['Air Programs']

['Air Quality']

06/23/2023

...

§65.140 Applicability.

The provisions of this subpart and of subpart A of this part (including the startup, shutdown, and malfunction provisions in §65.6) apply to routing emissions to processes, fuel gas systems, closed vent systems, control devices, and recovery devices where another subpart expressly references the use of this subpart.

§65.141 Definitions.

All terms used in this subpart shall have the meaning given them in the Act and in subpart A of this part. If a term is defined in both subpart A of this part and in other subparts that reference the use of this subpart, the term shall have the meaning given in subpart A of this part for purposes of this subpart.

§65.142 Standards.

(a) Storage vessel requirements. The owner or operator expressly referenced to this subpart from subpart C of this part shall comply with the following requirements, as applicable:

(1) Closed vent system and flare. Owners or operators subject to §65.42(b)(4) who route storage vessel emissions through a closed vent system to a flare shall meet the requirements in §65.143 for closed vent systems; §65.147 for flares; and §65.157(a), (b), and (c) for provisions regarding flare compliance determinations; and the monitoring, recordkeeping, and reporting requirements referenced therein. No other provisions of this subpart apply to storage vessel emissions routed through a closed vent system to a flare.

(2) Closed vent system and nonflare control device. Owners or operators subject to §65.42(b)(5) who route storage vessel emissions through a closed vent system to a nonflare control device shall meet the requirements in §65.143 for closed vent systems and §65.145 for nonflare control devices and the monitoring, recordkeeping, and reporting requirements referenced therein. No other provisions of this subpart apply to storage vessel emissions routed through a closed vent system to a nonflare control device unless specifically required in the monitoring plan submitted under §65.145(c).

(3) Route to a fuel gas system or process. Owners or operators subject to §65.42(b)(6) who route storage vessel emissions to a fuel gas system or to a process shall meet the requirements in §65.144 and the monitoring, recordkeeping, and reporting requirements referenced therein. No other provisions of this subpart apply to storage vessel emissions being routed to a fuel gas system or to a process.

(b) Process vent requirements. The owner or operator expressly referenced to this subpart from subpart D of this part or 40 CFR part 60, subpart DDD, shall comply with the following requirements, as applicable:

(1) Flare. Owners or operators subject to §65.63(a)(1) or 40 CFR 60.562-1(a)(1)(i)(C) who route process vent emissions to a flare shall meet the applicable requirements in §65.143 for closed vent systems; §65.147 for flares; and §65.157(a), (b), and (c) for provisions regarding flare compliance determinations; and the monitoring, recordkeeping, and reporting requirements referenced therein. No other provisions of this subpart apply to process vent emissions routed through a closed vent system to a flare.

(2) Nonflare control device. Owners or operators subject to §65.63(a)(2) or 40 CFR 60.562-1(a)(1)(i)(A) or (B) who route process vent emissions to a nonflare control device shall meet the applicable requirements in §65.143 for closed vent systems; the requirements applicable to the control devices being used in §§65.148 through 65.152 or §65.155 the applicable general monitoring requirements of §65.156 the applicable performance test requirements and procedures of §§65.157 and 65.158; and the monitoring, recordkeeping, and reporting requirements referenced therein. Owners or operators subject to the halogen reduction device requirements of §65.63(b)(1) must also comply with §65.154 and the monitoring, recordkeeping, and reporting requirements referenced therein. The requirements of §§65.144 through 65.146 do not apply to process vents. No other provisions of this subpart apply to process vent emissions routed through a closed vent system to a nonflare control device.

(3) Final recovery devices. Owners or operators subject to §65.63(a)(3) who use a final recovery device to maintain the TRE index value of a Group 2A process vent above 1.0 shall meet the requirements in §65.153, and the monitoring, recordkeeping, and reporting requirements referenced therein applicable to the recovery device being used and the applicable monitoring requirements in §65.156, and the recordkeeping and reporting requirements referenced therein, except for §65.156(c)(2)(ii). No other provisions of this subpart apply to Group 2A process vents.

(c) Transfer rack requirements. The owner or operator expressly referenced to this subpart from subpart E of this part shall comply with the following requirements, as applicable:

(1) Closed vent system and flare. Owners or operators subject to §65.83(a)(2) who route transfer rack emissions through a closed vent system to a flare shall meet the applicable requirements in §65.143 for closed vent systems; §65.147 for flares; and §65.157(a), (b), and (c) for provisions regarding flare compliance determinations; and the monitoring, recordkeeping, and reporting requirements referenced therein. No other provisions of this subpart apply to transfer rack emissions routed through a closed vent system to a flare.

(2) Closed vent system and nonflare control device for low-throughput transfer racks. Owners or operators of low-throughput transfer racks subject to §65.83(a)(1) who route low-throughput transfer rack emissions through a closed vent system to a nonflare control device shall meet the applicable requirements in §65.143 for closed vent systems and §65.145 for nonflare control devices and the monitoring, recordkeeping, and reporting requirements referenced therein. Owners or operators subject to the halogen reduction requirements of §65.83(b)(1) must also comply with the recordkeeping requirement of §65.160(d) and the reporting requirement of §65.165(d). No other provisions of this subpart apply to low-throughput transfer rack emissions routed through a closed vent system to a nonflare control device unless specifically required in the monitoring plan submitted under §65.145(c).

(3) Closed vent system and nonflare control devices for high-throughput transfer racks. Owners or operators of high-throughput transfer racks subject to §65.83(a)(1) who route high-throughput transfer rack emissions through a closed vent system to a nonflare control device shall meet the applicable requirements in §65.143 for closed vent systems; the requirements applicable to the control device being used in §§65.148 through 65.152 or §65.155 the applicable general monitoring of §65.156 the applicable performance test requirements and procedures of §§65.157 and 65.158; and the monitoring, recordkeeping, and reporting requirements referenced therein. Owners or operators subject to the halogen reduction device requirements of §65.83(b)(1) must also comply with §65.154 and the monitoring, recordkeeping, and reporting requirements referenced therein. The requirements of §§65.144 through 65.146 do not apply to high-throughput transfer rack emissions routed through a closed vent system to a nonflare control device. No other provisions of this subpart apply to high-throughput transfer rack emissions routed through a closed vent system to a nonflare control device.

(4) Route to a fuel gas system or to a process. Owners or operators subject to §65.83(a)(4) of this part who route transfer rack emissions to a fuel gas system or to a process shall meet the applicable requirements in §65.144 and the monitoring, recordkeeping, and reporting requirements referenced therein. No other provisions of this subpart apply to transfer rack emissions being routed to a fuel gas system or to a process.

(d) Equipment leak requirements. The owner or operator expressly referenced to this subpart from subpart F of this part shall comply with the following requirements, as applicable:

(1) Closed vent system and flare. Owners or operators subject to §65.115(b) who route equipment leak emissions through a closed vent system to a flare shall meet the requirements in §65.143 for closed vent systems; §65.147 for flares; and §65.157(a), (b), and (c) for provisions regarding flare compliance determinations; and the monitoring, recordkeeping, and reporting requirements referenced therein. No other provisions of this subpart apply to equipment leak emissions routed through a closed vent system to a flare.

(2) Closed vent system and nonflare control device. Owners or operators subject to §65.115(b) who route equipment leak emissions through a closed vent system to a nonflare control device shall meet the requirements in §65.143 for closed vent systems, §65.146 for nonflare control devices used for equipment leak emissions, and the monitoring, recordkeeping, and reporting requirements referenced therein. No other provisions of this subpart apply to equipment leak emissions routed through a closed vent system to a nonflare control device.

(3) Route to a fuel gas system or to a process. Owners or operators subject to §65.115(b) who route equipment leak emissions to a fuel gas system or to a process shall meet the requirements in §65.144 and the monitoring, recordkeeping, and reporting requirements referenced therein. No other provisions of this subpart apply to equipment leak emissions being routed to a fuel gas system or to a process.

