['Air Programs']

['Air Quality']

11/20/2023

...

§60.560 Applicability and designation of affected facilities.

(a) Affected facilities. The provisions of this subpart apply to affected facilities involved in the manufacture of polypropylene, polyethylene, polystyrene, or poly (ethylene terephthalate) as defined in §60.561 of this subpart. The affected facilities designated below for polypropylene and polyethylene are inclusive of all equipment used in the manufacture of these polymers, beginning with raw materials preparation and ending with product storage, and cover all emissions emanating from such equipment.

(1) For process emissions from any polypropylene and polyethylene manufacturing process that uses a continuous process, the affected facilities are each of the following process sections: each raw materials preparation section, each polymerization reaction section, each material recovery section, each product finishing section, and each product storage section. These process sections are affected facilities for process emissions that are emitted continuously and for process emissions that are emitted intermittently.

(2) For process emissions from polystyrene manufacturing processes that use a continuous process, the affected facilities are each material recovery section. These process sections are affected facilities for only those process emissions that are emitted continuously.

(3) For process emissions from poly(ethylene terephthalate) manufacturing processes that use a continuous process, the affected facilities are each polymerization reaction section. If the process uses dimethyl terephthalate, then each material recovery section is also an affected facility. If the process uses terephthalic acid, then each raw materials preparation section is also an affected facility. These process sections are affected facilities for only those process emissions that are emitted continuously.

(4) For VOC emissions from equipment leaks from polypropylene, polyethylene, and polystyrene (including expandable polystyrene) manufacturing processes, the affected facilities are each group of fugitive emissions equipment (as defined in §60.561) within any process unit (as defined in §60.561). This subpart does not apply to VOC emissions from equipment leaks from poly(ethylene terephthalate) manufacturing processes.

(i) Affected facilities with a design capacity to produce less than 1,000 Mg/yr (1,102 ton/yr) shall be exempt from §60.562-2.

(ii) Addition or replacement of equipment for the purposes of improvement which is accomplished without a capital expenditure shall not by itself be considered a modification under §60.562-2.

(b) Applicability dates. The applicability date identifies when an affected facility becomes subject to a standard. Usually, a standard has a single applicability date. However, some polypropylene and polyethylene affected facilities have a September 30, 1987, applicability date and others have a January 10, 1989, applicability date. The following paragraphs identify the applicability dates for all affected facilities subject to this subpart.

(1) Polypropylene and polyethylene. Each process section in a polypropylene or polyethylene production process is a potential affected facility for both continuous and intermittent emissions. The applicability date depends on when the process section was constructed, modified, or reconstructed and, in some instances, on the type of production process.

(i) The applicability date for any polypropylene or polyethylene affected facility that is constructed, modified, or reconstructed after January 10, 1989, regardless of the type of production process being used, is January 10, 1989.

(ii) Only some polypropylene or polyethylene process sections that are constructed, modified, or reconstructed on or before January 10, 1989, but after September 30, 1987, are affected facilities. These process sections (and the type of emissions to be controlled) are identified by an “x” in table 1. The applicability date for the process sections (and the emissions to be controlled) that are identified by an “x” in table 1 is September 30, 1987. Since the affected facilities that have a September 30, 1987, applicability date are determined by the type of production process (e.g., liquid phase, gas phase), each owner or operator shall identify the particular production process that applies to his or her particular process.

| Polymer | Production process(es) | Process section | Emissions | |

|---|---|---|---|---|

| Continuous | Intermittent | |||

| Polypropylene | Liquid Phase | Raw Materials Preparation | X | |

| Polymerization Reaction | X | |||

| Material Recovery | X | X | ||

| Product Finishing | X | |||

| Product Storage | ||||

| Polypropylene | Gas Phase | Raw Materials Preparation | ||

| Polymerization Reaction | X | |||

| Material Recovery | X | |||

| Product Finishing | ||||

| Product Storage | ||||

| Low Density Polyethylene | High Pressure | Raw Materials Preparation | X | |

| Polymerization Reaction | X | |||

| Material Recovery | X | |||

| Product Finishing | X | |||

| Product Storage | X | |||

| Low Density Polyethylene | Low Pressure | Raw Materials Preparation | X | X |

| High Density Polyethylene | Gas Phase | Polymerization Reaction | X | |

| Material Recovery | ||||

| Product Finishing | X | |||

| Product Storage | ||||

| High Density Polyethylene | Liquid Phase Slurry | Raw Materials Preparation | X | |

| Polymerization Reaction | ||||

| Material Recovery | X | |||

| Product Finishing | X | |||

| Product Storage | ||||

| High Density Polyethylene | Liquid Phase Solution | Raw Materials Preparation | X | X |

| Polymerization Reaction | X | |||

| Material Recovery | X | X | ||

| Product Finishing | ||||

| Product Storage | ||||

(2) Polystyrene. The applicability date for each polystyrene affected facility is September 30, 1987.

(3) Poly(ethylene terephthalate). The applicability date for each poly(ethylene terephthalate) affected facility is September 30, 1987.

(c) Any facility under paragraph (a) of this section that commences construction, modification, or reconstruction after its applicability date as identified under paragraph (b) of this section is subject to the requirements of this subpart, except as provided in paragraphs (d) through (f) of this section.

(d) Any polypropylene or polyethylene affected facility with a September 30, 1987, applicability date that commenced construction, modification, or reconstruction after September 30, 1987, and on or before January 10, 1989, with an uncontrolled emission rate (as defined in footnote a to table 2) at or below those identified in table 2 is not subject to the requirements of §60.562-1 unless and until its uncontrolled emission rate exceeds that rate listed for it in table 2 or it is modified or reconstructed after January 10, 1989. At such time, such facility becomes subject to §60.562-1 and the procedures identified in §60.562-1(a) shall be used to determine the control of emissions from the facility.

| Production process | Process section | Uncontrolled emission rate, kg TOC/Mg product (See associated footnote) |

|---|---|---|

| a “Uncontrolled emission rate” refers to the emission rate of a vent stream that vents directly to the atmosphere and to the emission rate of a vent stream to the atmosphere that would occur in the absence of any add-on control devices but after any material recovery devices that constitute part of the normal material recovery operations in a process line where potential emissions are recovered for recycle or resale. b Emission rate applies to continuous emissions only. c Emission rate applies to intermittent emissions only. d Total emission rate for non-emergency intermittent emissions from raw materials preparation, polymerization reaction, material recovery, product finishing, and product storage process sections. e See footnote d. f Emission rate applies to both continuous and intermittent emissions. g Emission rate applies to non-emergency intermittent emissions only. h Applies to modified or reconstructed affected facilities only. i Includes emissions from the cooling water tower. j Applies to a process line producing low viscosity poly(ethylene terephthlalate). k Applies to a process line producing high viscosity poly(ethylene terephathalate). l See footnote m. m Applies to the sum of emissions to the atmosphere from the polymerization reaction section (including emissions from the cooling tower) and the raw materials preparation section (i.e., the esterifiers). | ||

| Polypropylene, liquid phase process | Raw Materials Preparation | 0.15 b |

| Polymerization Reaction | 0.14 b, 0.24 c | |

| Material Recovery | 0.19 b | |

| Product Finishing | 1.57 b | |

| Polypropylene, gas phase process | Polymerization Reaction | 0.12 c |

| Material Recovery | 0.02 b | |

| Low Density Polyethylene, low pressure process | Raw Materials Preparation | 0.41 d |

| Polymerization Reaction | (e) | |

| Material Recovery | (e) | |

| Product Finishing | (e) | |

| Product Storage | (e) | |

| Low Density Polythylene, low pressure process | Raw Materials Preparation | 0.05 f |

| Polymerization Reaction | 0.03 g | |

| Product Finishing | 0.01 b | |

| High Density Polyethylene, liquid phase slurry process | Raw Materials Preparation | 0.25 c |

| Material Recovery | 0.11 b | |

| Product Finishing | 0.41 b | |

| High Density Polyethylene, liquid phase solution process | Raw Materials Preparation | 0.24 f |

| Polymerization Reaction | 0.16 c | |

| Material Recovery | 1.68 f | |

| High Density Polyethylene, gas phase process | Raw Materials Preparation | 0.05 f |

| Polymerization Reaction | 0.03 g | |

| Product Finishing | 0.01 b | |

| Polystyrene, continuous process | Material Recovery | 0.05 b h |

| Poly(ethylene terephalate), dimethyl terephthalate process | Material Recovery | 0.12 b h |

| Polymerization Reaction | 1.80 h i j | |

| Poly(ethlyene terephthalate), terephthalic acid process | Raw Materials Preparation | (l) |

| Polymerization Reaction | 1.80 h j m | |

| 3.92 h k m | ||

(e)(1) Modified or reconstructed affected facilities at polystyrene and poly(ethylene terephthalate) plants with uncontrolled emission rates at or below those identified in table 2 are exempt from the requirements of §60.562-1 unless and until its uncontrolled emission rate exceeds that rate listed for it in table 2. This exemption does not apply to new polystyrene or poly(ethylene terephthalate) affected facilities.

(2) Emissions from modified or reconstructed affected facilities that are controlled by an existing control device and that have uncontrolled emission rates greater than the uncontrolled threshold emission rates identified in table 2 are exempt from the requirements of §60.562-1 unless and until the existing control device is modified, reconstructed, or replaced.

(f) No process section of an experimental process line is considered an affected facility for continuous or intermittent process emissions.

(g) Individual vent streams that emit continuous emissions with uncontrolled annual emissions of less than 1.6 Mg/yr (1.76 ton/yr) or with a weight percent TOC of less than 0.10 percent from a new, modified, or reconstructed polypropylene or polyethylene affected facility are exempt from the requirements of §60.562-1(a)(1). If at a later date, an individual stream's uncontrolled annual emissions become 1.6 Mg/yr (1.76 ton/yr) or greater (if the stream was exempted on the basis of the uncontrolled annual emissions exemption) or VOC concentration becomes 0.10 weight percent or higher (if the stream was exempted on the basis of the VOC concentration exemption), then the stream is subject to the requirements of §60.562-1.

(h) Emergency vent streams, as defined in §60.561, from a new, modified, or reconstructed polypropylene or polyethylene affected facility are exempt from the requirements of §60.562-1(a)(2).

(i) An owner or operator of a polypropylene or polyethylene affected facility that commenced construction, modification, or reconstruction after September 30, 1987, and on or before January 10, 1989, and that is in a process line in which more than one type of polyolefin (i.e., polypropylene, low density polyethylene, high density polyethylene, or their copolymers) is produced shall select one of the polymer/production process combinations in table 1 for purposes of determining applicable affected facilities and uncontrolled threshold emissions rates.

