['Air Programs']

['Air Quality', 'Acid Rain']

07/31/2023

...

�75.30 General provisions.

(a) Except as provided in �75.34, the owner or operator shall provide substitute data for each affected unit using a continuous emission monitoring system according to the missing data procedures in this subpart whenever the unit combusts any fuel and:

(1) A valid, quality-assured hour of SO2 concentration data (in ppm) has not been measured and recorded for an affected unit by a certified SO2 pollutant concentration monitor, or by an approved alternative monitoring method under subpart E of this part, except as provided in paragraph (d) of this section; or

(2) A valid, quality-assured hour of flow data (in scfh) has not been measured and recorded for an affected unit from a certified flow monitor, or by an approved alternative monitoring system under subpart E of this part; or

(3) A valid, quality-assured hour of NOX emission rate data (in lb/mmBtu) has not been measured or recorded for an affected unit, either by a certified NOX-diluent continuous emission monitoring system or by an approved alternative monitoring system under subpart E of this part; or

(4) A valid, quality-assured hour of CO2 concentration data (in percent CO2, or percent O2 converted to percent CO2 using the procedures in appendix F to this part) has not been measured and recorded for an affected unit, either by a certified CO2 continuous emission monitoring system or by an approved alternative monitoring method under subpart E of this part; or

(5) A valid, quality-assured hour of NOX concentration data (in ppm) has not been measured or recorded for an affected unit, either by a certified NOX concentration monitoring system used to determine NOX mass emissions, as defined in �75.71(a)(2), or by an approved alternative monitoring system under subpart E of this part; or

(6) A valid, quality-assured hour of CO2 or O2 concentration data (in percent CO2, or percent O2) used for the determination of heat input has not been measured and recorded for an affected unit, either by a certified CO2 or O2 diluent monitor, or by an approved alternative monitoring method under subpart E of this part; or

(7) A valid, quality-assured hour of moisture data (in percent H2O) has not been measured or recorded for an affected unit, either by a certified moisture monitoring system or an approved alternative monitoring method under subpart E of this part. This requirement does not apply when a default percent moisture value, as provided in ��75.11(b) or 75.12(b), is used to account for the hourly moisture content of the stack gas; or

(8) A valid, quality-assured hour of heat input rate data (in mmBtu/hr) has not been measured and recorded for a unit from a certified flow monitor and a certified diluent (CO2 or O2) monitor or by an approved alternative monitoring system under subpart E of this part.

(b) However, the owner or operator shall have no need to provide substitute data according to the missing data procedures in this subpart if the owner or operator uses SO2, CO2, NOX, or O2 concentration, flow rate, percent moisture, or NOX emission rate data recorded from either a certified redundant or regular non-redundant backup CEMS, a like-kind replacement non-redundant backup analyzer, or a backup reference method monitoring system when the certified primary monitor is not operating or is out-of-control. A redundant or non-redundant backup continuous emission monitoring system must have been certified according to the procedures in �75.20 prior to the missing data period. Non-redundant backup continuous emission monitoring system must pass a linearity check (for pollutant concentration monitors) or a calibration error test (for flow monitors) prior to each period of use of the certified backup monitor for recording and reporting emissions. Use of a certified backup monitoring system or backup reference method monitoring system is optional and at the discretion of the owner or operator.

(c) When the certified primary monitor is not operating or out-of-control, then data recorded for an affected unit from a certified backup continuous emission monitor or backup reference method monitoring system are used, as if such data were from the certified primary monitor, to calculate monitor data availability in �75.32, and to provide the quality-assured data used in the missing data procedures in ��75.31 and 75.33, such as the �hour after� value.

(d) The owner or operator shall comply with the applicable provisions of this paragraph during hours in which a unit with an SO2 continuous emission monitoring system combusts only gaseous fuel.

(1) Whenever a unit with an SO2 CEMS combusts only natural gas or pipeline natural gas (as defined in �72.2 of this chapter) and the owner or operator is using the procedures in section 7 of appendix F to this part to determine SO2 mass emissions pursuant to �75.11(e)(1), the owner or operator shall, for purposes of reporting heat input data under �75.57(b)(5), and for the calculation of SO2 mass emissions using Equation F-23 in section 7 of appendix F to this part, substitute for missing data from a flow monitoring system, CO2 diluent monitor or O2 diluent monitor using the missing data substitution procedures in �75.36.

(2) Whenever a unit with an SO2 CEMS combusts gaseous fuel and the owner or operator uses the gas sampling and analysis and fuel flow procedures in appendix D to this part to determine SO2 mass emissions pursuant to �75.11(e)(2), the owner or operator shall substitute for missing total sulfur content, gross calorific value, and fuel flowmeter data using the missing data procedures in appendix D to this part and shall also, for purposes of reporting heat input data under �75.54(b)(5) or �75.57(b)(5), as applicable, substitute for missing data from a flow monitoring system, CO2 diluent monitor, or O2 diluent monitor using the missing data substitution procedures in �75.36.

(3) The owner or operator of a unit with an SO2 monitoring system shall not include hours when the unit combusts only gaseous fuel in the SO2 data availability calculations in �75.32 or in the calculations of substitute SO2 data using the procedures of either �75.31 or �75.33, for hours when SO2 emissions are determined in accordance with �75.11(e)(1) or (e)(2). For the purpose of the missing data and availability procedures for SO2 pollutant concentration monitors in ��75.31 and 75.33 only, all hours during which the unit combusts only gaseous fuel shall be excluded from the definition of �monitor operating hour,� �quality-assured monitor operating hour,� �unit operating hour,� and �unit operating day,� when SO2 emissions are determined in accordance with �75.11(e)(1) or (e)(2).

(4) During all hours in which a unit with an SO2 continuous emission monitoring system combusts only gaseous fuel and the owner or operator uses the SO2 monitoring system to determine SO2 mass emissions pursuant to �75.11(e)(3), the owner or operator shall determine the percent monitor data availability for SO2 in accordance with �75.32 and shall use the standard SO2 missing data procedures of �75.33.

[60 FR 26528, 26566, May 17, 1995, as amended at 61 FR 59160, Nov. 20, 1996; 64 FR 28600, May 26, 1999; 67 FR 40433, June 12, 2002]

�75.31 Initial missing data procedures.

(a) During the first 720 quality-assured monitor operating hours following initial certification of the required SO2, CO2, O2, or moisture monitoring system(s) at a particular unit or stack location (i.e., the date and time at which quality assured data begins to be recorded by CEMS(s) installed at that location), and during the first 2,160 quality assured monitor operating hours following initial certification of the required NOX-diluent, NOX concentration, or flow monitoring system(s) at the unit or stack location, the owner or operator shall provide substitute data required under this subpart according to the procedures in paragraphs (b) and (c) of this section. The owner or operator of a unit shall use these procedures for no longer than three years (26,280 clock hours) following initial certification.

