...

(a) Data collection and analysis. To demonstrate precision equal to or better than the continuous emission monitoring system, the owner or operator shall conduct an F-test, a correlation analysis, and a t-test for bias as described in this section. The t-test shall be performed only on sample data at the normal operating level and primary fuel supply, whereas the F-test and the correlation analysis must be performed on each of the data sets required under paragraphs (a)(4) and (a)(5) of this section. The owner or operator shall collect and analyze data according to the following requirements:

(1) Data from the alternative monitoring system and the continuous emission monitoring system shall be collected and paired in a manner that ensures each pair of values applies to hourly average emissions during the same hour.

(2) An alternative monitoring system that directly measures emissions shall have probes or other measuring devices in locations that are in proximity to the continuous emission monitoring system and shall provide data on the same parameters as those measured by the continuous emission monitoring system. Data from the alternative monitoring system shall meet the statistical tests for precision in paragraph (c) of this section and the t-test for bias in appendix A of this part.

(3) An alternative monitoring system that indirectly quantifies emission values by measuring inputs, operating characteristics, or outputs and then applying a regression or another quantitative technique to estimate emissions, shall meet the statistical tests for precision in paragraph (c) of this section and the t-test for bias in appendix A of this part.

(4) For flow monitor alternatives, the alternative monitoring system must provide sample data for each of three different exhaust gas velocities while the unit or units, if more than one unit exhausts into the stack or duct, is burning its primary fuel at:

(i) A frequently used low operating level, selected within the range between the minimum safe and stable operating level and 50 percent of the maximum operating level,

(ii) A frequently used high operating level, selected within the range between 80 percent of the maximum operating level and the maximum operating level, and

(iii) The normal operating level, or an evenly spaced intermediary level between low and high levels used if the normal operating level is within a specified range (10.0 percent of the maximum operating level), of either paragraphs (a)(4) (i) or (ii) of this section.

(5) For pollutant concentration monitor alternatives, the alternative monitoring system shall provide sample data for the primary fuel supply and for all alternative fuel supplies that have significantly different sulfur content.

(6) For the normal unit operating level and primary fuel supply, paired hourly sample data shall be provided for at least 90.0 percent of the hours during 720 unit operating hours. For each of the remaining two operating levels for flow monitor alternatives, and for each alternative fuel supply for pollutant concentration monitor alternatives, paired hourly sample data shall be provided for at least 24 successive unit operating hours.

(7) The owner or operator shall not use missing data substitution procedures to provide sample data.

(8) If the collected data meet the requirements of the F-test, the correlation test, and the t-test at one or more, but not all, of the operating levels or fuel supplies, the owner or operator may elect to continue collecting the paired data for up to 1,440 additional operating hours and repeat the statistical tests using the data for the entire 30- to 90-day period.

(9) The owner or operator shall provide two separate time series data plots for the data at each operating level or fuel supply described in paragraphs (a)(4) and (a)(5) of this section. Each data plot shall have a horizontal axis that represents the clock hour and calendar date of the readings and shall contain a separate data point for every hour for the duration of the performance evaluation. The data plots shall show the following:

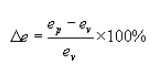

(i) Percentage difference versus time where the vertical axis represents the percentage difference between each paired hourly reading generated by the continuous emission monitoring system (or reference method) and the alternative emission monitoring system as calculated using the following equation:

(Eq. 10)

where,

Δ e = Percentage difference between the readings generated by the alternative monitoring system and the continuous emission monitoring system.

ep = Measured value from the alternative monitoring system.

ev = Measured value from the continuous emission monitoring system.

(ii) Alternative monitoring system readings and continuous emission monitoring system (or reference method) readings versus time where the vertical axis represents hourly pollutant concentrations or volumetric flow, as appropriate, and two different symbols are used to represent the readings from the alternative monitoring system and the continuous emission monitoring system (or reference method), respectively.

(b) Data screening and calculation adjustments. In preparation for conducting the statistical tests described in paragraph (c) of this section, the owner or operator may screen the data for lognormality and time dependency autocorrelation. If either is detected, the owner or operator shall make the following calculation adjustments:

(1) Lognormality. The owner or operator shall conduct any screening and adjustment for lognormality according to the following procedures.