(j) Alternative means of compliance - (1) Option to comply with part 65. Owners or operators may choose to comply with 40 CFR part 65, subpart G, for continuous process vents that are subject to this subpart, that choose to comply with §60.562-1(a)(1)(i)(A), (B), or (C) as allowed in §60.562-1(a)(1) and (b)(1)(iii). The requirements of 40 CFR part 65, subpart G, satisfy the requirements of paragraph (c) of this section and §§60.563 through 60.566, except for §60.565(g)(1). Other provisions applying to owners or operators who choose to comply with 40 CFR part 65 are provided in 40 CFR 65.1.

(2) Part 60, subpart A. Owners or operators who choose to comply with 40 CFR part 65, subpart G, must also comply with §§60.1, 60.2, 60.5, 60.6, 60.7(a)(1) and (4), 60.14, 60.15, and 60.16 for those process vents. All sections and paragraphs of subpart A of this part that are not mentioned in this paragraph (j)(2) do not apply to owners or operators of process vents complying with 40 CFR part 65, subpart G, except that provisions required to be met prior to implementing 40 CFR part 65 still apply. Owners and operators who choose to comply with 40 CFR part 65, subpart G, must comply with 40 CFR part 65, subpart A.

(3) Initial startup notification. Each owner or operator subject to the provisions of this subpart that chooses to comply with 40 CFR part 65, subpart G, at initial startup shall notify the Administrator of the specific provisions of 40 CFR part 65, subpart G, with which the owner or operator has elected to comply. Notification shall be submitted with the notification of initial startup required by 40 CFR 65.5(b).

(Note:

The numerical emission limits in these standards are expressed in terms of total organic compounds, measured as total organic compounds less methane and ethane.)

[55 FR 51035, Dec. 11, 1990; 56 FR 12299, Mar. 22, 1991, as amended at 65 FR 61765, Oct. 17, 2000; 65 FR 78278, Dec. 14, 2000]

§60.561 Definitions.

As used in this subpart, all terms not defined herein shall have the meaning given them in the Act, in subpart A of part 60, or in subpart VV of part 60, and the following terms shall have the specific meanings given them.

Boiler means any enclosed combustion device that extracts useful energy in the form of steam.

Capital expenditure means, in addition to the definition in 40 CFR 60.2, an expenditure for a physical or operational change to an existing facility that exceeds P, the product of the facility's replacement cost, R, and an adjusted annual asset guideline repair allowance, A, as reflected by the following equation: P = R × A, where

(a) The adjusted annual asset guideline repair allowance, A, is the product of the percent of the replacement cost, Y, and the applicable basic annual asset guideline repair allowance, B, as reflected by the following equation: A = Y × (B ÷ 100);

(b) The percent Y is determined from the following equation: Y = 1.0 − 0.57 log X, where X is 1986 minus the year of construction; and

(c) The applicable basic annual asset guideline repair allowance, B, is equal to 12.5.

Car-sealed means, for purposes of these standards, a seal that is placed on the device used to change the position of a valve (e.g., from opened to closed) such that the position of the valve cannot be changed without breaking the seal and requiring the replacement of the old seal once broken with a new seal.

Closed vent system means a system that is not open to the atmosphere and that is composed of piping, connections, and, if necessary, flow inducing devices that transport gas or vapor from a piece or pieces of equipment to a control device.

Continuous emissions means any gas stream containing VOC that is generated essentially continuously when the process line or any piece of equipment in the process line is operating.

Continuous process means a polymerization process in which reactants are introduced in a continuous manner and products are removed either continuously or intermittently at regular intervals so that the process can be operated and polymers produced essentially continuously.

Control device means an enclosed combustion device, vapor recovery system, or flare.

Copolymer means a polymer that has two different repeat units in its chain.

Decomposition means, for the purposes of these standards, an event in a polymerization reactor that advances to the point where the polymerization reaction becomes uncontrollable, the polymer begins to break down (decompose), and it becomes necessary to relieve the reactor instantaneously in order to avoid catastrophic equipment damage or serious adverse personnel safety consequences.

Decomposition emissions refers to those emissions released from a polymer production process as the result of a decomposition or during attempts to prevent a decomposition.

Emergency vent stream means, for the purposes of these standards, an intermittent emission that results from a decomposition, attempts to prevent decompositions, power failure, equipment failure, or other unexpected cause that requires immediate venting of gases from process equipment in order to avoid safety hazards or equipment damage. This includes intermittent vents that occur from process equipment where normal operating parameters (e.g., pressure or temperature) are exceeded such that the process equipment can not be returned to normal operating conditions using the design features of the system and venting must occur to avoid equipment failure or adverse safety personnel consequences and to minimize adverse effects of the runaway reaction. This does not include intermittent vents that are designed into the process to maintain normal operating conditions of process vessels including those vents that regulate normal process vessel pressure.

End finisher means a polymerization reaction vessel operated under very low pressures, typically at pressures of 2 mm Hg (1 in. H2O) or less, in order to produce high viscosity poly(ethylene terephthalate). An end finisher is preceded in a high viscosity poly(ethylene terephthalate) process line by one or more polymerization vessels operated under less severe vacuums, typically between 5 and 10 mm Hg (3 and 5 in. H2O). A high viscosity poly(ethylene terephthalate) process line may have one or more end finishers.

Existing control device means, for the purposes of these standards, an air pollution control device that has been in operation on or before September 30, 1987, or that has been in operation between September 30, 1987, and January 10, 1989, on those continuous or intermittent emissions from a process section that is marked by an “ - ” in table 1 of this subpart.

Existing control device is reconstructed means, for the purposes of these standards, the capital expenditure of at least 50 percent of the replacement cost of the existing control device.

Existing control device is replaced means, for the purposes of these standards, the replacement of an existing control device with another control device.

Expandable polystyrene means a polystyrene bead to which a blowing agent has been added using either an in-situ suspension process or a post-impregnation suspension process.

Experimental process line means a polymer or copolymer manufacturing process line with the sole purpose of operating to evaluate polymer manufacturing processes, technologies, or products. An experimental process line does not produce a polymer or resin that is sold or that is used as a raw material for nonexperimental process lines.

Flame zone means that portion of the combustion chamber in a boiler occupied by the flame envelope.

Fugitive emissions equipment means each pump, compressor, pressure relief device, sampling connection system, open-ended valve or line, valve, and flange or other connector in VOC service and any devices or systems required by subpart VV of this part.

Gas phase process means a polymerization process in which the polymerization reaction is carried out in the gas phase; i.e., the monomer(s) are gases in a fluidized bed of catalyst particles and granular polymer.

High density polyethylene (HDPE) means a thermoplastic polymer or copolymer comprised of at least 50 percent ethylene by weight and having a density of greater than 0.940 gm/cm 33 (58.7 lb/ft 3).

High pressure process means the conventional production process for the manufacture of low density polyethylene in which a reaction pressure of about 15,000 psig (103,000 kPa gauge) or greater is used.

High viscosity poly(ethylene terephthalate) means poly(ethylene terephthalate) that has an intrinsic viscosity of 0.9 or higher and is used in such applications as tire cord and seat belts.

Incinerator means an enclosed combustion device that is used for destroying VOC.

In-situ suspension process means a manufacturing process in which styrene, blowing agent, and other raw materials are added together within a reactor for the production of expandable polystyrene.

Intermittent emissions means those gas streams containing VOC that are generated at intervals during process line operation and includes both planned and emergency releases.

Liquid phase process means a polymerization process in which the polymerization reaction is carried out in the liquid phase; i.e., the monomer(s) and any catalyst are dissolved, or suspended in a liquid solvent.

Liquid phase slurry process means a liquid phase polymerization process in which the monomer(s) are in solution (completely dissolved) in a liquid solvent, but the polymer is in the form of solid particles suspended in the liquid reaction mixture during the polymerization reaction; sometimes called a particle form process.

Liquid phase solution process means a liquid phase polymerization process in which both the monomer(s) and polymer are in solution (completely dissolved) in the liquid reaction mixture.

Low density polyethylene (LDPE) means a thermoplastic polymer or copolymer comprised of at least 50 percent ethylene by weight and having a density of 0.940 g/cm 3 (58.7 lb/ft 3) or less.

Low pressure process means a production process for the manufacture of low density polyethylene in which a reaction pressure markedly below that used in a high pressure process is used. Reaction pressure of current low pressure processes typically go up to about 300 psig (2,070 kPa gauge).

Low viscosity poly(ethylene terephthalate) means a poly(ethylene terephthalate) that has an intrinsic viscosity of less than 0.75 and is used in such applications as clothing, bottle, and film production.

Material recovery section means the equipment that recovers unreacted or by-product materials from any process section for return to the process line, off-site purification or treatment, or sale. Equipment designed to separate unreacted or by-product material from the polymer product are to be included in this process section, provided at least some of the material is recovered for reuse in the process, off-site purification or treatment, or sale, at the time the process section becomes an affected facility. Otherwise such equipment are to be assigned to one of the other process sections, as appropriate. Equipment that treats recovered materials are to be included in this process section, but equipment that also treats raw materials are not to be included in this process section. The latter equipment are to be included in the raw materials preparation section. If equipment is used to return unreacted or by-product material directly to the same piece of process equipment from which it was emitted, then that equipment is considered part of the process section that contains the process equipment. If equipment is used to recover unreacted or by-product material from a process section and return it to another process section or a different piece of process equipment in the same process section or sends it off-site for purification, treatment, or sale, then such equipment are considered part of a material recovery section. Equipment used for the on-site recovery of ethylene glycol from poly(ethylene terephthalate) plants, however, are not included in the material recovery section, but are covered under the standards applicable to the polymerization reaction section (§60.562-1(c)(1)(ii)(A) or (2)(ii)(A)).

Operating day means, for the purposes of these standards, any calendar day during which equipment used in the manufacture of polymer was operating for at least 8 hours or one labor shift, whichever is shorter. Only operating days shall be used in determining compliance with the standards specified in §60.562-1(c)(1)(ii)(B), (1)(ii)(C), (2)(ii)(B), and (2)(ii)(C). Any calendar day in which equipment is used for less than 8 hours or one labor shift, whichever is less, is not an “operating day” and shall not be used as part of the rolling 14-day period for determining compliance with the standards specified in §60.562-1(c)(1)(ii)(B), (1)(ii)(C), (2)(ii)(B), and (2)(ii)(C).

Polyethylene means a thermoplastic polymer or copolymer comprised of at least 50 percent ethylene by weight; see low density polyethylene and high density polyethylene.

Poly(ethylene terephthalate) (PET) means a polymer or copolymer comprised of at least 50 percent bis-(2-hydroxyethyl)-terephthalate (BHET) by weight.

Poly(ethylene terephthalate) (PET) manufacture using dimethyl terephthalate means the manufacturing of poly(ethylene terephthalate) based on the esterification of dimethyl terephthalate (DMT) with ethylene glycol to form the intermediate monomer bis-(2-hydroxyethyl)-terephthalate (BHET) that is subsequently polymerized to form PET.