(b) SO2, CO2, or O2 concentration data, and moisture data. For each hour of missing SO2 or CO2 emissions concentration data (including CO2 data converted from O2 data using the procedures in appendix F of this part), or missing O2 or CO2 diluent concentration data used to calculate heat input, or missing moisture data, the owner or operator shall calculate the substitute data as follows:

(1) Whenever prior quality-assured data exist, the owner or operator shall substitute, by means of the data acquisition and handling system, for each hour of missing data, the average of the hourly SO2, CO2, or O2 concentrations or moisture percentages recorded by a certified monitor for the unit operating hour immediately before and the unit operating hour immediately after the missing data period.

(2) Whenever no prior quality assured SO2, CO2, or O2 concentration data or moisture data exist, the owner or operator shall substitute, as applicable, for each hour of missing data, the maximum potential SO2 concentration or the maximum potential CO2 concentration or the minimum potential O2 concentration or (unless Equation 19-3, 19-4 or 19-8 in Method 19 in appendix A-7 to part 60 of this chapter is used to determine NOX emission rate) the minimum potential moisture percentage, as specified, respectively, in sections 2.1.1.1, 2.1.3.1, 2.1.3.2 and 2.1.5 of appendix A to this part. If Equation 19-3, 19-4 or 19-8 in Method 19 in appendix A-7 to part 60 of this chapter is used to determine NOX emission rate, substitute the maximum potential moisture percentage, as specified in section 2.1.6 of appendix A to this part.

(c) Volumetric flow and NOX emission rate or NOX concentration data (load ranges or operational bins used). The procedures in this paragraph apply to affected units for which load-based ranges or non-load-based operational bins, as defined, respectively, in sections 2 and 3 of appendix C to this part are used to provide substitute NOX and flow rate data. For each hour of missing volumetric flow rate data, NOX emission rate data, or NOX concentration data used to determine NOX mass emissions:

(1) Whenever prior quality-assured data exist in the load range (or operational bin) corresponding to the operating load (or operating conditions) at the time of the missing data period, the owner or operator shall substitute, by means of the automated data acquisition and handling system, for each hour of missing data, the arithmetic average of all of the prior quality-assured hourly flow rates, NOX emission rates, or NOX concentrations in the corresponding load range (or operational bin) as determined using the procedure in appendix C to this part. When non-load-based operational bins are used, if essential operating or parametric data are unavailable for any hour in the missing data period, such that the operational bin cannot be determined, the owner or operator shall, for that hour, substitute (as applicable) the maximum potential flow rate as specified in section 2.1.4.1 of appendix A to this part or the maximum potential NOX emission rate or the maximum potential NOX concentration as specified in section 2.1.2.1 of appendix A to this part.

(2) This paragraph (c)(2) does not apply to non-load-based units using operational bins. Whenever no prior quality-assured flow or NOX emission rate or NOX concentration data exist for the corresponding load range, the owner or operator shall substitute, for each hour of missing data, the average hourly flow rate or the average hourly NOX emission rate or NOX concentration at the next higher level load range for which quality-assured data are available.

(3) Whenever no prior quality-assured flow rate or NOX emission rate or NOX concentration data exist for the corresponding load range, or any higher load range (or for non-load-based units using operational bins, when no prior quality-assured data exist in the corresponding operational bin), the owner or operator shall, as applicable, substitute, for each hour of missing data, the maximum potential flow rate as specified in section 2.1.4.1 of appendix A to this part or shall substitute the maximum potential NOX emission rate or the maximum potential NOX concentration, as specified in section 2.1.2.1 of appendix A to this part. Alternatively, where a unit with add-on NOX emission controls can demonstrate that the controls are operating properly during the hour, as provided in �75.34(d), the owner or operator may substitute, as applicable, the maximum controlled NOX emission rate (MCR) or the maximum expected NOX concentration (MEC).

(d) Non-load-based volumetric flow and NOX emission rate or NOX concentration data (operational bins not used). The procedures in this paragraph, (d), apply only to affected units that do not produce electrical output (in megawatts) or thermal output (in klb/hr of steam) and for which operational bins are not used. For each hour of missing volumetric flow rate data, NOX emission rate data, or NOX concentration data used to determine NOX mass emissions:

(1) Whenever prior quality-assured data exist at the time of the missing data period, the owner or operator shall substitute, by means of the automated data acquisition and handling system, for each hour of missing data, the arithmetic average of all of the prior quality-assured hourly average flow rates or NOX emission rates or NOX concentrations.

(2) Whenever no prior quality-assured flow rate, NOX emission rate, or NOX concentration data exist, the owner or operator shall, as applicable, substitute for each hour of missing data, the maximum potential flow rate as specified in section 2.1.4.1 of appendix A to this part or the maximum potential NOX emission rate or the maximum potential NOX concentration as specified in section 2.1.2.1 of appendix A to this part.

[64 FR 28601, May 26, 1999, as amended at 67 FR 40433, June 12, 2002; 70 FR 28680, May 18, 2005; 73 FR 4346, Jan. 24, 2008; 76 FR 17311, Mar. 28, 2011]

�75.32 Determination of monitor data availability for standard missing data procedures.

(a) Following initial certification of the required SO2, CO2, O2, or moisture monitoring system(s) at a particular unit or stack location (i.e., the date and time at which quality assured data begins to be recorded by CEMS(s) at that location), the owner or operator shall begin calculating the percent monitor data availability as described in paragraph (a)(1) of this section, and shall, upon completion of the first 720 quality-assured monitor operating hours, record, by means of the automated data acquisition and handling system, the percent monitor data availability for each monitored parameter. Similarly, following initial certification of the required NOX-diluent, NOX concentration, or flow monitoring system(s) at a unit or stack location, the owner or operator shall begin calculating the percent monitor data availability as described in paragraph (a)(1) of this section, and shall, upon completion of the first 2,160 quality-assured monitor operating hours, record, by means of the automated data acquisition and handling system, the percent monitor data availability for each monitored parameter. Notwithstanding these requirements, if three years (26,280 clock hours) have elapsed since the date and hour of initial certification and fewer than 720 (or 2,160, as applicable) quality-assured monitor operating hours have been recorded, the owner or operator shall begin recording the percent monitor data availability. The percent monitor data availability shall be calculated for each monitored parameter at each unit or stack location, as follows:

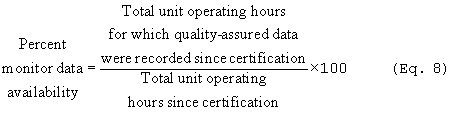

(1) Prior to completion of 8,760 unit or stack operating hours following initial certification, the owner or operator shall, for the purpose of applying the standard missing data procedures of �75.33, use Equation 8 to calculate, hourly, percent monitor data availability.

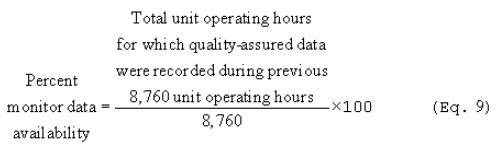

(2) Upon completion of 8,760 unit (or stack) operating hours following initial certification and thereafter, the owner or operator shall, for the purpose of applying the standard missing data procedures of �75.33, use Equation 9 to calculate hourly, percent monitor data availability. Notwithstanding this requirement, if three years (26,280 clock hours) have elapsed since initial certification and fewer than 8,760 unit or stack operating hours have been accumulated, the owner or operator shall begin using a modified version of Equation 9, as described in paragraph (a)(3) of this section.