(i) Apply the log transformation to each measured value of either the certified continuous emissions monitoring system or certified flow monitor, using the following equation:

lv = ln ev

(Eq. 11)

where,

ev = Hourly value generated by the certified continuous emissions monitoring system or certified flow monitoring system

lv = Hourly lognormalized data values for the certified monitoring system

and to each measured value, ep, of the proposed alternative monitoring system, using the following equation to obtain the lognormalized data values, lp:

lp = ln ep

(Eq. 12)

where,

ep = Hourly value generated by the proposed alternative monitoring system.

lp = Hourly lognormalized data values for the proposed alternative monitoring system.

(ii) Separately test each set of transformed data, lv and lp, for normality, using the following:

(A) Shapiro-Wilk test;

(B) Histogram of the transformed data; and

(C) Quantile-Quantile plot of the transformed data.

(iii) The transformed data in a data set will be considered normally distributed if all of the following conditions are satisfied:

(A) The Shapiro-Wilk test statistic, W, is greater than or equal to 0.75 or is not statistically significant at α = 0.05.

(B) The histogram of the data is unimodal and symmetric.

(C) The Quantile-Quantile plot is a diagonal straight line.

(iv) If both of the transformed data sets, lv and lp, meet the conditions for normality, specified in paragraphs (b)(1)(iii) (A) through (C) of this section, the owner or operator may use the transformed data, lv and lp, in place of the original measured data values in the statistical tests for alternative monitoring systems as described in paragraph (c) of this section and in appendix A of this part.

(v) If the transformed data are used in the statistical tests in paragraph (c) of this section and in appendix A of this part, the owner or operator shall provide the following:

(A) Copy of the original measured values and the corresponding transformed data in printed and electronic format.

(B) Printed copy of the test results and plots described in paragraphs (b)(1) (i) through (iii) of this section.

(2) Time dependency (autocorrelation). The screening and adjustment for time dependency are conducted according to the following procedures:

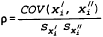

(i) Calculate the degree of autocorrelation of the data on their LAG1 values, where the degree of autocorrelation is represented by the Pearson autocorrelation coefficient, ρ, computed from an AR(1) autoregression model, such that:

(Eq. 13)

where,

x′i = The original data value at hour i.

x″i = The LAG1 data value at hour i.

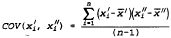

COV(x′i, x″i) = The autocovariance of x′i and defined by,

(Eq. 14)

where,

n = The total number of observations in which both the original value, x′i, and the lagged value, x″i, are available in the data set.

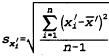

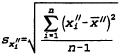

s′x i = The standard deviation of the original data values, x′i defined by,

(Eq. 15)

where,

s″x i = The standard deviation of the LAG1 data values, x″i, defined by

(Eq. 16)

where,

x′ = The mean of the original data values, x′i defined by

(Eq. 17)

where,

x″ = The mean of the LAG1 data values, x″i, defined by

(Eq. 18)

where,

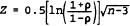

(ii) The data in a data set will be considered autocorrelated if the autocorrelation coefficient, ρ, is significant at the 5 percent significance level. To determine if this condition is satisfied, calculate Z using the following equation:

(Eq. 19)

If Z >1.96, then the autocorrelation coefficient, ρ, is significant at the 5 percent significance level (a = 0.05).

(iii) If the data in a data set satisfy the conditions for autocorrelation, specified in paragraph (b)(2)(ii) of this section, the variance of the data, S2, may be adjusted using the following equation:

S2adj = VIF × S2

(Eq. 20)

where,

S2 = The original, unadjusted variance of the data set.

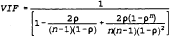

VIF = The variance inflation factor, defined by

(Eq. 21)

S2adj = The autocorrelation-adjusted variance for the data set.

(iv) The procedures described in paragraphs (b)(2)(i)-(iii) of this section may be separately applied to the following data sets in order to derive distinct autocorrelation coefficients and variance inflation factors for each data set:

(A) The set of measured hourly values, ev, generated by the certified continuous emissions monitoring system or certified flow monitoring system.

