[]

[]

08/01/2021

...

Authority: 42 U.S.C. 7401 et seq.

Subpart A - General Provisions

§62.01 Definitions.

As used in this part, all terms not defined herein shall have the meaning given to them in the Clean Air Act and in part 60 of this chapter.

§62.02 Introduction.

(a) This part sets forth the Administrator's approval and disapproval of State plans for the control of pollutants and facilities under section 111(d), and section 129 as applicable, of the Act, and the Administrator's promulgation of such plans or portions of plans thereof. Approval of a plan or any portion of a plan is based on a determination by the Administrator that it meets the requirements of section 111(d), and section 129 as applicable, of the Act and provisions of part 60 of this chapter.

(b)(1) If a State does not submit a complete, approvable plan, the Administrator may then promulgate a substitute plan or part of a plan. The promulgated provision, plus the approved parts of the State plan, constitute the applicable plan for purposes of the act.

(2) The part 60 subpart A of this chapter general provisions and appendices to part 60 apply to part 62, except as follows: 40 CFR 60.7(a)(1), 60.7(a)(3), and 60.8(a) and where special provisions set forth under the applicable subpart of this part shall apply instead of any conflicting provisions.

(c) The Administrator will promulgate substitute provisions for the disapproved regulatory provisions only. If a nonregulatory provision is disapproved, however, it will be noted in this part and a detailed explanation will be sent to the State.

(d) Section 62.12 provides information on availability of applicable plans. The Administrator and state and local agencies shall enforce

(1) Regulatory provisions of a plan approved or promulgated by the Administrator, and

(2) All permit conditions or denials issued in carrying out the approved or promulgated regulations for the review of designated facilities.

(e) Each State's plan is dealt with in a separate subpart, with separate headings for different pollutants and facilities. The plans shall include an introductory section identifying the plan by name and the date of its submittal. Additional sections are included as necessary to specifically identify disapproved provisions, to set forth reasons for disapproval, and to set forth provisions of the plan promulgated by the Administrator. Except as otherwise specified, all supplemental information submitted to the Administrator with respect to any plan has been submitted by the Governor of the State.

(f) Revisions to applicable plans will be included in this part when approved or promulgated by the Administrator.

(g) Substitute plans promulgated by the Administrator for States that do not have approved plans are contained in separate subparts that appear after the subparts for States. These Federal plans include sections identifying the applicability of the plan, emission limits, compliance schedules, recordkeeping and reporting, performance testing, and monitoring requirements.

[43 FR 51393, Nov. 3, 1978, as amended at 63 FR 63201, Nov. 12, 1998; 68 FR 5158, Jan. 31, 2003; 84 FR 45657, Aug. 30, 2019]

§62.03 Extensions.

The Administrator may, whenever he determines necessary, extend the period for submission of any plan or plan revision or portion thereof.

§62.04 Approval status.

The approval status of each State's plan or portions thereof, are set forth in each subpart. All plans are approved unless specifically disapproved in the appropriate subpart.

§62.05 Legal authority.

(a) The Administrator's determination of the absence or inadequacy of legal authority required to be included in the plan is set forth in each subpart. This includes the legal authority of local agencies and State governmental agencies other than an air pollution control agency if such other agencies are assigned responsibility for carrying out a plan or portion thereof.

(b) No legal authority as such is promulgated by the Administrator. Where required regulatory provisions are not included in the plan by the State because of inadequate authority, substitute provisions are promulgated by the Administrator.

§62.06 Negative declarations.

A State may submit to the Administrator a letter certifying that no designated facilities exist in the State if such is the case. The negative declaration will be in lieu of a plan.

§62.07 Emission standards, compliance schedules.

(a) In each subpart, emission standards and compliance schedules which have been disapproved by the Administrator are identified, and those promulgated by the Administrator are set forth.

(b) The Administrator's approval or promulgation of any compliance schedule shall not affect the responsibility of the owner or operator to comply with any applicable emission limitation on or after the date for final compliance specified in the applicable schedule.

§62.08 Emission inventories and source surveillance.

(a) Each subpart identifies the plan provisions for source surveillance which are disapproved, and sets forth the Administrator's promulgation of necessary provisions for requiring designated sources to maintain records, make reports, and submit information.

(b) The Administrator will not promulgate provisions for disapproved State or local agency procedures for testing, inspection, investigation, or detection. However, detailed critiques of such portions will be provided to the State.

§62.09 Revision of plans by Administrator.

After notice and opportunity for public hearing in each affected State, the Administrator may revise any provision of an applicable plan if:

(a) The provision was promulgated by the Administrator and

(b) The plan, as revised, will be consistent with the Act and with the requirements of part 60, subpart B of this chapter.

§62.10 Submission to Administrator.