(3) When calculating percent monitor data availability using Equation 8 or 9, the owner or operator shall include all unit operating hours, and all monitor operating hours for which quality-assured data were recorded by a certified primary monitor; a certified redundant or non-redundant backup monitor or a reference method for that unit; or by an approved alternative monitoring system under subpart E of this part. No hours from more than three years (26,280 clock hours) earlier shall be used in Equation 9. For a unit that has accumulated fewer than 8,760 unit operating hours in the previous three years (26,280 clock hours), replace the words �during previous 8,760 unit operating hours� in the numerator of Equation 9 with �in the previous three years� and replace �8,760� in the denominator of Equation 9 with �total unit operating hours in the previous three years.� The owner or operator of a unit with an SO2 monitoring system shall, when SO2 emissions are determined in accordance with �75.11(e)(1) or (e)(2), exclude hours in which a unit combusts only gaseous fuel from calculations of percent monitor data availability for SO2 pollutant concentration monitors, as provided in �75.30(d).

(b) The monitor data availability shall be calculated for each hour during each missing data period. The owner or operator shall record the percent monitor data availability for each hour of each missing data period to implement the missing data substitution procedures.

[58 FR 3701, Jan. 11, 1993, as amended at 60 FR 26529, 26567, May 17, 1995; 61 FR 59160, Nov. 20, 1996; 64 FR 28602, May 26, 1999; 67 FR 40434, June 12, 2002; 70 FR 28680, May 18, 2005; 73 FR 4346, Jan. 24, 2008; 76 FR 17311, Mar. 28, 2011]

�75.33 Standard missing data procedures for SO2, NOX, and flow rate.

(a) Following initial certification of the required SO2, NOX, and flow rate monitoring system(s) at a particular unit or stack location (i.e., the date and time at which quality-assured data begins to be recorded by CEMS(s) at that location) and upon completion of the first 720 quality-assured monitor operating hours (for SO2) or the first 2,160 quality-assured monitor operating hours (for flow, NOX emission rate, or NOX concentration), the owner or operator shall provide substitute data required under this subpart according to the procedures in paragraphs (b) and (c) of this section and depicted in Table 1 (SO2) and Table 2 of this section (NOX, flow). The owner or operator may either implement the provisions of paragraphs (b) and (c) of this section on a non-fuel-specific basis, or may, as described in paragraphs (b)(5), (b)(6), (c)(7) and (c)(8) of this section, provide fuel-specific substitute data values. Notwithstanding these requirements, if three years (26,280 clock hours) have elapsed since the date and hour of initial certification, and fewer than 720 (or 2,160, as applicable) quality-assured monitor operating hours have been recorded, the owner or operator shall begin using the missing data procedures of this section. The owner or operator of a unit shall substitute for missing data using quality-assured monitor operating hours of data from no earlier than three years (26,280 clock hours) prior to the date and time of the missing data period.

(b) SO2 concentration data. For each hour of missing SO2 concentration data,

(1) If the monitor data availability is equal to or greater than 95.0 percent, the owner or operator shall calculate substitute data by means of the automated data acquisition and handling system for that hour of the missing data period according to the following procedures:

(i) For a missing data period less than or equal to 24 hours, substitute the average of the hourly SO2 concentrations recorded by an SO2 pollutant concentration monitor for the hour before and the hour after the missing data period.

(ii) For a missing data period greater than 24 hours, substitute the greater of:

(A) The 90th percentile hourly SO2 concentration recorded by an SO2 pollutant concentration monitor during the previous 720 quality-assured monitor operating hours; or

(B) The average of the hourly SO2 concentrations recorded by an SO2 pollutant concentration monitor for the hour before and the hour after the missing data period.

(2) If the monitor data availability is at least 90.0 percent but less than 95.0 percent, the owner or operator shall calculate substitute data by means of the automated data acquisition and handling system for that hour of the missing data period according to the following procedures:

(i) For a missing data period of less than or equal to 8 hours, substitute the average of the hourly SO2 concentrations recorded by an SO2 pollutant concentration monitor for the hour before and the hour after the missing data period.

(ii) For a missing data period of more than 8 hours, substitute the greater of:

(A) the 95th percentile hourly SO2 concentration recorded by an SO2 pollutant concentration monitor during the previous 720 quality-assured monitor operating hours; or

(B) The average of the hourly SO2 concentrations recorded by an SO2 pollutant concentration monitor for the hour before and the hour after the missing data period.

(3) If the monitor data availability is at least 80.0 percent but less than 90.0 percent, the owner or operator shall substitute for that hour of the missing data period the maximum hourly SO2 concentration recorded by an SO2 pollutant concentration monitor during the previous 720 quality-assured monitor operating hours.

(4) If the monitor data availability is less than 80.0 percent, the owner or operator shall substitute for that hour of the missing data period the maximum potential SO2 concentration, as defined in section 2.1.1.1 of appendix A to this part.

(5) For units that combust more than one type of fuel, the owner or operator may opt to implement the missing data routines in paragraphs (b)(1) through (b)(4) of this section on a fuel-specific basis. If this option is selected, the owner or operator shall document this in the monitoring plan required under �75.53.

(6) Use the following guidelines to implement paragraphs (b)(1) through (b)(4) of this section on a fuel-specific basis:

(i) Separate the historical, quality-assured SO2 concentration data according to the type of fuel combusted;

(ii) For units that co-fire different types of fuel, either group the co-fired hours with the historical data for the fuel with the highest SO2 emission rate (e.g., if diesel oil and pipeline natural gas are co-fired, count co-fired hours as oil-burning hours), or separate the co-fired hours from the single-fuel hours;

(iii) For the purposes of providing substitute data under paragraph (b)(4) of this section, determine a separate, fuel-specific maximum potential SO2 concentration (MPC) value for each type of fuel combusted in the unit, in a manner consistent with section 2.1.1.1 of appendix A to this part. For fuel that qualifies as pipeline natural gas or natural gas (as defined in �72.2 of this chapter), the owner or operator shall, for the purposes of determining the MPC, either determine the maximum total sulfur content and minimum gross calorific value (GCV) of the gas by fuel sampling and analysis or shall use a default total sulfur content of 0.05 percent by weight (dry basis) and a default GCV value of 950 Btu/scf. For co-firing, the MPC value shall be based on the fuel with the highest SO2 emission rate. The exact methodology used to determine each fuel-specific MPC value shall be documented in the monitoring plan for the unit or stack; and

(iv) For missing data periods that require 720-hour (or, if applicable, 3-year) lookbacks, use historical data for the type of fuel combusted during each hour of the missing data period to determine the appropriate substitute data value for that hour. For co-fired missing data hours, if the historical data are separated into single-fuel and co-fired hours, use co-fired data to provide the substitute data values. Otherwise, use data for the fuel with the highest SO2 emission rate to provide substitute data values for co-fired missing data hours.

(7) Table 1 summarizes the provisions of paragraphs (b)(1) through (b)(6) of this section.