Poly(ethylene terephthalate) (PET) manufacture using terephthalic acid means the manufacturing of poly(ethylene terephthalate) based on the esterification reaction of terephthalic acid (TPA) with ethylene glycol to form the intermediate monomer bis-(2-hydroxyethyl)-terephthalate (BHET) that is subsequently polymerized to form PET.

Polymerization reaction section means the equipment designed to cause monomer(s) to react to form polymers, including equipment designed primarily to cause the formation of short polymer chains (oligomers or low polymers), but not including equipment designed to prepare raw materials for polymerization, e.g., esterification vessels. For the purposes of these standards, the polymerization reaction section begins with the equipment used to transfer the materials from the raw materials preparation section and ends with the last vessel in which polymerization occurs. Equipment used for the on-site recovery of ethylene glycol from poly(ethylene terephthalate) plants, however, are included in this process section, rather than in the material recovery process section.

Polypropylene (PP) means a thermoplastic polymer or copolymer comprised of at least 50 percent propylene by weight.

Polystyrene (PS) means a thermoplastic polymer or copolymer comprised of at least 80 percent styrene or para-methylstyrene by weight.

Post-impregnation suspension process means a manufacturing process in which polystyrene beads are first formed in a suspension process, washed, dried, or otherwise finished and then added with a blowing agent to another reactor in which the beads and blowing agent are reacted to produce expandable polystyrene.

Process heater means a device that transfers heat liberated by burning fuel to fluids contained in tubular coils, including all fluids except water that is heated to produce steam.

Process line means a group of equipment assembled that can operate independently if supplied with sufficient raw materials to produce polypropylene, polyethylene, polystyrene, (general purpose, crystal, or expandable) or poly(ethylene terephthalate) or one of their copolymers. A process line consists of the equipment in the following process sections (to the extent that these process sections are present at a plant): raw materials preparation, polymerization reaction, product finishing, product storage, and material recovery.

Process section means the equipment designed to accomplish a general but well-defined task in polymer production. Process sections include raw materials preparation, polymerization reaction, material recovery, product finishing, and product storage and may be dedicated to a single process line or common to more than one process line.

Process unit means equipment assembled to perform any of the physical and chemical operations in the production of polypropylene, polyethylene, polystyrene, (general purpose, crystal, or expandable), or poly(ethylene terephthalate) or one of their copolymers. A process unit can operate independently if supplied with sufficient feed or raw materials and sufficient storage facilities for the product. Examples of process units are raw materials handling and monomer recovery.

Product finishing section means the equipment that treats, shapes, or modifies the polymer or resin to produce the finished end product of the particular facility, including equipment that prepares the product for product finishing. For the purposes of these standards, the product finishing section begins with the equipment used to transfer the polymerized product from the polymerization reaction section and ends with the last piece of equipment that modifies the characteristics of the polymer. Product finishing equipment may accomplish product separation, extruding and pelletizing, cooling and drying, blending, additives introduction, curing, or annealing. Equipment used to separate unreacted or by-product material from the product are to be included in this process section, provided the material separated from the polymer product is not recovered at the time the process section becomes an affected facility. If the material is being recovered, then the separation equipment are to be included in the material recovery section. Product finishing does not include polymerization, the physical mixing of the pellets to obtain a homogenous mixture of the polymer (except as noted below), or the shaping (such as fiber spinning, molding, or fabricating) or modification (such as fiber stretching and crimping) of the finished end product. If physical mixing occurs in equipment located between product finishing equipment (i.e., before all the chemical and physical characteristics have been “set” by virtue of having passed through the last piece of equipment in the product finishing section), then such equipment are to be included in this process section. Equipment used to physically mix the finished product that are located after the last piece of equipment in the product finishing section are part of the product storage section.

Product storage section means the equipment that is designed to store the finished polymer or resin end product of the particular facility. For the purposes of these standards, the product storage section begins with the equipment used to transfer the finished product out of the product finishing section and ends with the containers used to store the final product. Any equipment used after the product finishing section to recover unreacted or by-product material are to be considered part of a material recovery section. Product storage does not include any intentional modification of the characteristics of any polymer or resin product, but does include equipment that provide a uniform mixture of product, provided such equipment are used after the last product finishing piece of equipment. This process section also does not include the shipment of a finished polymer or resin product to another facility for further finishing or fabrication.

Raw materials preparation section means the equipment located at a polymer manufacturing plant designed to prepare raw materials, such as monomers and solvents, for polymerization. For the purposes of these standards, this process section begins with the equipment used to transfer raw materials from storage and recovered material from material recovery process sections, and ends with the last piece of equipment that prepares the material for polymerization. The raw materials preparation section may include equipment that accomplishes purification, drying, or other treatment of raw materials or of raw and recovered materials together, activation of catalysts, and esterification including the formation of some short polymer chains (oligomers), but does not include equipment that is designed primarily to accomplish the formation of oligomers, the treatment of recovered materials alone, or the storage of raw materials.

Recovery system means an individual unit or series of material recovery units, such as absorbers, condensers, and carbon adsorbers, used for recovering volatile organic compounds.

Total organic compounds (TOC) means those compounds measured according to the procedures specified in §60.564.

Vent stream means any gas stream released to the atmosphere directly from an emission source or indirectly either through another piece of process equipment or a material recovery device that constitutes part of the normal recovery operations in a polymer process line where potential emissions are recovered for recycle or resale, and any gas stream directed to an air pollution control device. The emissions released from an air pollution control device are not considered a vent stream unless, as noted above, the control device is part of the normal material recovery operations in a polymer process line where potential emissions are recovered for recycle or resale.

Volatile organic compounds (VOC) means, for the purposes of these standards, any reactive organic compounds as defined in §60.2 Definitions.

[55 FR 51035, Dec. 11, 1990; 56 FR 9178, Mar. 5, 1991; 56 FR 12299, Mar. 22, 1991; 65 FR 61767, Oct. 17, 2000]

§60.562-1 Standards: Process emissions.

(a) Polypropylene, low density polyethylene, and high density polyethylene. Each owner or operator of a polypropylene, low density polyethylene, or high density polyethylene process line containing a process section subject to the provisions of this subpart shall comply with the provisions in this section on and after the date on which the initial performance test required by §60.8 is completed, but not later than 60 days after achieving the maximum production rate at which the affected facility will be operated, or 180 days after initial startup whichever comes first.

(1) Continuous emissions. For each vent stream that emits continuous emissions from an affected facility as defined in §60.560(a)(1) , the owner or operator shall use the procedures identified in paragraphs (a)(1) (ii) and (iii) of this section for determining which continuous emissions are to be controlled and which level of control listed in paragraph (a)(1)(i) of this section is to be met. The owner or operator shall use the procedures identified in paragraphs (a)(1) (ii) and (iii) of this section each time a process section is constructed, modified, or reconstructed at the plant site.

(i) Level of control Continuous emission streams determined to be subject to control pursuant to the procedures identified in paragraphs (a)(1) (ii) and (iii) of this section, as applicable, shall meet one of the control levels identified in paragraphs (a)(1)(i) (A) through (D) of this section. The procedures in paragraphs (a)(1) (ii) and (iii) of this section identify which level of control may be met. The level of control identified in paragraph (a)(1)(i)(D) of this section is limited to certain continuous emission streams, which are identified through the procedures in paragraphs (a)(1) (ii) and (iii) of this section.

(A) Reduce emissions of total organic compounds (minus methane and ethane) (TOC) by 98 weight percent, or to a concentration of 20 parts per million by volume (ppmv) on a dry basis, whichever is less stringent. The TOC is expressed as the sum of the actual compounds, not carbon equivalents. If an owner or operator elects to comply with the 20 ppmv standard, the concentration shall include a correction to 3 percent oxygen only when supplemental combustion air is used to combust the vent stream.

(B) Combust the emissions in a boiler or process heater with a design heat input capacity of 150 million Btu/hour or greater by introducing the vent stream into the flame zone of the boiler or process heater. (Note: A boiler or process heater of lesser design heat capacity may be used, but must demonstrate compliance with paragraph (a)(1)(i)(A) of this section.)

(C) Combust the emissions in a flare that meets the conditions specified in §60.18 . If the flare is used to control both continuous and intermittent emissions, the flare shall meet the conditions specified in §60.18 at all times (i.e., which controlling continuous emissions alone or when controlling both continuous and intermittent emissions).

(D) Vent the emissions to a control device located on the plant site.

