...

§65.80 Applicability.

(a) The provisions of this subpart and of subpart A of this part apply to control of regulated material emissions from transfer racks where a referencing subpart references the use of this subpart for such emissions control.

(b) If a physical or process change is made that causes a transfer rack to fall outside the criteria in the referencing subpart that required the transfer rack to control emission of regulated material, the owner or operator may elect to comply with the provisions for transfer racks not subject to control contained in the referencing subpart instead of the provisions of this subpart.

§65.81 Definitions.

All terms used in this subpart shall have the meaning given them in the Act and in subpart A of this part. If a term is defined in both subpart A of this part and in other subparts that reference the use of this subpart, the term shall have the meaning given in subpart A of this part for purposes of this subpart.

§65.82 Design requirements.

(a) The owner or operator shall equip each transfer rack with either one of the following equipment:

(1) A closed vent system which routes the regulated material vapors to a control device as provided in §65.83(a)(1) and (2).

(2) Process piping which routes the regulated material vapors to a process or a fuel gas system as provided in §65.83(a)(4), or to a vapor balance system as provided in §65.83(a)(3).

(b) Each closed vent system shall be designed to collect the regulated material displaced from tank trucks or railcars during loading and to route the collected regulated material to a control device as provided in §65.83(a)(1) and (2).

(c) Process piping shall be designed to collect the regulated material displaced from tank trucks or railcars during loading and to route the collected regulated material vapors to a process or a fuel gas system as provided in §65.83(a)(4), or to a vapor balance system as provided in §65.83(a)(3).

(d) Each closed vent system shall meet the applicable requirements of §65.143.

(e) If the collected regulated material vapors are routed to a process or a fuel gas system as provided in §65.83(a)(4), then each owner or operator shall meet the applicable requirements of §65.142(c).

§65.83 Performance requirements.

(a) The owner or operator of the transfer rack shall comply with paragraph (a)(1), (2), (3), or (4) of this section.

(1) 98 Percent or 20 parts per million by volume standard. Use a control device to reduce emissions of regulated material by 98 weight-percent or to an exit concentration of 20 parts per million by volume, whichever is less stringent. For combustion devices, the emission reduction or concentration shall be calculated on a dry basis, corrected to 3 percent oxygen. The owner or operator shall meet the applicable requirements of §65.142(c). Compliance may be achieved by using any combination of control devices.

(2) Flare. Reduce emissions of regulated material using a flare meeting the applicable requirements of §65.142(c).

(3) Vapor balancing. Reduce emissions of regulated material using a vapor balancing system designed and operated to collect regulated material vapors displaced from tank trucks or railcars during loading; and to route the collected regulated material vapors to the storage vessel from which the liquid being loaded originated, or to another storage vessel connected to a common header, or to compress and route collected regulated material vapors to a process. Transfer racks for which the owner or operator is using a vapor balancing system are exempt from the closed vent system design requirements of §65.82(b) and (d), the halogenated vent stream control requirements of paragraph (b) of this section, the control device operation requirements of §65.84(b), the monitoring requirements of §65.86, and the requirements of subpart G of this part.

(4) Route to a process or fuel gas system. Route emissions of regulated material to a process or fuel gas system. The owner or operator shall meet the applicable requirements of §65.142(c) and is exempt from the closed vent system design requirements of paragraphs §65.82(b) and (d), the halogenated vent stream control requirements of paragraph (b) of this section, the control device operation requirements of §65.84(b), and the monitoring requirements of §65.86. If the emissions are routed to a process, the regulated material in the emissions shall predominantly meet one of, or a combination of, the ends specified in the following:

(i) Recycled and/or consumed in the same manner as a material that fulfills the same function in that process;

(ii) Transformed by chemical reaction into materials that are not regulated materials;

(iii) Incorporated into a product; and/or

(iv) Recovered.