(c) Volumetric flow rate, NOX emission rate and NOX concentration data. Use the procedures in this paragraph to provide substitute NOX and flow rate data for all affected units for which load-based ranges have been defined in accordance with section 2 of appendix C to this part. For units that do not produce electrical or thermal output (i.e., non-load-based units), use the procedures in this paragraph only to provide substitute data for volumetric flow rate, and only if operational bins have been defined for the unit, as described in section 3 of appendix C to this part. Otherwise, use the applicable missing data procedures in paragraph (d) or (e) of this section for non-load-based units. For each hour of missing volumetric flow rate data, NOX emission rate data, or NOX concentration data used to determine NOX mass emissions:

(1) If the monitor data availability is equal to or greater than 95.0 percent, the owner or operator shall calculate substitute data by means of the automated data acquisition and handling system for that hour of the missing data period according to the following procedures:

(i) For a missing data period less than or equal to 24 hours, substitute, as applicable, for each missing hour, the arithmetic average of the flow rates or NOX emission rates or NOX concentrations recorded by a monitoring system during the previous 2,160 quality-assured monitor operating hours at the corresponding unit load range or operational bin, as determined using the procedure in appendix C to this part.

(ii) For a missing data period greater than 24 hours, substitute, as applicable, for each missing hour, the greater of:

(A) The 90th percentile hourly flow rate or the 90th percentile NOX emission rate or the 90th percentile NOX concentration recorded by a monitoring system during the previous 2,160 quality-assured monitor operating hours at the corresponding unit load range or operational bin, as determined using the procedure in appendix C to this part; or

(B) The average of the recorded hourly flow rates, NOX emission rates or NOX concentrations recorded by a monitoring system for the hour before and the hour after the missing data period.

(2) If the monitor data availability is at least 90.0 percent but less than 95.0 percent, the owner or operator shall calculate substitute data by means of the automated data acquisition and handling system for that hour of the missing data period according to the following procedures:

(i) For a missing data period of less than or equal to 8 hours, substitute, as applicable, the arithmetic average hourly flow rate or NOX emission rate or NOX concentration recorded by a monitoring system during the previous 2,160 quality-assured monitor operating hours at the corresponding unit load range or operational bin, as determined using the procedure in appendix C to this part.

(ii) For a missing data period greater than 8 hours, substitute, as applicable, for each missing hour, the greater of:

(A) The 95th percentile hourly flow rate or the 95th percentile NOX emission rate or the 95th percentile NOX concentration recorded by a monitoring system during the previous 2,160 quality-assured monitor operating hours at the corresponding unit load range or operational bin, as determined using the procedure in appendix C to this part; or

(B) The average of the hourly flow rates, NOX emission rates or NOX concentrations recorded by a monitoring system for the hour before and the hour after the missing data period.

(3) If the monitor data availability is at least 80.0 percent but less than 90.0 percent, the owner or operator shall, by means of the automated data acquisition and handling system, substitute, as applicable, for that hour of the missing data period, the maximum hourly flow rate or the maximum hourly NOX emission rate or the maximum hourly NOX concentration recorded during the previous 2,160 quality-assured monitor operating hours at the corresponding unit load range or operational bin, as determined using the procedure in appendix C to this part.

(4) If the monitor data availability is less than 80.0 percent, the owner or operator shall substitute, as applicable, for that hour of the missing data period, the maximum potential flow rate, as defined in section 2.1.4.1 of appendix A to this part, or the maximum NOX emission rate, as defined in section 2.1.2.1 of appendix A to this part, or the maximum potential NOX concentration, as defined in section 2.1.2.1 of appendix A to this part. In addition, when non-load-based operational bins are used, the owner or operator shall substitute the maximum potential flow rate for any hour in the missing data period in which essential operating or parametric data are unavailable and the operational bin cannot be determined.

(5) This paragraph, (c)(5), does not apply to non-load-based, affected units using operational bins. Whenever no prior quality-assured flow rate data, NOX concentration data or NOX emission rate data exist for the corresponding load range, the owner or operator shall substitute, as applicable, for each hour of missing data, the maximum hourly flow rate or the maximum hourly NOX concentration or maximum hourly NOX emission rate at the next higher level load range for which quality-assured data are available.

(6) Whenever no prior quality-assured flow rate data, NOX concentration data or NOX emission rate data exist at either the corresponding load range (or a higher load range) or at the corresponding operational bin, the owner or operator shall substitute, as applicable, either the maximum potential NOX emission rate or the maximum potential NOX concentration, as defined in section 2.1.2.1 of appendix A to this part or the maximum potential flow rate, as defined in section 2.1.4.1 of appendix A to this part.

(7) This paragraph (c)(7) does not apply to affected units using non-load-based operational bins. For units that combust more than one type of fuel, the owner or operator may opt to implement the missing data routines in paragraphs (c)(1) through (c)(6) of this section on a fuel-specific basis. If this option is selected, the owner or operator shall document this in the monitoring plan required under �75.53.

(8) This paragraph, (c)(8), does not apply to affected units using non-load-based operational bins. Use the following guidelines to implement paragraphs (c)(1) through (c)(6) of this section on a fuel-specific basis:

(i) Separate the historical, quality-assured NOX emission rate, NOX concentration, or flow rate data according to the type of fuel combusted;

(ii) For units that co-fire different types of fuel, either group the co-fired hours with the historical data for the fuel with the highest NOX emission rate, NOX concentration or flow rate, or separate the co-fired hours from the single-fuel hours;

(iii) For the purposes of providing substitute data under paragraph (c)(4) of this section, a separate, fuel-specific maximum potential concentration (MPC), maximum potential NOX emission rate (MER), or maximum potential flow rate (MPF) value (as applicable) shall be determined for each type of fuel combusted in the unit, in a manner consistent with �72.2 of this chapter and with section 2.1.2.1 or 2.1.4.1 of appendix A to this part. For co-firing, the MPC, MER or MPF value shall be based on the fuel with the highest emission rate or flow rate (as applicable). Furthermore, for a unit with add-on NOX emission controls, a separate fuel-specific maximum controlled NOX emission rate (MCR) or maximum expected NOX concentration (MEC) value (as applicable) shall be determined for each type of fuel combusted in the unit. The exact methodology used to determine each fuel-specific MPC, MER, MEC, MCR or MPF value shall be documented in the monitoring plan for the unit or stack.