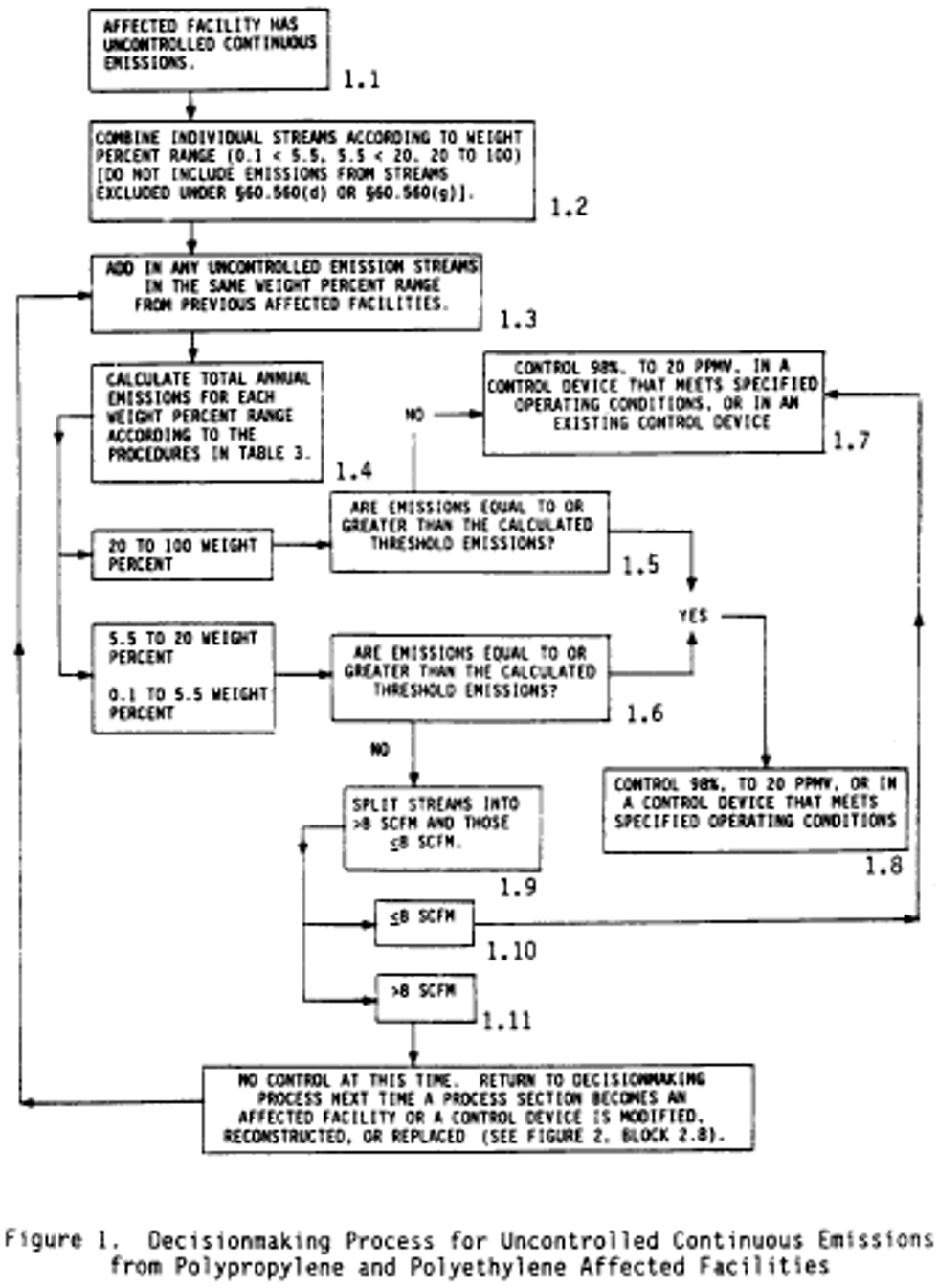

(ii) Uncontrolled Continuous Emissions. For each vent stream that emits continuous emissions from an affected facility as defined in §60.560(a)(1) and that is not controlled in an existing control device, the owner or operator shall use the procedures identified in table 3 to identify those continuous emissions from each constructed, modified, or reconstructed affected facility that are to be controlled. The owner shall include in the procedure all uncontrolled continuous vent streams from previously constructed, modified, or reconstructed affected facilities at the plant site each time a process section is constructed, modified, or reconstructed at the plant site. In applying the procedures shown in table 3, the stream characteristics may be either measured or calculated as specified in §60.564(d) . For modified or reconstructed affected facilities, these stream characteristics are to be determined after a modification or reconstruction determination has been made by the Administrator, but before any actual changes have been undertaken, and then again after the actual changes have been made. Figure 1 provides a summary overview of the control determination procedure described in table 3.

| Procedure a | Applicable TOC weight percent range | Control/no control criteria | Applicable standard |

|---|---|---|---|

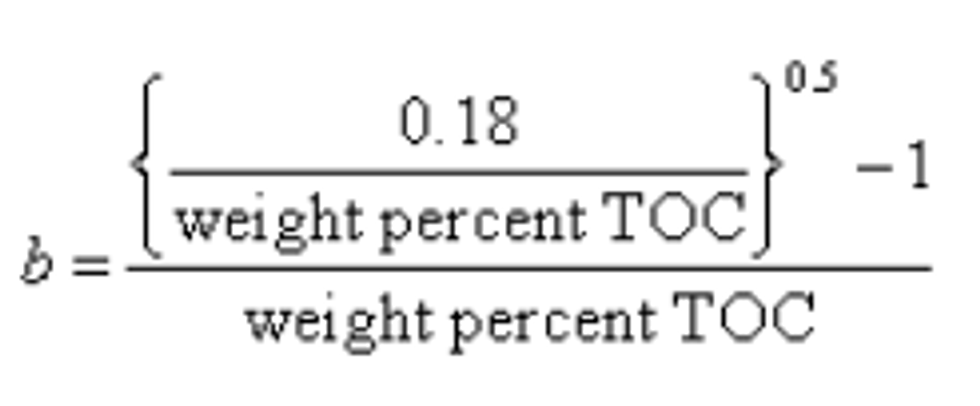

| a Individual streams excluded under §60.560(g) from the requirements of §60.562-1 are to be excluded from all calculations in this table. This paragraph exempts all individual emission streams with individual uncontrolled annual emission rates of less than 1.6 Mg/yr and all individual emission streams with individual TOC concentrations of less than 0.10 percent TOC by weight. b For the 0.10 to less than 5.5 weight percent range, the following equations are used: | |||

| 1. Sum all uncontrolled streams with TOC weight percent within the applicable weight percent range from all affected facilities at a plant site | 0.10 < 5.5 | 1. If total combined uncontrolled emissions are equal to or greater than the calculated threshold emissions (CTE) b , control | 1. §60.562-1(a)(1)(i) (A) , (B), or (C). |

| 2. Calculate total uncontrolled annual emissions for each weight percent range. For modified or affected facilities, use the total uncontrolled emissions after modification or reconstruction | 2. If total combined uncontrolled emission are less than the CTE b , control only individual streams with volume flow rates of 8 scfm or less | 2. §60.562-1(a)(1)(i) (A) through (D). | |

| 3. Calculate composite TOC concentration (weight percent) for streams in the 0.10 to less than 5.5 weight percent range and for streams in the 5.5 to less than 20 weight percent range. For modified or reconstructed affected facilities, calculate the composite VOC concentration before and after modification and reconstruction | 5.5 < 20 | 1. If total combined uncontrolled emissions are equal to or greater than CTE b , control | 1. §60.562-1(a)(1)(i) (A) , (B), or (C) 2. If total combined uncontrolled emissions are less than the CTE b , control only individual streams with volume flow rates of 8 scfm or less. |

| 4. Select the higher of the two TOC concentrations for each weight percent range for vent streams from a modified or reconstructed affected facility | 20 to 100 | 1. If total combined uncontrolled emissions are equal to or greater than 18.2 Mg/yr, control | 1. §60.562-1(a)(1)(i) (A) , (B), or (C). |

| 5. Calculate the threshold emissions for the 0.10 to less than 5.5 weight percent range and for the 5.5 to less than 20 weight percent range using the respective composite TOC concentration selected above | 2. If total combined uncontrolled emissions are less than 18.2 Mg/yr, control | 2. §60.562-1(a)(1)(i) (A) through (D). | |

| If the percent composite TOC concentration is | Use this equation to calculate threshold emissions |

|---|---|

| 0.10<0.12 | (a × 7.5 × 10 6 ) 226 |

| 0.12<0.2 | (b × 58.3) 116.8 |

| 0.2<0.3 | (c × 3020) 71.8 |

| 0.3<0.4 | (d × 547) 54.5 |

| 0.4<0.6 | 48.3 31 (0.6−weight percent TOC) |

| 0.6<5.5 | 48.3 |

where: a = (0.12 − weight percent TOC). 2 5

c = (0.3−weight percent TOC) 2

d = (0.4−weight percent TOC). 1 5

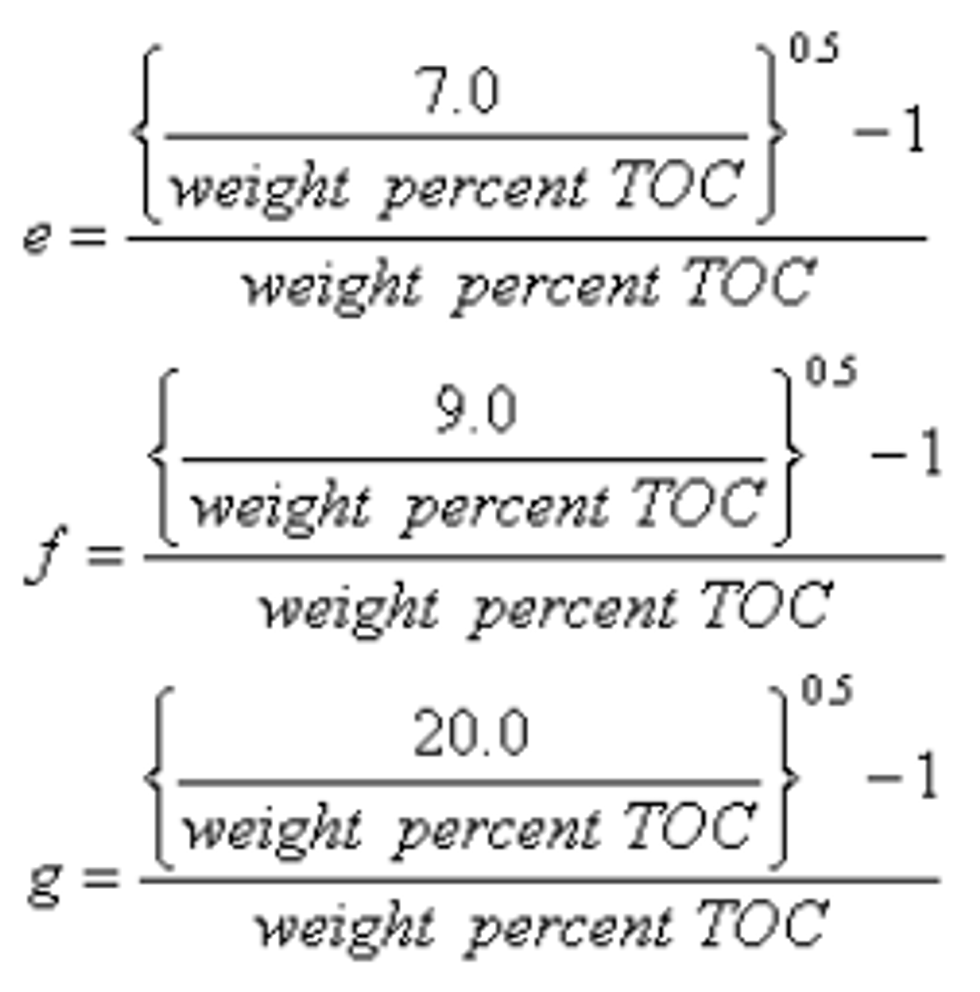

For the 5.5 to less than 20 weight percent range, the following equations are used.