(b) Additional control requirements for halogenated vent streams. Halogenated vent streams from transfer racks that are combusted shall be controlled according to paragraph (b)(1) or (2) of this section. The owner or operator shall either designate the transfer rack vent stream as a halogenated vent stream or shall determine whether the vent stream is halogenated using the procedures specified in §65.85(c). If determined, the halogen concentration in the vent stream shall be recorded and reported in the Initial Compliance Status Report as specified in §65.160(d). If the owner or operator designates the vent stream as a halogenated vent stream, then this shall also be recorded and reported in the Initial Compliance Status Report.

(1) Halogen reduction device following combustion. If a combustion device is used to comply with paragraph (a)(1) of this section for a halogenated vent stream, then the vent stream exiting the combustion device shall be ducted to a halogen reduction device including, but not limited to, a scrubber before it is discharged to the atmosphere, and the halogen reduction device shall meet the requirements of paragraph (b)(1)(i) or (ii) of this section, as applicable. The halogenated vent stream shall not be combusted using a flare.

(i) Except as provided in paragraph (b)(1)(ii) of this section, the halogen reduction device shall reduce overall emissions of hydrogen halides and halogens by 99 percent or shall reduce the outlet mass emission rate of total hydrogen halides and halogens to 0.45 kilogram per hour (0.99 pound per hour) or less, whichever is less stringent. The owner or operator shall meet the applicable requirements of §65.142(c).

(ii) If a scrubber or other halogen reduction device was installed prior to December 31, 1992, the halogen reduction device shall reduce overall emissions of hydrogen halides and halogens by 95 percent or shall reduce the outlet mass of total hydrogen halides and halogens to less than 0.45 kilogram per hour (0.99 pound per hour), whichever is less stringent. The owner or operator shall meet the applicable requirements of §65.142(c).

(2) Halogen reduction device prior to combustion. A halogen reduction device, such as a scrubber, or other technique may be used to make the vent stream nonhalogenated by reducing the vent stream halogen atom mass emission rate to less than 0.45 kilogram per hour (0.99 pound per hour) prior to any combustion control device used to comply with the requirements of paragraph (a)(1) or (2) of this section. The mass emission rate of halogen atoms contained in organic compounds prior to the combustor shall be determined according to the procedures in §65.85(c). The owner or operator shall maintain the record specified in §65.160(d) and submit the report specified in §65.165(d).

§65.84 Operating requirements.

(a) Closed vent systems or process piping. An owner or operator of a transfer rack shall operate it in such a manner that emissions are routed through the equipment specified in either paragraph (a)(1) or (2) of this section.

(1) A closed vent system which routes the regulated material vapors to a control device as provided in §65.83(a)(1) and (2).

(2) Process piping which routes the regulated material vapors to a process or a fuel gas system as provided in §65.83(a)(4) or to a vapor balance system as provided in §65.83(a)(3).

(b) Control device operation. Whenever regulated material emissions are vented to a control device used to comply with the provisions of this subpart, such control device shall be operating.

(c) Tank trucks and railcars. The owner or operator shall load regulated material only into tank trucks and railcars that meet one of the following two requirements and shall maintain the records specified in §65.87:

(1) Have a current certification in accordance with the U.S. Department of Transportation (DOT) pressure test requirements of 49 CFR part 180 for tank trucks and 49 CFR 173.31 for railcars; or

(2) Have been demonstrated to be vapor-tight within the preceding 12 months as determined by the procedures in §65.85(a). Vapor-tight means that the pressure in a truck or railcar tank will not drop more than 750 pascals (0.11 pound per square inch) within 5 minutes after it is pressurized to a minimum of 4,500 pascals (0.65 pound per square inch).

(d) Pressure relief device. The owner or operator of a transfer rack subject to the provisions of this subpart shall ensure that no pressure relief device in the loading equipment of each tank truck or railcar shall begin to open to the atmosphere during loading. Pressure relief devices needed for safety purposes are not subject to paragraph (d) of this section.