(iv) For missing data periods that require 2,160-hour (or, if applicable, 3-year) lookbacks, use historical data for the type of fuel combusted during each hour of the missing data period to determine the appropriate substitute data value for that hour. For co-fired missing data hours, if the historical data are separated into single-fuel and co-fired hours, use co-fired data to provide the substitute data values. Otherwise, use data for the fuel with the highest NOX emission rate, NOX concentration or flow rate (as applicable) to provide substitute data values for co-fired missing data hours. Tables 1 and 2 follow.

| HB/HA = hour before and hour after the CEMS outage. * Quality-assured, monitor operating hours, during unit operation. May be either fuel-specific or non-fuel-specific. For units that report data only for the ozone season, include only quality assured monitor operating hours within the ozone season in the lookback period. Use data from no earlier than 3 years prior to the missing data period. 1 Where a unit with add-on SO2 emission controls can demonstrate that the controls are operating properly during the missing data period, as provided in �75.34, the unit may use the maximum controlled concentration from the previous 720 quality-assured monitor operating hours. 2 During unit operating hours. 3 Where a unit with add-on SO2 emission controls can demonstrate that the controls are operating properly during the missing data period, the unit may report the greater of: (a) the maximum expected SO2 concentration or (b) 1.25 times the maximum controlled value from the previous 720 quality-assured monitor operating hours (see �75.34). X Use this algorithm for moisture except when Equation 19-3, 19-4 or 19-8 in Method 19 in appendix A-7 to part 60 of this chapter is used for NOX emission rate. ** Use this algorithm for moisture only when Equation 19-3, 19-4 or 19-8 in Method 19 in appendix A-7 to part 60 of this chapter is used for NOX emission rate. | |||

| Trigger conditions | Calculation routines | ||

| Monitor data availability (percent) | Duration (N) of CEMS outage

(hours) 2 | Method | Lookback period |

| 95 or more | N ?24 | Average | HB/HA. |

| N >24 | For SO2, CO2, and H2O **, the greater of: | ||

| Average | HB/HA. | ||

| 90th percentile | 720 hours. * | ||

| For O2 and H2O X, the lesser of: | HB/HA. | ||

| 10th percentile | 720 hours. * | ||

| 90 or more, but below 95 | N ?8 | Average | HB/HA. |

| N >8 | For SO2, CO2, and H2O **, the greater of: | ||

| Average | HB/HA. | ||

| 95th percentile | 720 hours. * | ||

| For O2 and H2O X, the lesser of: | |||

| Average | HB/HA. | ||

| 5th Percentile | 720 hours. * | ||

| 80 or more, but below 90 | N >0 | For SO2, CO2, and H2O **, | |

| Maximum value 1 | 720 hours. * | ||

| For O2 and H2O X: | |||

| Minimum value 1 | 720 hours. * | ||

| Below 80 | N >0 | Maximum potential concentration 3 or % (for SO2, CO2, and H2O**) or | |

| Minimum potential concentration or % (for O2 and H2O X) | None. | ||

| HB/HA = hour before and hour after the CEMS outage. * Quality-assured, monitor operating hours, using data at the corresponding load range (�load bin�) for each hour of the missing data period. May be either fuel-specific or non-fuel-specific. For units that report data only for the ozone season, include only quality assured monitor operating hours within the ozone season in the lookback period. Use data from no earlier than three years prior to the missing data period. 1 Where a unit with add-on NOX emission controls can demonstrate that the controls are operating properly during the missing data period, as provided in �75.34, the unit may use the maximum controlled NOX concentration or emission rate from the previous 2,160 quality-assured monitor operating hours. Units with add-on controls that report NOX mass emissions on a year-round basis under subpart H of this part may use separate ozone season and non-ozone season data pools to provide substitute data values, as described in �75.34(a)(2). 2 During unit operating hours. 3 Alternatively, where a unit with add-on NOX emission controls can demonstrate that the controls are operating properly during the missing data period, as provided in �75.34, the unit may report the greater of: (a) the maximum expected NOX concentration (or maximum controlled NOX emission rate, as applicable); or (b) 1.25 times the maximum controlled value at the corresponding load bin, from the previous 2,160 quality-assured monitor operating hours. | ||||

| Trigger conditions | Calculation routines | |||

| Monitor data availability

(percent) | Duration (N) of CEMS outage

(hours) 2 | Method | Lookback period | Load ranges |

| 95 or more | N ?24 | Average | 2,160 hours * | Yes. |

| N >24 | The greater of: | |||

| Average | HB/HA | No. | ||

| 90th percentile | 2,160 hours * | Yes. | ||

| 90 or more, but below 95 | N ?8 | Average | 2,160 hours * | Yes. |

| N >8 | The greater of: | |||

| Average | HB/HA | No. | ||

| 95th percentile | 2,160 hours * | Yes. | ||

| 80 or more, but below 90 | N >0 | Maximum value 1 | 2,160 hours * | Yes. |

| Below 80 | N >0 | Maximum potential NOX emission rate 3; or maximum potential NOX concentration 3; or maximum potential flow rate | None | No. |

(9) The load-based provisions of paragraphs (c)(1) through (c)(8) of this section are summarized in Table 2 of this section. The non-load-based provisions for volumetric flow rate, found in paragraphs (c)(1) through (c)(4), and (c)(6) of this section, are presented in Table 4 of this section.

(d) Non-load-based NOX emission rate and NOX concentration data. Use the procedures in this paragraph to provide substitute NOX data for affected units that do not produce electrical output (in megawatts) or thermal output (in klb/hr of steam). For each hour of missing NOX emission rate data, or NOX concentration data used to determine NOX mass emissions:

(1) If the monitor data availability is equal to or greater than 95.0 percent, the owner or operator shall calculate substitute data by means of the automated data acquisition and handling system for that hour of the missing data period according to the following procedures:

(i) For a missing data period less than or equal to 24 hours, substitute, as applicable, for each missing hour, the arithmetic average of the NOX emission rates or NOX concentrations recorded by a monitoring system in a 2,160 hour lookback period. The lookback period may be comprised of either:

(A) The previous 2,160 quality-assured monitor operating hours, or

(B) The previous 2,160 quality-assured monitor operating hours at the corresponding operational bin, if operational bins, as defined in section 3 of appendix C to this part, are used.

(ii) For a missing data period greater than 24 hours, substitute, for each missing hour, the 90th percentile NOX emission rate or the 90th percentile NOX concentration recorded by a monitoring system during the previous 2,160 quality-assured monitor operating hours (or during the previous 2,160 quality-assured monitor operating hours at the corresponding operational bin, if operational bins are used).

(2) If the monitor data availability is at least 90.0 percent but less than 95.0 percent, the owner or operator shall calculate substitute data by means of the automated data acquisition and handling system for that hour of the missing data period according to the following procedures:

(i) For a missing data period of less than or equal to eight hours, substitute, as applicable, the arithmetic average of the hourly NOX emission rates or NOX concentrations recorded by a monitoring system during the previous 2,160 quality-assured monitor operating hours (or during the previous 2,160 quality-assured monitor operating hours at the corresponding operational bin, if operational bins are used).

(ii) For a missing data period greater than eight hours, substitute, for each missing hour, the 95th percentile hourly flow rate or the 95th percentile NOX emission rate or the 95th percentile NOX concentration recorded by a monitoring system during the previous 2,160 quality-assured monitor operating hours (or during the previous 2,160 quality-assured monitor operating hours at the corresponding operational bin, if operational bins are used).

(3) If the monitor data availability is at least 80.0 percent but less than 90.0 percent, the owner or operator shall, by means of the automated data acquisition and handling system, substitute, as applicable, for that hour of the missing data period, the maximum hourly NOX emission rate or the maximum hourly NOX concentration recorded during the previous 2,160 quality-assured monitor operating hours (or during the previous 2,160 quality-assured monitor operating hours at the corresponding operational bin, if operational bins are used).

