['Air Programs']

['Air Quality']

05/13/2025

...

Authority: 42 U.S.C. 7401 et seq.

Subpart A - General Provisions

§65.1 Applicability.

(a) The provisions of this subpart apply to owners or operators expressly referenced to this part from a subpart of 40 CFR part 60, 61, or 63 for which the owner or operator has chosen to comply with the provisions of this part as an alternative to the provisions in the referencing subpart as specified in paragraph (b) of this section.

(b) Owners or operators may choose to comply with this part for any regulated source subject to a referencing subpart.

(c) Compliance with this part instead of the referencing subparts does not alter the applicability of the referencing subparts. This part applies to only the equipment, process vents, storage vessels, or transfer operations to which the referencing subparts apply. This part does not extend applicability to equipment, process vents, storage vessels, or transfer operations that are not regulated by the referencing subpart.

(d) The provisions of 40 CFR part 60, subpart A; 40 CFR part 61, subpart A; and 40 CFR part 63, subpart A, that are listed in table 1 of this subpart still apply to owners or operators of regulated sources expressly referenced to this part. The owner or operator shall comply with the provisions in table 1 of this subpart in the column corresponding to the referencing subpart. All provisions of 40 CFR part 60, subpart A; 40 CFR part 61, subpart A; and 40 CFR part 63, subpart A, not expressly referenced in table 1 of this subpart do not apply, and the provisions of this part apply instead, except that provisions which were required to be met prior to implementation of this part 65 still apply.

(e) The provisions of the referencing subparts that are listed in table 2 of this subpart still apply to owners or operators of regulated sources expressly referenced to this part. The owner or operator shall comply with the provisions in table 2 of this subpart in the row corresponding to the referencing subpart. All provisions of the referencing subparts not expressly referenced in table 2 to this subpart do not apply and the provisions of this part apply instead, except that provisions which were required to be met prior to implementation of this part 65 still apply.

(f) Implementation date. Owners or operators who choose to comply with this part shall comply by the dates specified in paragraph (f)(1) of this section, as applicable, and shall meet the requirement in paragraph (f)(2) of this section.

(1) Owners or operators shall implement this part as specified in an implementation schedule or at initial startup. The implementation date shall be established by mutual agreement with the Administrator or delegated authority. The implementation schedule shall be included in the source's title V permit. For non-title V sources, the implementation schedule shall be proposed by the source in the Initial Notification for Part 65 Applicability as specified in §65.5(c).

(2) There shall be no gaps in compliance between compliance with the referencing subpart and compliance with this part.

(g) Transitioning out of this part. Owners or operators who decide to no longer comply with this part and to comply with the provisions in the referencing subpart instead shall comply with the following, as applicable:

(1) This transition shall be carried out on a date established in a title V permit or if the source is not a title V source, by a date established by agreement with the Administrator or delegated authority. The transition date shall be proposed in a title V permit amendment, or for non-title V sources, in a periodic report or separate notice.

(2) There shall be no gaps in compliance between compliance with this part and compliance with the referencing subpart provisions.

(h) Overlap with other subparts of this part. When provisions of another subpart of this part conflict with the provisions of this subpart, the provisions of the other subpart shall apply.

(i) Equipment assignment procedures. If specific items of equipment (pumps, compressors, agitators, pressure relief devices, sampling connection systems, open-ended valves or lines, valves, connectors, instrumentation systems, surge control vessels, and bottoms receivers) that are part of a process unit complying with this part are managed by different administrative organizations (for example, different companies, affiliates, departments, divisions, etc.), those items of equipment may be aggregated with any process unit within the plant site.

§65.2 Definitions.

All terms used in this part shall have the meaning given them in the Act and in this section. If a term is defined both in this section and in other parts that reference the use of this part, the term shall have the meaning given in this section for purposes of this part. If a term is not defined in the Act or in this section, the term shall have the meaning given in the referencing subpart for purposes of this part. The terms follow:

Act means the Clean Air Act (42 U.S.C. 7401 et seq.).

Administrator means the Administrator of the United States Environmental Protection Agency (EPA) or his or her authorized representative (for example, a State that has been delegated the authority to implement the provisions of this part).

Approved permit program means a State permit program approved by the Administrator as meeting the requirements of part 70 of this chapter or a Federal permit program established in this chapter pursuant to title V of the Act (42 U.S.C. 7661).

Automated continuous parameter monitoring system means a continuous parameter monitoring system that automatically both records the measured data and calculates hourly averages.

Automated monitoring and recording system means any means of measuring values of monitored parameters and creating a hard copy or computer record of the measured values that does not require manual reading of monitoring instruments and manual transcription of data values. Automated monitoring and recording systems include, but are not limited to, computerized systems, strip charts, and circular charts.

Batch process means a process in which the equipment is fed intermittently or discontinuously. Processing then occurs in this equipment after which the equipment is generally emptied. Examples of industries that use batch processes include pharmaceutical production and pesticide production.

Batch product-process equipment train means the collection of equipment (for example, connectors, reactors, valves, pumps) configured to produce a specific product or intermediate by a batch process.

Boiler means any enclosed combustion device that extracts useful energy in the form of steam and is not an incinerator or a process heater. Boiler also means any industrial furnace as defined in 40 CFR 260.10.

Bottoms receiver means a tank that collects distillation bottoms before the stream is sent for storage or for further downstream processing.

By compound means by individual stream components, not carbon equivalents.

Car-seal means a seal that is placed on a device that is used to change the position of a valve (for example, from opened to closed) in such a way that the position of the valve cannot be changed without breaking the seal.

Closed vent system means a system that is not open to the atmosphere and is composed of piping, ductwork, connections, and, if necessary, flow inducing devices that transport gas or vapor from an emission point to a control device. A closed vent system does not include the vapor collection system that is part of any tank truck or railcar or the loading arm or hose that is used for vapor return. For transfer racks, the closed vent system begins at, and includes, the first block valve on the downstream side of the loading arm or hose used to convey displaced vapors.

Closed vent system shutdown means a work practice or operational procedure that stops production from a process unit or part of a process unit during which it is technically feasible to clear process material from a closed vent system or part of a closed vent system consistent with safety constraints and during which repairs can be effected. An unscheduled work practice or operational procedure that stops production from a process unit or part of a process unit for less than 24 hours is not a closed vent system shutdown. An unscheduled work practice or operational procedure that would stop production from a process unit or part of a process unit for a shorter period of time than would be required to clear the closed vent system or part of the closed vent system of materials and start up the unit, and would result in greater emissions than delay of repair of leaking components until the next scheduled closed vent system shutdown, is not a closed vent system shutdown. The use of spare equipment and technically feasible bypassing of equipment without stopping production are not closed vent system shutdowns.

Closed-loop system means an enclosed system that returns process fluid to a process.

Closed-purge system means a system or combination of systems and portable containers to capture purged liquids. Containers must be covered or closed when not being filled or emptied.

Combustion device means an individual unit of equipment, such as a flare, incinerator, process heater, or boiler, used for the combustion of organic emissions.

Compliance date means the date by which a regulated source is required to be in compliance with a relevant standard, limitation, prohibition, or any federally enforceable requirement established by the Administrator (or a State with an approved permit program) pursuant to the Act.

Connector means flanged, screwed, or other joined fittings used to connect two pipelines or a pipeline and a piece of equipment. A common connector is a flange. Joined fittings welded completely around the circumference of the interface are not considered connectors for the purpose of this regulation. For the purpose of reporting and recordkeeping, connector means joined fittings that are not inaccessible, ceramic, or ceramic-lined (for example, porcelain, glass, or glass-lined) as described in §65.108(e)(2).