Except as otherwise provided in §60.23 of this chapter, all requests, reports, applications, submittals, and other communications to the Administrator pursuant to this part shall be submitted in duplicate and addressed to the appropriate Regional office of the Environmental Protection Agency.” The Regional offices are as follows:

| Region and jurisdiction | Address |

|---|---|

| I—Connecticut, Maine, Massachusetts, New Hampshire, Rhode Island, and Vermont | Director, Enforcement and Compliance Assurance Division, U.S. EPA Region I, 5 Post Office Square—Suite 100 (04-2), Boston, MA 02109-3912, Attn: Air Compliance Clerk. |

| II—New York, New Jersey, Puerto Rico, Virgin Islands | 290 Broadway, New York, NY 10007-1866. |

| III - Delaware, District of Columbia, Maryland, Pennsylvania, Virginia, West Virginia | Air Protection Division, Mail Code 3AP00, 1650 Arch Street, Philadelphia, PA 19103-1129. |

| IV—Alabama, Florida, Georgia, Mississippi, Kentucky, North Carolina, South Carolina, Tennessee | 61 Forsyth Street SW, Atlanta, GA 30303-3104. |

| V - Illinois, Indiana, Michigan, Minnesota, Ohio, Wisconsin | Mail Code A-17J, 77 West Jackson Blvd., Chicago, Il 60604-3590. |

| VI—Arkansas, Louisiana, New Mexico, Oklahoma, Texas | 1201 Elm Street, Suite 500, Dallas, TX 75270. |

| VII - Iowa, Kansas, Missouri, Nebraska | Air and Waste Management Division 11201 Renner Boulevard, Lenexa, Kansas 66219. |

| VIII - Colorado, Montana, North Dakota, South Dakota, Utah, Wyoming | Director, Air Program, Office of Partnerships and Regulatory Assistance, Mail Code 8P-AR, 1595 Wynkoop Street, Denver, CO 80202-1129. |

| IX - Arizona, California, Hawaii, Nevada, the territories of American Samoa and Guam; the Commonwealth of the Northern Mariana Islands; the territories of Baker Island, Howland Island, Jarvis Island, Johnston Atoll, Kingman Reef, Midway Atoll, Palmyra Atoll, and Wake Islands; and certain U.S. Government activities in the freely associated states of the Republic of the Marshall Islands, the Federated States of Micronesia, and the Republic of Palau | 75 Hawthorne Street, San Francisco, CA 94105. |

[43 FR 51393, Nov. 3, 1978, as amended at 62 FR 1834, Jan. 14, 1997; 68 FR 35729, June 17, 2003; 73 FR 24871, May 6, 2008; 74 FR 66923, Dec. 17, 2009; 75 FR 69352, Nov. 12, 2010; 76 FR 49673, Aug. 11, 2011; 78 FR 37977, June 25, 2013; 84 FR 34069, July 17, 2019; 84 FR 44230, Aug. 23, 2019; 84 FR 45657, Aug. 30, 2019]

§62.11 Severability.

The provisions promulgated in this part and the various applications thereof are distinct and severable. If any provision of this part or the application thereof to any person or circumstances is held invalid, such invalidity shall not affect other provisions or application of such provision to other persons or circumstances which can be given effect without the invalid provision or application.

§62.12 Availability of applicable plans.

Copies of the applicable plans will be available for public inspection at the following locations:

(a) EPA Docket Center, Room 3334, WJC West Building, 1301 Constitution Avenue NW, Washington, DC.

(b) The applicable EPA Regional office, at the address listed in §62.10.

[84 FR 45658, Aug. 30, 2019]

§62.13 Federal plans.

The Federal plans apply to owners and operators of affected facilities that are not covered by an EPA approved and currently effective State or Tribal plan. This Federal plan, or portions thereof, also applies to each affected facility located in any State or portion of Indian country whose approved State or Tribal plan for that area is subsequently vacated in whole or in part. Affected facilities are defined in each Federal plan.

(a) The substantive requirements of the municipal waste combustor Federal plan are contained in subpart FFF of this part. These requirements include emission limits, compliance schedules, testing, monitoring, and reporting and recordkeeping requirements.

(b) The substantive requirements of the municipal solid waste landfills Federal plan that implements 40 CFR part 60, subpart Cc of this chapter, are contained in subpart GGG of this part. These requirements include emission limits, compliance schedules, testing, monitoring, and reporting and recordkeeping requirements. After June 21, 2021, per paragraph (j) of this section, the substantive requirements of the municipal solid waste landfills Federal plan are contained in subpart OOO of this part and owners and operators of municipal solid waste landfills must comply with subpart OOO of this part or a state/tribal plan implementing 40 CFR part 60, subpart Cf of this chapter, instead of subpart GGG of this part.

(c) The substantive requirements of the hospital/ medical/infectious waste incinerator Federal plan are contained in subpart HHH of this part. These requirements include emission limits, compliance schedules, testing, monitoring and reporting and recordkeeping requirements.