(e) Combined emissions. When emissions of different kinds (for example, emissions from process vents, transfer racks, and/or storage vessels) are combined, the owner or operator shall comply with the requirements of either paragraph (e)(1) or (2) of this section:

(1) Comply with the applicable requirements of this subpart for each kind of emissions in the stream (for example, the requirements of §65.142(b) for process vents, and the requirements of §65.142(c) for transfer racks); or

(2) Comply with the first set of requirements identified in paragraphs (e)(2)(i) through (iii) of this section which applies to any individual emission stream that is included in the combined stream. Compliance with the first applicable set of requirements identified in paragraphs (e)(2)(i) through (iii) of this section constitutes compliance with all other requirements in paragraphs (e)(2)(i) through (iii) of this section applicable to other types of emissions in the combined stream. The hierarchy is as follows:

(i) The requirements of §65.142(b) for Group 1 process vents, including applicable monitoring, recordkeeping, and reporting;

(ii) The requirements of §65.142(c) for high-throughput transfer racks, including applicable monitoring, recordkeeping, and reporting;

(iii) The requirements of §65.142(a) for control of emissions from storage vessels or low-throughput transfer racks, including monitoring, recordkeeping, and reporting.

§65.143 Closed vent systems.

(a) Closed vent system equipment and operating requirements. The provisions of paragraph (a) of this section apply to closed vent systems collecting regulated material from a storage vessel, process vent, transfer rack, or equipment leaks.

(1) Collection of emissions. Each closed vent system shall be designed and operated to collect the regulated material vapors from the emission point and to route the collected vapors to a control device.

(2) Period of operation. Closed vent systems used to comply with the provisions of this subpart shall be operated at all times when emissions are vented to them.

(3) Bypass monitoring. Except for pressure relief devices needed for safety purposes, low leg drains, high point bleeds, analyzer vents, and open-ended valves or lines, the owner or operator shall comply with either of the following provisions for each closed vent system that contains bypass lines that could divert a vent stream to the atmosphere:

(i) Properly install, maintain, and operate a flow indicator that takes a reading at least once every 15 minutes. Records shall be generated as specified in §65.163(a)(1)(i). The flow indicator shall be installed at the entrance to any bypass line.

(ii) Secure the bypass line valve in the non-diverting position with a car-seal or a lock-and-key type configuration. A visual inspection of the seal or closure mechanism shall be performed at least once every month to ensure the valve is maintained in the non-diverting position and the vent stream is not diverted through the bypass line. Records shall be generated as specified in §65.163(a)(1)(ii).

(4) Loading arms at transfer racks. Each closed vent system collecting regulated material from a transfer rack shall be designed and operated so that regulated material vapors collected at one loading arm will not pass through another loading arm in the rack to the atmosphere.

(5) Pressure relief devices in a transfer rack's closed vent system. The owner or operator of a transfer rack subject to the provisions of this subpart shall ensure that no pressure relief device in the transfer rack's closed vent system shall open to the atmosphere during loading. Pressure relief devices needed for safety purposes are not subject to paragraph (a)(5) of this section.

(b) Closed vent system inspection requirements. The provisions of paragraph (b) of this section apply to closed vent systems collecting regulated material from a storage vessel, transfer rack or equipment leaks. Inspection records shall be generated as specified in §65.163(a)(3) and (4).

(1) Except for closed vent systems operated and maintained under negative pressure and as provided in paragraphs (b)(2) and (3) of this section, each closed vent system shall be inspected as specified in paragraph (b)(1)(i) or (ii) of this section.

(i) If the closed vent system is constructed of hard-piping, the owner or operator shall comply with the following requirements:

(A) Conduct an initial inspection according to the procedures in paragraph (c) of this section; and

(B) Conduct annual visual inspections for visible, audible, or olfactory indications of leaks.

(ii) If the closed vent system is constructed of ductwork, the owner or operator shall conduct an initial and annual inspection according to the procedures in paragraph (c) of this section.

(2) Any parts of the closed vent system that are designated as described in §65.163(a)(2) as unsafe to inspect are exempt from the inspection requirements of paragraph (b)(1) of this section if the following conditions are met:

(i) The owner or operator determines that the equipment is unsafe to inspect because inspecting personnel would be exposed to an imminent or potential danger as a consequence of complying with paragraph (b)(1) of this section; and

(ii) The owner or operator has a written plan that requires inspection of the equipment as frequently as practical during safe-to-inspect times. Inspection is not required more than once annually.

(3) Any parts of the closed vent system that are designated, as described in §65.163(a)(2), as difficult-to-inspect are exempt from the inspection requirements of paragraph (b)(1) of this section if the following provisions apply:

(i) The owner or operator determines that the equipment cannot be inspected without elevating the inspecting personnel more than 2 meters (7 feet) above a support surface; and

(ii) The owner or operator has a written plan that requires inspection of the equipment at least once every 5 years.

(c) Closed vent system inspection procedures. The provisions of paragraph (c) of this section apply to closed vent systems collecting regulated material from a storage vessel, transfer rack, or equipment leaks.

(1) Each closed vent system subject to paragraph (c) of this section shall be inspected according to the procedures specified in paragraphs (c)(1)(i) through (vii) of this section.

(i) Inspections shall be conducted in accordance with Method 21 of appendix A of 40 CFR part 60 except as specified in this section.

(ii) Except as provided in paragraph (c)(1)(iii) of this section, the detection instrument shall meet the performance criteria of Method 21 of appendix A of 40 CFR part 60, except the instrument response factor criteria in section 3.1.2(a) of Method 21 shall be for the representative composition of the process fluid not each individual organic compound in the stream. For process streams that contain nitrogen, air, water, or other inerts that are not organic hazardous air pollutants or volatile organic compounds, the response factor shall be determined on an inert-free basis. The response factor may be determined at any concentration for which the monitoring for leaks will be conducted. Maintain the record specified by §65.163(a)(5).

(iii) If no instrument is available at the plant site that will meet the performance criteria specified in paragraph (c)(1)(ii) of this section, the instrument readings may be adjusted by multiplying by the representative response factor of the process fluid calculated on an inert-free basis as described in paragraph (c)(1)(ii) of this section.

(iv) The detection instrument shall be calibrated before use on each day of its use by the procedures specified in Method 21 of appendix A of 40 CFR part 60.

(v) Calibration gases shall be as specified in the following:

(A) Zero air (less than 10 parts per million hydrocarbon in air).

(B) Mixtures of methane in air at a concentration less than 10,000 parts per million. A calibration gas other than methane in air may be used if the instrument does not respond to methane or if the instrument does not meet the performance criteria specified in paragraph (c)(1)(ii) of this section. In such cases, the calibration gas may be a mixture of one or more of the compounds to be measured in air.

(C) If the detection instrument's design allows for multiple calibration scales, then the lower scale shall be calibrated with a calibration gas that is no higher than 2,500 parts per million.

(vi) An owner or operator may elect to adjust or not adjust instrument readings for background. If an owner or operator elects not to adjust readings for background, all such instrument readings shall be compared directly to 500 parts per million to determine whether there is a leak. If an owner or operator elects to adjust instrument readings for background, the owner or operator shall measure background concentration using the procedures in this section. The owner or operator shall subtract the background reading from the maximum concentration indicated by the instrument.

(vii) If the owner or operator elects to adjust for background, the arithmetic difference between the maximum concentration indicated by the instrument and the background level shall be compared with 500 parts per million for determining whether there is a leak.

(2) The instrument probe shall be traversed around all potential leak interfaces as close to the interface as possible as described in Method 21 of appendix A of 40 CFR part 60.

(3) Except as provided in paragraph (c)(4) of this section, inspections shall be performed when the equipment is in regulated material service or in use with any other detectable gas or vapor.

(4) Inspections of the closed vent system collecting regulated material from a transfer rack shall be performed only while a tank truck or railcar is being loaded or is otherwise pressurized to normal operating conditions with regulated material or any other detectable gas or vapor.