(4) If the monitor data availability is less than 80.0 percent, the owner or operator shall substitute, as applicable, for that hour of the missing data period, the maximum NOX emission rate, as defined in �72.2 of this chapter, or the maximum potential NOX concentration, as defined in section 2.1.2.1 of appendix A to this part. In addition, when operational bins are used, the owner or operator shall substitute (as applicable) the maximum potential NOX emission rate or the maximum potential NOX concentration for any hour in the missing data period in which essential operating or parametric data are unavailable and the operational bin cannot be determined.

(5) If operational bins are used and no prior quality-assured NOX concentration data or NOX emission rate data exist for the corresponding operational bin, the owner or operator shall substitute, as applicable, either the maximum potential NOX emission rate, as defined in �72.2 of this chapter, or the maximum potential NOX concentration, as defined in section 2.1.2.1 of appendix A to this part.

(6) Table 3 of this section summarizes the provisions of paragraphs (d)(1) through (d)(5) of this section.

(e) Non-load-based volumetric flow rate data. (1) If operational bins, as defined in section 3 of appendix C to this part, are used for a unit that does not produce electrical or thermal output, use the missing data procedures in paragraph (c) of this section to provide substitute volumetric flow rate data for the unit.

(2) If operational bins are not used, modify the procedures in paragraph (c) of this section as follows:

(i) In paragraphs (c)(1) through (c)(3), the words �previous 2,160 quality-assured monitor operating hours� shall apply rather than �previous 2,160 quality-assured monitor operating hours at the corresponding unit load range or operational bin, as determined using the procedure in appendix C to this part;�

(ii) The last sentence in paragraph (c)(4) does not apply;

(iii) Paragraphs (c)(5), (c)(7), and (c)(8) are not applicable; and

(iv) In paragraph (c)(6), the words, �for either the corresponding load range (or a higher load range) or at the corresponding operational bin� do not apply.

(3) Table 4 of this section summarizes the provisions of paragraphs (e)(1) and (e)(2) of this section. Tables 3 and 4 follow:

| * If operational bins are used, the lookback period is 2,160 quality-assured, monitor operating hours, and data at the corresponding operational bin are used to provide substitute data values. If operational bins are not used, the lookback period is the previous 2,160 quality-assured monitor operating hours. For units that report data only for the ozone season, include only quality-assured monitor operating hours within the ozone season in the lookback period. Use data from no earlier than three years prior to the missing data period. 1 During unit operation. 2 Alternatively, where a unit with add-on NOX emission controls can demonstrate that the controls are operating properly, as provided in �75.34, the unit may report the greater of: (a) the maximum expected NOX concentration, (or maximum controlled NOX emission rate, as applicable); or (b) 1.25 times the maximum controlled value at the corresponding operational bin (if applicable), from the previous 2,160 quality-assured monitor operating hours. 3 Where a unit with add-on NOX emission controls can demonstrate that the controls are operating properly during the missing data period, as provided in �75.34, the unit may use the maximum controlled NOX concentration or emission rate from the previous 2,160 quality-assured monitor operating hours. Units with add-on controls that report NOX mass emissions on a year-round basis under subpart H of this part may use separate ozone season and non-ozone season data pools to provide substitute data values, as described in �75.34(a)(2). | |||

| Trigger conditions | Calculation routines | ||

| Monitor data availability

(percent) | Duration (N) of CEMS outage

(hours) 1 | Method | Lookback period |

| 95 or more | N ?24 | Average | 2,160 hours. * |

| N >24 | 90th percentile | 2,160 hours. * | |

| 90 or more, but below 95 | N ?8 | Average | 2,160 hours. * |

| N >8 | 95th percentile | 2,160 hours. * | |

| 80 or more, but below 90 | N >0 | Maximum value 3 | 2,160 hours. * |

| Below 80, or operational bin indeterminable | N >0 | Maximum potential NOX emission rate 2 or maximum potential NOX concentration 2 | None. |

| * If operational bins are used, the lookback period is the previous 2,160 quality-assured, monitor operating hours and data at the corresponding operational bin are used to provide substitute data values. If operational bins are not used, the lookback period is the previous 2,160 quality-assured, monitor operating hours. For units that report data only for the ozone season, include only quality-assured monitor operating hours within the ozone season in the lookback period. Use data from no earlier than three years prior to the missing data period. 1 During unit operation. | |||

| Trigger conditions | Calculation routines | ||

| Monitor data availability (percent) | Duration (N) of CEMS outage

(hours) 1 | Method | Lookback

period |

| 95 or more | N ?24 | Average | 2160 hours* |

| N >24 | The greater of:

Average 90th percentile | HB/HA 2160 hours* | |

| 90 or more, but below 95 | N ?8 | Average | 2160 hours* |

| N >8 | The greater of:

Average 95th percentile HB/HA 2160 hours* | ||

| 80 or more, but below 90 | N >0 | Maximum value | 2160 hours* |

| Below 80, or operational bin indeterminable | N >0 | Maximum potential flow rate | None |

[58 FR 3701, Jan. 11, 1993, as amended at 60 FR 26529, May 17, 1995; 61 FR 25582, May 22, 1996; 64 FR 28602, May 26, 1999; 67 FR 40434, June 12, 2002; 67 FR 53505, Aug. 16, 2002; 67 FR 57274, Sept. 9, 2002; 70 FR 28680, May 18, 2005; 73 FR 4346, Jan. 24, 2008; 76 FR 17311, Mar. 28, 2011]

�75.34 Units with add-on emission controls.

(a) The owner or operator of an affected unit equipped with add-on SO2 and/or NOX emission controls shall provide substitute data in accordance with paragraphs (a)(1), through (a)(5) of this section for each hour in which quality-assured data from the outlet SO2 and/or NOX monitoring system(s) are not obtained.

(1) The owner or operator may use the missing data substitution procedures specified in ��75.31 through 75.33 to provide substitute data for any missing data hour(s) in which the add-on emission controls are documented to be operating properly, as described in the quality assurance/quality control program for the unit, required by section 1 in appendix B of this part. To provide the necessary documentation, the owner or operator shall, for each missing data period, record parametric data to verify the proper operation of the SO2 or NOX add-on emission controls during each hour, as described in paragraph (d) of this section. For any missing data hour(s) in which such parametric data are either not provided or, if provided, do not demonstrate that proper operation of the SO2 or NOX add-on emission controls has been maintained, the owner or operator shall substitute (as applicable) the maximum potential NOX concentration (MPC) as defined in section 2.1.2.1 of appendix A to this part, the maximum potential NOX emission rate, as defined in �72.2 of this chapter, or the maximum potential concentration for SO2, as defined by section 2.1.1.1. Alternatively, for SO2 or NOX, the owner or operator may substitute, if available, the hourly SO2 or NOX concentration recorded by a certified inlet monitor, in lieu of the MPC. For each hour in which data from an inlet monitor are reported, the owner or operator shall use a method of determination code (MODC) of �22� (see Table 4a in �75.57). In addition, under �75.64(c), the designated representative shall submit as part of each electronic quarterly report, a certification statement, verifying the proper operation of the SO2 or NOX add-on emission control for each missing data period in which the missing data procedures of ��75.31 through 75.33 were applied; or