(B) The set of hourly values, ep, generated by the proposed alternative monitoring system,

(C) The set of hourly differences, ev-ep, between the hourly values, ev, generated by the certified continuous emissions monitoring system or certified flow monitoring system and the hourly values, ep, generated by the proposed alternative monitoring system.

(v) For any data set, listed in paragraph (b)(2)(iv) of this section, that satisfies the conditions for autocorrelation specified in paragraph (b)(2)(ii) of this section, the owner or operator may adjust the variance of that data set, using equation 20 of this section.

(A) The adjusted variance may be used in place of the corresponding original variance, as calculated using equation 23 of this section, in the F-test (Equation 24) of this section.

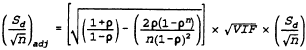

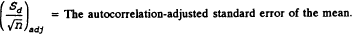

(B) In place of the standard error of the mean,

in the bias test Equation A-9 of appendix A of this part the following adjusted standard error of the mean may be used:

(Eq. 22)where

(vi) For each data set in which a variance adjustment is used, the owner or operator shall provide the following:

(A) All values in the data set in printed and electronic format.

(B) Values of the autocorrelation coefficient, its level of significance, the variance inflation factor, and the unadjusted original and adjusted values found in equations 20 and 22 of this section.

(C) Equation and related statistics of the AR(1) autoregression model of the data set.

(D) Printed documentation of the intermediate calculations used to derive the autocorrelation coefficient and the Variance Inflation Factor.

(c) Statistical Tests. The owner or operator shall perform the F-test and correlation analysis as described in this paragraph and the t-test for bias described in appendix A of this part to demonstrate the precision of the alternative monitoring system.

(1) F-test. The owner or operator shall conduct the F-test according to the following procedures.

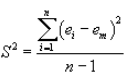

(i) Calculate the variance of the certified continuous emission monitoring system or certified flow monitor as applicable, Sv2, and the proposed method, Sp2, using the following equation.

(Eq. 23)

where,

ei = Measured values of either the certified continuous emission monitoring system or certified flow monitor, as applicable, or proposed method.

em = Mean of either the certified continuous emission monitoring system or certified flow monitor, as applicable, or proposed method values.

n = Total number of paired samples.

(ii) Determine if the variance of the proposed method is significantly different from that of the certified continuous emission monitoring system or certified flow monitor, as applicable, by calculating the F-value using the following equation.

(Eq. 24)

Compare the experimental F-value with the critical value of F at the 95-percent confidence level with n-1 degrees of freedom. The critical value is obtained from a table for F-distribution. If the calculated F-value is greater than the critical value, the proposed method is unacceptable.

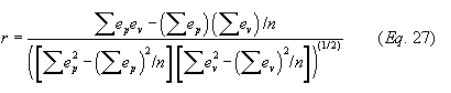

(2) Correlation analysis. The owner or operator shall conduct the correlation analysis according to the following procedures.

(i) Plot each of the paired emissions readings as a separate point on a graph where the vertical axis represents the value (pollutant concentration or volumetric flow, as appropriate) generated by the alternative monitoring system and the horizontal axis represents the value (pollutant concentration or volumetric flow, as appropriate) generated by the continuous emission monitoring system (or reference method). On the graph, draw a horizontal line representing the mean value, ep, for the alternative monitoring system and a vertical line representing the mean value, ev, for the continuous emission monitoring system where,

(Eq. 25)

(Eq. 26)

where,

ep = Hourly value generated by the alternative monitoring system.

ev = Hourly value generated by the continuous emission monitoring system.

n = Total number of hours for which data were generated for the tests.

A separate graph shall be produced for the data generated at each of the operating levels or fuel supplies described in paragraphs (a)(4) and (a)(5) of this section.

(ii) Use the following equation to calculate the coefficient of correlation, r, between the emissions data from the alternative monitoring system and the continuous emission monitoring system using all hourly data for which paired values were available from both monitoring systems.

(Eq. 27)

(iii) If the calculated r-value is less than 0.8, the proposed method is unacceptable.

[58 FR 3701, Jan. 11, 1993, as amended at 60 FR 26530, May 17, 1995; 60 FR 40296, Aug. 8, 1995; 67 FR 40440, June 12, 2002]