(d) Closed vent system leak repair provisions. The provisions of paragraph (d) of this section apply to closed vent systems collecting regulated material from a storage vessel, transfer rack, or equipment leak.

(1) If there are visible, audible, or olfactory indications of leaks at the time of the annual visual inspections required by paragraph (b)(1)(i)(B) of this section, the owner or operator shall follow either of the following procedures:

(i) The owner or operator shall eliminate the indications of the leak.

(ii) The owner or operator shall monitor the equipment according to the procedures in paragraph (c) of this section.

(2) Leaks as indicated by an instrument reading greater than 500 parts per million by volume above background shall be repaired as soon as practical except as provided in paragraph (d)(3) of this section. Records shall be generated as specified in §65.163(a)(3) when a leak is detected.

(i) A first attempt at repair shall be made no later than 5 calendar days after the leak is detected.

(ii) Except as provided in paragraph (d)(3) of this section, repairs shall be completed no later than 15 calendar days after the leak is detected or at the beginning of the next introduction of vapors to the system, whichever is later.

(3) Delay of repair of a closed vent system for which leaks have been detected is allowed if repair within 15 days after a leak is detected is technically infeasible without a closed vent system shutdown, as defined in §65.2, or if the owner or operator determines that emissions resulting from immediate repair would be greater than the emissions likely to result from delay of repair. Repair of such equipment shall be completed as soon as practical, but not later than the end of the next closed vent system shutdown.

§65.144 Fuel gas systems and processes to which storage vessel, transfer rack, or equipment leak regulated material emissions are routed.

(a) Equipment and operating requirements for fuel gas systems and processes. (1) Except during periods of startup, shutdown, and malfunction as specified in §65.3(a), the fuel gas system or process shall be operating at all times when regulated material emissions are routed to it.

(2) The owner or operator of a transfer rack subject to the provisions of this subpart shall ensure that no pressure relief device in the transfer rack's system returning vapors to a fuel gas system or process shall open to the atmosphere during loading. Pressure relief devices needed for safety purposes are not subject to this paragraph (a)(2).

(3) Each process piping system collecting regulated material from a transfer rack shall be designed and operated so that regulated material vapors collected at one loading arm will not pass through another loading arm in the rack to the atmosphere.

(b) Fuel gas system and process compliance determination. (1) If emissions are routed to a fuel gas system, there is no requirement to conduct a performance test or design evaluation.

(2) For storage vessels and transfer racks, and if emissions are routed to a process, the regulated material in the emissions shall predominantly meet one of, or a combination of, the following conditions, and the compliance demonstration requirements in paragraph (b)(3) of this section, if applicable:

(i) Recycled and/or consumed in the same manner as a material that fulfills the same function in that process;

(ii) Transformed by chemical reaction into materials that are not regulated materials;

(iii) Incorporated into a product; and/or

(iv) Recovered.

(3) To demonstrate compliance with paragraph (b)(2) of this section for a storage vessel, the owner or operator shall prepare a design evaluation (or engineering assessment) that demonstrates the extent to which one or more of the conditions specified in paragraphs (b)(2)(i) through (iv) of this section are being met. The owner or operator shall submit the design evaluation as specified in §65.165(a)(1).

(c) Statement of connection to fuel gas system. For storage vessels and transfer racks, the owner or operator shall submit the statement of connection reports for fuel gas systems specified in §65.165(a)(2) and/or (a)(3), as appropriate.

§65.145 Nonflare control devices used to control emissions from storage vessels or low-throughput transfer racks.

(a) Nonflare control device equipment and operating requirements. The owner or operator shall operate and maintain the nonflare control device, including a halogen reduction device for a low-throughput transfer rack, so that the monitored parameters defined as required in paragraph (c) of this section remain within the ranges specified in the Initial Compliance Status Report whenever emissions of regulated material are routed to the control device and halogen reduction device, except during periods of startup, shutdown, and malfunction as specified in §65.3(a).

(b) Nonflare control device design evaluation or performance test requirements. When using a control device other than a flare, the owner or operator shall comply with the requirements in paragraph (b)(1)(i), (ii), or (iii) of this section except as provided in paragraph (b)(2) of this section. Owners or operators of halogenated low-throughput transfer rack vent streams routed to a combustion device and then to a halogen reduction device to meet the specifications of §65.83(b)(1), must also meet the requirements of paragraph (b)(3) of this section.

(1) Unless a design evaluation or performance test as required in the referencing subpart was previously conducted and submitted for the storage vessel or low-throughput transfer rack, the owner or operator shall either prepare and submit with the Initial Compliance Status Report, as specified in §65.165(b), a design evaluation that includes the information specified in paragraph (b)(1)(i) of this section, or the results of the performance test as described in paragraph (b)(1)(ii) or (iii) of this section.

(i) Design evaluation. The design evaluation shall include documentation demonstrating that the control device being used achieves the required control efficiency during the reasonably expected maximum storage vessel filling or transfer loading rate. This documentation is to include a description of the gas stream that enters the control device, including flow and regulated material content; and additionally for storage vessels, the effects of varying liquid level conditions; and the information specified in paragraphs (b)(1)(i)(A) through (E) of this section, as applicable. This documentation shall be submitted with the Initial Compliance Status Report as specified in §65.165(b).

(A) The efficiency determination is to include consideration of all vapors, gases, and liquids, other than fuels, received by the control device.

(B) If an enclosed combustion device with a minimum residence time of 0.5 seconds and a minimum temperature of 760°C is used to meet the emission reduction requirement specified in §65.42(b)(5) for storage vessels, or §65.83(a)(1) for transfer racks, documentation that those conditions exist is sufficient to meet the requirements of paragraph (b)(1)(i) of this section.

(C) Except as provided in paragraph (b)(1)(i)(B) of this section for enclosed combustion devices, the design evaluation shall include the estimated autoignition temperature of the stream being combusted, the flow rate of the stream, the combustion temperature, and the residence time at the combustion temperature.

(D) For carbon adsorbers, the design evaluation shall include the estimated affinity of the regulated pollutant vapors for carbon, the amount of carbon in each bed, the number of beds, the humidity, the temperature, the flow rate of the inlet stream and, if applicable, the desorption schedule, the regeneration stream pressure or temperature, and the flow rate of the regeneration stream. For vacuum desorption, pressure drop shall be included.

(E) For condensers, the design evaluation shall include the final temperature of the stream vapors, the type of condenser, and the design flow rate of the emission stream.

(ii) Performance test. A performance test is acceptable to demonstrate compliance with §65.42(b)(5) for storage vessels, and §65.83(a)(1) for low-throughput transfer racks. The owner or operator is not required to prepare a design evaluation for the control device as described in paragraph (b)(1)(i) of this section if a performance test will be performed that meets the following criteria:

(A) The performance test demonstrates that the control device achieves greater than or equal to the required control efficiency specified in §65.42(b)(5) for storage vessels, or §65.83(a)(1) for transfer racks; and

(B) The performance test meets the applicable performance test requirements of §§65.157 and 65.158, and the results are submitted as part of the Initial Compliance Status Report as specified in §65.165(b).

(iii) If the control device used to comply with §65.42(b)(5) for storage vessels, or with §65.83(a)(1) for low-throughput transfer racks, as applicable, is also used to comply with §65.63(a)(2) for process vents, or §65.83(a)(1) for high-throughput transfer racks, a performance test required by §65.148(b), §65.149(b), §65.150(b), §65.151(b), §65.152(b), or §65.155(b) is acceptable to demonstrate compliance with §65.42(b)(5) for storage vessels, or §65.83(a)(1) for low-throughput transfer racks, as applicable. The owner or operator is not required to prepare a design evaluation for the control device as described in paragraph (b)(1)(i) of this section, if a performance test will be performed which meets the following criteria:

(A) The performance test demonstrates that the control device achieves greater than or equal to the required control efficiency specified in §65.42(b)(5) for storage vessels, or §65.83(a)(1) for transfer racks; and

(B) The performance test is submitted as part of the Initial Compliance Status Report as specified in §65.165(b).