(2) This paragraph, (a)(2), applies only to a unit which, as provided in �75.74(a) or �75.74(b)(1), reports NOX mass emissions on a year-round basis under a state or Federal NOX mass emissions reduction program that adopts the emissions monitoring provisions of this part. If the add-on NOX emission controls installed on such a unit are operated only during the ozone season or are operated in a more efficient manner during the ozone season than outside the ozone season, the owner or operator may implement the missing data provisions of paragraph (a)(1) of this section in the following alternative manner:

(i) The historical, quality-assured NOX emission rate or NOX concentration data may be separated into two categories, i.e., data recorded inside the ozone season and data recorded outside the ozone season;

(ii) For the purposes of the missing data lookback periods described under ��75.33 (c)(1) , (c)(2), (c)(3) and (c)(5) of this section, the substitute data values shall be taken from the appropriate database, depending on the date(s) and hour(s) of the missing data period. That is, if the missing data period occurs inside the ozone season, the ozone season data shall be used to provide substitute data. If the missing data period occurs outside the ozone season, data from outside the ozone season shall be used to provide substitute data.

(iii) A missing data period that begins outside the ozone season and continues into the ozone season shall be considered to be two separate missing data periods, one ending on April 30, hour 23, and the other beginning on May 1, hour 00;

(iv) For missing data hours outside the ozone season, the procedures of �75.33 may be applied unconditionally, i.e., documentation of the operational status of the emission controls is not required in order to apply the standard missing data routines.

(3) For each missing data hour in which the percent monitor data availability for SO2 or NOX, calculated in accordance with �75.32, is less than 90.0 percent and is greater than or equal to 80.0 percent; and parametric data establishes that the add-on emission controls were operating properly (i.e. within the range of operating parameters provided in the quality assurance/quality control program) during the hour, the owner or operator may:

(i) Replace the maximum SO2 concentration recorded in the 720 quality-assured monitor operating hours immediately preceding the missing data period, with the maximum controlled SO2 concentration recorded in the previous 720 quality-assured monitor operating hours; or

(ii) Replace the maximum NOX concentration(s) or NOX emission rate(s) from the appropriate load bin(s) (based on a lookback through the 2,160 quality-assured monitor operating hours immediately preceding the missing data period), with the maximum controlled NOX concentration(s) or emission rate(s) from the appropriate load bin(s) in the same 2,160 quality-assured monitor operating hour lookback period.

(4) The designated representative may petition the Administrator under �75.66 for approval of site-specific parametric monitoring procedure(s) for calculating substitute data for missing SO2 pollutant concentration, NOX pollutant concentration, and NOX emission rate data in accordance with the requirements of paragraphs (b) and (c) of this section and appendix C to this part. The owner or operator shall record the data required in appendix C to this part, pursuant to �75.58(b).

(5) For each missing data hour in which the percent monitor data availability for SO2 or NOX, calculated in accordance with �75.32, is below 80.0 percent and parametric data establish that the add-on emission controls were operating properly (i.e. within the range of operating parameters provided in the quality assurance/quality control program),in lieu of reporting the maximum potential value, the owner or operator may substitute, as applicable, the greater of:

(i) The maximum expected SO2 concentration or 1.25 times the maximum hourly controlled SO2 concentration recorded in the previous 720 quality-assured monitor operating hours;

(ii) The maximum expected NOX concentration or 1.25 times the maximum hourly controlled NOX concentration recorded in the previous 2,160 quality-assured monitor operating hours at the corresponding unit load range or operational bin;

(iii) The maximum controlled hourly NOX emission rate (MCR) or 1.25 times the maximum hourly controlled NOX emission rate recorded in the previous 2,160 quality-assured monitor operating hours at the corresponding unit load range or operational bin;

(iv) For the purposes of implementing the missing data options in paragraphs (a)(5)(i) through (a)(5)(iii) of this section, the maximum expected SO2 and NOX concentrations shall be determined, respectively, according to sections 2.1.1.2 and 2.1.2.2 of appendix A to this part. The MCR shall be calculated according to the basic procedure described in section 2.1.2.1(b) of appendix A to this part, except that the words �maximum potential NOX emission rate (MER)� shall be replaced with the words �maximum controlled NOX emission rate (MCR)� and the NOX MEC shall be used instead of the NOX MPC.

(b) For an affected unit equipped with add-on SO2 emission controls, the designated representative may petition the Administrator to approve a parametric monitoring procedure, as described in appendix C of this part, for calculating substitute SO2 concentration data for missing data periods. The owner or operator shall use the procedures in ��75.31, 75.33, or 75.34(a) for providing substitute data for missing SO2 concentration data unless a parametric monitoring procedure has been approved by the Administrator.

(1) Where the monitor data availability is 90.0 percent or more for an outlet SO2 pollutant concentration monitor, the owner or operator may calculate substitute data using an approved parametric monitoring procedure.

(2) Where the monitor data availability for an outlet SO2 pollutant concentration monitor is less than 90.0 percent, the owner or operator shall calculate substitute data using the procedures in �75.34(a)(1) or (2), even if the Administrator has approved a parametric monitoring procedure.

(c) For an affected unit with NOX add-on emission controls, the designated representative may petition the Administrator to approve a parametric monitoring procedure, as described in appendix C of this part, in order to calculate substitute NOX emission rate data for missing data periods. The owner or operator shall use the procedures in �75.31 or 75.33 for providing substitute data for missing NOX emission rate data prior to receiving the Administrator's approval for a parametric monitoring procedure.

(1) Where monitor data availability for a NOX continuous emission monitoring system is 90.0 percent or more, the owner or operator may calculate substitute data using an approved parametric monitoring procedure.

(2) Where monitor data availability for a NOX continuous emission monitoring system is less than 90.0 percent, the owner or operator shall calculate substitute data using the procedure in �75.34(a)(1) or (2), even if the Administrator has approved a parametric monitoring procedure.

(d) In order to implement the options in paragraphs (a)(1), (a)(3) and (a)(5) of this section; and ��75.31(c)(3) and 75.72(c)(3), the owner or operator shall keep records of information as described in �75.58(b)(3) to verify the proper operation of all add-on SO2 or NOX emission controls, during all periods of SO2 or NOX emission missing data. If the owner or operator elects to implement the missing data option in paragraph (a)(2) of this section, the records in �75.58(b)(3) are required to be kept only for the ozone season. The owner or operator shall document in the quality assurance/quality control (QA/QC) program required by section 1 of appendix B to this part, the parameters monitored and (as applicable) the ranges and combinations of parameters that indicate proper operation of the controls. The owner or operator shall provide the information recorded under �75.58(b)(3) and the related QA/QC program information to the Administrator, to the EPA Regional Office, or to the appropriate State or local agency, upon request.

[60 FR 26567, May 17, 1995, as amended at 61 FR 59160, Nov. 20, 1996; 64 FR 28604, May 26, 1999; 67 FR 40438, June 12, 2002; 73 FR 4348, Jan. 24, 2008; 76 FR 17312, Mar. 28, 2011]

�75.35 Missing data procedures for CO 2.

