous coal; 12.0% for sub-bituminous coal; 13.0% for lignite coal; 15.0% for wood and 18.0% for natural gas (boilers, only).

(c) Determination of NOX emission rate. The owner or operator shall calculate hourly, quarterly, and annual NOX emission rates (in lb/mmBtu) by combining the NOX concentration (in ppm), diluent concentration (in percent O2 or CO2), and percent moisture (if applicable) measurements according to the procedures in appendix F to this part.

(d) Gas-fired peaking units or oil-fired peaking units. The owner or operator of an affected unit that qualifies as a gas-fired peaking unit or oil-fired peaking unit, as defined in §72.2 of this chapter, based on information submitted by the designated representative in the monitoring plan shall comply with one of the following:

(1) Meet the general operating requirements in §75.10 for a NOX continuous emission monitoring system; or

(2) Provide information satisfactory to the Administrator using the procedure specified in appendix E of this part for estimating hourly NOX emission rate. However, if in the years after certification of an excepted monitoring system under appendix E of this part, a unit's operations exceed a capacity factor of 20 percent in any calendar year or exceed a capacity factor of 10.0 percent averaged over three years, the owner or operator shall install, certify, and operate a NOX-diluent continuous emission monitoring system no later than December 31 of the following calendar year. If the required CEMS has not been installed and certified by that date, the owner or operator shall report the maximum potential NOX emission rate (MER) (as defined in §72.2 of this chapter) for each unit operating hour, starting with the first unit operating hour after the deadline and continuing until the CEMS has been provisionally certified.

(e) Low mass emissions units. Notwithstanding the requirements of paragraphs (a) and (d) of this section, the owner or operator of an affected unit that qualifies as a low mass emissions unit under §75.19(a) and (b) shall comply with one of the following:

(1) Meet the general operating requirements in §75.10 for a NOX continuous emission monitoring system;

(2) Meet the requirements specified in paragraph (d)(2) of this section for using the excepted monitoring procedures in appendix E to this part, if applicable; or

(3) Use the low mass emissions excepted methodology in §75.19(c) for estimating hourly NOX emission rate and hourly NOX mass emissions, if applicable under §75.19(a) and (b). If this option is selected for NOX, the LME methodology must also be used for SO2 and CO2 when these parameters are required to be monitored by applicable program(s).

(f) Other units. The owner or operator of an affected unit that combusts wood, refuse, or other material in addition to oil or gas shall comply with the monitoring provisions specified in paragraph (a) of this section.

[58 FR 3701, Jan. 11, 1993, as amended at 60 FR 26520, May 17, 1995; 63 FR 57499, Oct. 27, 1998; 64 FR 28591, May 26, 1999; 67 FR 40423, June 12, 2002; 73 FR 4342, Jan. 24, 2008]

§75.13 Specific provisions for monitoring CO 2 emissions.

(a) CO2 continuous emission monitoring system. If the owner or operator chooses to use the continuous emission monitoring method, then the owner or operator shall meet the general operating requirements in §75.10 for a CO2 continuous emission monitoring system and flow monitoring system for each affected unit. The owner or operator shall comply with the applicable provisions specified in §§75.11(a) through (e) or §75.16, except that the phrase “CO2 continuous emission monitoring system” shall apply rather than “SO2 continuous emission monitoring system,” the phrase “CO2 concentration” shall apply rather than “SO2 concentration,” the term “maximum potential concentration of CO2” shall apply rather than “maximum potential concentration of SO2,” and the phrase “CO2 mass emissions” shall apply rather than “SO2 mass emissions.”

(b) Determination of CO2 emissions using appendix G to this part. If the owner or operator chooses to use the appendix G method, then the owner or operator shall follow the procedures in appendix G to this part for estimating daily CO2 mass emissions based on the measured carbon content of the fuel and the amount of fuel combusted. For units with wet flue gas desulfurization systems or other add-on emissions controls generating CO2, the owner or operator shall use the procedures in appendix G to this part to estimate both combustion-related emissions based on the measured carbon content of the fuel and the amount of fuel combusted and sorbent-related emissions based on the amount of sorbent injected. The owner or operator shall calculate daily, quarterly, and annual CO2 mass emissions (in tons) in accordance with the procedures in appendix G to this part.