(d) The substantive requirements of the commercial and industrial solid waste incineration units Federal plan are contained in subpart III of this part. These requirements include emission limits, compliance schedules, testing, monitoring, and reporting and recordkeeping requirements.

(e) The substantive requirements of the small municipal waste combustion unit Federal plan are contained in subpart JJJ of this part. These requirements include emission limits, compliance schedules, testing, monitoring, and reporting and recordkeeping requirements.

(f) [Reserved]

(g) The substantive requirements of the sewage sludge incineration units Federal plan are contained in subpart LLL of this part. These requirements include emission limits, compliance schedules, testing, monitoring, and reporting and recordkeeping requirements.

(h) [Reserved]

(i) [Reserved]

(j) The substantive requirements of the municipal solid waste landfills Federal plan that implements 40 CFR part 60, subpart Cf of this chapter, are contained in subpart OOO of this part. These requirements include emission limits, compliance schedules, testing, monitoring, and reporting and recordkeeping requirements.

[63 FR 63201, Nov. 12, 1998, as amended at 65 FR 49881, Aug. 15, 2000; 68 FR 5158, Jan. 31, 2003; 68 FR 57539, Oct. 3, 2003; 86 FR 27769, May 21, 2021]

Subpart B - Alabama

Authority: Sec. 110(a) and 111(d), Clean Air Act (42 U.S.C. 7410(a) and 7411(d)).

§62.107 Identification of sources.

(a) Approval of State Plan for Commercial and Industrial Solid Waste Incineration Units. Effective February 10, 2020, EPA approved Alabama's State Plan for Commercial and Solid Waste Incineration Units, which is codified at Alabama Rule 335-3-3-.05, amended December 8, 2017, and which is incorporated by reference. The plan applies to each existing commercial and industrial solid waste incineration unit and air curtain incineration unit in the State of Alabama that commenced construction on or before June 4, 2010, or commenced modification or construction after June 4, 2010, but no later than August 7, 2013, as such incineration units are defined in 40 CFR 60.2875 and 40 CFR part 60.

(b) Incorporation by reference. (1) The material incorporated by reference in this section was approved by the Director of the Federal Register Office in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. Copies of the material may be inspected or obtained from the EPA Docket Center—Public Reading Room, EPA West Building, Room 3334, 1301 Constitution Avenue NW, Washington, DC 20004 or U.S. EPA, Region 4, Air Analysis and Support Branch, 61 Forsyth Street, Atlanta, GA 30303. The telephone number for the Public Reading Room is (202) 566-1744. Copies may be inspected at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, email fedreg.legal@nara.gov or go to: www.archives.gov/federal-register/cfr/ibr-locations.html.

(2) State of Alabama, Alabama Department of Environmental Management. 1400 Coliseum Boulevard, Montgomery, AL 36110, 334-271-7700, adem.alabama.gov.

(i) Administrative Rule 335-3-3-3.05, Incineration of Commercial and Industrial Solid Waste (Administrative Code division 335-3, Air Division—Air Pollution Control Program), adopted October 20, 2017.

(ii) [Reserved]

[68 FR 4105, Jan. 28, 2003; 85 FR 1120, Jan. 9, 2020]

Subpart B - Alabama

Authority: Sec. 110(a) and 111(d), Clean Air Act (42 U.S.C. 7410(a) and 7411(d)).

§62.107 Identification of sources.

(a) Approval of State Plan for Commercial and Industrial Solid Waste Incineration Units. Effective February 10, 2020, EPA approved Alabama's State Plan for Commercial and Solid Waste Incineration Units, which is codified at Alabama Rule 335-3-3-.05, amended December 8, 2017, and which is incorporated by reference. The plan applies to each existing commercial and industrial solid waste incineration unit and air curtain incineration unit in the State of Alabama that commenced construction on or before June 4, 2010, or commenced modification or construction after June 4, 2010, but no later than August 7, 2013, as such incineration units are defined in 40 CFR 60.2875 and 40 CFR part 60.

(b) Incorporation by reference. (1) The material incorporated by reference in this section was approved by the Director of the Federal Register Office in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. Copies of the material may be inspected or obtained from the EPA Docket Center—Public Reading Room, EPA West Building, Room 3334, 1301 Constitution Avenue NW, Washington, DC 20004 or U.S. EPA, Region 4, Air Analysis and Support Branch, 61 Forsyth Street, Atlanta, GA 30303. The telephone number for the Public Reading Room is (202) 566-1744. Copies may be inspected at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, email fedreg.legal@nara.gov or go to: www.archives.gov/federal-register/cfr/ibr-locations.html.

(2) State of Alabama, Alabama Department of Environmental Management. 1400 Coliseum Boulevard, Montgomery, AL 36110, 334-271-7700, adem.alabama.gov.