(2) A design evaluation or performance test is not required if the owner or operator uses a combustion device meeting the criteria in paragraph (b)(2)(i), (ii), (iii), or (iv) of this section and reports as specified in §65.165(f).

(i) A boiler or process heater with a design heat input capacity of 44 megawatts (150 million British thermal units per hour) or greater.

(ii) A boiler or process heater burning hazardous waste for which the owner or operator meets either of the following requirements:

(A) The boiler or process heater has been issued a final permit under 40 CFR part 270 and complies with the requirements of 40 CFR part 266, subpart H; or

(B) The boiler or process heater has certified compliance with the interim status requirements of 40 CFR part 266, subpart H.

(iii) A hazardous waste incinerator for which the owner or operator meets either of the following requirements:

(A) The incinerator has been issued a final permit under 40 CFR part 270 and complies with the requirements of 40 CFR part 264, subpart O; or

(B) The incinerator has certified compliance with the interim status requirements of 40 CFR part 265, subpart O.

(iv) A boiler or process heater into which the vent stream is introduced with the primary fuel.

(3) Halogen reduction devices used for transfer racks. Unless a design evaluation or performance test as required in the referencing subpart was previously conducted and submitted for a halogen reduction device following a combustion device for a low-throughput transfer rack, the owner or operator shall either prepare and submit with the Initial Compliance Status Report, as specified in §65.165(b), a design evaluation that includes the information specified in paragraph (b)(3)(i) of this section, or the results of the performance test as described in paragraph (b)(3)(ii) or (iii) of this section. The provisions of this paragraph (b)(3) apply to owners or operators using a halogen reduction device following a combustion device to comply with §65.83(b)(1).

(i) Design evaluation. The design evaluation shall include documentation demonstrating that the halogen reduction device being used achieves the required control efficiency during the reasonably expected maximum transfer loading rate. This documentation is to include a description of the gas stream that enters the halogen reduction device, including flow and regulated material content. The efficiency determination is to include consideration of all vapors, gases, and liquids, other than fuels, received by the halogen reduction device. This documentation shall be submitted with the Initial Compliance Status Report as specified in §65.165(b).

(ii) Performance test. A performance test is acceptable to demonstrate compliance with §65.83(b)(1) for low-throughput transfer racks. The owner or operator is not required to prepare a design evaluation for the halogen reduction device as described in paragraph (b)(3)(i) of this section if a performance test will be performed that meets the following criteria:

(A) The performance test demonstrates that the halogen reduction device achieves greater than or equal to the required control efficiency specified in §65.83(b)(1) for transfer racks; and

(B) The performance test meets the applicable performance test requirements of §§65.157 and 65.158, and the results are submitted as part of the Initial Compliance Status Report as specified in §65.165(b).

(iii) If the halogen reduction device used to comply with §65.83(b)(1) for low-throughput transfer racks, is also used to comply with §65.63(b)(1) for process vents, or §65.83(b)(1) for high-throughput transfer racks, a performance test required by §65.154(b) is acceptable to demonstrate compliance with §65.83(b)(1) for low-throughput transfer racks. The owner or operator is not required to prepare a design evaluation for the halogen reduction device as described in paragraph (b)(3)(i) of this section, if a performance test will be performed which meets the following criteria:

(A) The performance test demonstrates that the halogen reduction device achieves greater than or equal to the required control efficiency specified in §65.83(b)(1) for transfer racks; and

(B) The performance test is submitted as part of the Initial Compliance Status Report as specified in §65.165(b).

(c) Nonflare control device monitoring requirements. (1) Unless previously established under an applicable standard prior to the implementation date of this part as specified in §65.1(f), the owner or operator shall submit with the Initial Compliance Status Report a monitoring plan containing the information specified in §65.165(b) to identify the parameters that will be monitored to assure proper operation of the control device. The owner or operator of a halogenated low-throughput transfer rack vent stream routed to a combustion device and then to a halogen reduction device to meet the specifications of §65.83(b)(1) shall submit with the Initial Compliance Status Report a monitoring plan containing the information specified in §65.165(b) to identify the parameters that will be monitored to assure proper operation of the halogen reduction device.

(2) The owner or operator shall monitor the parameters specified in the Initial Compliance Status Report or in the operating permit. Records shall be generated as specified in §65.163(b)(1).

§65.146 Nonflare control devices used for equipment leaks only.

(a) Equipment and operating requirements. (1) Owners or operators using a nonflare control device to meet the applicable requirements in §65.115(b) shall meet the requirements of this section.

(2) Control devices used to comply with the provisions of this subpart shall be operated at all times when emissions are vented to them.

(b) Performance test requirements. A performance test is not required for any nonflare control device used only to control emissions from equipment leaks.

(c) Monitoring requirements. Owners or operators of control devices that are used only to comply with the provisions of §65.115(b) shall monitor these control devices to ensure that they are operated and maintained in conformance with their design. The owner or operator shall maintain the records as specified in §65.163(d).

§65.147 Flares.

(a) Flare equipment and operating requirements. Flares subject to this subpart shall meet the performance requirements of paragraphs (a)(1) through (7) of this section.

(1) Flares shall be operated at all times when emissions are vented to them.

(2) Flares shall be designed for and operated with no visible emissions as determined by the methods specified in paragraph (b)(3)(i) of this section, except for periods not to exceed a total of 5 minutes during any 2 consecutive hours.

(3) Flares shall be operated with a flare flame or at least one pilot flame present at all times, as determined by the methods specified in paragraph (c) of this section.

(4) An owner/operator has the choice of adhering to either the heat content specifications in paragraph (a)(4)(ii) of this section and the maximum tip velocity specifications in paragraph (a)(6) of this section, or adhering to the requirements in paragraph (a)(4)(i) of this section.

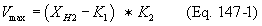

(i)(A) Flares shall be used that have a diameter of 3 inches or greater, are nonassisted, have a hydrogen content of 8.0 percent (by volume), or greater, and are designed for and operated with an exit velocity less than 37.2 m/sec (122 ft/sec) and less than the velocity, Vmax, as determined by Equation 147-1 of this section:

Where:

Vmax = Maximum permitted velocity, m/sec.

K1 = Constant, 6.0 volume-percent hydrogen.

K2 = Constant, 3.9 (m/sec)/volume-percent hydrogen.

XH2 = The volume-percent of hydrogen, on a wet basis, as calculated by using the American Society for Testing and Materials (ASTM) Method D1946-77 (incorporated by reference as specified in §65.13).

(B) The actual exit velocity of a flare shall be determined by the method specified in paragraph (b)(3)(iii) of this section.

(ii) Flares shall be used only when the net heating value of the gas being combusted is 11.2 megajoules per standard cubic meter (300 British thermal units per standard cubic foot) or greater if the flare is steam-assisted or air-assisted, or when the net heating value of the gas being combusted is 7.45 megajoules per standard cubic meter (200 British thermal units per standard cubic foot) or greater if the flare is nonassisted. The net heating value of the gas being combusted shall be determined by the methods specified in paragraph (b)(3)(ii) of this section.

(5) Flares used to comply with this section shall be steam-assisted, air-assisted, or nonassisted.

(6) Steam-assisted and nonassisted flares shall be designed for and operated with an exit velocity as determined by the methods specified in paragraph (b)(3)(iii) of this section, less than 18.3 meters per second (60 feet per sec) except as provided in the following two paragraphs, as applicable:

(i) Steam-assisted and nonassisted flares shall be designed for and operated with an exit velocity as determined by the methods specified in paragraph (b)(3)(iii) of this section, equal to or less than 122 meters per second (400 feet per second) if the net heating value of the gas being combusted is greater than 37.3 megajoules per standard cubic meter (1,000 British thermal units per standard cubic foot).