(c) Determination of CO2 mass emissions using an O2 monitor according to appendix F to this part. If the owner or operator chooses to use the appendix F method, then the owner or operator shall determine hourly CO2 concentration and mass emissions with a flow monitoring system; a continuous O2 concentration monitor; fuel F and Fc factors; and, where O2 concentration is measured on a dry basis (or where Equation F-14b in appendix F to this part is used to determine CO2 concentration), either, a continuous moisture monitoring system, as specified in §75.11(b)(2), or a fuel-specific default moisture percentage (if applicable), as defined in §75.11(b)(1); and by using the methods and procedures specified in appendix F to this part. For units using a common stack, multiple stack, or bypass stack, the owner or operator may use the provisions of §75.16, except that the phrase “CO2 continuous emission monitoring system” shall apply rather than “SO2 continuous emission monitoring system,” the term “maximum potential concentration of CO2” shall apply rather than “maximum potential concentration of SO2,” and the phrase “CO2 mass emissions” shall apply rather than “SO2 mass emissions.”

(d) Determination of CO2 mass emissions from low mass emissions units. The owner or operator of a unit that qualifies as a low mass emissions unit under §75.19(a) and (b) shall comply with one of the following:

(1) Meet the general operating requirements in §75.10 for a CO2 continuous emission monitoring system and flow monitoring system;

(2) Meet the requirements specified in paragraph (b) or (c) of this section for use of the methods in appendix G or F to this part, respectively; or

(3) Use the low mass emissions excepted methodology in §75.19(c) for estimating hourly CO2 mass emissions, if applicable under §75.19(a) and (b). If this option is selected for CO2, the LME methodology must also be used for NOX and SO2 when these parameters are required to be monitored by applicable program(s).

[58 FR 3701, Jan. 11, 1993, as amended at 60 FR 26521, May 17, 1995; 63 FR 57499, Oct. 27, 1998; 64 FR 28591, May 26, 1999; 67 FR 40423, June 12, 2002; 73 FR 4343, Jan. 24, 2008]

§75.14 Specific provisions for monitoring opacity.

(a) Coal-fired units and oil-fired units. The owner or operator shall meet the general operating provisions in §75.10 of this part for a continuous opacity monitoring system for each affected coal-fired or oil-fired unit, except as provided in paragraphs (b), (c), and (d) of this section and in §75.18. Each continuous opacity monitoring system shall meet the design, installation, equipment, and performance specifications in Performance Specification 1 in appendix B to part 60 of this chapter. Any continuous opacity monitoring system previously certified to meet Performance Specification 1 shall be deemed certified for the purposes of this part.

(b) Unit with wet flue gas pollution control system. If the owner or operator can demonstrate that condensed water is present in the exhaust flue gas stream and would impede the accuracy of opacity measurements, then the owner or operator of an affected unit equipped with a wet flue gas pollution control system for SO2 emissions or particulates is exempt from the opacity monitoring requirements of this part.

(c) Gas-fired units. The owner or operator of an affected unit that qualifies as gas-fired, as defined in §72.2 of this chapter, based on information submitted by the designated representative in the monitoring plan is exempt from the opacity monitoring requirements of this part. Whenever a unit previously categorized as a gas-fired unit is recategorized as another type of unit by changing its fuel mix, the owner or operator shall install, operate, and certify a continuous opacity monitoring system as required by paragraph (a) of this section by December 31 of the following calendar year.

(d) Diesel-fired units and dual-fuel reciprocating engine units. The owner or operator of an affected diesel-fired unit or a dual-fuel reciprocating engine unit is exempt from the opacity monitoring requirements of this part.

(e) Unit with a certified particulate matter (PM) monitoring system. If, for a particular affected unit, the owner or operator installs, certifies, operates, maintains, and quality-assures a continuous particulate matter (PM) monitoring system in accordance with Procedure 2 in appendix F to part 60 of this chapter, the unit shall be exempt from the opacity monitoring requirement of this part.

[58 FR 3701, Jan. 11, 1993, as amended at 61 FR 25581, May 22, 1996; 73 FR 4343, Jan. 24, 2008]

§75.15 [Reserved]

§75.16 Special provisions for monitoring emissions from common, bypass, and multiple stacks for SO 2 emissions and heat input determinations.

(a) [Reserved]

(b) Common stack procedures. The following procedures shall be used when more than one unit uses a common stack:

(1) Unit utilizing common stack with other affected unit(s). When a Phase I or Phase II affected unit utilizes a common stack with one or more other Phase I or Phase II affected units, but no nonaffected units, the owner or operator shall either:

(i) Install, certify, operate, and maintain an SO2 continuous emission monitoring system and flow monitoring system in the duct to the common stack from each affected unit; or

(ii) Install, certify, operate, and maintain an SO2 continuous emission monitoring system and flow monitoring system in the common stack and combine emissions for the affected units for recordkeeping and compliance purposes.