(e) Compatible system. The owner or operator of a transfer rack subject to the provisions of this subpart shall load regulated material only to tank trucks or railcars equipped with a vapor collection system that is compatible with the transfer rack's closed vent system or process piping.

(f) Loading while systems connected. The owner or operator of a transfer rack subject to this subpart shall load regulated material only to tank trucks or railcars whose collection systems are connected to the transfer rack's closed vent systems or process piping.

§65.85 Procedures.

(a) Vapor tightness. For the purposes of demonstrating vapor tightness to determine compliance with §65.84(c)(2), the following procedures and equipment shall be used:

(1) The pressure test procedures specified in Method 27 of appendix A of 40 CFR part 60; and

(2) A pressure measurement device that has a precision of ±2.5 millimeters of mercury (0.10 inch) or better and that is capable of measuring above the pressure at which the tank truck or railcar is to be tested for vapor tightness.

(b) Engineering assessment. Engineering assessment to determine if a vent stream is halogenated or flow rate of a gas stream includes, but is not limited to, the following examples:

(1) Previous test results, provided the tests are representative of current operating practices at the process unit.

(2) Bench-scale or pilot-scale test data representative of the process under representative operating conditions.

(3) Maximum flow rate or halogen emission rate specified or implied within a permit limit applicable to the process vent.

(4) Design analysis based on accepted chemical engineering principles, measurable process parameters, or physical or chemical laws or properties.

(5) All data, assumptions, and procedures used in the engineering assessment shall be documented.

(c) Halogenated vent stream determination. In order to determine whether a vent stream is halogenated, the mass emission rate of halogen atoms contained in organic compounds shall be calculated as specified in paragraphs (c)(1) and (2) of this section.

(1) The vent stream concentration of each organic compound containing halogen atoms (parts per million by volume by compound) shall be determined based on any of the following procedures:

(i) Process knowledge that no halogen or hydrogen halides are present in the vent stream; or

(ii) Applicable engineering assessment as specified in paragraph (b) of this section; or

(iii) Concentration of organic compounds containing halogens measured by Method 18 of appendix A of 40 CFR part 60; or

(iv) Any other method or data that have been validated according to the applicable procedures in Method 301 of appendix A of 40 CFR part 63.

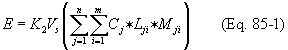

(2) Equation 85-1 of this section shall be used to calculate the mass emission rate of halogen atoms:

Where:

E = Mass of halogen atoms, dry basis, kilograms per hour.

K2 = Constant, 2.494 × 10?6 (parts per million)?1 (kilogram-mole per standard cubic meter) (minute/hour), where standard temperature is 20°C.

Vs = Flow rate of gas stream, dry standard cubic meters per minute, determined according to Method 2, 2A, 2C, or 2D of appendix A of 40 CFR part 60, as appropriate, or determined using engineering assessment as specified in paragraph (b) of this section.

n = Number of halogenated compounds j in the gas stream.

j = Halogenated compound j in the gas stream.

m = Number of different halogens i in each compound j of the gas stream.

i = Halogen atom i in compound j of the gas stream.

Cj = Concentration of halogenated compound j in the gas stream, dry basis, parts per million by volume.

Lji = Number of atoms of halogen i in compound j of the gas stream.

Mji = Molecular weight of halogen atom i in compound j of the gas stream, kilogram per kilogram-mole.

§65.86 Monitoring.

The owner or operator of a transfer rack equipped with a closed vent system and control device pursuant to §65.83(a)(1) or (2) shall monitor the closed vent system and control device as required under the applicable paragraphs specified in §65.142(c).

§65.87 Recordkeeping provisions.

The owner or operator of a transfer rack shall record that either the verification of U.S. Department of Transportation (DOT) tank certification or Method 27 of appendix A of 40 CFR part 60 testing required in §65.84(c) has been performed. Various methods for the record of verification can be used, such as a check off on a log sheet, a list of DOT serial numbers or Method 27 data, or a position description for gate security showing that the security guard will not allow any trucks on-site that do not have the appropriate documentation.