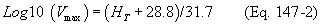

(ii) Steam-assisted and nonassisted flares shall be designed for and operated with an exit velocity as determined by the methods specified in paragraph (b)(3)(iii) of this section, less than the velocity, V max, and less than 122 meters per second (400 feet per sec), where the maximum permitted velocity, Vmax, is determined by Equation 147-2 of this section:

Where:

Vmax = Maximum permitted velocity, meters per second.

28.8 = Constant.

31.7 = Constant.

HT = The net heating value as determined in paragraph (b)(3)(ii) of this section.

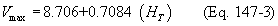

(7) Air-assisted flares shall be designed for and operated with an exit velocity as determined by the methods specified in paragraph (b)(3)(iii) of this section, less than the velocity, Vmax, where the maximum permitted velocity, Vmax, is determined by Equation 147-3 of this section:

Where:

Vmax = Maximum permitted velocity, meters per second.

8.706 = Constant.

0.7084 = Constant.

HT = The net heating value as determined in paragraph (b)(3)(ii) of this section.

(b) Flare compliance determination. (1) Unless an initial flare compliance determination of the flare was previously conducted and submitted under the referencing subpart, the owner or operator shall conduct an initial flare compliance determination of any flare used to comply with the provisions of this subpart. Flare compliance determination records shall be kept as specified in §65.159(a) and (b) and a flare compliance determination report shall be submitted as specified in §65.164. An owner or operator is not required to conduct a performance test to determine percent emission reduction or outlet regulated material or TOC concentration when a flare is used.

(2) Unless already permitted by the applicable title V permit, if an owner or operator elects to use a flare to replace an existing control device at a later date, the owner or operator shall notify the Administrator, either by amendment of the regulated source's title V permit or, if title V is not applicable, by submission of the notice specified in §65.167(a). Upon implementing the change, a flare compliance determination shall be performed using the methods specified in paragraph (b)(3) of this section within 180 days. The compliance determination report shall be submitted to the Administrator within 60 days of completing the determination as provided in §65.164(b)(2). If an owner or operator elects to use a flare to replace an existing final recovery device that is used on a Group 2A process vent, the owner or operator shall comply with the applicable provisions of §§65.63(e) and 65.67(b) and submit the notification specified in §65.167(a).

(3) Flare compliance determinations shall meet the requirements specified in paragraphs (b)(3)(i) through (iv) of this section.

(i) Method 22 of appendix A of part 60 shall be used to determine the compliance of flares with the visible emission provisions of this subpart. The observation period is 2 hours, except for transfer racks as provided in either one of the following:

(A) For transfer racks, if the loading cycle is less than 2 hours, then the observation period for that run shall be for the entire loading cycle.

(B) For transfer racks, if additional loading cycles are initiated within the 2-hour period, then visible emissions observations shall be conducted for the additional cycles.

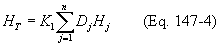

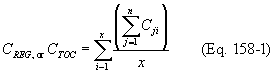

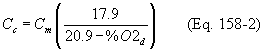

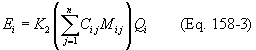

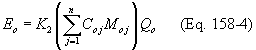

(ii) The net heating value of the gas being combusted in a flare shall be calculated using Equation 147-4 of this section:

Where:

HT = Net heating value of the sample, megajoules per standard cubic meter; where the net enthalpy per mole of offgas is based on combustion at 25°C and 760 millimeters of mercury (30 inches of mercury), but the standard temperature for determining the volume corresponding to 1 mole is 20°C;

K1 = 1.740 × 10?7 (parts per million by volume)?1 (gram-mole per standard cubic meter) (megajoules per kilocalories), where the standard temperature for gram mole per standard cubic meter is 20°C;

Dj = Concentration of sample component j, in parts per million by volume on a wet basis, as measured for organics by Method 18 of appendix A of 40 CFR part 60 and measured for hydrogen and carbon monoxide by American Society for Testing and Materials (ASTM) D1946-77 (incorporated by reference as specified in §65.13); and

Hj = Net heat of combustion of sample component j, kilocalories per gram-mole at 25°C and 760 millimeters of mercury (30 inches of mercury). The heats of combustion of stream components may be determined using ASTM D2382-76 (incorporated by reference as specified in §65.13) if published values are not available or cannot be calculated.

(iii) The actual exit velocity of a flare shall be determined by dividing the volumetric flow rate (in units of standard temperature and pressure), as determined by Method 2, 2A, 2C, or 2D of appendix A of 40 CFR part 60 as appropriate, by the unobstructed (free) cross-sectional area of the flare tip.

(iv) Flare flame or pilot monitors, as applicable, shall be operated during any flare compliance determination.

(c) Flare monitoring requirements. Where a flare is used, a device (including but not limited to a thermocouple, ultraviolet beam sensor, or infrared sensor) capable of continuously detecting that at least one pilot flame or the flare flame is present is required. Flame monitoring and compliance records shall be kept as specified in §65.159(c) and (d).

§65.148 Incinerators.

(a) Incinerator equipment and operating requirements. (1) Owners or operators using incinerators to meet the 98 weight-percent emission reduction or 20 parts per million by volume outlet concentration requirement as specified in §65.63(a)(2), or 40 CFR 60.562-1(a)(1)(i)(A) for process vents, or §65.83(a)(1) for high-throughput transfer racks, as applicable, shall meet the requirements of this section.

(2) Incinerators used to comply with the provisions of this subpart shall be operated at all times when emissions are vented to them.

(b) Incinerator performance test requirements. (1) Unless an initial performance test was previously conducted and submitted under the referencing subpart and except as specified in §65.157(b) and paragraph (b)(2) of this section, the owner or operator shall conduct an initial performance test of any incinerator used to comply with the provisions of this subpart according to the procedures in §§65.157 and 65.158. Performance test records shall be kept as specified in §65.160(a) and (b), and a performance test report shall be submitted as specified in §65.164. As provided in §65.145(b)(1), a performance test may be used as an alternative to the design evaluation for storage vessels and low-throughput transfer rack controls. As provided in §65.146(b), no performance test is required for equipment leaks.

(2) An owner or operator is not required to conduct a performance test for a hazardous waste incinerator for which the owner or operator has been issued a final permit under 40 CFR part 270 and complies with the requirements of 40 CFR part 264, subpart O, or has certified compliance with the interim status requirements of 40 CFR part 265, subpart O. The owner or operator shall report as specified in §65.165(f).

(3) Unless already permitted by the applicable title V permit, if an owner or operator elects to use an incinerator to replace an existing control device at a later date, the owner or operator shall notify the Administrator, either by amendment of the regulated source's title V permit or, if title V is not applicable, by submission of the notice specified in §65.167(a) before implementing the change. Upon implementing the change, an incinerator performance test shall be performed using the methods specified in §65.157 and within 180 days if required by paragraph (b)(1) of this section. The performance test report shall be submitted to the Administrator within 60 days of completing the determination as provided in §65.164(b)(2). If an owner or operator elects to use an incinerator to replace an existing recovery device that is used on a Group 2A process vent, the owner or operator shall comply with the applicable provisions of §§65.63(e) and 65.67(b) and submit the notification specified in §65.167(a).

(c) Incinerator monitoring requirements. (1) Where an incinerator is used, a temperature monitoring device capable of providing a continuous record that meets the provisions specified in paragraph (c)(1)(i) or (ii) of this section is required. Monitoring results shall be recorded as specified in §65.161. General requirements for monitoring and continuous parameter monitoring systems are contained in §65.156.

(i) Where an incinerator other than a catalytic incinerator is used, a temperature monitoring device shall be installed in the fire box or in the ductwork immediately downstream of the fire box in a position before any substantial heat exchange occurs.

(ii) Where a catalytic incinerator is used, temperature monitoring devices shall be installed in the gas stream immediately before and after the catalyst bed.

(2) The owner or operator shall establish a range for monitored parameters that indicates proper operation of the incinerator. In order to establish the range, the information required in §65.165(c) shall be submitted in the Initial Compliance Status Report or the operating permit application or amendment. The range may be based upon a prior performance test meeting the specifications of §65.157(b)(1) or upon existing ranges or limits established under a referencing subpart.

§65.149 Boilers and process heaters.

(a) Boiler and process heater equipment and operating requirements. (1) Owners or operators using boilers and process heaters to meet the 98 weight-percent emission reduction or 20 parts per million by volume outlet concentration requirement as specified in §65.63(a)(2), or 40 CFR 60.562-1(a)(1)(i)(B) for process vents, or §65.83(a)(1) for high-throughput transfer racks, as applicable, shall meet the requirements of this section.

(2) The vent stream shall be introduced into the flame zone of the boiler or process heater.

(3) Boilers and process heaters used to comply with the provisions of this subpart shall be operated at all times when emissions are vented to them.

(b) Boiler and process heater performance test requirements. (1) Unless an initial performance test was previously conducted and submitted under the referencing subpart, and except as specified in §65.157(b) and paragraph (b)(2) of this section, the owner or operator shall conduct an initial performance test of any boiler or process heater used to comply with the provisions of this subpart according to the procedures in §§65.157 and 65.158. Performance test records shall be kept as specified in §65.160(a) and (b), and a performance test report shall be submitted as specified in §65.164. As provided in §65.145(b)(1), a performance test may be used as an alternative to the design evaluation for storage vessels and low-throughput transfer rack controls. As provided in §65.146(b), no performance test is required to demonstrate compliance for equipment leaks.

(2) An owner or operator is not required to conduct a performance test when any of the control devices specified in paragraphs (b)(2)(i) through (iii) of this section are used. The owner or operator shall report as specified in §65.165(f).

(i) A boiler or process heater with a design heat input capacity of 44 megawatts (150 million British thermal units per hour) or greater.

(ii) A boiler or process heater into which the vent stream is introduced with the primary fuel or is used as the primary fuel.

(iii) A boiler or process heater burning hazardous waste for which the owner or operator meets either of the following requirements:

(A) The boiler or process heater has been issued a final permit under 40 CFR part 270 and complies with the requirements of 40 CFR part 266, subpart H; or

(B) The boiler or process heater has certified compliance with the interim status requirements of 40 CFR part 266, subpart H.

(3) Unless already permitted by the applicable title V permit, if an owner or operator elects to use a boiler or process heater to replace an existing control device at a later date, the owner or operator shall notify the Administrator, either by amendment of the regulated source's title V permit or, if title V is not applicable, by submission of the notice specified in §65.167(a) before implementing the change. Upon implementing the change, a boiler or process heater performance test shall be performed using the methods specified in §§65.157 and 65.158 within 180 days if required by paragraph (b)(1) of this section. The performance test report shall be submitted to the Administrator within 60 days of completing the determination as provided in §65.164(b)(2). If an owner or operator elects to use a boiler or process heater to replace an existing recovery device that is used on a Group 2A process vent, the owner or operator shall comply with the applicable provisions of §§65.63(e) and 65.67(b) and submit the notification specified in §65.167(a).

(c) Boiler and process heater monitoring requirements. (1) Where a boiler or process heater of less than 44 megawatts (150 million British thermal units per hour) design heat input capacity is used and the regulated vent stream is not introduced as or with the primary fuel, a temperature monitoring device in the fire box capable of providing a continuous record is required. Any boiler or process heater in which all vent streams are introduced with primary fuel or are used as the primary fuel is exempt from monitoring. Monitoring results shall be recorded as specified in §65.161. General requirements for monitoring and continuous parameter monitoring systems are contained in §65.156.

(2) Where monitoring is required, the owner or operator shall establish a range for monitored parameters that indicates proper operation of the boiler or process heater. In order to establish the range, the information required in §65.165(c) shall be submitted in the Initial Compliance Status Report or the operating permit application or amendment. The range may be based upon a prior performance test meeting the specifications of §65.157(b)(1) or upon existing ranges or limits established under a referencing subpart.

§65.150 Absorbers used as control devices.

(a) Absorber equipment and operating requirements. (1) Owners or operators using absorbers to meet the 98 weight-percent emission reduction or 20 parts per million by volume outlet concentration requirements as specified in §65.63(a)(2), or 40 CFR60.562-1(a)(1)(i)(A) for process vents, or §65.83(a)(1) for high-throughput transfer racks, as applicable, shall meet the requirements of this section.

(2) Absorbers used to comply with the provisions of this subpart shall be operated at all times when emissions are vented to them.

(b) Absorber performance test requirements. (1) Unless an initial performance test was previously conducted and submitted under the referencing subpart and except as specified in §65.157(b), the owner or operator shall conduct an initial performance test of any absorber used as a control device to comply with the provisions of this subpart according to the procedures in §§65.157 and 65.158. Performance test records shall be kept as specified in §65.160(a) and (b), and a performance test report shall be submitted as specified in §65.164. As provided in §65.145(b)(1), a performance test may be used as an alternative to the design evaluation for storage vessels and low-throughput transfer rack controls. As provided in §65.146(b), no performance test is required to demonstrate compliance for equipment leaks.

(2) Unless already permitted by the applicable title V permit, if an owner or operator elects to use an absorber to replace an existing recovery or control device at a later date, the owner or operator shall notify the Administrator, either by amendment of the regulated source's title V permit or, if title V is not applicable, by submission of the notice specified in §65.167(a) before implementing the change. Upon implementing the change, either of the following provisions, as applicable, shall be followed:

(i) Replace final recovery device. If an owner or operator elects to replace the final recovery device on a process vent with an absorber used as a control device, the owner or operator shall comply with the applicable provisions of §§65.63(e) and 65.67(b).

(ii) Replace control device. If an owner or operator elects to replace a control device on a Group 1 process vent or a high-throughput transfer rack with an absorber used as a control device, the owner or operator shall perform a performance test using the methods specified in §§65.157 and 65.158 within 180 days. The performance test report shall be submitted to the Administrator within 60 days of completing the test as provided in §65.164(b)(2).

(c) Absorber monitoring requirements. (1) Where an absorber is used as a control device, either an organic monitoring device capable of providing a continuous record or a scrubbing liquid temperature monitoring device and a specific gravity monitoring device, each capable of providing a continuous record, shall be used. Monitoring results shall be recorded as specified in §65.161. General requirements for monitoring and continuous parameter monitoring systems are contained in §65.156.

(2) The owner or operator shall establish a range for monitored parameters that indicates proper operation of the absorber. In order to establish the range, the information required in §65.165(c) shall be submitted in the Initial Compliance Status Report or the operating permit application or amendment. The range may be based upon a prior performance test meeting the specifications of §65.157(b)(1) or upon existing ranges or limits established under a referencing subpart.

§65.151 Condensers used as control devices.

(a) Condenser equipment and operating requirements. (1) Owners or operators using condensers to meet the 98 weight-percent emission reduction or 20 parts per million by volume outlet concentration requirements as specified in §65.63(a)(2), or 40 CFR 60.562-1(a)(1)(i)(A) for process vents, or §65.83(a)(1) for high-throughput transfer racks, as applicable, shall meet the requirements of this section.

(2) Condensers used to comply with the provisions of this subpart shall be operated at all times when emissions are vented to them.

(b) Condenser performance test requirements. (1) Unless an initial performance test was previously conducted and submitted under the referencing subpart and except as specified in §65.157(b), the owner or operator shall conduct an initial performance test of any condenser used as a control device to comply with the provisions of this subpart according to the procedures in §§65.157 and 65.158. Performance test records shall be kept as specified in §65.160(a) and (b), and a performance test report shall be submitted as specified in §65.164. As provided in §65.145(b)(1), a performance test may be used as an alternative to the design evaluation for storage vessels and low-throughput transfer rack controls. As provided in §65.146(b), no performance test is required to demonstrate compliance for equipment leaks.

(2) Unless already permitted by the applicable title V permit, if an owner or operator elects to use a condenser to replace an existing recovery or control device at a later date, the owner or operator shall notify the Administrator, either by amendment of the regulated source's title V permit or, if title V is not applicable, by submission of the notice specified in §65.167(a) before implementing the change. Upon implementing the change, either of the following provisions, as applicable, shall be followed:

(i) Replace final recovery device. If an owner or operator elects to replace the final recovery device on a process vent with a condenser used as a control device, the owner or operator shall comply with the applicable provisions of §§65.63(e) and 65.67(b).

(ii) Replace control device. If an owner or operator elects to replace a control device on a Group 1 process vent or a high-throughput transfer rack with a condenser used as a control device, the owner or operator shall perform a performance test using the methods specified in §§65.157 and 65.158 within 180 days. The performance test report shall be submitted to the Administrator within 60 days of completing the test as provided in §65.164(b)(2).

(c) Condenser monitoring requirements. (1) Where a condenser is used as a control device, an organic monitoring device capable of providing a continuous record or a condenser exit (product side) temperature monitoring device capable of providing a continuous record shall be used. Monitoring results shall be recorded as specified in §65.161. General requirements for monitoring and continuous parameter monitoring systems are contained in §65.156.

(2) The owner or operator shall establish a range for monitored parameters that indicates proper operation of the condenser. In order to establish the range, the information required in §65.165(c) shall be submitted in the Initial Compliance Status Report or the operating permit application or amendment. The range may be based upon a prior performance test meeting the specifications in §65.157(b)(1) or upon existing ranges or limits established under a referencing subpart.

§65.152 Carbon adsorbers used as control devices.

(a) Carbon adsorber equipment and operating requirements. (1) Owners or operators using carbon adsorbers to meet the 98 weight-percent emission reduction or 20 parts per million by volume outlet concentration requirements as specified in §65.63(a)(2), or 40 CFR 60.562-1(a)(1)(i)(A) for process vents, or §65.83(a)(1) for high-throughput transfer racks, as applicable, shall meet the requirements of this section.

(2) Carbon adsorbers used to comply with the provisions of this subpart shall be operated at all times when emissions are vented to them.

(b) Carbon adsorber performance test requirements. (1) Unless an initial performance test was previously conducted and submitted under the referencing subpart and except as specified in §65.157(b), the owner or operator shall conduct an initial performance test of any carbon absorber used as a control device to comply with the provisions of this subpart according to the procedures in §§65.157 and 65.158. Performance test records shall be kept as specified in §65.160(a) and (b), and a performance test report shall be submitted as specified in §65.164. As provided in §65.145(b)(1), a performance test may be used as an alternative to the design evaluation for storage vessels and low-throughput transfer rack controls. As provided in §65.146(b), no performance test is required to demonstrate compliance for equipment leaks.

(2) Unless already permitted by the applicable title V permit, if an owner or operator elects to use a carbon adsorber to replace an existing recovery or control device at a later date, the owner or operator shall notify the Administrator either by amendment of the regulated source's title V permit or, if title V is not applicable, by submission of the notice specified in §65.167(a) before implementing the change. Upon implementing the change, either of the following provisions, as applicable, shall be followed:

(i) Replace final recovery device. If an owner or operator elects to replace the final recovery device on a process vent with a carbon adsorber used as a control device, the owner or operator shall comply with the applicable provisions of §§65.63(e) and 65.67(b).

(ii) Replace control device. If an owner or operator elects to replace a control device on a Group 1 process vent or high-throughput transfer rack with a carbon adsorber used as a control device, the owner or operator shall perform a performance test using the methods specified in §§65.157 and 65.158 within 180 days. The performance test report shall be submitted to the Administrator within 60 days of completing the test as provided in §65.164(b)(2).

(c) Carbon adsorber monitoring requirements. (1) Where a carbon adsorber is used as a control device, an organic monitoring device capable of providing a continuous record, or an integrating regeneration stream flow monitoring device having an accuracy of ±10 percent or better capable of recording the total regeneration stream mass or volumetric flow for each regeneration cycle, and a carbon-bed temperature monitoring device capable of recording the carbon bed temperature after each regeneration and within 15 minutes of completing any cooling cycle, shall be used. Monitoring results shall be recorded as specified in §65.161. General requirements for monitoring and continuous parameter monitoring systems are contained in §65.156.

(2) The owner or operator shall establish a range for monitored parameters that indicates proper operation of the carbon adsorber. Where the regeneration stream flow and carbon-bed temperature are monitored, the range shall be in terms of the total regeneration stream flow per regeneration cycle and the temperature of the carbon-bed determined within 15 minutes of the completion of the regeneration cooling cycle. In order to establish the range, the information required in §65.165(c) shall be submitted in the Initial Compliance Status Report or the operating permit application or amendment. The range may be based upon a prior performance test meeting the specifications in §65.157(b)(1) or upon existing ranges or limits established under a referencing subpart.

§65.153 Absorbers, condensers, carbon adsorbers, and other recovery devices used as final recovery devices.

(a) Final recovery device equipment and operating requirements. (1) Owners or operators using a recovery device to meet the requirement to operate and maintain a TRE above 1.0 as specified in §65.63(a)(3) for process vents shall meet the requirements of this section.

(2) Recovery devices used to comply with the provisions of this subpart shall be operated at all times when emissions are vented to them.

(b) Recovery device performance test requirements. (1) There are no performance test requirements for recovery devices. Records of TRE index value determination shall be generated as specified in §65.160(c).

(2) Replace a final recovery device or control device. Unless already permitted by the applicable title V permit, if an owner or operator elects to use a recovery device to replace an existing final recovery or control device at a later date, the owner or operator shall notify the Administrator, either by amendment of the regulated source's title V permit or, if title V is not applicable, by submission of the notice specified in §65.167(a) before implementing the change. Upon implementing the change, the owner or operator shall comply with the applicable provisions of §§65.63(e) and 65.67(b).

(c) Recovery device monitoring requirements. (1) Where an absorber is the final recovery device in the recovery system and the TRE index value is between 1.0 and 4.0, either an organic monitoring device capable of providing a continuous record, or a scrubbing liquid temperature monitoring device and a specific gravity monitoring device, each capable of providing a continuous record, shall be used. Monitoring results shall be recorded as specified in §65.161. General requirements for monitoring and continuous parameter monitoring systems are contained in §65.156.

(2) Where a condenser is the final recovery device in the recovery system and the TRE index value is between 1.0 and 4.0, an organic monitoring device capable of providing a continuous record, or a condenser exit (product side) temperature monitoring device capable of providing a continuous record, shall be used. Monitoring results shall be recorded as specified in §65.161. General requirements for monitoring and continuous parameter monitoring systems are contained in §65.156.

(3) Where a carbon adsorber is the final recovery device in the recovery system and the TRE index value is between 1.0 and 4.0, an organic monitoring device capable of providing a continuous record, or an integrating regeneration stream flow monitoring device having an accuracy of ±10 percent or better capable of recording the total regeneration stream mass or volumetric flow for each regeneration cycle, and a carbon-bed temperature monitoring device capable of recording the carbon-bed temperature after each regeneration and within 15 minutes of completing any cooling cycle, shall be used. Monitoring results shall be recorded as specified in §65.161. General requirements for monitoring and continuous parameter monitoring systems are contained in §65.156.

(4) Unless previously approved by the Administrator under an applicable standard prior to the implementation date of this part, as specified in §65.1(f), if an owner or operator uses a recovery device other than those listed in this subpart, the owner or operator shall submit a description of planned monitoring, reporting and recordkeeping procedures as required under §65.162(e). The Administrator will approve or deny the proposed monitoring, reporting and recordkeeping requirements as part of the review of the submission or permit application or by other appropriate means.