(a) The owner or operator of a unit with a CO2 continuous emission monitoring system for determining CO2 mass emissions in accordance with �75.10 (or an O2 monitor that is used to determine CO2 concentration in accordance with appendix F to this part) shall substitute for missing CO2 pollutant concentration data using the procedures of paragraphs (b) and (d) of this section.

(b) During the first 720 quality-assured monitor operating hours following initial certification at a particular unit or stack location (i.e., the date and time at which quality-assured data begins to be recorded by a CEMS at that location), or (when implementing these procedures for a previously certified CO2 monitoring system) during the 720 quality-assured monitor operating hours preceding implementation of the standard missing data procedures in paragraph (d) of this section, the owner or operator shall provide substitute CO2 pollutant concentration data or substitute CO2 data for heat input determination, as applicable, according to the procedures in �75.31(b).

(c) [Reserved]

(d) Upon completion of 720 quality-assured monitor operating hours using the initial missing data procedures of �75.31(b), the owner or operator shall provide substitute data for CO2 concentration or substitute CO2 data for heat input determination, as applicable, in accordance with the procedures in �75.33(b) except that the term �CO2 concentration� shall apply rather than �SO2 concentration,� the term �CO2 pollutant concentration monitor� or �CO2 diluent monitor� shall apply rather than �SO2 pollutant concentration monitor,� and the term �maximum potential CO2 concentration, as defined in section 2.1.3.1 of appendix A to this part� shall apply, rather than �maximum potential SO2 concentration.�

[67 FR 40439, June 12, 2002]

�75.36 Missing data procedures for heat input rate determinations.

(a) When hourly heat input rate is determined using a flow monitoring system and a diluent gas (O2 or CO2) monitor, substitute data must be provided to calculate the heat input whenever quality-assured data are unavailable from the flow monitor, the diluent gas monitor, or both. When flow rate data are unavailable, substitute flow rate data for the heat input rate calculation shall be provided according to �75.31 or �75.33, as applicable. When diluent gas data are unavailable, the owner or operator shall provide substitute O2 or CO2 data for the heat input rate calculations in accordance with paragraphs (b) and (d) of this section.

(b) During the first 720 quality-assured monitor operating hours following initial certification at a particular unit or stack location (i.e., the date and time at which quality-assured data begins to be recorded by a CEMS at that location), or (when implementing these procedures for a previously certified CO2 or O2 monitor) during the 720 quality-assured monitor operating hours preceding implementation of the standard missing data procedures in paragraph (d) of this section, the owner or operator shall provide substitute CO2 or O2 data, as applicable, for the calculation of heat input (under section 5.2 of appendix F to this part) according to �75.31(b).

(c) [Reserved]

(d) Upon completion of 720 quality-assured monitor operating hours using the initial missing data procedures of �75.31(b), the owner or operator shall provide substitute data for CO2 or O2 concentration to calculate heat input rate, as follows. Substitute CO2 data for heat input rate determinations shall be provided according to �75.35(d). Substitute O2 data for the heat input rate determinations shall be provided in accordance with the procedures in �75.33(b), except that the term �O2 concentration� shall apply rather than the term �SO2 concentration� and the term �O2 diluent monitor� shall apply rather than the term �SO2 pollutant concentration monitor.� In addition, the term �substitute the lesser of� shall apply rather than �substitute the greater of;� the terms �minimum hourly O2 concentration� and �minimum potential O2 concentration, as determined under section 2.1.3.2 of appendix A to this part� shall apply rather than, respectively, the terms �maximum hourly SO2 concentration� and �maximum potential SO2 concentration, as determined under section 2.1.1.1 of appendix A to this part;� and the terms �10th percentile� and �5th percentile� shall apply rather than, respectively, the terms �90th percentile� and �95th percentile� (see Table 1 of �75.33).

[60 FR 26530, May 17, 1995, as amended at 64 FR 28604, May 26, 1999; 67 FR 40439, June 12, 2002]

�75.37 Missing data procedures for moisture.

(a) The owner or operator of a unit with a continuous moisture monitoring system shall substitute for missing moisture data using the procedures of this section.

(b) Where no prior quality-assured moisture data exist, substitute the minimum potential moisture percentage, from section 2.1.5 of appendix A to this part, except when Equation 19-3, 19-4 or 19-8 in Method 19 in appendix A to part 60 of this chapter is used to determine NOX emission rate. If Equation 19-3, 19-4 or 19-8 in Method 19 in appendix A to part 60 of this chapter is used to determine NOX emission rate, substitute the maximum potential moisture percentage, as specified in section 2.1.6 of appendix A to this part.

(c) During the first 720 quality-assured monitor operating hours following initial certification at a particular unit or stack location (i.e., the date and time at which quality-assured data begins to be recorded by a moisture monitoring system at that location), the owner or operator shall provide substitute data for moisture according to �75.31(b).

(d) Upon completion of the first 720 quality-assured monitor operating hours following initial certification, the owner or operator shall provide substitute data for moisture as follows:

(1) Unless Equation 19-3, 19-4 or 19-8 in Method 19 in appendix A to part 60 of this chapter is used to determine NOX emission rate, follow the missing data procedures in �75.33(b), except that the term �moisture percentage� shall apply rather than �SO2 concentration;� the term �moisture monitoring system� shall apply rather than the term �SO2 pollutant concentration monitor;� the term �substitute the lesser of� shall apply rather than �substitute the greater of;� the terms �minimum hourly moisture percentage� and �minimum potential moisture percentage, as determined under section 2.1.5 of appendix A to this part� shall apply rather than, respectively, the terms �maximum hourly SO2 concentration� and �maximum potential SO2 concentration, as determined under section 2.1.1.1 of appendix A to this part;� and the terms �10th percentile� and �5th percentile� shall apply rather than, respectively, the terms �90th percentile� and �95th percentile� (see Table 1 of �75.33).

(2) When Equation 19-3, 19-4 or 19-8 in Method 19 in appendix A to part 60 of this chapter is used to determine NOX emission rate:

(i) Provided that none of the following equations is used to determine SO2 emissions, CO2 emissions or heat input: Equation F-2, F-14b, F-16, F-17, or F-18 in appendix F to this part, or Equation 19-5 or 19-9 in Method 19 in appendix A to part 60 of this chapter, use the missing data procedures in �75.33(b), except that the term �moisture percentage� shall apply rather than �SO2 concentration,� the term �moisture monitoring system� shall apply rather than �SO2 pollutant concentration monitor,� and the term �maximum potential moisture percentage, as defined in section 2.1.6 of appendix A to this part� shall apply, rather than �maximum potential SO2 concentration;� or

(ii) If any of the following equations is used to determine SO2 emissions, CO2 emissions or heat input: Equation F-2, F-14b, F-16, F-17, or F-18 in appendix F to this part, or Equation 19-5 or 19-9 in Method 19 in appendix A to part 60 of this chapter, the owner or operator shall petition the Administrator under �75.66(l) for permission to use an alternative moisture missing data procedure.

[64 FR 28604, May 26, 1999, as amended at 67 FR 40439, June 12, 2002]

��75.38-75.39 [Reserved]

['Air Programs']

['Air Quality', 'Acid Rain']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.