| If the percent composite TOC concentration is | Use this equation to calculate threshold emissions |

|---|---|

| 5.5<7.0 | (e × 740) 31 |

| 7.0<9.0 | (f × 324) 25.0 |

| 9.0<20 | (g × 125) 18.2 |

where

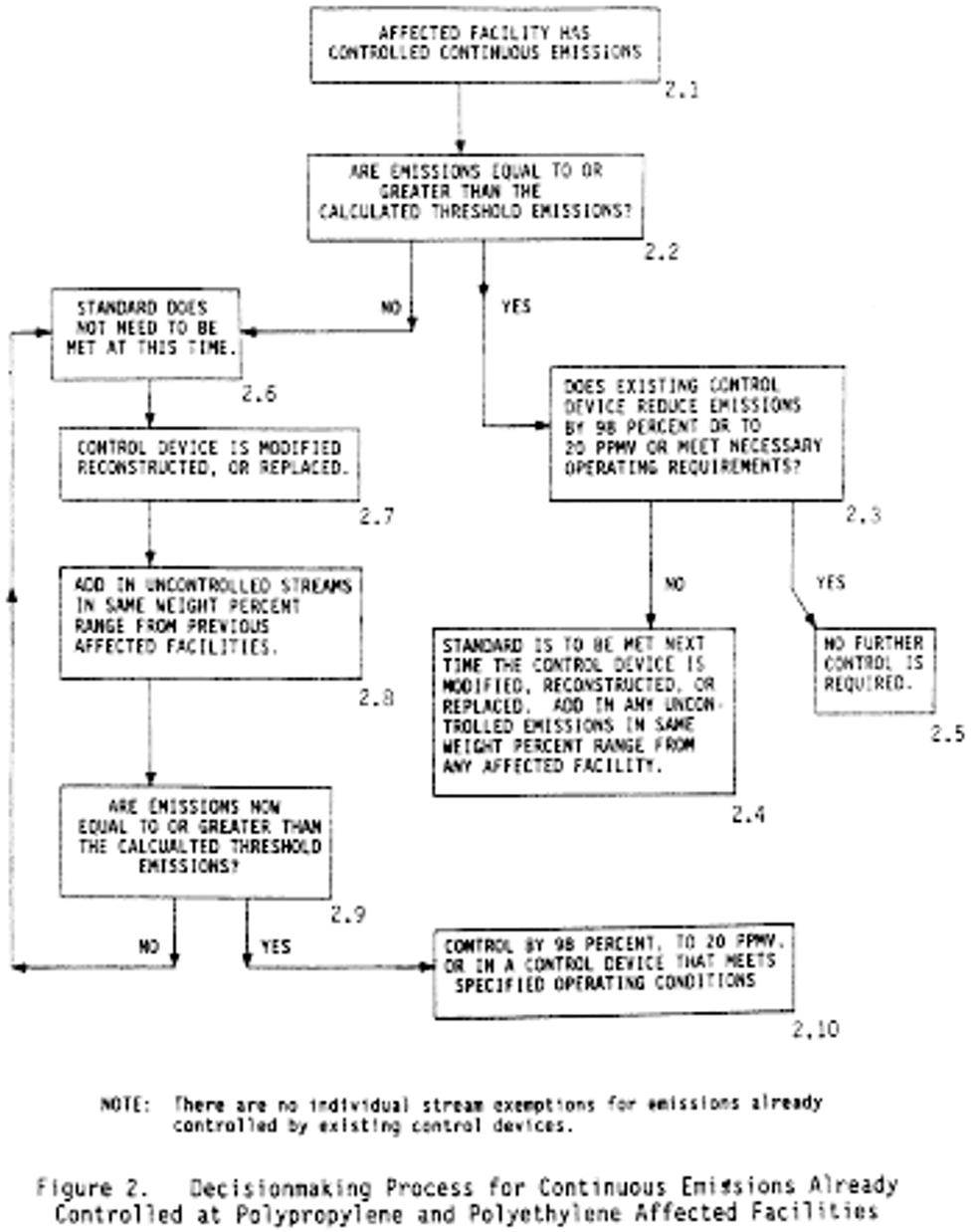

(iii) Controlled Continuous Emissions. For each vent stream that emits continuous emissions from an affected facility as defined in §60.560(a)(1) and that is controlled in an existing control device, each owner or operator shall determine whether the emissions entering the control device are greater than or equal to the calculated threshold emissions (CTE) level, which is to be calculated using the TOC concentration of the inlet vent stream and the equations in footnote b of table 3. If the inlet stream's TOC concentration is equal to or greater than 20 weight percent, the calculated threshold emissions level is 18.2 Mg/yr (20.1 ton/yr). If multiple emission streams are vented to the control device, the individual streams are not to be separated into individual weight percent ranges for calculation purposes as would be done for uncontrolled emission streams. Emissions vented to an existing control device are required to be controlled as described in paragraphs (a)(1)(iii) (A) and (B) of this section. Figure 2 illustrates the control determination procedure for controlled continuous emissions.

(A) If the annual emissions of the stream entering the control device are equal to or greater than the CTE levels, then compliance with one of the requirements identified in §60.562-1(a)(1)(i) (A) , (B), or (C) is required at such time the control device is reconstructed or replaced or has its operating conditions modified as a result of State or local regulations (including changes in the operating permit) including those instances where the control device is reconstructed, replaced, or modified in its operation at the same time the existing process section is modified or reconstructed and becomes an affected facility. If the existing control device already complies with one of the requirements identified in §60.562-1(a)(1)(i) (A) , (B), or (C), no further control is required.

(B) If the annual emissions of the stream entering the control device are less than the CTE level, then the requirements of §60.562-1(a)(1)(i) (A) , (B) , or (C) are not applicable at that time. However, if the control device is replaced, reconstructed, or modified at a later date, each owner or operator shall reevaluate the applicability of these standards. This is done by combining with the vent stream entering the control device any uncontrolled vent streams in the same weight percent range as the controlled vent stream and determining whether the annual emissions of the stream entering the control device plus the applicable uncontrolled vent streams are greater than or equal to the CTE level, which is based on the weighted TOC concentration of the controlled vent stream and the uncontrolled vent streams. If the annual emissions entering the control device (including the applicable uncontrolled vent streams) are greater than or equal to the CTE level, then compliance with one of the requirements identified in §60.562-1(a)(1)(i) (A) , (B) , or (C) is required at that time for both the controlled and uncontrolled vent streams. If the annual emissions are less than the CTE level, compliance with these standards is again not required at such time. However, if the control device is again replaced, reconstructed, or modified, each owner or operator shall repeat this determination procedure.

(2) Intermittent emissions. The owner or operator shall control each vent stream that emits intermittent emissions from an affected facility as defined in §60.560-1(a)(1) by meeting one of the control requirements specified in paragraphs (a)(2) (i) and (ii) of this section. If a vent stream that emits intermittent emissions is controlled in an existing flare, incinerator, boiler, or process heater, the requirements of this paragraph are waived until such time the control device is reconstructed or replaced or is modified in its operating conditions as a result of State or local regulation, including changes in the operating permit. This paragraph does not apply to emergency vent streams exempted by §60.560(h) and as defined in §60.561 .

(i) Combust the emissions in a flare that is:

(A) Designed for and operated with no visible emissions, except for periods not to exceed a total of 5 minutes during any 2 consecutive hours,

(B) Operated with a flame present at all times, and

(C) Designed to maintain a stable flame.

(ii) Combust the emissions in an incinerator, boiler, or process heater. Such emissions shall be introduced into the flame zone of a boiler or process heater.

(b) Polystyrene. Each owner or operator of a polystyrene process line containing process sections subject to the provisions of this subpart shall comply with the provisions in this section on and after the date on which the initial performance test required by §60.8 is completed, but not later than 60 days after achieving the maximum production rate at which the affected facility will be operated, or 180 days after initial startup, whichever comes first. Each owner or operator of a polystyrene process line using a continuous process shall:

(1) Limit the continuous TOC emissions from the material recovery section by complying with one of the following:

(i) Not allow continuous TOC emissions to be greater than 0.0036 kg TOC/Mg (0.0072 lb TOC/ton) product; or

(ii) Not allow the outlet gas stream temperature from each final condenser in the material recovery section to exceed −25°C (−13°F). For purposes of this standard, temperature excursions above this limit shall not be considered a violation when such excursions occur during periods of startup, shutdown, or malfunction; or

(iii) Comply with §60.562-1(a)(1)(i) (A) , (B) , or (C) .

(2) If continuous TOC emissions from the material recovery section are routed through an existing emergency vapor recovery system, then compliance with these standards is required when the emergency vapor recovery system undergoes modification, reconstruction, or replacement. In such instances, compliance with these standards shall be achieved no later than 180 days after completion of the modification, reconstruction, or replacement.

(c) Poly(ethylene terephthalate). Each owner or operator of a poly(ethylene terephthalate) process line containing process sections subject to the provisions of this subpart shall comply with the provisions in this section on and after the date on which the initial performance test required by §60.8 is completed, but not later than 60 days after achieving the maximum production rate at which the affected facility will be operated, or 180 days after initial startup, whichever comes first.

(1) Each owner or operator of a PET process line using a dimethyl terephthalate process shall:

(i) Limit the continuous TOC emissions from the material recovery section (i.e., methanol recovery) by complying with one of the following:

(A) Not allow the continuous TOC emissions to be greater than 0.018 kg TOC/Mg (0.036 lb TOC/ton) product; or

(B) Not allow the outlet gas stream temperature from each final condenser in the material recovery section (i.e., methanol recovery) to exceed 3°C ( 37°F). For purposes of this standard, temperature excursions above this limit shall not be considered a violation when such excursions occur during periods of startup, shutdown, or malfunction.

(ii) Limit the continuous TOC emissions and, if steam-jet ejectors are used to provide vacuum to the polymerization reactors, the ethylene glycol concentration from the polymerization reaction section by complying with the appropriate standard set forth below. The ethylene glycol concentration limits specified in paragraphs (c)(1)(ii) (B) and (C) of this section shall be determined by the procedures specified in §60.564(j) .

(A) Not allow continuous TOC emissions from the polymerization reaction section (including emissions from any equipment used to further recover the ethylene glycol, but excluding those emissions from the cooling tower) to be greater than 0.02 kg TOC/Mg (0.04 lb TOC/ton) product; and

(B) If steam-jet ejectors are used as vacuum producers and a low viscosity product is being produced using single or multiple end finishers or a high viscosity product is being produced using a single end finisher, maintain the concentration of ethylene glycol in the liquid effluent exiting the vacuum system servicing the polymerization reaction section at or below 0.35 percent by weight, averaged on a daily basis over a rolling 14-day period of operating days; or

(C) If steam-jet ejectors are used as vacuum producers and a high viscosity product is being produced using multiple end finishers, maintain an ethylene glycol concentration in the cooling tower at or below 6.0 percent by weight, averaged on a daily basis over a rolling 14-day period of operating days.

(2) Each owner or operator of a PET process line using a terephthalic acid process shall:

(i) Not allow the continuous TOC emissions from the esterification vessels in the raw materials preparation section to be greater than 0.04 kg TOC/Mg (0.08 lb TOC/ton) product.

(ii) Limit the continuous TOC emissions and, if steam-jet ejectors are used to provide vaccum to the polymerization reactors, the ethylene glycol concentration from the polymerization reaction section by complying with the appropriate standard set forth below. The ethylene glycol concentration limits specified in paragraphs (c)(2)(ii) (B) and (C) of this section shall be determined by the procedures specified in §60.564(j) .

(A) Not allow continuous TOC emissions from the polymerization reaction section (including emissions from any equipment used to further recover the ethylene glycol, but excluding those emissions from the cooling tower) to be greater than 0.02 kg TOC/Mg (0.04 lb TOC/ton) product; and

(B) If steam-jet ejectors are used as vacuum producers and a low viscosity product is being produced using single or multiple end finishers or a high viscosity product is being produced using a single end finisher, maintain the concentration of ethylene glycol in the liquid effluent exiting the vacuum system servicing the polymerization reaction section at or below 0.35 percent by weight, averaged on a daily basis over a rolling 14-day period of operating days; or

(C) If steam-jet ejectors are used as vacuum producers and a high viscosity product is being produced using multiple end finishers, maintain an ethylene glycol concentration in the cooling tower at or below 6.0 percent by weight, averaged on a daily basis over a rolling 14-day period of operating days.

(d) Closed vent systems and control devices used to comply with this subpart shall be operated at all times when emissions may be vented to them.

(e) Vent systems that contain valves that could divert a vent stream from a control device shall have car-sealed opened all valves in the vent system from the emission source to the control device and car-sealed closed all valves in vent system that would lead the vent stream to the atmosphere, either directly or indirectly, bypassing the control device.

[55 FR 51035, Dec. 11, 1990; 56 FR 9178, Mar. 5, 1991, as amended at 56 FR 12299, Mar. 22, 1991; 65 FR 61767, Oct. 17, 2000]

§60.562-2 Standards: Equipment leaks of VOC.

(a) Each owner or operator of an affected facility subject to the provisions of this subpart shall comply with the requirements specified in §60.482-1 through §60.482-10 as soon as practicable, but no later than 180 days after initial startup, except that indications of liquids dripping from bleed ports in existing pumps in light liquid service are not considered to be a leak as defined in §60.482-2(b)(2). For purposes of this standard, a “bleed port” is a technologically-required feature of the pump whereby polymer fluid used to provide lubrication and/or cooling of the pump shaft exits the pump, thereby resulting in a visible leak of fluid. This exemption expires when the existing pump is replaced or reconstructed.

(b) An owner or operator may elect to comply with the requirements specified in §§60.483-1 and 60.483-2.

(c) An owner or operator may apply to the Administrator for a determination of equivalency for any means of emission limitation that achieves a reduction in emissions of VOC at least equivalent to the reduction in emissions of VOC achieved by the controls required in this subpart. In doing so, the owner or operator shall comply with requirements specified in §60.484.

(d) Each owner or operator subject to the provisions of this subpart shall comply with the provisions specified in §60.485 except an owner or operator may use the following provision in addition to §60.485(e): Equipment is in light liquid service if the percent evaporated is greater than 10 percent at 150°C (302°F) as determined by ASTM Method D86-78, 82, 90, 95, or 96 (incorporated by reference as specified in §60.17).

(e) Each owner or operator subject to the provisions of this subpart shall comply with §§60.486 and 60.487.

[55 FR 51035, Dec. 11, 1990; 56 FR 12299, Mar. 22, 1991, as amended at 65 FR 61767, Oct. 17, 2000]

§60.563 Monitoring requirements.

(a) Whenever a particular item of monitoring equipment is specified in this section to be installed, the owner or operator shall install, calibrate, maintain, and operate according to manufacturer's specifications that item as follows:

(1) A temperature monitoring device to measure and record continuously the operating temperature to within 1 percent (relative to degrees Celsius) or ±0.5°C (±0.9°F), whichever is greater.

(2) A flame monitoring device, such as a thermocouple, an ultraviolet sensor, an infrared beam sensor, or similar device to indicate and record continuously whether a flare or pilot light flame is present, as specified.

(3) A flow monitoring indicator to indicate and record whether or not flow exists at least once every fifteen minutes.

(4) An organic monitoring device (based on a detection principle such as infrared, photoionization, or thermal conductivity) to indicate and record continuously the concentration level of organic compounds.

(5) A specific gravity monitoring device to measure and record continuously to within 0.02 specific gravity unit.

(b) The owner or operator shall install, as applicable, the monitoring equipment for the control means used to comply with §60.562-1, except §60.562-1(a)(1)(i)(D), as follows:

(1) If the control equipment is an incinerator:

(i) For a noncatalytic incinerator, a temperature monitoring device shall be installed in the firebox.

(ii) For a catalytic incinerator, temperature monitoring devices shall be installed in the gas stream immediately before and after the catalytic bed.

(2) If a flare is used:

(i) A flame monitoring device shall be installed to indicate the presence of a flare flame or a flame for each pilot light, if the flare is used to comply with §60.562-1(a)(1), including those flares controlling both continuous and intermittent emissions.

(ii) A thermocouple or equivalent monitoring device to indicate the presence of a flame at each pilot light, if used to comply with §60.562-1(a)(2).

(3) If a boiler or process heater is used:

(i) If the boiler or process heater has a heat input design capacity of less than 150 million Btu/hr, a temperature monitoring device shall be installed between the radiant section and the convection zone for watertube boilers and between the furnace (combustion zone) and the firetubes for firetube boilers.

(ii) If the boiler or process heater has a heat input design capacity of 150 million Btu/hr or greater, such records to indicate the periods of operation of the boiler or process heater shall be maintained. The records must be readily available for inspection.

(4) If an absorber is the final unit in a system:

(i) A temperature monitoring device and a specific gravity monitoring device for the scrubber liquid shall be installed, or

(ii) An organic monitoring device shall be installed at the outlet of the absorber.

(5) If a condenser is the final unit in a system:

(i) A temperature monitoring device shall be installed at the condenser exit (product side), or

(ii) An organic monitoring device shall be installed at the outlet of the condenser.

(6) If a carbon adsorber is the final unit in a system, an organic monitoring device shall be installed at the outlet of the carbon bed.

(c) Owners or operators of control devices used to comply with the provisions of this subpart, except §60.562-1(a)(1)(i)(D), shall monitor these control devices to ensure that they are operated and maintained in conformance with their designs.

(d) Owners or operators using a vent system that contains valves that could divert a vent stream from a control device used to comply with the provisions of this subpart shall do one or a combination of the following:

(1) Install a flow indicator immediately downstream of each valve that if opened would allow a vent stream to bypass the control device and be emitted, either directly or indirectly, to the atmosphere. The flow indicator shall be capable of recording flow at least once every fifteen minutes.

(2) Monitor the valves once a month, checking the position of the valves and the condition of the car seal, and identify all times when the car seals have been broken and the valve position has been changed (i.e., from opened to closed for valves in the vent piping to the control device and from closed to open for valves that allow the stream to be vented directly or indirectly to the atmosphere).

(e) An owner or operator complying with the standards specified under §60.562-1, except §60.562-1(a)(1)(i)(D), with control devices other than an incinerator, boiler, process heater, flare, absorber, condenser, or carbon adsorber or by any other means shall provide to the Administrator information describing the operation of the control device and the process parameter(s) which would indicate proper operation and maintenance of the device. The Administrator may request further information and will specify appropriate monitoring procedures or requirements.

[55 FR 51035, Dec. 11, 1990; 56 FR 12299, Mar. 22, 1991]

§60.564 Test methods and procedures.

(a) In conducting the performance tests required in §60.8, the owner or operator shall use as reference methods and procedures the test methods in appendix A of this part or other methods and procedures specified in this section, except as provided under §60.8(b). Owners or operators complying with §60.562-1(a)(1)(i)(D) need not perform a performance test on the control device, provided the control device is not used to comply with any other requirement of §60.562-1(a).

(1) Whenever changes are made in production capacity, feedstock type or catalyst type, or whenever there is replacement, removal, or addition of a control device, each owner or operator shall conduct a performance test according to the procedures in this section as appropriate, in order to determine compliance with §60.562-1.

(2) Where a boiler or process heater with a design heat input capacity of 150 million Btu/hour or greater is used, the requirement for an initial performance test is waived, in accordance with §60.8(b). However, the Administrator reserves the option to require testing at such other times as may be required, as provided for in §114 of the Act.

(3) The owner or operator shall determine the average organic concentration for each performance test run using the equipment described in §60.563(a)(4). The average organic concentration shall be determined from measurements taken at least every 15 minutes during each performance test run. The average of the three runs shall be the base value for the monitoring program.

(4) When an absorber is the final unit in the system, the owner or operator shall determine the average specific gravity for each performance test run using specific gravity monitoring equipment described in §60.563(a)(5). An average specific gravity shall be determined from measurements taken at least every 15 minutes during each performance test run. The average of the three runs shall be the base value for the monitoring program.

(5) When a condenser is the final unit in the system, the owner or operator shall determine the average outlet temperature for each performance test run using the temperature monitoring equipment described in §60.563(a)(1). An average temperature shall be determined from measurements taken at least every 15 minutes during each performance test run while the vent stream is normally routed and constituted. The average of the three runs shall be the base value for the monitoring program.

(b) The owner or operator shall determine compliance with the emission concentration standard in §60.562-1 (a)(1)(i)(A) or (b)(1)(iii) if applicable [if not, see paragraph (c) of this section] as follows:

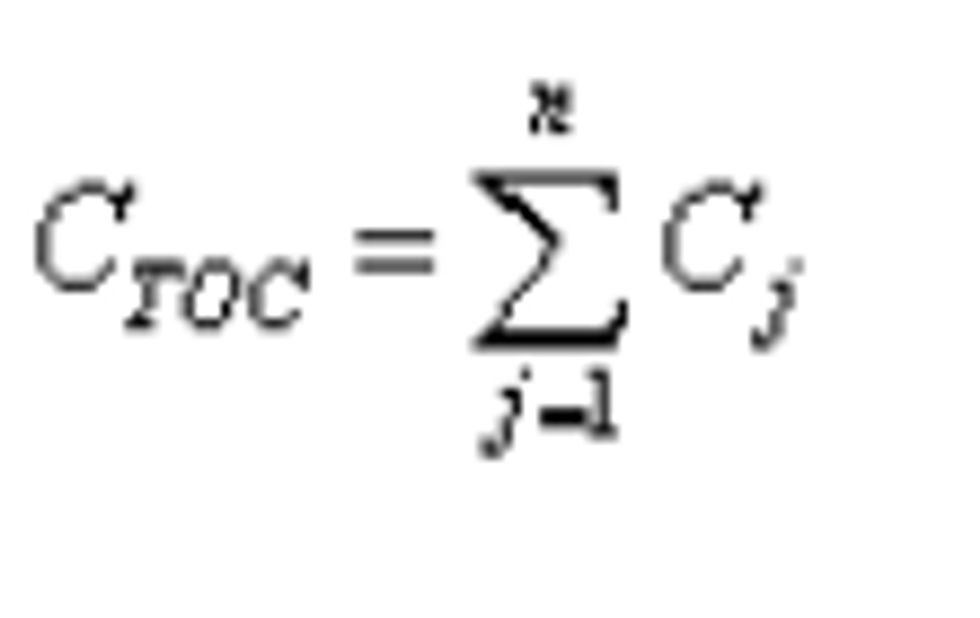

(1) The TOC concentration is the sum of the individual components and shall be computed for each run using the following equation:

where:

CTOC = Concentration of TOC (minus methane and ethane), dry basis, ppmv.

Cj = the concentration of sample component j, ppm.

n = Number of components in the sample.

(i) Method 18 shall be used to determine the concentration of each individual organic component (Cj) in the gas stream. Method 1 or 1A, as appropriate, shall be used to determine the sampling site at the outlet of the control device. Method 4 shall be used to determine the moisture content, if necessary.

(ii) The sampling time for each run shall be 1 hour in which either an integrated sample or four grab samples shall be taken. If grab sampling is used, then the samples shall be taken at 15 minute intervals.

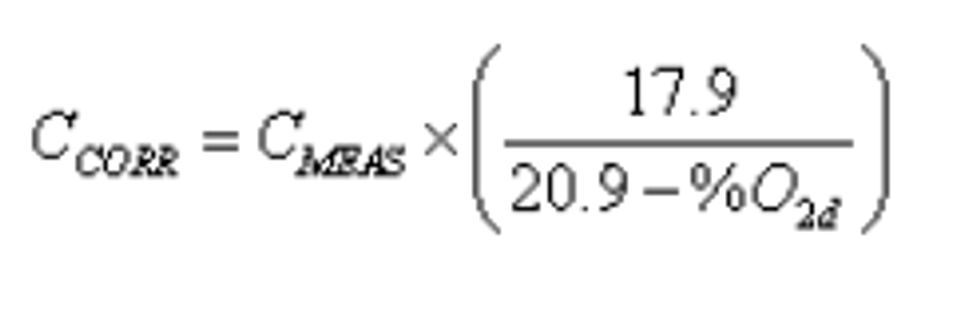

(2) If supplemental combustion air is used, the TOC concentration shall be corrected to 3 percent oxygen and shall be computed using the following equation:

where:

CCORR = Concentration of TOC corrected to 3 percent oxygen, dry basis, ppm by volume.

CMEAS = Concentration of TOC (minus methane and ethane), dry basis, ppm by volume, as calculated in paragraph (b)(1) of this section.

%O2d = Concentration of O2, dry basis, percent by volume.

The emission rate correction factor, integrated sampling and analysis procedure of Method 3 shall be used to determine the oxygen concentration (%O2d). The sampling site shall be the same as that of the TOC sample and the samples shall be taken during the same time that the TOC samples are taken.

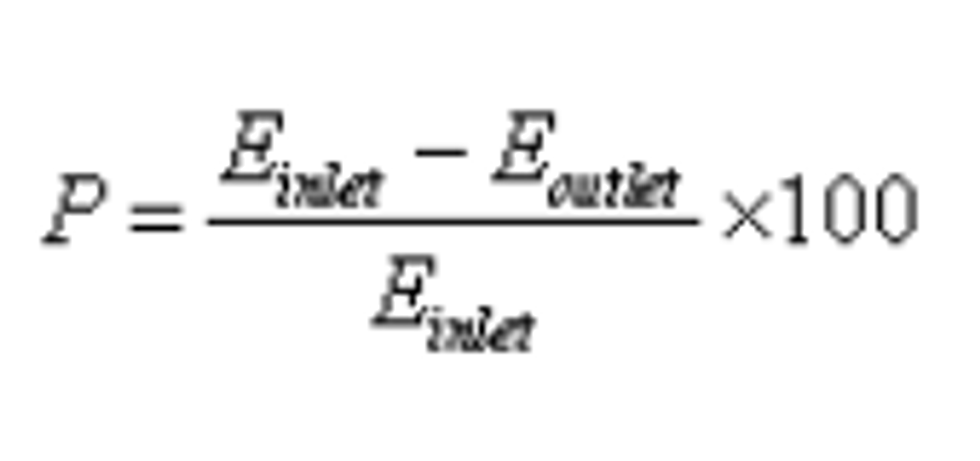

(c) If paragraph (b) of this section is not applicable, then the owner or operator shall determine compliance with the percent emission reduction standard in §60.562-1 (a)(1)(i)(A) or (b)(1)(iii) as follows:

(1) The emission reduction of TOC (minus methane and ethane) shall be determined using the following equation:

where:

P = Percent emission reduction, by weight.

Einlet = Mass rate of TOC entering the control device, kg TOC/hr (lb TOC/hr).

Eoutlet = Mass rate of TOC, discharged to the atmosphere, kg TOC/hr (lb TOC/hr).

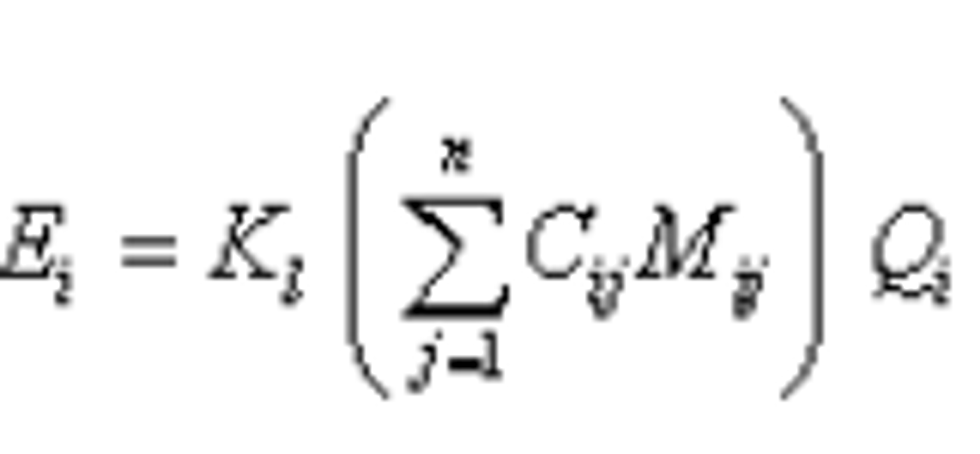

(2) The mass rates of TOC (Ei, Eo) shall be computed using the following equations:

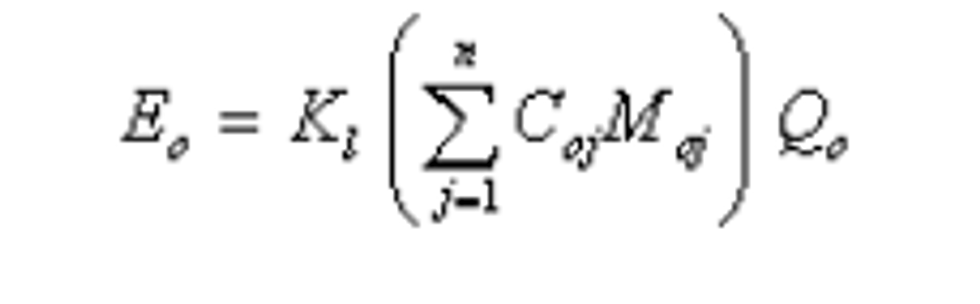

where:

Cij,Coj = Concentration of sample component “j” of the gas stream at the inlet and outlet of the control device, respectively, dry basis, ppmv.

Mij,Moj = Molecular weight of sample component “j” of the gas stream at the inlet and outlet of the control device respectively, g/g-mole (lb/lb-mole).

Qi,Qo = Flow rate of the gas stream at the inlet and outlet of the control device, respectively, dscm/hr (dscf/hr).

K1 = 4.157 × 10−8 [(kg)/g-mole)] / [(g)(ppm)(dscm)] {5.711 × 10−15 [(lb)/(lb-mole)] / (lb)(ppm)(dscf)]}

(i) Method 18 shall be used to determine the concentration of each individual organic component (Cij, Coj) in the gas stream. Method 1 or 1A, as appropriate, shall be used to determine the inlet and outlet sampling sites. The inlet site shall be before the inlet of the control device and after all product recovery units.

(ii) Method 2, 2A, 2C, or 2D, as appropriate, shall be used to determine the volumetric flow rates (Qi, Qo). If necessary, Method 4 shall be used to determine the moisture content. Both determinations shall be compatible with the Method 18 determinations.

(iii) Inlet and outlet samples shall be taken simultaneously. The sampling time for each run shall be 1 hour in which either an integrated sample or four grab samples shall be taken. If grab sampling is used, then the samples shall be taken at 15 minute intervals.

(d) An owner or operator shall determine compliance with the individual stream exemptions in §60.560(g) and the procedures specified in table 3 for compliance with §60.562-1(a)(1) as identified in paragraphs (d)(1) and (2) of this section. An owner or operator using the procedures specified in §60.562-1(a)(1) for determining which continuous process emissions are to be controlled may use calculations demonstrated to be sufficiently accurate as to preclude the necessity of actual testing for purposes of calculating the uncontrolled annual emissions and weight percent of TOC. Owners or operators seeking to exempt streams under §60.560(g) must use the appropriate test procedures specified in this section.

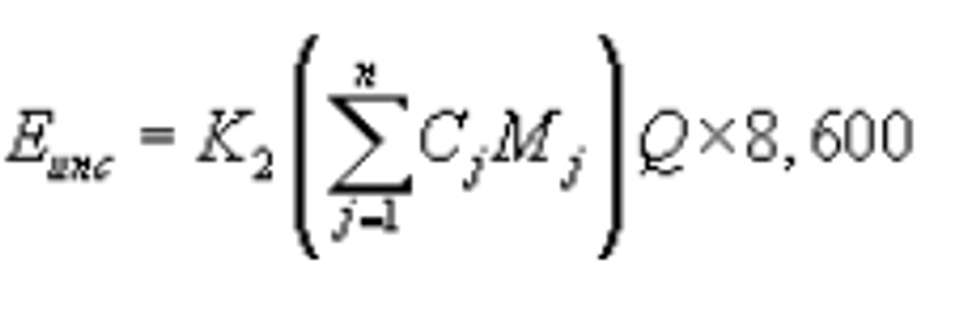

(1) The uncontrolled annual emissions of the individual vent stream shall be determined using the following equation:

Where:

Eunc = uncontrolled annual emissions, Mg/yr (ton/yr)

Cj = concentration of sample component j of the gas stream, dry basis, ppmv

Mj = molecular weight of sample component j of the gas stream, g/g-mole (lb/lb-mole)

Q = flow rate of the gas stream, dscm/hr (dscf/hr)

K2 = 4.157 × 10−11 [(Mg)(g-mole)]/[(g)(ppm)(dscm)] (metric units)

= 1.298 × 10−12 [(ton)(lb-mole)]/[(lb)(ppm)(dscf)] (English units)

8,600 = operating hours per year

(i) Method 18 shall be used to determine the concentration of each individual organic component (Cj) in the gas stream. Method 1 or 1A, as appropriate, shall be used to determine the sampling site. If the gas stream is controlled in an existing control device, the sampling site shall be before the inlet of the control device and after all product recovery units.

(ii) Method 2, 2A, 2C, or 2D, as appropriate, shall be used to determine the volumetric flow rate (Q). If necessary, Method 4 shall be used to determine the moisture content. Both determinations shall be compatible with the Method 18 determinations.

(iii) The sampling time for each run shall be 1 hour in which either an integrated sample or four grab samples shall be taken. If grab sampling is used, then the samples shall be taken at 15 minute intervals.

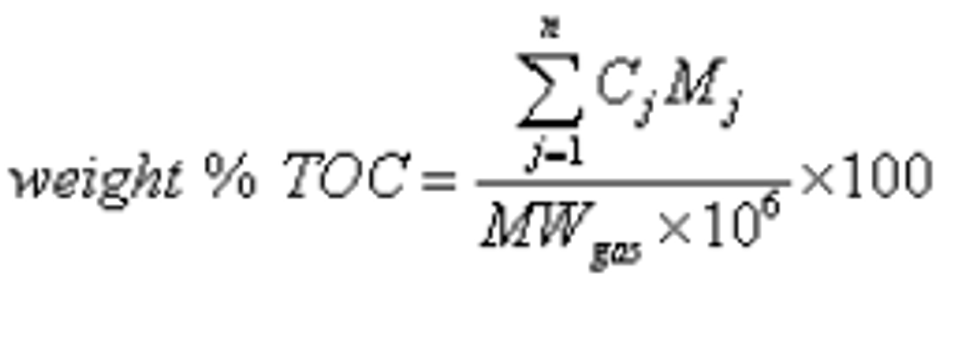

(2) The weight percent VOC of the uncontrolled individual vent stream shall be determined using the following equation:

where:

Cj = concentration of sample TOC component “j” of the gas stream, dry basis, ppmv.

Mj = Molecular weight of sample TOC component “j” of the gas stream, g/g-mole (1b/1b-mole).

MWgas = Average molecular weight of the entire gas stream, g/g-mole (1b/1b-mole).

(i) Method 18 shall be used to determine the concentration of each individual organic component (Cj) in the gas stream. Method 1 or 1A, as appropriate, shall be used to determine the sampling site. If the gas stream is controlled in an existing control device, the sampling site shall be before the inlet of the control device and after all product recovery units. If necessary, Method 4 shall be used to determine the moisture content. This determination shall be compatible with the Method 18 determinations.

(ii) The average molecular weight of the gas stream shall be determined using methods approved by the Administrator. If the carrier component of the gas stream is nitrogen, then an average molecular weight of 28 g/g-mole (lb/lb-mole) may be used in lieu of testing. If the carrier component of the gas stream is air, then an average molecular weight of 29 g/g-mole (lb/lb-mole) may be used in lieu of testing.

(iii) The sampling time for each run shall be 1 hour in which either an integrated sample or four grab samples shall be taken. If grab sampling is used, then the samples shall be taken at 15 minute intervals.

(e) The owner or operator shall determine compliance of flares with the visible emission and flare provisions in §60.562-1 as follows:

(1) Method 22 shall be used to determine visible emissions. The observation period for each run shall be 2 hours.

(2) The monitoring device of §60.563(b)(2) shall be used to determine whether a flame is present.

(f) The owner or operator shall determine compliance with the net heating value provisions in §60.18 as referenced by §60.562-1(a)(1)(i)(C). The net heating value of the process vent stream being combusted in a flare shall be computed as follows:

Where:

HT = Vent stream net heating value, MJ/scm (Btu/scf), where the net enthalpy per mole of offgas is based on combustion at 25°C and 760 mm Hg (68°F and 30 in. Hg), but the standard temperature for determining the volume corresponding to one mole is 20°C (68°F).

K3 = 1.74 × 10−7 (1/ppm)(g-mole/scm)(MJ/kcal) (metric units), where standard temperature for (g-mole/scm) is 20°C.

= 4.67 × 10−6 (1/ppm)(lb-mole/scf)(Btu/kcal) (English units) where standard temperature for (lb/mole/scf) is 68°F.

Cj = Concentration on a wet basis of compound j in ppm.

Hj = Net heat of combustion of compound j, kcal/(g-mole) (kcal/(lb-mole)), based on combustion at 25°C and 760 mm Hg (77°F and 30 in. Hg).

(1) Method 18 shall be used to determine the concentration of each individual organic component (Cj) in the gas stream. Method 1 or 1A, as appropriate, shall be used to determine the sampling site to the inlet of the flare. Using this same sample, ASTM D1946-77 or 90 (Reapproved 1994) (incorporated by reference - see §60.17) shall be used to determine the hydrogen and carbon monoxide content.

(2) The sampling time for each run shall be 1 hour in which either an integrated sample or four grab samples shall be taken. If grab sampling is used, then the samples shall be taken at 15 minute intervals.

(3) Published or calculated values shall be used for the net heats of combustion of the sample components. If values are not published or cannot be calculated, ASTM D2382-76 or 88 or D4809-95 (incorporated by reference - see §60.17) may be used to determine the net heat of combustion of component “j.”

(g) The owner or operator shall determine compliance with the exit velocity provisions in §60.18 as referenced by §60.562-1(a)(1)(i)(C) as follows:

(1) If applicable, the net heating value (HT) of the process vent shall be determined according to the procedures in paragraph (f) of this section to determine the applicable velocity requirements.

(2) If applicable, the maximum permitted velocity (Vmax) for steam-assisted and nonassisted flares shall be computed using the following equation:

Where:

Vmax = Maximum permitted velocity, m/sec (ft/sec)

K4 = 28.8 (metric units), 1212 (English units)

K5 = 31.7 (metric units), 850.8 (English units)

HT = The net heating value as determined in paragraph (f) of this section, MJ/scm (Btu/scf).

(3) The maximum permitted velocity, Vmax, for air-assisted flares shall be determined by the following equation:

Where:

Vmax = Maximum permitted velocity, m/sec (ft/sec).

K6 = 8.706 m/sec (metric units)

= 28.56 ft/sec (English units)

K7 = 0.7084 [(m/sec)/MJ/scm)] (metric units)

= 0.00245 [(ft/sec)/Btu/scf)] (English units)

HT = The net heating value as determined in paragraph (f) of this section, MJ/scm (Btu/scf).

(4) The actual exit velocity of a flare shall be determined by dividing the volumetric flow rate (in units of standard temperature and pressure), as determined by Method 2, 2A, 2C, or 2D as appropriate, by the unobstructed (free) cross sectional area of the flare tip.

(h) The owner or operator shall determine compliance with the mass emission per mass product standards in §§60.560(d) and (e) and in §§60.562-1(b)(1)(i), (c)(1)(i)(A), (c)(1)(ii)(A), (c)(2)(i), and (c)(2)(ii)(A).

(1) The emission rate of TOC shall be computed using the following equation:

Where:

ERTOC = Emission rate of total organic compounds (minus methane and ethane), kg TOC/Mg (lb TOC/ton) product

ETOC = Emission rate of total organic compounds (minus methane and ethane) in the sample, kg/hr (lb/hr)

Pp = The rate of polymer production, kg/hr (lb/hr)

K5 = 1,000 kg/Mg (metric units)

= 2,000 lb/ton (English units)

(2) The mass rate of TOC, ETOC, shall be determined according to the procedures, as appropriate, in paragraph (c)(2) of this section. The sampling site for determining compliance with §§60.560 (d) and (e) shall be before any add-on control devices and after all product recovery devices. Otherwise, the sampling site shall be at the outlet of the control device.

(3) The rate of polymer production, Pp, shall be determined by dividing the weight of polymer pulled (in kg (lb)) from the process line during the performance test by the number of hours taken to perform the performance test. The weight of polymer pulled shall be determined by direct measurement or, subject to prior approval by the Administrator, computed from materials balance by good engineering practice.

(i) The owner or operator shall determine continuous compliance with the temperature requirements in §§60.562-1(b)(1)(ii) and 60.562-1(c)(1)(i)(B) by using the temperature monitoring equipment described in §60.563(a)(1). An average temperature shall be determined from measurements taken at least every 15 minutes every three hours while the vent stream is normally routed and constituted. Each three-hour period constitutes a performance test.

(j) For purposes of determining compliance with §60.562-1(c) (1)(ii)(B), (1)(ii)(C), (2)(ii)(B), or (2)(ii)(C), the ethylene glycol concentration in either the cooling tower or the liquid effluent from steam-jet ejectors used to produce a vacuum in the polymerization reactors, whichever is applicable, shall be determined:

(1) Using procedures that conform to the methods described in ASTM D2908-74 or 91, “Standard Practice for Measuring Volatile Organic Matter in Water by Aqueous-Injection Gas Chromatography” (incorporated by reference - see §60.17), except as provided in paragraph (j)(2) of this section:

(i) At least one sample per operating day shall be collected using the grab sampling procedures of ASTM D3370-76 or 96a, “Standard Practices for Sampling Water” (incorporated by reference - see §60.17). An average ethylene glycol concentration by weight shall be calculated on a daily basis over a rolling 14-day period of operating days, except as provided in paragraphs (j)(1) (ii) and (iii) of this section. Each daily average ethylene glycol concentration so calculated constitutes a performance test. Exceedance of the standard during the reduced testing program specified in paragraphs (j)(1) (ii) and (iii) of this section is a violation of these standards.

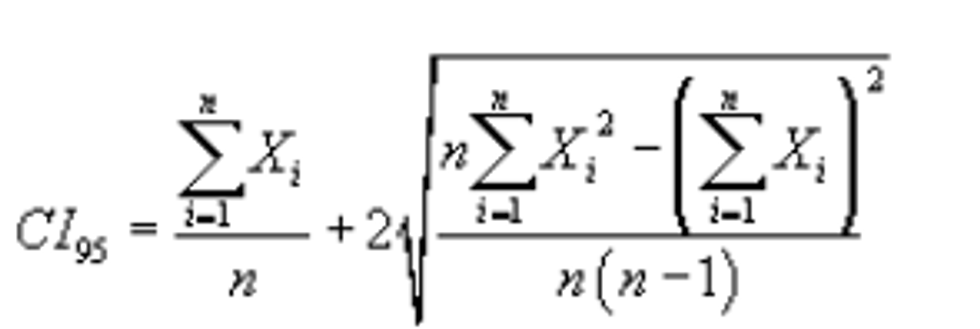

(ii) For those determining compliance with §60.562-1(c) (1)(ii)(B) or (2)(ii)(B), the owner or operator may elect to reduce the sampling program to any 14 consecutive day period once every two calendar months, if at least seventeen consecutive 14-day rolling average concentrations immediately preceding the reduced sampling program are each less than 0.10 weight percent ethylene glycol. If the average concentration obtained over the 14 day sampling during the reduced testing period exceeds the upper 95 percent confidence interval calculated from the most recent test results in which no one 14-day average exceeded 0.10 weight percent ethylene glycol, then the owner or operator shall reinstitute a daily sampling program. A reduced sampling program can be reinstituted if the requirements specified in this paragraph are met.