Continuous parameter monitoring system or CPMS means the total equipment that may be required to meet the data acquisition and availability requirements of this part used to sample, condition (if applicable), analyze, and provide a record of process or control system parameters.

Continuous record means documentation, either in hard copy or computer-readable form, of data values measured at least once every 15 minutes and recorded at the frequency specified in §65.161(a).

Continuous seal means a seal that is designed to form a continuous closure that completely covers the space between the wall of the storage vessel and the edge of the floating roof. A continuous seal may be a vapor-mounted, liquid-mounted, or metallic shoe seal. A continuous seal may be constructed of fastened segments so as to form a continuous seal.

Control device means any combustion device, recovery device, or any combination of these devices used to comply with this part. Such equipment or devices include, but are not limited to, absorbers, carbon adsorbers, condensers, incinerators, flares, boilers, and process heaters. For process vents (as defined in this section), recovery devices are not considered control devices except for the recovery devices specified in §65.63(a)(2)(ii). A fuel gas system is not a control device. For a steam stripper, a primary condenser is not considered a control device.

Control system means the combination of the closed vent system and the control devices used to collect and control vapors or gases from a regulated source.

Day means a calendar day.

Distance piece means an open or enclosed casing through which the piston rod travels, separating the compressor cylinder from the crankcase.

Double block and bleed system means two block valves connected in series with a bleed valve or line that can vent the line between the two block valves.

Ductwork means a conveyance system such as those commonly used for heating and ventilation systems. It is often made of sheet metal and often has sections connected by screws or crimping. Hard-piping is not ductwork.

Emission point means an individual process vent, storage vessel, transfer rack, wastewater stream, or equipment leak.

Empty or emptying means the removal of the stored liquid from a storage vessel. Storage vessels where stored liquid is left on the walls, as bottom clingage, or in pools due to bottom irregularities are considered empty. Lowering of the stored liquid level, so that the floating roof is resting on its legs, as necessitated by normal vessel operation (for example, when changing stored material or when transferring material out of the vessel for shipment) is not considered emptying.

Equipment means each of the following that is subject to control under the referencing subpart: pump, compressor, agitator, pressure relief device, sampling connection system, open-ended valve or line, valve, connector, and instrumentation system; and any control devices or systems used to comply with subpart F of this part.

Equivalent method means any method of sampling and analyzing for an air pollutant that has been demonstrated to the Administrator's satisfaction to have a consistent and quantitatively known relationship to the reference method under specified conditions.

External floating roof or EFR means a pontoon-type (noncontact) or double-deck-type (contact) roof that is designed to rest on the stored liquid surface in a storage vessel with no fixed roof.

Failure, EFR (referred to as EFR failure) is defined as any time the external floating roof's primary seal has holes, tears, or other openings in the shoe, seal fabric, or seal envelope; or the secondary seal has holes, tears, or other openings in the seal or the seal fabric; or the gaskets no longer close off the stored liquid surface from the atmosphere; or a slotted membrane has more than 10 percent open area.

Failure, internal floating roof type A (referred to as IFR type A failure) means any time, as determined during visual inspection through roof hatches, in which the internal floating roof is not resting on the surface of the stored liquid inside the storage vessel and is not resting on the leg supports; or there is stored liquid on the floating roof; or there are holes, tears, or other openings in the seal or seal fabric; or there are visible gaps between the seal and the wall of the storage vessel.

Failure, internal floating roof type B (referred to as IFR type B failure) means any time, as determined during internal inspections, the internal floating roof's primary seal has holes, tears, or other openings in the seal or the seal fabric; or the secondary seal (if one has been installed) has holes, tears, or other openings in the seal or the seal fabric; or the gaskets no longer close off the stored liquid surface from the atmosphere; or a slotted membrane has more than 10 percent open area.

Fill or filling means the introduction of liquids into a storage vessel, but not necessarily to complete capacity.

First attempt at repair, for the purposes of subparts F and G of this part, means to take action for the purpose of stopping or reducing leakage of organic material to the atmosphere, followed by monitoring as specified in §§65.104(b) and 65.143(c), as appropriate, to verify whether the leak is repaired, unless the owner or operator determines by other means that the leak is not repaired.

Fixed roof means a roof that is mounted (for example, permanently affixed) on a storage vessel in a stationary manner and that does not move with fluctuations in stored liquid level.

Flame zone means the portion of the combustion chamber in a boiler or process heater occupied by the flame envelope.

Floating roof means a roof consisting of an external floating roof or an internal floating roof that is designed to rest upon and is supported by the stored liquid and is equipped with a continuous seal.

Flow indicator means a device that indicates whether gas flow is present in a line, or whether the valve position would allow gas flow to be present in a line.

Force majeure means, for purposes of §65.157, an event that will be or has been caused by circumstances beyond the control of the affected facility, its contractors, or any entity controlled by the affected facility that prevents the owner or operator from complying with the regulatory requirement to conduct performance tests within the specified timeframe despite the affected facility's best efforts to fulfill the obligation. Examples of such events are acts of nature, acts of war or terrorism, or equipment failure or safety hazard beyond the control of the affected facility.

Fuel gas means gases that are combusted to derive useful work or heat.

Fuel gas system means the offsite and onsite piping and flow and pressure control system that gathers gaseous stream(s) generated by onsite operations, may blend them with other sources of gas, and transports the gaseous stream for use as fuel gas in combustion devices or in-process combustion equipment, such as furnaces and gas turbines, either singly or in combination.

Group 1 process vent means a process vent for which the flow rate is greater than or equal to 0.011 standard cubic meter per minute (0.39 cubic feet per minute); the total concentration is greater than or equal to the appropriate value in table 1 of subpart D of this part, and the total resource effectiveness index value, calculated according to §65.64(h) is less than or equal to 1.0.

Group 2A process vent means a process vent that is not Group 1 or Group 2B for which monitoring and recordkeeping are required to demonstrate a total resource effectiveness index value greater than 1.0.

Group 2B process vent means a process vent that is not Group 1 or Group 2A for which monitoring and recordkeeping are not required to demonstrate a total resource effectiveness index value greater than 4.0, or which is exempt from control requirements due to the vent stream's flow rate, regulated material concentration, or total resource effectiveness index value.

Halogenated vent stream or halogenated stream means, for purposes of this part, a vent stream determined to be halogenated by the procedures specified in §65.85(c) for transfer racks and in §65.64(g) for process vents, as applicable.

Halogens and hydrogen halides means hydrogen chloride (HCl), chlorine (Cl2), hydrogen bromide (HBr), bromine (Br2), and hydrogen fluoride (HF).

Hard-piping means pipe or tubing that is manufactured and installed using good engineering judgment and standards, such as ASME B31.3, Process Piping (available from the American Society of Mechanical Engineers, PO Box 2900, Fairfield, NJ 07007-2900).

High-throughput transfer racks means those transfer racks that transfer greater than or equal to a total of 11.8 million liters per year (3.12 million gallons per year) of liquid containing regulated material.

In food/medical service means that a piece of equipment in regulated material service contacts a process stream used to manufacture a Food and Drug Administration-regulated product where leakage of a barrier fluid into the process stream would cause any of the following:

(1) A dilution of product quality so that the product would not meet written specifications;

(2) An exothermic reaction that is a safety hazard;

(3) The intended reaction to be slowed down or stopped; or

(4) An undesired side reaction to occur.

In gas/vapor service means that a piece of equipment in regulated material service contains a gas or vapor when in operation.

In heavy liquid service means that a piece of equipment in regulated material service is not in gas/vapor service or in light liquid service.

In light liquid service means that a piece of equipment in regulated material service contains a liquid that meets the following conditions:

(1) The vapor pressure of one or more of the organic compounds is greater than 0.3 kilopascals at 20°C (0.04 pounds per square inch at 68°F);

(2) The total concentration of the pure organic compound constituents having a vapor pressure greater than 0.3 kilopascals at 20°C (0.04 pounds per square inch at 68°F) is equal to or greater than 20 percent by weight of the total process stream; and

(3) The fluid is a liquid at operating conditions. (Note: Vapor pressures may be determined by standard reference texts or American Society for Testing and Materials (ASTM) D-2879, available from American Society for Testing and Materials, 1916 Race Street, Philadelphia, Pennsylvania 19103; or University Microfilms International, 300 North Zeeb Road, Ann Arbor, Michigan 48106.)

In liquid service means that a piece of equipment in regulated material service is not in gas/vapor service.

In regulated material service means, for the purposes of the equipment leak provisions of subpart F of this part, equipment which meets the definition of “in volatile organic compound service,” “in volatile hazardous air pollutant service,” “in benzene service,” “in vinyl chloride service,” or “in organic hazardous air pollutant service” as defined in the referencing subpart.

In vacuum service means that equipment is operating at an internal pressure that is at least 5 kilopascals (0.7 pounds per square inch) below ambient pressure.

In-situ sampling systems means nonextractive samplers or in-line samplers.

Incinerator means an enclosed combustion device that is used for destroying organic compounds. Auxiliary fuel may be used to heat waste gas to combustion temperatures. Any energy recovery section present is not physically formed into one manufactured or assembled unit with the combustion section; rather, the energy recovery section is a separate section following the combustion section and the two are joined by ducts or connections carrying flue gas. This energy recovery section limitation does not apply to an energy recovery section used solely to preheat the incoming vent stream or combustion air.

Initial startup means, for new or reconstructed sources, the first time the source begins production. For additions or changes not defined as a new source by an applicable referencing subpart, initial startup means the first time additional or changed equipment is put into operation. Initial startup does not include operation solely for testing equipment. Initial startup does not include subsequent startup (as defined in this section) of process units following malfunctions or process unit shutdowns. Except for equipment leaks, initial startup also does not include subsequent startups (as defined in this section) of process units following changes in product for flexible operation units or following recharging of equipment in batch operation.

Instrumentation system means a group of equipment components used to condition and convey a sample of the process fluid to analyzers and instruments for the purpose of determining process operating conditions (for example, composition, pressure, flow). Valves and connectors are the predominant type of equipment used in instrumentation systems; however, other types of equipment may also be included in these systems. Only valves nominally 0.5 inches and smaller in diameter and connectors nominally 0.75 inches and smaller in diameter are considered instrumentation systems for the purposes of subpart F of this part.

Intermediate change to monitoring means a modification to federally required monitoring involving “proven technology” (generally accepted by the scientific community as equivalent or better) that is applied on a site-specific basis and that may have the potential to decrease the stringency of the associated emission limitation or standard. Though site-specific, an intermediate change may set a national precedent for a source category and may ultimately result in a revision to the federally required monitoring. Examples of intermediate changes to monitoring include, but are not limited to:

(1) Use of a continuous monitoring system (CEMS) in lieu of a parameter monitoring approach;

(2) Decreased frequency for non-continuous parameter monitoring or physical inspections;

(3) Changes to quality control requirements for parameter monitoring; and

(4) Use of an electronic data reduction system in lieu of manual data reduction.

Intermediate change to test method means a within-method modification to a federally enforceable test method involving “proven technology” (generally accepted by the scientific community as equivalent or better) that is applied on a site-specific basis and that may have the potential to decrease the stringency of the associated emission limitation or standard. Though site-specific, an intermediate change may set a national precedent for a source category and may ultimately result in a revision to the federally enforceable test method. In order to be approved, an intermediate change must be validated according to EPA Method 301 (40 CFR part 63, appendix A) to demonstrate that it provides equal or improved accuracy or precision. Examples of intermediate changes to a test method include, but are not limited to:

(1) Modifications to a test method's sampling procedure including substitution of sampling equipment that has been demonstrated for a particular sample matrix; and use of a different impinger absorbing solution;

(2) Changes in sample recovery procedures and analytical techniques, such as changes to sample holding times and use of a different analytical finish with proven capability for the analyte of interest; and

(3) “Combining” a federally required method with another proven method for application to processes emitting multiple pollutants.

Internal floating roof or IFR means a pontoon-type (noncontact) or double-deck-type (contact) roof that is designed to rest or float on the stored liquid surface inside a storage vessel that has a fixed roof.

Liquid-mounted seal means a foam-or liquid-filled continuous seal mounted in contact with the stored liquid.

Liquids dripping means any visible leakage from a seal including dripping, spraying, misting, clouding, and ice formation. Indications of liquids dripping include puddling or new stains that are indicative of an existing evaporated drip.

Loading cycle means the time period from the beginning of filling a tank truck or railcar until flow to the control device ceases as determined by the flow indicator.

Low-throughput transfer racks means those transfer racks that transfer less than a total of 11.8 million liters per year (3.12 million gallons per year) of liquid containing regulated material.

Major change to monitoring means a modification to federally required monitoring that uses “unproven technology or procedures” (not generally accepted by the scientific community) or is an entirely new method (sometimes necessary when the required monitoring is unsuitable). A major change to monitoring may be site-specific or may apply to one or more source categories and will almost always set a national precedent. Examples of major changes to monitoring include, but are not limited to:

(1) Use of a new monitoring approach developed to apply to a control technology not contemplated in the applicable regulation in this part;

(2) Use of a predictive emission monitoring system (PEMS) in place of a required continuous emission monitoring system (CEMS);

(3) Use of alternative calibration procedures that do not involve calibration gases or test cells;

(4) Use of an analytical technology that differs from that specified by a performance specification;

(5) Decreased monitoring frequency for a continuous emission monitoring system, continuous opacity monitoring system, predictive emission monitoring system, or continuous parameter monitoring system;

(6) Decreased monitoring frequency for a leak detection and repair program; and

(7) Use of alternative averaging times for reporting purposes.

Major change to test method means a modification to a federally enforceable test method that uses “unproven technology or procedures” (not generally accepted by the scientific community) or is an entirely new method (sometimes necessary when the required test method is unsuitable). A major change to a test method may be site-specific or may apply to one or more source categories and will almost always set a national precedent. In order to be approved, a major change must be validated according to EPA Method 301 (40 CFR part 63, appendix A). Examples of major changes to a test method include, but are not limited to:

(1) Use of an unproven analytical finish;

(2) Use of a method developed to fill a test method gap;

(3) Use of a new test method developed to apply to a control technology not contemplated in the applicable regulation in this part; and

(4) Combining two or more sampling/analytical methods (at least one unproven) into one for application to processes emitting multiple pollutants.

Malfunction means any sudden, infrequent, and not reasonably preventable failure of air pollution control equipment, monitoring equipment, process equipment, or a process to operate in a normal or usual manner which causes, or has the potential to cause, the emission limitations in an applicable standard to be exceeded. Failures that are caused in part by poor maintenance or careless operation are not malfunctions. Malfunctions that do not affect a regulated source or compliance with this part are not malfunctions for purposes of this part.

Metallic shoe seal or mechanical shoe seal means metal sheets that are held vertically against the wall of the storage vessel by springs, weighted levers, or other mechanisms and connected to the floating roof by braces or other means. A flexible coated fabric (envelope) spans the annular space between the metal sheet and the floating roof.

Minor change to monitoring means:

(1) A modification to federally required monitoring that:

(i) Does not decrease the stringency of the compliance and enforcement measures of the relevant standard;

(ii) Has no national significance (e.g., does not affect implementation of the applicable regulation in this part for other affected sources, does not set a national precedent, and individually does not result in a revision to the monitoring requirements); and

(iii) Is site-specific, made to reflect or accommodate the operational characteristics, physical constraints, or safety concerns of an affected source.

(2) Examples of minor changes to monitoring include, but are not limited to:

(i) Modifications to a sampling procedure, such as use of an improved sample conditioning system to reduce maintenance requirements;

(ii) Increased monitoring frequency; and

(iii) Modification of the environmental shelter to moderate temperature fluctuation and thus protect the analytical instrumentation.

Minor change to test method means:

(1) A modification to a federally enforceable test method that:

(i) Does not decrease the stringency of the emission limitation or standard;

(ii) Has no national significance (e.g., does not affect implementation of the applicable regulation in this part for other affected sources, does not set a national precedent, and individually does not result in a revision to the test method); and

(iii) Is site-specific, made to reflect or accommodate the operational characteristics, physical constraints, or safety concerns of an affected source.

(2) Examples of minor changes to a test method include, but are not limited to:

(i) Field adjustments in a test method's sampling procedure, such as a modified sampling traverse or location to avoid interference from an obstruction in the stack, increasing the sampling time or volume, use of additional impingers for a high moisture situation, accepting particulate emission results for a test run that was conducted with a lower than specified temperature, substitution of a material in the sampling train that has been demonstrated to be more inert for the sample matrix; and

(ii) Changes in recovery and analytical techniques such as a change in quality control/quality assurance requirements needed to adjust for analysis of a certain sample matrix.

Nonautomated monitoring and recording system means manual reading of values measured by monitoring instruments and manual transcription of those values to create a record. Nonautomated systems do not include strip charts nor circular charts.

Nonrepairable means that it is technically infeasible to repair a piece of equipment from which a leak has been detected without a process unit shutdown.

One-hour period means the 60-minute period commencing on the hour.

Onsite or on-site means, with respect to records required to be maintained by this part, that the records are stored at a location within a plant site that encompasses the regulated source. Onsite includes, but is not limited to, storage at the regulated source to which the records pertain, or storage in central files elsewhere at the plant site.

Open-ended valve or line means any valve except relief valves having one side of the valve seat in contact with process fluid and one side open to the atmosphere, either directly or through open piping.

Organic monitoring device means a device used to indicate the concentration level of organic compounds based on a detection principle such as infrared, photo ionization, or thermal conductivity.

Owner or operator means any person who owns, leases, operates, controls, or supervises a regulated source or a stationary source of which a regulated source is a part.

Part 70 permit means any permit issued, renewed, or revised pursuant to part 70 of this chapter.

Performance test means the collection of data resulting from the execution of a test method (usually three emission test runs) used to demonstrate compliance with a relevant emission standard as specified in the performance test section of the relevant standard.

Permit program means a comprehensive State operating permit system established pursuant to title V of the Act (42 U.S.C. 7661) and regulations codified in part 70 of this chapter and applicable State regulations, or a comprehensive Federal operating permit system established pursuant to title V of the Act and regulations codified in part 71 of this chapter.

Permitting authority means one of the following:

(1) The State air pollution control agency, local agency, other State agency, or other agency authorized by the Administrator to carry out a permit program under part 70 of this chapter; or

(2) The Administrator, in the case of EPA-implemented permit programs under title V of the Act (42 U.S.C. 7661) and part 71 of this chapter.

Plant site means all contiguous or adjoining property that is under common control, including properties that are separated only by a road or other public right-of-way. Common control includes properties that are owned, leased, or operated by the same entity, parent entity, subsidiary, or any combination thereof.

Polymerizing monomer means, for the purposes of this part, a compound which may form polymer buildup in pump mechanical seals resulting in rapid mechanical seal failure.

Pressure release means the emission of materials resulting from the system pressure being greater than the set pressure of the relief device. This release can be one release or a series of releases over a short time period.

Pressure relief device or valve means a device used to prevent operating pressures from exceeding the maximum allowable working pressure of the process equipment. A common pressure relief device is a spring-loaded pressure relief valve. Devices that are actuated either by a pressure of less than or equal to 2.5 pounds per square inch gauge or by a vacuum are not pressure relief devices.

Primary fuel means the fuel that provides the principal heat input to the device. To be considered primary, the fuel must be able to sustain operation without the addition of other fuels.

Process heater means an enclosed combustion device that transfers heat liberated by burning fuel directly to process streams or to heat transfer liquids other than water. A process heater may, as a secondary function, heat water in unfired heat recovery sections.

Process unit means the equipment specified in the definitions of process unit or chemical manufacturing process unit in the applicable referencing subpart. If the referencing subpart does not define process unit, then, for the purposes of this part, process unit means the equipment assembled and connected by pipes or ducts to process raw materials and to manufacture an intended product.

Process unit shutdown means a work practice or operational procedure that stops production from a process unit or part of a process unit during which it is technically feasible to clear process material from a process unit or part of a process unit consistent with safety constraints and during which repairs can be effected. An unscheduled work practice or operational procedure that stops production from a process unit or part of a process unit for less than 24 hours is not a process unit shutdown. An unscheduled work practice or operational procedure that would stop production from a process unit or part of a process unit for a shorter period of time than would be required to clear the process unit or part of the process unit of materials and start up the unit, and would result in greater emissions than delay of repair of leaking components until the next scheduled process unit shutdown is not a process unit shutdown. The use of spare equipment and technically feasible bypassing of equipment without stopping production are not process unit shutdowns.

Process vent means a process vent or vent stream as they are defined in the referencing subpart.

Recovery device means an individual unit of equipment capable of and normally used for the purpose of recovering chemicals for fuel value (i.e., net positive heating value), use, reuse, or for sale for fuel value, use, or reuse. Equipment capable of and used for the purpose of recovering chemicals, but not normally for use, reuse or sale, are not recovery devices but are control devices. Examples of equipment that may be recovery devices include absorbers, carbon adsorbers, condensers, oil-water separators or organic-water separators, or organic removal devices such as decanters, strippers, or thin-film evaporation units.

Reference method means any method of sampling and analyzing for an air pollutant as specified in an applicable subpart, the appendices to 40 CFR part 60 or 63, or in appendix B of 40 CFR part 61.

Referencing subpart means 40 CFR part 60, subparts Ka, Kb, VV, DDD, III, NNN, and RRR; 40 CFR part 61, subparts V, Y, and BB; and 40 CFR part 63, subparts G and H.

Regulated material means, for the purposes of this part, the material regulated by the specific referencing subpart, including volatile organic liquids (VOL), volatile organic compounds (VOC), organic hazardous air pollutants (HAP's), benzene, vinyl chloride, or other chemicals or groups of chemicals.

Regulated source means, for the purposes of this part, the stationary source, the group of stationary sources, or the portion of a stationary source that is regulated by a relevant standard or other requirement established pursuant to this part, or 40 CFR part 60, 61, or 63.

Relief device or valve means a device or valve used only to release an unplanned, nonroutine discharge. A relief device or valve discharge can result from an operator error, a malfunction such as a power failure or equipment failure, or other unexpected cause that requires immediate venting of gas from process equipment in order to avoid safety hazards or equipment damage.

Repaired means, for the purposes of subparts F and G of this part, that equipment meets the following conditions:

(1) Is adjusted, or otherwise altered, to eliminate a leak as defined in the applicable section of this part; and

(2) Unless otherwise specified in applicable provisions of this part, is monitored as specified in §§65.104(b) and 65.143(c) to verify that emissions from the equipment are below the applicable leak definition.

Routed to a process or route to a process means the emissions are conveyed to any enclosed portion of a process unit where the emissions are predominantly recycled and/or consumed in the same manner as a material that fulfills the same function in the process and/or transformed by chemical reaction into materials that are not regulated materials and/or incorporated into a product; and/or recovered.

Run means one of a series of emission or other measurements needed to determine emissions for a representative operating period or cycle as specified in this part. Unless otherwise specified, a run may be either intermittent or continuous within the limits of good engineering practice.

Sampling connection system means an assembly of equipment within a process unit used during periods of representative operation to take samples of the process fluid. Equipment used to take nonroutine grab samples is not considered a sampling connection system.

Secondary fuel means a fuel fired through a burner other than the primary fuel burner that provides supplementary heat in addition to the heat provided by the primary fuel.

Sensor means a device that measures a physical quantity or the change in a physical quantity, such as temperature, pressure, flow rate, pH, or liquid level.

Set pressure means, for the purposes of subparts F and G of this part, the pressure at which a properly operating pressure relief device begins to open to relieve atypical process system operating pressure.

Shutdown means the cessation of operation of a regulated source (for example, chemical manufacturing process unit or a reactor, air oxidation reactor, distillation unit) and equipment required or used to comply with this part, or the emptying and degassing of a storage vessel. Shutdown is defined here for purposes including, but not limited to, periodic maintenance, replacement of equipment, or repair. Shutdown does not include the routine rinsing or washing of equipment in batch operation between batches.

Simultaneous loading means, for a shared control device, loading of regulated materials from more than one transfer arm at the same time so that the beginning and ending times of loading cycles coincide or overlap and there is no interruption in vapor flow to the shared control device.

Single-seal system means, for the purposes of subpart C of this part, a floating roof having one continuous seal. This seal may be a vapor-mounted, liquid-mounted, or metallic shoe seal.

Specific gravity monitoring device means a unit of equipment used to monitor specific gravity and having a minimum accuracy of ±0.02 specific gravity units.

Startup means the setting into operation of a regulated source (for example, chemical manufacturing process unit or a reactor, air oxidation reactor, distillation unit, a storage vessel after emptying and degassing) and/or equipment required or used to comply with this part. Startup includes initial startup, operation solely for testing equipment, the recharging of equipment in batch operation, and transitional conditions due to changes in product for flexible operation units.

State means all non-Federal authorities, including local agencies, interstate associations, and statewide programs, that have delegated authority to implement the provisions of this part; the referencing subparts; and/or the permit program established under part 70 of this chapter. The term State shall have its conventional meaning where clear from the context.

Steam jet ejector means a steam nozzle that discharges a high-velocity jet across a suction chamber that is connected to the equipment to be evacuated.

Stuffing box pressure means the fluid (liquid or gas) pressure inside the casing or housing of a piece of equipment, on the process side of the inboard seal.

Surge control vessel means feed drums, recycle drums, and intermediate vessels. Surge control vessels are used within a process unit (as defined in the specific subpart that references this part) when in-process storage, mixing, or management of flow rates or volumes is needed to assist in production of a product.

Temperature monitoring device means a unit of equipment used to monitor temperature and having a minimum accuracy of ±1 percent of the temperature being monitored expressed in degrees Celsius or ±1.2 degrees Celsius (°C), whichever is greater.

Title V permit means any permit issued, renewed, or revised pursuant to Federal or State regulations established under 40 CFR part 70 or 71 to implement title V of the Act (42 U.S.C. 7661).

Total organic compounds or TOC means those compounds measured according to the procedures specified in §§65.64(c) and 65.158(b)(3)(ii)(A), as applicable. Those compounds that the Administrator has determined do not contribute appreciably to the formation of ozone and that are specifically excluded from the definition of volatile organic compound at 40 CFR 51.100(s), as amended, are to be excluded for the purposes of measuring the hourly emission rate as required in §65.64(f) for process vents subject to subpart III, NNN, or RRR of part 60 of this chapter.

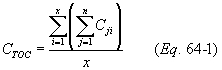

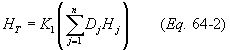

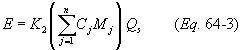

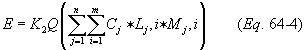

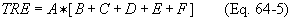

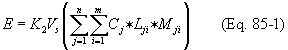

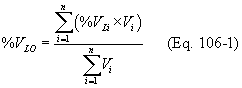

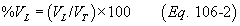

Total resource effectiveness index value or TRE index value means a calculated value used to determine whether control is required for a process vent. It is based on process vent flow rate, emission rate of regulated material, net heating value, and corrosion properties (halogenated compound content), as quantified by the equations given under §65.64(h).

Vapor balancing system means a piping system that is designed to collect regulated material vapors displaced from tank trucks or railcars during loading and to route the collected regulated material vapors to the storage vessel from which the liquid being loaded originated, or to another storage vessel connected by a common header; or to compress and route to a process or a fuel gas system the collected regulated material vapors.

Vapor-mounted seal means a continuous seal that is mounted so that there is a vapor space between the stored liquid and the bottom of the seal.

Visible emission means the observation of an emission of opacity or optical density above the threshold of vision.

[65 FR 78285, Dec. 14, 2000, as amended at 71 FR 20471, Apr. 20, 2006; 72 FR 48942, Aug. 27, 2007]

§65.3 Compliance with standards and operation and maintenance requirements.

(a) Requirements. (1) Except as provided in paragraph (a)(2) of this section, the emission standards and established parameter ranges of this part shall apply at all times except during periods of startup, shutdown (as defined in §65.2), malfunction, or nonoperation of the regulated source (or specific portion thereof) resulting in cessation of the emissions to which this part applies. However, if a startup, shutdown, malfunction, or period of nonoperation of one portion of a regulated source does not affect the ability of a particular emission point to comply with the specific provisions to which it is subject, then that emission point shall still be required to comply with the applicable provisions of this part during the startup, shutdown, malfunction, or period of nonoperation. For example, if there is an over pressure in the reactor area, a storage vessel in a chemical manufacturing process unit would still be required to be controlled in accordance with subpart C of this part. Similarly, the degassing of a storage vessel would not affect the ability of a process vent to meet the requirements of subpart D or G of this part.

(2) Sections 65.106 through 65.118 shall apply at all times except during periods of startup or shutdown (as defined in §65.2), malfunction, process unit shutdown (as defined in §65.2), or nonoperation of the regulated source (or specific portion thereof) in which the lines are drained and depressurized resulting in cessation of the emissions to which subpart F of this part applies.

(3) During startups, shutdowns, and malfunctions when the emission standards of this part do not apply pursuant to paragraphs (a)(1) and (2) of this section, the owner or operator shall implement, to the extent reasonably available, measures to prevent or minimize emissions in excess of those that would have occurred if there were no startup, shutdown, or malfunction and the owner or operator complied with the relevant provisions of this part. The measures to be taken may include, but are not limited to, air pollution control technologies, recovery technologies, work practices, pollution prevention, monitoring, and/or changes in the manner of operation of the regulated source. Backup control devices are not required but may be used if available. This paragraph (a)(3) does not apply to Group 2A or Group 2B process vents.

(4) Malfunctions shall be corrected as soon as practical after their occurrence. This paragraph (a)(4) does not apply to Group 2A or Group 2B process vents.

(5) Operation and maintenance requirements established pursuant to section 112 of the Act are enforceable independent of emissions limitations or other requirements in relevant standards.

(b) Compliance determination procedures— (1) Parameter monitoring: Compliance with operating conditions. The parameter monitoring data for emission points that are required to perform continuous monitoring shall be used to determine compliance with the required operating conditions for the monitored control devices or recovery devices. For each excursion, except for excused excursions and as provided for in paragraph (b)(2) of this section, the owner or operator shall be deemed to have failed to have applied the control in a manner that achieves the required operating conditions. Excused excursions are provided for in §65.156(d)(2).

(2) Parameter monitoring: Excursions. If the conditions of paragraph (b)(2)(i) or (ii) of this section are met, an excursion is not a violation and, in cases where continuous monitoring is required, the excursion does not count toward the number of excused excursions. Nothing in this paragraph (b)(2) shall be construed to allow or excuse a monitoring parameter excursion caused by any activity that violates other applicable provisions of this part.

(i) During periods of startup, shutdown, or malfunction (and the source is operated during such periods in accordance with §65.3(a)(3)), a monitoring parameter is outside its established range or monitoring data cannot be collected; or

(ii) During periods of nonoperation of the regulated source or portion thereof (resulting in cessation of the emissions to which the monitoring applies).

(3) Operation and maintenance procedures. Determination of whether acceptable operation and maintenance procedures are being used will be based on information available to the Administrator that may include, but is not limited to, monitoring results, review of operation and maintenance procedures (including the startup, shutdown, and malfunction plan, if applicable, required in §65.6(a), as applicable), review of operation and maintenance records, inspection of the regulated source, and alternatives approved as specified in §65.7.

(4) Emissions standards. Paragraphs (b)(4)(i) and (ii) of this section shall govern the use of data, tests, and requirements to determine compliance with emissions standards. Paragraphs (b)(4)(i) and (ii) do not apply to Group 2A or Group 2B process vents. Compliance with design, equipment, work practice, and operational standards, including those for equipment leaks, shall be determined according to paragraph (b)(5) of this section.

(i) Performance test. The Administrator will determine compliance with emission standards of this part based on the results of performance tests conducted according to the procedures specified in subpart G of this part, unless otherwise specified in a subpart of this part.

(ii) Operation and maintenance requirements. The Administrator will determine compliance with emission standards of this part by evaluation of an owner or operator's conformance with operation and maintenance requirements, including the evaluation of monitoring data, as specified in subparts of this part.

(5) Design, equipment, work practice, or operational standards. Paragraphs (b)(5)(i) and (ii) do not apply to Group 2A or Group 2B process vents.

(i) Records and inspection. The Administrator will determine compliance with design, equipment, work practice, or operational standards by review of records, inspection of the regulated source, and other procedures specified in this part.

(ii) Operation and maintenance. The Administrator will determine compliance with design, equipment, work practice, or operational standards by evaluation of an owner or operator's conformance with operation and maintenance requirements as specified in paragraph (a) of this section, in other subparts of this part, and in applicable provisions of §65.6(b).

(c) Finding of compliance. The Administrator will make a finding concerning a regulated source's compliance with an emission standard, design standard, work practice, operational standard or operating and maintenance requirement as specified in paragraphs (a) and (b) of this section upon obtaining all the compliance information required by the relevant standard (including the written reports of performance test results, monitoring results, and other information, if applicable) and any information available to the Administrator needed to determine whether proper operation and maintenance practices are being used. Standards in this part and methods of determining compliance are given in metric units followed by the equivalents in English units. The Administrator will make findings of compliance with the standards of this part using metric units.

(d) Compliance times. All terms that define a period of time for completion of required tasks (for example, weekly, monthly, quarterly, annually) unless specified otherwise in the section or paragraph that imposes the requirement refer to the standard calendar periods.

(1) Notwithstanding time periods specified for completion of required tasks, time periods may be changed by mutual agreement between the owner or operator and the Administrator as specified in §65.5(h)(3) (for example, a period could begin on the compliance date or another date, rather than on the first day of the standard calendar period). For each time period that is changed by agreement, the revised period applies until it is changed. A new request is not necessary for each recurring period.

(2) When the period specified for compliance is a standard calendar period, if the initial compliance date occurs after the beginning of the period, compliance shall be required according to the schedule specified in the following paragraphs, as appropriate:

(i) Compliance shall be required before the end of the standard calendar period within which the compliance deadline occurs if there remain at least 3 days for tasks that must be performed weekly, at least 2 weeks for tasks that must be performed monthly, at least 1 month for tasks that must be performed each quarter, or at least 3 months for tasks that must be performed annually; or

(ii) In all other cases, compliance shall be required before the end of the first full standard calendar period after the period within which the initial compliance deadline occurs.

(3) In all instances where a provision requires completion of a task during each of multiple successive periods, an owner or operator may perform the required task at any time during the specified period provided the task is conducted at a reasonable interval after completion of the task during the previous period.

[65 FR 78285, Dec. 14, 2000, as amended at 71 FR 20471, Apr. 20, 2006]

§65.4 Recordkeeping.

(a) Maintaining notifications, records, and reports. Except as provided in paragraph (b) of this section, the owner or operator of each regulated source subject to this part shall keep copies of notifications, reports, and records required by this part for the length of time specified in the following, as applicable:

(1) If an owner or operator is required to obtain or operate a regulated source under a title V permit, then all applicable notifications, reports, and records for that regulated source shall be maintained for at least 5 years, except for the records required in §65.47(b) for storage vessel capacity, §65.104(e)(2) for valve and connector monitoring, and §65.163(d)(1) for closed vent system design specifications.

(2) If an owner or operator is not required to obtain or operate a regulated source under a title V permit, then all notifications, reports, and records for that regulated source required by this part shall be maintained for at least 2 years, except for the records required in §65.47(b) for storage vessel capacity, §65.104(e)(2) for valve and connector monitoring, and §65.163(d)(1) for closed vent system design specifications.

(b) Copies of reports. If an owner or operator submits reports to the applicable EPA Regional Office, the owner or operator is not required to maintain copies of those reports. If the EPA Regional Office has waived the requirement of §65.5(g)(1) for submittal of copies of reports, the owner or operator is not required to maintain copies of the waived reports. Paragraph (b) of this section applies only to reports and not the underlying records which must be maintained as specified throughout this part.

(c) Availability of records. All applicable records shall be maintained in such a manner that they can be readily accessed and are suitable for inspection as specified in the following:

(1) Except as specified in paragraph (c)(2) of this section, records of the most recent 2 years shall be retained onsite or shall be accessible to an inspector while onsite. The records of the remaining 3 years, where required, may be retained offsite.

(2) For sources referenced to this part from 40 CFR part 63, subpart G or H, the most recent 6 months of records shall be retained on site or shall be accessible to an inspector while onsite from a central location by computer or other means that provides access within 2 hours after a request. The remaining 4 and one-half years of records, where required, may be retained offsite.

(3) Records specified in paragraph (c)(1) or (2) of this section may be maintained in hard copy or computer-readable form including, but not limited to, on paper, microfilm, computer, computer disk, magnetic tape, or microfiche.

§65.5 Reporting requirements.

(a) Required reports. Each owner or operator of a regulated source subject to this subpart shall submit the following reports, as applicable:

(1) A Notification of Initial Startup described in paragraph (b) of this section.

(2) An Initial Notification for Part 65 Applicability described in paragraph (c) of this section.

(3) An Initial Compliance Status Report described in paragraph (d) of this section.

(4) Periodic reports described in paragraph (e) of this section.

(5) Other reports shall be submitted as specified elsewhere in this part.

(6) Startup, Shutdown, and Malfunction Reports described in §65.6(c).

(b) Notification of Initial Startup— (1) Contents. Any owner or operator of a regulated source which elects to comply with this part at initial startup shall send the Administrator written notification of the actual date of initial startup of a regulated source.

(2) Due date. The notification of the actual date of initial startup shall be postmarked within 15 days after such date.

(c) Initial Notification for Part 65 Applicability. Owners or operators of regulated sources that have been subject to a 40 CFR part 60, 61, or 63 standard, and who wish to comply with this part, and who are not operating the regulated source under an approved title V permit shall notify the Administrator of their intent. The notice shall include the information specified in paragraphs (c)(1) through (7) of this section, as applicable, and may accompany the application for a construction permit for the regulated source. This notification may be waived by the Administrator.

(1) Identification of the storage vessels subject to subpart C of this part.

(2) Identification of the process vents subject to subpart D of this part, including process vent group status as specified in §65.62(a).

(3) Identification of the process vents subject to 40 CFR part 60, subpart DDD, complying with requirements of subpart G of this part.

(4) Identification of the transfer racks subject to subpart E of this part.

(5) For equipment leaks, identification of the process units subject to subpart F of this part.

(6) The proposed implementation schedule specified in §65.1(f)(1) for sources identified in paragraphs (c)(1) through (5) of this section.

(7) Process unit identification. As an alternative to requirements specified in paragraphs (c)(1) through (4) of this section, the process units can be identified instead of the individual pieces of equipment. For this alternative, the kind of emission point in the process unit that will comply must also be identified.

(d) Initial Compliance Status Report—(1) Contents. The owner or operator shall submit an Initial Compliance Status Report for each regulated source subject to this part containing the information specified in the subparts of this part. Unless the required information has already been submitted under requirements of the applicable referencing subpart, this information can be submitted as part of a title V permit application or amendment.

(2) Due date. The owner or operator shall submit the Initial Compliance Status Report for each regulated source within 240 days after the applicable compliance date specified in the referencing subparts, or within 60 days after the completion of the initial performance test or initial compliance determination, whichever is earlier. Initial compliance Status Reports may be combined for multiple regulated sources as long as the due date requirements for all sources covered in the combined report are met.

(e) Periodic reports. The owner or operator of a source subject to monitoring requirements of this part or to other requirements of this part where periodic reporting is specified, shall submit a periodic report.

(1) Contents. Periodic reports shall include all information specified in subparts of this part.

(2) Due date. The periodic report shall be submitted semiannually no later than 60 calendar days after the end of each 6-month period. The first report shall be submitted as specified in the following, as applicable:

(i) The first report shall be submitted no later than the last day of the month that includes the date 8 months after the date the source became subject to this part or since the last part 60, 61, or 63 periodic report was submitted for the applicable requirement, whichever is earlier.

(ii) For sources electing to comply with the CAR at initial startup, the first report shall cover the 6 months after the Initial Compliance Status Report is due. The first report shall be submitted no later than the last day of the month that includes the date 8 months after the Initial Compliance Status Report is due.

(3) Overlap with title V reports. Information required by this part, which is submitted with a title V periodic report, need not also be included in a subsequent periodic report required by this part. The title V report shall be referenced in the periodic report required by this part.

(f) General report content. All reports and notifications submitted pursuant to this part, including reports that combine information from this part and a referencing subpart, shall include the following information:

(1) The name, address, and telephone number (fax number may also be provided) of the owner or operator.

(2) The name, address and telephone number of the person to whom inquiries should be addressed, if different than the owner/operator.

(3) The address (physical location) of the reporting facility.

(4) Identification of each regulated source covered in the submission and identification of which subparts (referencing subparts and this part 65) options from this part are applicable to that regulated source. Summaries and groupings of this information are permitted.

(g) Report and notification submission — (1) Submission. All reports and notifications required under this part shall be sent to the Administrator at the appropriate EPA Regional Office and to the delegated State authority, except that requests for permission to use an alternative means of emission limitation as provided for in §65.8(a) shall be submitted to the Director of the EPA Office of Air Quality Planning and Standards, U.S. Environmental Protection Agency, MD-10, Research Triangle Park, North Carolina, 27711. The EPA Regional Office may waive the requirement to receive a copy of any reports or notifications at its discretion.

(2) Submission of copies. If any State requires a notice that contains all the information required in a report or notification listed in this part, an owner or operator may send the appropriate EPA Regional Office a copy of the report or notification sent to the State to satisfy the requirements of this part for that report or notification.

(3) Method of submission. Wherever this subpart specifies “postmark” dates, submittals may be sent by methods other than the U.S. Mail (for example, by fax or courier). Submittals shall be sent on or before the specified date.

(4) Submission by electronic media. If acceptable to both the Administrator and the owner or operator of a source, reports may be submitted on electronic media.

(h) Adjustment to timing of submittals and review of required communications — (1) Alignment with title V submission. An owner or operator may submit periodic reports required by this part on the same schedule as the title V periodic report for the facility. The owner or operator using this option need not obtain prior approval, but must assure no reporting gaps from the last periodic report for the relevant standards. The owner or operator shall clearly identify the change in reporting schedule in the first report filed under paragraph (h) of this section. The requirements of paragraph (e) of this section are not waived when implementing this change.

(2) Request for adjustment. An owner or operator may arrange by mutual agreement (which may be a standing agreement) with the Administrator a common schedule on which periodic reports required by this part shall be submitted throughout the year as long as the reporting period is not extended. An owner or operator who wishes to request a change in a time period or postmark deadline for a particular requirement shall request the adjustment in writing as soon as practical before the subject activity is required to take place. The owner or operator shall include in the request whatever information he or she considers useful to convince the Administrator that an adjustment is warranted. A request for a change to the periodic reporting schedule need only be made once for every schedule change and not once for every semiannual report submitted.

(3) Approval of request for adjustment. If, in the Administrator's judgment, an owner or operator's request for an adjustment to a particular time period or postmark deadline is warranted, the Administrator will approve the adjustment. The Administrator will notify the owner or operator in writing of approval or disapproval of the request for an adjustment within 15 calendar days of receiving sufficient information to evaluate the request.

(4) Notification of delay. If the Administrator is unable to meet a specified deadline, the owner or operator will be notified of any significant delay and informed of the amended schedule.

(i) Unless already submitted in a previous report, an owner or operator shall report in a title V permit application or as otherwise specified by the permitting authority, the information listed in paragraphs (i)(1) through (5) of this section. This information shall be submitted to the Administrator if the regulated source is not a title V source.

(1) A list designating each emission point complying with subparts C through G of this part and whether each process vent is Group 1, Group 2A, or Group 2B.

(2) The control technology or method of compliance that will be applied to each emission point.

(3) A statement that the compliance demonstration, monitoring, inspection, recordkeeping, and reporting provisions in subparts C through G of this part that are applicable to each emission point will be implemented beginning on the date of compliance as specified in the referencing subpart.

(4) The monitoring information in §65.162(e) if, for any emission point, the owner or operator of a source seeks to comply through use of a control technique other than those for which monitoring parameters are specified in §§65.148 through 65.154.

(5) Any requests for alternatives to the continuous operating parameter monitoring and recordkeeping provisions, as specified in §65.162(d).

§65.6 Startup, shutdown, and malfunction plan and procedures.

(a) Paragraphs (b) and (c) of this section do not apply to Group 2A or Group 2B process vents.

(b) Startup, shutdown, and malfunction plan — (1) Description and purpose of plan. The owner or operator of a regulated source shall develop a written startup, shutdown, and malfunction plan that describes, in detail, procedures for operating and maintaining the regulated source during periods of startup, shutdown, and malfunction and a program of corrective action for malfunctioning process and air pollution control equipment used to comply with the relevant standard. The plan shall also address routine or otherwise predictable CPMS malfunctions. This plan shall be developed by the owner or operator by the regulated source's implementation date as specified in §65.1(f), or for sources referenced from 40 CFR part 63, subpart F, by the compliance date specified in that subpart. The requirement to develop this plan shall be incorporated into the source's title V permit. This requirement is optional for equipment that must comply with subpart F of this part. It is not optional for equipment equipped with a closed vent system and control device subject to subpart G of this part. The purposes of the startup, shutdown, and malfunction plan are described in the following:

(i) To ensure that owners or operators are prepared to correct malfunctions as soon as practical after their occurrence in order to minimize excess emissions of regulated material (excess emissions are defined in §65.3(a)(4)); and

(ii) To reduce the reporting burden associated with periods of startup, shutdown, and malfunction (including corrective action taken to restore malfunctioning process and air pollution control equipment to its normal or usual manner of operation).

(2) Operation of source. During periods of startup, shutdown, and malfunction, the owner or operator of a regulated source shall operate and maintain such source (including associated air pollution control equipment and CPMS) in accordance with §65.3(a). The general duty to minimize emissions during a period of startup, shutdown, or malfunction does not require the owner or operator to achieve emission levels that would be required by the applicable standard at other times if this is not consistent with safety and good air pollution control practices, nor does it require the owner or operator to make any further efforts to reduce emissions if levels required by the applicable standard have been achieved. Determination of whether such operation and maintenance procedures are being used will be based on information available to the Administrator which may include, but is not limited to, monitoring results, review of operation and maintenance procedures (including the startup, shutdown, and malfunction plan required in paragraph (b)(1) of this section), review of operation and maintenance records, and inspection of the source.

(3) Use of additional procedures. To satisfy the requirements of this section to develop a startup, shutdown, and malfunction plan, the owner or operator may use the regulated source's standard operating procedures (SOP) manual, or an Occupational Safety and Health Administration (OSHA) or other plan, provided the alternative plans meet all the requirements of this section and are made available for inspection when requested by the Administrator.

(4) Revisions to the plan. Based on the results of a determination made under §65.3(b)(3), the Administrator may require that an owner or operator of a regulated source make changes to the startup, shutdown, and malfunction plan for that source. The Administrator may require reasonable revisions to a startup, shutdown, and malfunction plan, if the Administrator finds that the plan is inadequate as specified in the following:

(i) Does not address a startup, shutdown, and malfunction event of the CPMS, the air pollution control equipment, or the regulated source that has occurred; or

(ii) Fails to provide for the operation of the regulated source (including associated air pollution control equipment and CPMS) during a startup, shutdown, and malfunction event in a manner consistent with good air pollution control practices for minimizing emissions to the extent practical; or

(iii) Does not provide adequate procedures for correcting malfunctioning process and/or air pollution control equipment as quickly as practicable; or

(iv) Does not provide adequate measures to prevent or minimize excess emissions to the extent practical as specified and defined in §65.3(a)(4).

(5) Additional malfunction plan requirements. If the startup, shutdown, and malfunction plan fails to address or inadequately addresses an event that meets the characteristics of a malfunction but was not included in the startup, shutdown, and malfunction plan at the time the owner or operator developed the plan, the owner or operator shall revise the startup, shutdown, and malfunction plan within 45 days after the event to include detailed procedures for operating and maintaining the regulated source during similar malfunction events, and a program of corrective action for similar malfunctions of process or air pollution control equipment or CPMS.

(6) Retain plan on site. The current plan must be kept on site at all times.

(c) Periodic startup, shutdown, and malfunction reports. During the reporting period, reports shall only be required for startup, shutdown, and malfunction during which excess emissions as defined in §65.3(a)(4) occur. A startup, shutdown, and malfunction report can be submitted as part of a periodic report required under §65.5(e), or on a more frequent basis if specified otherwise in a relevant standard or as established otherwise by the permitting authority in the source's title V permit. The startup, shutdown, and malfunction report shall be delivered or postmarked by the 30th day following the end of each calendar half (or other calendar reporting period, as appropriate), unless the information is submitted with the periodic report. The report shall include the following information, as appropriate:

(1) The name, title, and signature of the owner or operator or other responsible official certifying its accuracy.

(2) The number of startup, shutdown, malfunction events and the total duration of all periods of startup, shutdown, and malfunction for the reporting period.

(3) If actions taken by an owner or operator during a startup, shutdown, and malfunction of a regulated source, or of a control device or monitoring system required for compliance (including actions taken to correct a malfunction) are consistent with the procedures specified in the source's startup, shutdown, and malfunction plan, then the owner or operator shall state such information in a startup, shutdown, and malfunction report, and describe the actions taken. Such description can take the form of a checklist; only one checklist is necessary if actions taken are the same for multiple events during the reporting period.

(4) If at any time an action taken by an owner or operator, during a startup, shutdown, or malfunction (including actions taken to correct a malfunction) during which excess emissions occur, as defined in §65.3(a)(4), is not consistent with the procedures specified in the regulated source's startup, shutdown, and malfunction plan, the owner or operator shall report the actions taken for that event as part of the periodic report. The report shall explain the circumstances of the event, the reasons for not following the startup, shutdown, and malfunction plan, and whether any excess emissions and/or parameter monitoring exceedances are believed to have occurred.

[65 FR 78285, Dec. 14, 2000, as amended at 71 FR 20471, Apr. 20, 2006]

§65.7 Monitoring, recordkeeping, and reporting waivers and alternatives, and alternative work practice for equipment leaks.

(a) Waiver of recordkeeping or reporting requirements — (1) Waiver application. The owner or operator may apply for a waiver from recordkeeping or reporting requirements if the regulated source is achieving the relevant standard(s), or the source is operating under an extension of compliance under 40 CFR 63.6(i), or a waiver of compliance under 40 CFR 61.10(b), or the owner or operator has requested an extension or waiver of compliance and the Administrator is still considering that request. The waiver application shall be submitted in writing to the Administrator.

(2) Extension of compliance request. If an application for a waiver of recordkeeping or reporting is made, the application shall accompany the request for an extension of compliance under 40 CFR 63.6(i) or the request for a waiver of compliance under 40 CFR 61.10(b), any required compliance progress report or compliance status report required in the source's title V permit application or a permit modification application, or a periodic report required under this part, whichever is applicable. The application shall include whatever information the owner or operator considers useful to convince the Administrator that a waiver of recordkeeping or reporting is warranted.