(2) Unit utilizing common stack with nonaffected unit(s). When one or more Phase I or Phase II affected units utilizes a common stack with one or more nonaffected units, the owner or operator shall either:

(i) Install, certify, operate, and maintain an SO2 continuous emission monitoring system and flow monitoring system in the duct to the common stack from each Phase I and Phase II unit; or

(ii) Install, certify, operate, and maintain an SO2 continuous emission monitoring system and flow monitoring system in the common stack; and

(A) Designate the nonaffected units as opt-in units in accordance with part 74 of this chapter and combine emissions for recordkeeping and compliance purposes; or

(B) Install, certify, operate, and maintain an SO2 continuous emission monitoring system and flow monitoring system in the duct from each nonaffected unit; determine SO2 mass emissions from the affected units as the difference between SO2 mass emissions measured in the common stack and SO2 mass emissions measured in the ducts of the nonaffected units, not to be reported as an hourly average value less than zero; combine emissions for the Phase I and Phase II affected units for recordkeeping and compliance purposes; and calculate and report SO2 mass emissions from the Phase I and Phase II affected units, pursuant to an approach approved by the Administrator, such that these emissions are not underestimated; or

(C) Record the combined emissions from all units as the combined SO2 mass emissions for the Phase I and Phase II affected units for recordkeeping and compliance purposes; or

(D) Petition through the designated representative and provide information satisfactory to the Administrator on methods for apportioning SO2 mass emissions measured in the common stack to each of the units using the common stack and on reporting the SO2 mass emissions. The Administrator may approve such demonstrated substitute methods for apportioning and reporting SO2 mass emissions measured in a common stack whenever the demonstration ensures that there is a complete and accurate accounting of all emissions regulated under this part and, in particular, that the emissions from any affected unit are not underestimated.

(c) Unit with bypass stack. Whenever any portion of the flue gases from an affected unit can be routed through a bypass stack so as to avoid the installed SO2 continuous emission monitoring system and flow monitoring system, the owner or operator shall either:

(1) Install, certify, operate, and maintain separate SO2 continuous emission monitoring systems and flow monitoring systems on the main stack and the bypass stack and calculate SO2 mass emissions for the unit as the sum of the SO2 mass emissions measured at the two stacks; or

(2) Monitor SO2 mass emissions at the main stack using SO2 and flow rate monitoring systems and measure SO2 mass emissions at the bypass stack using the reference methods in §75.22(b) for SO2 and flow rate and calculate SO2 mass emissions for the unit as the sum of the emissions recorded by the installed monitoring systems on the main stack and the emissions measured by the reference method monitoring systems; or

(3) Install, certify, operate, and maintain SO2 and flow rate monitoring systems only on the main stack. If this option is chosen, report the following values for each hour during which emissions pass through the bypass stack: the maximum potential concentration of SO2 as determined under section 2.1.1.1 of appendix A to this part (or, if available, the SO2 concentration measured by a certified monitor located at the control device inlet may be reported instead), and the hourly volumetric flow rate value that would be substituted for the flow monitor installed on the main stack or flue under the missing data procedures in subpart D of this part if data from the flow monitor installed on the main stack or flue were missing for the hour. The maximum potential SO2 concentration may be specific to the type of fuel combusted in the unit during the bypass (see §75.33(b)(5)). The option in this paragraph, (c)(3), may only be used if use of the bypass stack is limited to unit startup, emergency situations (e.g., malfunction of a flue gas desulfurization system), and periods of routine maintenance of the flue gas desulfurization system or maintenance on the main stack. If this option is chosen, it is not necessary to designate the exhaust configuration as a multiple stack configuration in the monitoring plan required under §75.53, with respect to SO2 or any other parameter that is monitored only at the main stack. Calculate SO2 mass emissions for the unit as the sum of the emissions calculated with the substitute values and the emissions recorded by the SO2 and flow monitoring systems installed on the main stack.

(d) Unit with multiple stacks or ducts. When the flue gases from an affected unit utilize two or more ducts feeding into two or more stacks (that may include flue gases from other affected or nonaffected units), or when the flue gases utilize two or more ducts feeding into a single stack and the owner or operator chooses to monitor in the ducts rather than the stack, the owner or operator shall either: