['Air Programs']

['Hazardous Air Pollutants']

02/25/2022

...

§61.300 Applicability.

(a) The affected facility to which this subpart applies is the total of all loading racks at which benzene is loaded into tank trucks, railcars, or marine vessels at each benzene production facility and each bulk terminal. However, specifically exempted from this regulation are loading racks at which only the following are loaded: Benzene-laden waste (covered under subpart FF of this part), gasoline, crude oil, natural gas liquids, petroleum distillates (e.g., fuel oil, diesel, or kerosene), or benzene-laden liquid from coke by-product recovery plants.

(b) Any affected facility under paragraph (a) of this section which loads only liquid containing less than 70 weight-percent benzene is exempt from the requirements of this subpart, except for the recordkeeping and reporting requirements in §61.305(i).

(c) Comply with standards at each loading rack. Any affected facility under paragraph (a) of this section shall comply with the standards in §61.302 or as specified in paragraph (f) of this section, if applicable, at each loading rack that is handling a liquid containing 70 weight-percent or more benzene.

(d) Any affected facility under paragraph (a) of this section whose annual benzene loading is less than 1.3 million liters of 70 weight-percent or more benzene is exempt from the requirements of this subpart, except for the recordkeeping and reporting requirements in §61.305(i).

(e) The owner or operator of an affected facility, as defined in §61.300(a) that loads a marine vessel shall be in compliance with the provisions of this subpart on and after July 23, 1991. If an affected facility that loads a marine vessel also loads a tank truck or railcar, the marine vessel loading racks shall be in compliance with the provisions of this subpart on and after July 23, 1991, while the tank truck loading racks and the railcar loading racks shall be in compliance as required by §61.12.

(f) Alternative means of compliance - (1) Option to comply with part 65. Owners or operators may choose to comply with 40 CFR part 65, subpart E, to satisfy the requirements of §§61.302 through 61.306 for all tank truck or railcar loading racks that are subject to this subpart. Loading racks are referred to as transfer racks in 40 CFR part 65, subpart E. Other provisions applying to owners or operators who choose to comply with 40 CFR part 65 are provided in 40 CFR 65.1. All marine vessel loading racks shall comply with the provisions in §§61.302 through 61.306.

(2) Part 61, subpart A. Owners or operators who choose to comply with 40 CFR part 65, subpart E, must also comply with §§61.01, 61.02, 61.05 through 61.08, 61.10(b) through (d), 61.11, and 61.15 for those loading racks. All sections and paragraphs of subpart A of this part that are not mentioned in this paragraph (f)(2) do not apply to owners or operators of loading racks complying with 40 CFR part 65, subpart E, except that provisions required to be met prior to implementing 40 CFR part 65 still apply. Owners and operators who choose to comply with 40 CFR part 65, subpart E, must comply with 40 CFR part 65, subpart A.

[55 FR 8341, Mar. 7, 1990, as amended at 55 FR 45804, Oct. 31, 1990; 65 FR 78284, Dec. 14, 2000]

§61.301 Definitions.

As used in this subpart, all terms not defined herein shall have the meaning given them in the Act, or in subpart A or subpart V of part 61.

Bulk terminal means any facility which receives liquid product containing benzene by pipelines, marine vessels, tank trucks, or railcars, and loads the product for further distribution into tank trucks, railcars, or marine vessels.

Car-sealed means having a seal that is placed on the device used to change the position of a valve (e.g., from open to closed) such that the position of the valve cannot be changed without breaking the seal and requiring the replacement of the old seal, once broken, with a new seal.

Control device means all equipment used for recovering or oxidizing benzene vapors displaced from the affected facility.

Incinerator means any enclosed combustion device that is used for destroying organic compounds and that does not extract energy in the form of steam or process heat. These devices do not rely on the heating value of the waste gas to sustain efficient combustion. Auxiliary fuel is burned in the device and the heat from the fuel flame heats the waste gas to combustion temperature. Temperature is controlled by controlling combustion air or fuel.

Leak means any instrument reading of 10,000 ppmv or greater using Method 21 of 40 CFR part 60, appendix A.

Loading cycle means the time period from the beginning of filling a tank truck, railcar, or marine vessel until flow to the control device ceases, as measured by the flow indicator.

Loading rack means the loading arms, pumps, meters, shutoff valves, relief valves, and other piping and valves necessary to fill tank trucks, railcars, or marine vessels.

Marine vessel means any tank ship or tank barge which transports liquid product such as benzene.

Nonvapor tight means any tank truck, railcar, or marine vessel that does not pass the required vapor-tightness test.

Process heater means a device that transfers heat liberated by burning fuel to fluids contained in tubes, except water that is heated to produce steam.

Steam generating unit means any enclosed combustion device that uses fuel energy in the form of steam.

Vapor collection system means any equipment located at the affected facility used for containing benzene vapors displaced during the loading of tank trucks, railcars, or marine vessels. This does not include the vapor collection system that is part of any tank truck, railcar, or marine vessel vapor collection manifold system.

Vapor-tight marine vessel means a marine vessel with a benzene product tank that has been demonstrated within the preceding 12 months to have no leaks. This demonstration shall be made using Method 21 of part 60, appendix A, during the last 20 percent of loading and during a period when the vessel is being loaded at its maximum loading rate. A reading of greater than 10,000 ppm as methane shall constitute a leak. As an alternative, a marine vessel owner or operator may use the vapor-tightness test described in §61.304(f) to demonstrate vapor tightness. A marine vessel operated at negative pressure is assumed to be vapor-tight for the purpose of this standard.

Vapor-tight tank truck or vapor-tight railcar means a tank truck or railcar for which it has been demonstrated within the preceding 12 months that its product tank will sustain a pressure change of not more than 750 pascals within 5 minutes after it is pressurized to a minimum of 4,500 pascals. This capability is to be demonstrated using the pressure test procedure specified in Method 27 of appendix A to 40 CFR part 60, and a pressure measurement device which has a precision of ±2.5 mm water and which is capable of measuring above the pressure at which the tank truck or railcar is to be tested for vapor tightness.

[55 FR 8341, Mar. 7, 1990, as amended at 65 FR 62159, Oct. 17, 2000]

§61.302 Standards.

(a) The owner or operator of an affected facility shall equip each loading rack with a vapor collection system that is:

(1) Designed to collect all benzene vapors displaced from tank trucks, railcars, or marine vessels during loading, and

(2) Designed to prevent any benzene vapors collected at one loading rack from passing through another loading rack to the atmosphere.

(b) The owner or operator of an affected facility shall install a control device and reduce benzene emissions routed to the atmosphere through the control device by 98 weight percent. If a boiler or process heater is used to comply with the percent reduction requirement, then the vent stream shall be introduced into the flame zone of such a device.

(c) The owner or operator of an affected facility shall operate any flare used to comply with paragraph (b) of this section in accordance with the requirements of §60.18 (b) through (f).

(d) The owner or operator of an affected facility shall limit loading of benzene into vapor-tight tank trucks and vapor-tight railcars using the following procedures:

(1) The owner or operator shall obtain the vapor-tightness documentation described in §61.305(h) for each tank truck or railcar loaded at the affected facility. The test date in the documentation must be within the preceding 12 months. The vapor-tightness test to be used for tank trucks and railcars is Method 27 of appendix A to 40 CFR part 60.

(2) The owner or operator shall cross-check the identification number for each tank truck or railcar to be loaded with the file of vapor-tightness documentation before the corresponding tank truck or railcar is loaded. If no documentation is on file, the owner or operator shall obtain a copy of the information from the tank truck or railcar operator before the tank truck or railcar is loaded.

(3) Alternate procedures to those described in paragraphs (d)(1) and (d)(2) of this section may be used upon application to, and approval by, the Administrator.

(e) The owner or operator of an affected facility shall limit the loading of marine vessels to those vessels that are vapor tight as determined by either paragraph (e)(1), (e)(2), (e)(3), or (e)(4) of this section.

(1) The owner or operator of an affected facility shall ensure that each marine vessel is loaded with the benzene product tank below atmospheric pressure (i.e., at negative pressure). If the pressure is measured at the interface between the shoreside vapor collection pipe and the marine vessel vapor line, the pressure measured according to the procedures in §61.303(f) must be below atmospheric pressure.

(2) The owner or operator of an affected facility shall use the following procedure to obtain the vapor-tightness documentation described in §61.305(h). The vapor-tightness test for marine vessels is Method 21 of appendix A to 40 CFR part 60, and shall be applied to any potential sources of vapor leaks. A reading of 10,000 ppmv or greater as methane shall constitute a leak.

(i) The owner or operator of an affected facility shall obtain the leak test documentation described in §61.305(h) for each marine vessel prior to loading, if available. The date of the test listed in the documentation must be within the 12 preceding months.

(ii) If there is no documentation of a successful leak test conducted on the marine vessel in the preceding 12 months, the owner or operator of an affected facility shall require that a leak test of the marine vessel be conducted during the final 20 percent of loading of the marine vessel or shall not load the vessel. The test shall be conducted when the marine vessel is being loaded at the maximum allowable loading rate.

(A) If no leak is detected, the owner or operator of an affected facility shall require that the documentation described in §61.305(h) is completed prior to departure of the vessel. The owner or operator of the affected facility shall retain a copy of the vapor-tightness documentation on file.

(B) If any leak is detected, the owner or operator of an affected facility shall require that the vapor-tightness failure be documented for the marine vessel owner or operator prior to departure of the vessel. The owner or operator of the affected facility shall retain a copy of the vapor-tightness documentation on file. Delay of repair of equipment for which leaks have been detected will be allowed if the repair is technically infeasible without dry-docking the vessel. This equipment will be excluded from future Method 21 of appendix A to 40 CFR part 60 tests until repairs are effected. Repair of this equipment shall occur the next time the vessel is dry-docked.

(iii) If the marine vessel has failed its most recent vapor-tightness test as described in §61.302(e)(2)(ii), the owner or operator of the affected facility shall require that the owner or operator of the nonvapor-tight marine vessel provide documentation that the leaks detected during the previous vapor-tightness test have been repaired, or proof that repair is technically infeasible without dry-docking the vessel. Once the repair documentation has been provided, the owner or operator may load the marine vessel. The owner or operator shall require that the vapor-tightness test described in §61.302(e)(2)(ii) be conducted during loading, and shall retain a copy of the vapor-tightness documentation on file.

(3) The owner or operator of an affected facility shall obtain a copy of the marine vessel's vapor-tightness documentation described in §61.305(h) for a test conducted within the preceding 12 months in accordance with §61.304(f).

(4) Alternate procedures to those described in paragraphs (e)(1), (e)(2) and (e)(3) of this section may be used upon application to, and approval by, the Administrator.

(f) The owner or operator of an affected facility shall limit loading of benzene to tank trucks, railcars, and marine vessels equipped with vapor collection equipment that is compatible with the affected facility's vapor collection system.

(g) The owner or operator of an affected facility shall limit loading of tank trucks, railcars, and marine vessels to tank trucks, railcars, and marine vessels whose collection systems are connected to the affected facility's vapor collection systems.

(h) The owner or operator of an affected facility shall ensure that the vapor collection and benzene loading equipment of tank trucks and railcars shall be designed and operated to prevent gauge pressure in the tank truck or railcar tank from exceeding, during loading, the initial pressure the tank was pressured up to and shown to be vapor tight at during the most recent vapor-tightness test using Method 27 of appendix A to 40 CFR part 60. This vapor-tightness test pressure is not to be exceeded when measured by the procedures specified in §61.304(c).

(i) The owner or operator of an affected facility shall ensure that no pressure-vacuum vent in the affected facility's vapor collection system for tank trucks and railcars shall begin to open at a system pressure less than the maximum pressure at which the tank truck or railcar is operated.

(j) The owner or operator of an affected facility shall ensure that the maximum normal operating pressure of the marine vessel's vapor collection equipment shall not exceed 0.8 times the relief set pressure of the pressure-vacuum vents. This level is not to be exceeded when measured by the procedures specified in §61.304(d).

(k) The owner or operator of an affected facility shall inspect the vapor collection system and the control device for detectable emissions, and shall repair any leaks detected, in accordance with §61.242-11 (e) and (f). This inspection of the vapor collection system and control device shall be done during the loading of tank trucks, railcars, or marine vessels.

(l) Vent systems that contain valves that could divert a vent stream from a control device shall have car-sealed opened all valves in the vent system from the emission source to the control device, and car-sealed closed all valves in the vent system that would lead the vent stream to the atmosphere, either directly or indirectly, bypassing the control device.

[55 FR 8341, Mar. 7, 1990, as amended at 65 FR 62159, Oct. 17, 2000]

§61.303 Monitoring requirements.

(a) Each owner or operator of an affected facility that uses an incinerator to comply with the percent reduction requirement specified under §61.302(b) shall install, calibrate, maintain, and operate according to manufacturer's specifications a temperature monitoring device equipped with a continuous recorder and having an accuracy of ±1 percent of the combustion temperature being measured expressed in degrees Celsius or ±0.5°C, whichever is greater.

(1) Where an incinerator other than a catalytic incinerator is used, the owner or operator of the affected facility shall install a temperature monitoring device in the firebox.

(2) Where a catalytic incinerator is used, the owner or operator shall install temperature monitoring devices in the gas stream immediately before and after the catalyst bed.

(b) Each owner or operator of an affected facility that uses a flare to comply with §61.302(b) shall install, calibrate, maintain, and operate according to manufacturer's specifications a heat sensing device, such as an ultraviolet beam sensor or thermocouple, at the pilot light to indicate the presence of a flame during the entire loading cycle.

(c) Each owner or operator of an affected facility that uses a steam generating unit or process heater to comply with §61.302(b) shall comply with the following requirements. Where a steam generating unit with a design heat input capacity of less than 44 MW (150 × 10 6 BTU/hr) is used to comply with §61.302(b), the owner or operator of an affected facility shall comply with paragraph (c)(1) of this section. Where a steam generating unit or process heater with a design heat input capacity of 44 MW (150 × 10 6 BTU/hr) or greater is used to comply with §61.302(b), the owner or operator of an affected facility shall comply with paragraph (c)(2) of this section.

(1) Install in the firebox, calibrate, maintain, and operate according to manufacturer's specifications a temperature monitoring device equipped with a continuous recorder and having an accuracy of ±1 percent of the temperature being measured expressed in degrees Celsius or ±0.5°C, whichever is greater, for steam generating units or process heaters of less than 44 MW (150 × 10 6 BTU/hr) design heat input capacity.

(2) Monitor and record the periods of operation of the steam generating units or process heater if the design heat input capacity of the steam generating unit or process heater is 44 MW (150 × 10 6 BTU/hr) or greater. The records must be readily available for inspection.

(d) Each owner or operator of an affected facility that uses a carbon adsorption system to comply with the percent reduction requirement specified under §61.302(b) shall install, calibrate, maintain, and operate according to manufacturer's specifications a device that continuously indicates and records the concentration or reading of organic compounds in the outlet gas stream of each carbon adsorber bed.

(e) The owner or operator of an affected facility who wishes to demonstrate compliance with the standards specified under §61.302(b) using control devices other than an incinerator, steam generating unit, process heater, carbon adsorber, or flare shall provide the Administrator with information describing the operation of the control device and the process parameter(s) that would indicate proper operation and maintenance of the device. The Administrator may request further information and will specify appropriate monitoring procedures or requirements.

(f) Each owner or operator of an affected facility complying with §61.302(e)(1) shall install, calibrate, maintain, and operate a recording pressure measurement device (magnehelic gauge or equivalent device) and an audible and visible alarm system that is activated when the pressure vacuum specified in §61.302(e)(1) is not attained. The owner or operator shall place the alarm system so that it can be seen and heard where cargo transfer is controlled and on the open deck.

(g) Owners or operators using a vent system that contains valves that could divert a vent stream from a control device used to comply with the provisions of this subpart shall do one or a combination of the following:

(1) Install a flow indicator immediately downstream of each valve that if opened would allow a vent stream to bypass the control device and be emitted, either directly or indirectly, to the atmosphere. The flow indicator shall be capable of recording flow at least once every 15 minutes.

(2) Monitor the valves once a month, checking the position of the valves and the condition of the car seal, and identify all times when the car seals have been broken and the valve position has been changed (i.e., from opened to closed for valves in the vent piping to the control device and from closed to open for valves that allow the stream to be vented directly or indirectly to the atmosphere).

[55 FR 8341, Mar. 7, 1990, as amended at 65 FR 62159, Oct. 17, 2000]

§61.304 Test methods and procedures.

(a) The procedures for determining compliance with §61.302(b) for all control devices other than flares is as follows:

(1) All testing equipment shall be prepared and installed as specified in the appropriate test methods.

(2) The time period for a performance test shall be not less than 6 hours, during which at least 300,000 liters of benzene are loaded. If the throughput criterion is not met during the initial 6 hours, the test may be either continued until the throughput criterion is met, or resumed the next day with at least another 6 complete hours of testing.

(3) For intermittent control devices:

(i) The vapor holder level of the intermittent control device shall be recorded at the start of the performance test. The end of the performance test shall coincide with the time when the vapor holder is at its original level.

(ii) At least two startups and shutdowns of the control device shall occur during the performance test. If this does not occur under an automatically controlled operation, the system shall be manually controlled.

(4) An emission testing interval shall consist of each 5-minute period during the performance test. For each interval:

(i) The reading from each measurement instrument shall be recorded.

(ii) Method 1 or 1A of part 60, appendix A, as appropriate, shall be used for selection of the sampling site,

(iii) The volume exhausted shall be determined using Method 2, 2A, 2C, or 2D of part 60, appendix A, as appropriate.

(iv) The average benzene concentration upstream and downstream of the control device in the vent shall be determined using Method 25A or Method 25B of appendix A of this part, using benzene as the calibration gas. The average benzene concentration shall correspond to the volume measurement by taking into account the sampling system response time.

(5) The mass emitted during each testing interval shall be calculated as follows:

Mi = FKVS C

where:

Mi = Mass of benzene emitted during testing interval i, kg.

Vs = Volume of air-vapor mixture exhausted, m 3 at standard conditions.

C = Benzene concentration (as measured) at the exhaust vent, ppmv.

K = Density, (kg/m 3 benzene), standard conditions.

K = 3.25 for benzene.

F = Conversion factor, (m 3 benzene/m 3 air)(1/ppmv).

F = 10/?6/.

s = Standard conditions, 20°C and 760 mm Hg.

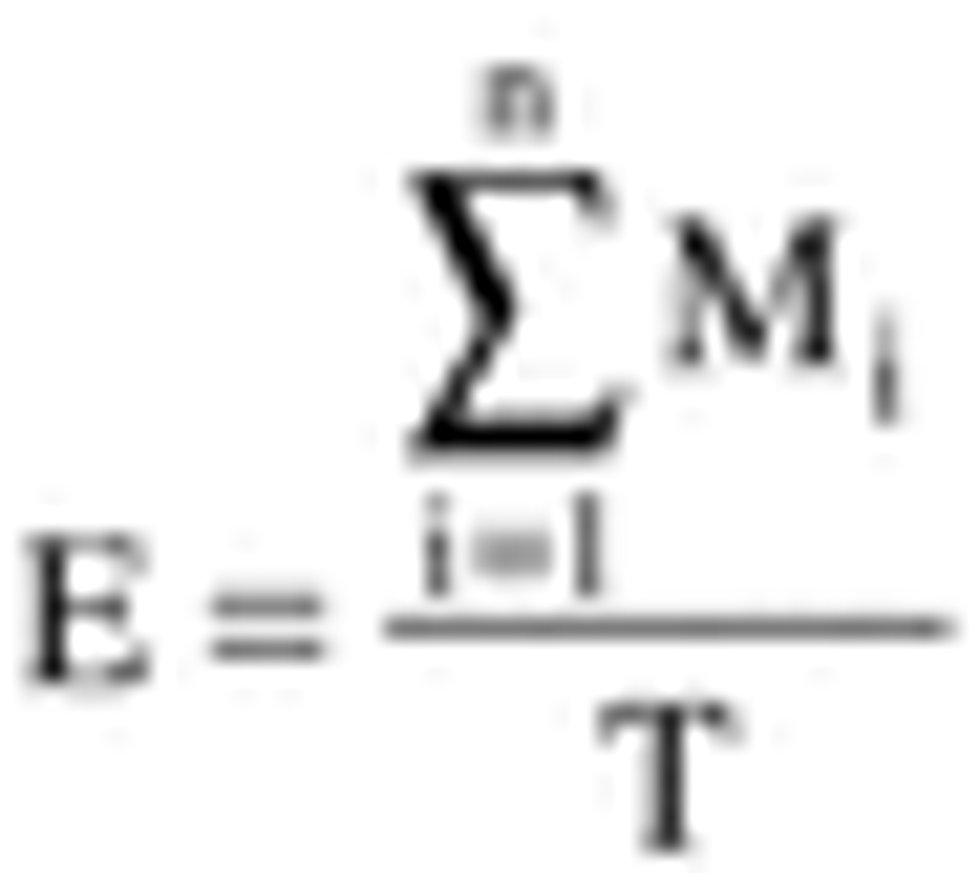

(6) The benzene mass emission rates before and after the control device shall be calculated as follows:

where:

E = Mass flow rate of benzene emitted, kg/hr.

Mi = Mass of benzene emitted during testing interval i, kg.

T = Total time of all testing intervals, hr.

n = Number of testing intervals.

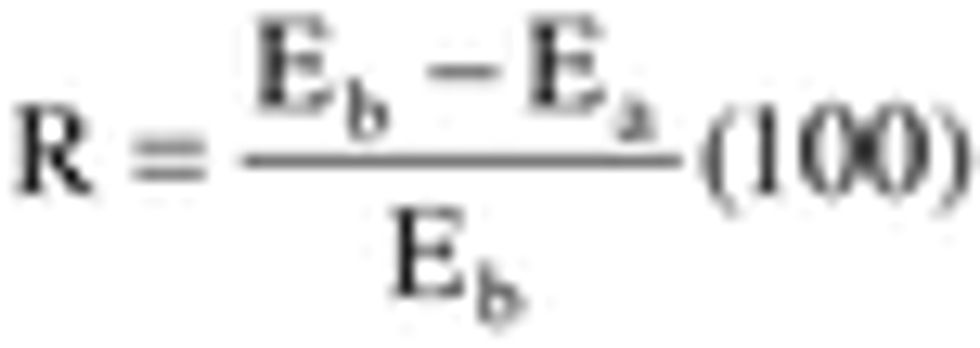

(7) The percent reduction across the control device shall be calculated as follows:

where:

R = Control efficiency of control device, %.

Eb = Mass flow rate of benzene prior to control device, kg/hr.

Ea = Mass flow rate of benzene after control device, kg/hr.

(b) When a flare is used to comply with §61.302(b), a performance test according to Method 22 of appendix A of 40 CFR part 60 shall be performed to determine visible emissions. The observation period shall be at least 2 hours. Performance testing shall be conducted during at least three complete loading cycles with a separate test run for each loading cycle. The observation period for detecting visible emissions shall encompass each loading cycle. Integrated sampling to measure process vent stream flow rate shall be performed continuously during each loading cycle.

(c) For the purpose of determining compliance with §61.302(h), the following procedures shall be used:

(1) Calibrate and install a pressure measurement device (liquid manometer, magnehelic gauge, or equivalent instrument), which has a precision of ±2.5 mm H20 in the range that the tank truck or railcar was initially pressured to during the most recent vapor-tightness test.

(2) Connect the pressure measurement device to a pressure tap in the affected facility's vapor collection system, located as close as possible to the connection with the tank truck or railcar.

(3) During the performance test, record the pressure every 5 minutes while a tank truck or railcar is being loaded, and record the highest instantaneous pressure that occurs during each loading cycle. Every loading rack shall be tested at least once during the performance test.

(4) If more than one loading rack is used simultaneously, then the performance test shall be conducted simultaneously to represent the maximum capacity.

(d) For the purpose of determining compliance with §61.302(j), the following procedures shall be used:

(1) Calibrate and install a pressure measurement device (liquid manometer, magnehelic gauge, or equivalent instrument), capable of measuring up to the relief set pressure of the pressure-vacuum vents.

(2) Connect the pressure measurement device to a pressure tap in the affected facility's vapor collection system, located as close as possible to the connection with the marine vessel.

(3) During the performance test, record the pressure every 5 minutes while a marine vessel is being loaded, and record the highest instantaneous pressure that occurs during each loading cycle.

(e) Immediately prior to a performance test required for determination of compliance with §61.302(b), all potential sources of vapor leakage in the affected facility's vapor collection system equipment shall be inspected for detectable emissions as required in §61.302(k). The monitoring shall be conducted only while a vapor-tight tank truck, railcar, or marine vessel is being loaded. All identified leaks in the terminal's vapor collection system shall be repaired prior to conducting the performance test.

(f) The following test method shall be used to comply with the marine vessel vapor-tightness requirements of §61.302(e)(3):

(1) Each benzene product tank shall be pressurized with dry air or inert gas to not less than 1.0 psig and not more than the pressure of the lowest relief valve setting.

(2) Once the pressure is obtained, the dry air or inert gas source shall be shut off.

(3) At the end of one-half hour, the pressure in the benzene product tank and piping shall be measured. The change in pressure shall be calculated using the following formula:

? P = Pi - Pf

where:

? P = Change in pressure, inches of water.

Pi = Pressure in tank when air/gas source is shut off, inches of water.

Pf = Pressure in tank at the end of one-half hour after air/gas source is shut off, inches of water.

(4) The change in pressure, ? P, shall be compared to the pressure drop calculated using the following formula:

? PM = 0.861 Pia L/V

where:

? PM = Maximum allowable pressure change, inches of water.

Pia = Pressure in tank when air/gas source is shut off, pounds per square inch, absolute (psia).

L = Maximum permitted loading rate of vessel, barrels per hour.

V = Total volume of product tank, barrels.

(5) If ?P??PM, the vessel is vapor tight.

(6) If ?P>?PM, the vessel is not vapor tight and the source of the leak must be identified and repaired prior to retesting.

[55 FR 8341, Mar. 7, 1990; 55 FR 12444, Apr. 3, 1990, as amended at 65 FR 62159, Oct. 17, 2000]

§61.305 Reporting and recordkeeping.

(a) Each owner or operator of an affected facility subject to the provisions of this subpart shall keep an up-to-date, readily accessible record of the following data measured during each performance test, and also include the following data in the report of the initial performance test required under §61.13. Where a steam generating unit or process heater with a design heat input capacity of 44 MW (150 × 10 6 BTU/hr) or greater is used to comply with §61.302(b), a report containing performance test data need not be submitted, but a report containing the information in §61.305(a)(3)(i) is required.

(1) Where an owner or operator subject to the provisions of this subpart is complying with §61.302(b) through use of an incinerator:

(i) The average firebox temperature of the incinerator (or the average temperature upstream and downstream of the catalyst bed), measured at least every 2 minutes during a loading cycle if the total time period of the loading cycle is less than 3 hours and every 15 minutes if the total time period of the loading cycle is equal to or greater than 3 hours. The measured temperature shall be averaged over the loading cycle.

(ii) The percent reduction of benzene determined as specified in §61.304(a) achieved by the incinerator.

(iii) The duration of the loading cycle.

(2) Where an owner or operator subject to the provisions of this subpart is complying with §61.302 (b) and (c) through use of a smokeless flare or other flare design (i.e., steam-assisted, air-assisted or nonassisted), all visible emission readings, heat content determination, flow rate measurements, maximum permitted velocity calculations, and exit velocity determinations made during the performance test, continuous records of the flare pilot flame monitoring measured continuously during the loading cycle, duration of all loading cycles and records of all loading cycles during which the pilot flame is absent for each vent stream.

(3) Where an owner or operator subject to the provisions of this subpart is complying with §61.302(b) through the use of a steam generating unit or process heater:

(i) A description of the location at which the vent stream is introduced into the steam generating unit or process heater.

(ii) The average combustion temperature of the steam generating unit or process heater with a design heat input capacity of less than 44 MW (150 × 10 6 BTU/hr), measured with the following frequency: at least every 2 minutes during a loading cycle if the total time period of the loading cycle is less than 3 hours, and every 15 minutes if the total time period of the loading cycle is equal to or greater than 3 hours. The measured temperature shall be averaged over the loading cycle.

(iii) The duration of the loading cycle.

(4) Where an owner or operator subject to the provisions of this subpart is complying with §61.302(b) through the use of a carbon adsorption system, the control efficiency, R, of the carbon adsorption system, and all supporting performance test data and calculations used to determine that value.

(5) Each owner or operator subject to the provisions of this subpart shall submit with the initial performance test an engineering report describing in detail the vent system used to vent each affected vent stream to a control device. This report shall include all valves and vent pipes that could vent the stream to the atmosphere, thereby bypassing the control device, and identify which valves are car-sealed opened and which valves are car-sealed closed.

(b) Each owner or operator subject to the provisions of this subpart shall keep up-to-date, readily accessible continuous records of the equipment operating parameters specified to be monitored under §61.303 (a), (c), and (d) as well as up-to-date, readily accessible records of periods of operation during which the parameter boundaries established during the most recent performance test are exceeded. The Administrator may at any time require a report of these data. Periods of operation during which the parameter boundaries established during the most recent performance tests are exceeded are defined as follows:

(1) For thermal incinerators, all loading cycles during which the average combustion temperature was more than 28°C (50°F) below the average loading cycle combustion temperature during the most recent performance test at which compliance with §61.302(b) was determined.

(2) For catalytic incinerators, all loading cycles during which the average temperature of the vent stream immediately before the catalyst bed is more than 28°C (50°F) below the average temperature of the process vent stream during loading cycles during the most recent performance test at which compliance with §61.302(b) was determined.

(3) All loading cycles during which the average combustion temperature was more than 28°C (50°F) below the average combustion temperature during the most recent performance test at which compliance with §61.302(b) was determined for steam generating units or process heaters with a design heat input capacity of less than 44 MW (150 × 10 6 BTU/hr).

(4) For steam generating units or process heaters, whenever there is a change in the location at which the vent stream is introduced into the flame zone as required under §61.302(b).

(5) For carbon adsorbers, all 3-hour periods of operation during which the average VOC concentration or reading of organics in the exhaust gases is more than 20 percent greater than the average exhaust gas concentration or reading measured by the organics monitoring device during the most recent determination of the recovery efficiency of the carbon adsorber that demonstrated that the facility was in compliance.

(c) If a vent system containing valves that could divert the emission stream away from the control device is used, each owner or operator subject to the provisions of this subpart shall keep for at least 2 years up-to-date, readily accessible continuous records of:

(1) All periods when flow is indicated if flow indicators are installed under §61.303(g)(1).

(2) All times when maintenance is performed on car-sealed valves, when the car seal is broken, and when the valve position is changed (i.e., from open to closed for valves in the vent piping to the control device and from closed to open for valves that vent the stream directly or indirectly to the atmosphere bypassing the control device) if valves are monitored under §60.303(g)(2).

(d) Each owner or operator of an affected facility subject to the provisions of this subpart who uses a steam generating unit or process heater with a design heat input capacity of 44 MW (150 × 10 6 BTU/hr) or greater to comply with §61.302(b) shall keep an up-to-date, readily accessible record of all periods of operation of the steam generating unit or process heater. Examples of such records could include records of steam use, fuel use, or monitoring data collected pursuant to other State or Federal regulatory requirements.

(e) Each owner or operator of an affected facility subject to the provisions of this subpart shall keep up-to-date, readily accessible records of the flare pilot flame monitoring specified under §61.303(b), as well as up-to-date, readily accessible records of any absence of the pilot flame during a loading cycle.

(f) Each owner or operator of an affected facility subject to the requirements of §61.302 shall submit to the Administrator quarterly reports of the following information. The owner or operator shall submit the initial report within 90 days after the effective date of this subpart or 90 days after startup for a source that has an initial startup date after the effective date.

(1) Periods of operation where there were exceedances of monitored parameters recorded under §61.305(b).

(2) All periods recorded under §61.305(c)(1) when the vent stream is diverted from the control device.

(3) All periods recorded under §61.305(d) when the steam generating unit or process heater was not operating.

(4) All periods recorded under §61.305(e) in which the pilot flame of the flare was absent.

(5) All times recorded under §61.305(c)(2) when maintenance is performed on car-sealed valves, when the car seal is broken, and when the valve position is changed.

(g) The owner or operator of an affected facility shall keep the vapor-tightness documentation required under §61.302 (d) and (e) on file at the affected facility in a permanent form available for inspection.

(h) The owner or operator of an affected facility shall update the documentation file required under §61.302 (d) and (e) for each tank truck, railcar, or marine vessel at least once per year to reflect current test results as determined by the appropriate method. The owner or operator shall include, as a minimum, the following information in this documentation:

(1) Test title;

(2) Tank truck, railcar, or marine vessel owner and address;

(3) Tank truck, railcar, or marine vessel identification number;

(4) Testing location;

(5) Date of test;

(6) Tester name and signature;

(7) Witnessing inspector: name, signature, and affiliation; and

(8) Test results, including, for railcars and tank trucks, the initial pressure up to which the tank was pressured at the start of the test.

(i) Each owner or operator of an affected facility complying with §61.300(b) or §61.300(d) shall record the following information. The first year after promulgation the owner or operator shall submit a report containing the requested information to the Director of the Emission Standards Division, (MD-13), U.S. Environmental Protection Agency, Research Triangle Park, North Carolina 27711. After the first year, the owner or operator shall continue to record; however, no reporting is required. The information shall be made available if requested. The information shall include, as a minimum:

(1) The affected facility's name and address;

(2) The weight percent of the benzene loaded;

(3) The type of vessel loaded (i.e., tank truck, railcar, or marine vessel); and

(4) The annual amount of benzene loaded into each type of vessel.

[55 FR 8341, Mar. 7, 1990, as amended at 65 FR 62159, Oct. 17, 2000]

§61.306 Delegation of authority.

(a) In delegating implementation and enforcement authority to a State under section 112(d) of the Act, the authorities contained in paragraph (b) of this section shall be retained by the Administrator and not transferred to a State.

(b) Authorities which will not be delegated to States: No restrictions.

['Air Programs']

['Hazardous Air Pollutants']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.