(5) The owner or operator shall establish a range for monitored parameters that indicates proper operation of the recovery device. In order to establish the range, the information required in §65.165(c) shall be submitted in the Initial Compliance Status Report or the operating permit application or amendment. The range may be based upon a prior performance test meeting the specifications in §65.157(b)(1) or upon existing ranges or limits established under a referencing subpart. Where the regeneration stream flow and carbon-bed temperature are monitored, the range shall be in terms of the total regeneration stream flow per regeneration cycle, and the temperature of the carbon-bed determined within 15 minutes of the completion of the regeneration cooling cycle.

§65.154 Halogen scrubbers and other halogen reduction devices.

(a) Halogen scrubber and other halogen reduction device equipment and operating requirements. (1) An owner or operator of halogen scrubbers and other halogen reduction devices subject to this subpart shall reduce the overall emissions of hydrogen halides and halogens by 99 percent, or reduce the outlet mass of total hydrogen halides and halogens to less than 0.45 kilograms per hour (0.99 pound per hour) as specified in §65.63(b) for process vents, or §65.83(b) for transfer racks, as applicable, and shall meet the requirements of this section.

(2) Halogen scrubbers and other halogen reduction devices used to comply with the provisions of this subpart shall be operated at all times when emissions are vented to them.

(b) Halogen scrubber and other halogen reduction device performance test requirements. Unless an initial performance test was previously conducted and submitted under the referencing subpart, an owner or operator of a combustion device followed by a halogen scrubber or other halogen reduction device to control halogenated vent streams in accordance with §65.63(b)(1) for process vents, or §65.83(b)(1) for transfer racks shall conduct an initial performance test to determine compliance with the control efficiency or emission limits for hydrogen halides and halogens according to the procedures in §§65.157 and 65.158. Performance test records shall be kept as specified in §65.160(a) and (b), and a performance test report shall be submitted as specified in §65.164.

(c) Halogen scrubber and other halogen reduction device monitoring requirements. (1) Where a halogen scrubber is used, the monitoring equipment specified in paragraphs (c)(1)(i) and (ii) of this section is required for the scrubber. Monitoring results shall be recorded as specified in §65.161. General requirements for monitoring and continuous parameter monitoring systems are contained in §65.156.

(i) A pH monitoring device capable of providing a continuous record shall be installed to monitor the pH of the scrubber effluent.

(ii) A flow meter capable of providing a continuous record shall be located at the scrubber influent for liquid flow. Gas stream flow shall be determined using one of the following procedures:

(A) The owner or operator may determine gas stream flow using the design blower capacity, with appropriate adjustments for pressure drop.

(B) If the scrubber is subject to regulations in 40 CFR parts 264 through 266 that have required a determination of the liquid to gas (L/G) ratio prior to the applicable compliance date for the chemical manufacturing process unit of which it is part, as specified in 40 CFR 63.100(k) (if the referencing subpart is 40 CFR part 63, subpart F), or prior to the implementation date as specified in §65.1(f) (for all other referencing subparts), the owner or operator may determine gas stream flow by the method that had been utilized to comply with those regulations. A determination that was conducted prior to that compliance date may be utilized to comply with this subpart if it is still representative.

(C) The owner or operator may prepare and implement a gas stream flow determination plan that documents an appropriate method that will be used to determine the gas stream flow. The plan shall require determination of gas stream flow by a method that will at least provide a value for either a representative or the highest gas stream flow anticipated in the scrubber during representative operating conditions other than startups, shutdowns, or malfunctions. The plan shall include a description of the methodology to be followed and an explanation of how the selected methodology will reliably determine the gas stream flow and a description of the records that will be maintained to document the determination of gas stream flow. The owner or operator shall maintain the plan as specified in §65.5.

(2) Where a halogen reduction device other than a scrubber is used, the procedures in §65.162(e) shall be followed to establish monitoring parameters.

(3) The owner or operator shall establish a range for monitored parameters that indicates proper operation of the scrubber or other halogen reduction device. In order to establish the range, the information required in §65.165(c) shall be submitted in the Initial Compliance Status Report or the operating permit application or amendment. The range may be based upon a prior performance test meeting the specifications in §65.157(b)(1), or upon existing ranges or limits established under a referencing subpart.

§65.155 Other control devices.

(a) Other control device equipment and operating requirements. (1) Owners or operators using a control device other than one listed in §§65.147 through 65.152 to meet the 98 weight-percent emission reduction or 20 parts per million by volume outlet concentration requirements specified in §65.63(a)(2), or 40 CFR 60.562-1(a)(1)(i)(A) for process vents, or §65.83(a)(1) for high-throughput transfer racks, as applicable, shall meet the requirements of this section.

(2) Other control devices used to comply with the provisions of this subpart shall be operated at all times when emissions are vented to them.

(b) Other control device performance test requirements. (1) Unless an initial performance test was previously conducted and submitted under the referencing subpart, an owner or operator of a control device other than those specified in §§65.147 through 65.152, to comply with §65.63(a)(2) for process vents, or §65.83(a)(1) for high-throughput transfer racks, shall perform an initial performance test according to the procedures in §§65.157 and 65.158. Performance test records shall be kept as specified in §65.160(a) and (b), and a performance test report shall be submitted as specified in §65.164.

(2) Unless already permitted by the applicable title V permit, if an owner or operator elects to use another control device to replace an existing control device at a later date, the owner or operator shall notify the Administrator, either by amendment of the regulated source's title V permit or, if title V is not applicable, by submission of the notice specified in §65.167(a) before implementing the change. Upon implementing the change, another control device performance test shall be performed using the methods specified in §§65.157 and 65.158 within 180 days if required by paragraph (b)(1) of this section. The performance test report shall be submitted to the Administrator within 60 days of completing the determination as provided in §65.164(b)(2). If an owner or operator elects to use a control device to replace an existing recovery device that is used on a Group 2A process vent, the owner or operator shall comply with the applicable provisions of §§65.63(e) and 65.67(b) and submit the notification specified in §65.167(a).

(c) Other control device monitoring requirements. (1) Unless previously submitted and approved under the referencing subpart, if an owner or operator uses a control device other than those listed in this subpart, the owner or operator shall submit a description of planned monitoring, reporting, and recordkeeping procedures as required under §65.162(e). The Administrator will approve, deny, or modify based on the reasonableness of the proposed monitoring, reporting, and recordkeeping requirements as part of the review of the submission or permit application or by other appropriate means.

(2) The owner or operator shall establish a range for monitored parameters that indicates proper operation of the control device. To establish the range, the information required in §65.165(c) shall be submitted in the Initial Compliance Status Report or the operating permit application or amendment. The range may be based upon a prior performance test meeting the specifications in §65.157(b)(1) or upon existing ranges or limits established under a referencing subpart.

§65.156 General monitoring requirements for control and recovery devices.

(a) General monitoring requirement applicability. (1) This section applies to the owner or operator of a regulated source required to monitor under this subpart.

(2) Flares subject to §65.147(c) are not subject to the requirements of this section.

(3) Flow indicators are not subject to the requirements of this section.

(b) Conduct of monitoring. (1) Monitoring shall be conducted as set forth in this section and in the relevant sections of this subpart unless either of the following provisions applies :

(i) The Administrator specifies or approves the use of minor or intermediate changes in the specified monitoring requirements or procedures as provided in §65.7(b), (c), and (d); or

(ii) The Administrator specifies or approves the use of major changes in the specified monitoring requirements or procedures as provided in §65.7(b), (c), and (d).

(2) When one CPMS is used as a backup to another CPMS, the owner or operator shall report the results from the CPMS used to meet the monitoring requirements of this subpart. If both such CPMS are used during a particular reporting period to meet the monitoring requirements of this part, then the owner or operator shall report the results from each CPMS for the relevant compliance period.

(c) Operation and maintenance of continuous parameter monitoring systems. (1) All monitoring equipment shall be installed, calibrated, maintained, and operated according to manufacturers specifications or other written procedures that provide adequate assurance that the equipment would reasonably be expected to monitor accurately.