(i) Administrative Rule 335-3-3-3.05, Incineration of Commercial and Industrial Solid Waste (Administrative Code division 335-3, Air Division—Air Pollution Control Program), adopted October 20, 2017.

(ii) [Reserved]

[68 FR 4105, Jan. 28, 2003; 85 FR 1120, Jan. 9, 2020]

Subpart C - Alaska

Subpart D - Arizona

Subpart E - Arkansas

Subpart F - California

Subpart G - Colorado

Subpart H - Connecticut

Subpart I - Delaware

Subpart J - District of Columbia

Subpart K - Florida

Authority: Secs. 110(a) and 111(d), Clean Air Act (42 U.S.C. 7410(a) and 7411(d)).

Subpart L - Georgia

Authority: Secs. 110(a) and 111(d), Clean Air Act (42 U.S.C. 7410(a) and 7411(d)).

Subpart M - Hawaii

Subpart N - Idaho

Subpart O - Illinois

Subpart P - Indiana

Subpart Q - Iowa

Subpart R - Kansas

Subpart S - Kentucky

Subpart T - Louisiana

Subpart U - Maine

Subpart V - Maryland

Authority: Clean Air Act, sec. 111(d).

Subpart W - Massachusetts

Subpart X - Michigan

Subpart Y - Minnesota

Subpart Z - Mississippi

Subpart AA - Missouri

Subpart BB - Montana

Subpart CC - Nebraska

Subpart DD - Nevada

Subpart EE - New Hampshire

Subpart FF - New Jersey

Subpart GG - New Mexico

§62.7850 Identification of plan.

(a) Title of plan. “State of New Mexico Designated Facility Plan” (§ 111(d)).

(b) The plan was officially submitted as follows:

(1) Sulfuric acid plants on May 15, 1981.

(c) Affected facilities: The plan includes the following facilities:

(1) Sulfuric acid plants.

Subpart HH - New York

Subpart II - North Carolina

Authority: Secs. 110(a) and 111(d), Clean Air Act (42 U.S.C. 7410(a) and 7411(d)).

Subpart JJ - North Dakota

Subpart KK - Ohio

Subpart LL - Oklahoma

Subpart MM - Oregon

Subpart NN - Pennsylvania

Subpart OO - Rhode Island

Subpart PP - South Carolina

Subpart QQ - South Dakota

Subpart RR - Tennessee

§62.10630 Identification of sources.

(a) Approval of State Plan for Commercial and Industrial Solid Waste Incineration Units. Effective February 10, 2020, EPA approved Alabama's State Plan for Commercial and Solid Waste Incineration Units, which is codified at Alabama Rule 335-3-3-.05, amended December 8, 2017, and which is incorporated by reference. The plan applies to each existing commercial and industrial solid waste incineration unit and air curtain incineration unit in the State of Alabama that commenced construction on or before June 4, 2010, or commenced modification or construction after June 4, 2010, but no later than August 7, 2013, as such incineration units are defined in 40 CFR 60.2875 and 40 CFR part 60.

(b) Incorporation by reference. (1) The material incorporated by reference in this section was approved by the Director of the Federal Register Office in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. Copies of the material may be inspected or obtained from the EPA Docket Center—Public Reading Room, EPA West Building, Room 3334, 1301 Constitution Avenue NW, Washington, DC 20004 or U.S. EPA, Region 4, Air Analysis and Support Branch, 61 Forsyth Street, Atlanta, GA 30303. The telephone number for the Public Reading Room is (202) 566-1744. Copies may be inspected at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, email fedreg.legal@nara.gov or go to: www.archives.gov/federal-register/cfr/ibr-locations.html.

(2) State of Alabama, Alabama Department of Environmental Management. 1400 Coliseum Boulevard, Montgomery, AL 36110, 334-271-7700, adem.alabama.gov.

(i) Administrative Rule 335-3-3-3.05, Incineration of Commercial and Industrial Solid Waste (Administrative Code division 335-3, Air Division—Air Pollution Control Program), adopted October 20, 2017.

(ii) [Reserved]

[70 FR 10893, Mar. 7, 2005; 85 FR 1125, Jan. 9, 2020]

Subpart SS - Texas

Subpart TT - Utah

Subpart UU - Vermont

Subpart VV - Virginia

Subpart WW - Washington

Subpart XX - West Virginia

Subpart YY - Wisconsin

Subpart ZZ - Wyoming

Subpart AAA - American Samoa

Subpart BBB - Puerto Rico

Subpart CCC - Virgin Islands

Subpart DDD - Northern Mariana Islands

Subpart EEE [Reserved]

Subpart FFF - Federal Plan Requirements for Large Municipal Waste Combustors Constructed on or Before September 20, 1994

§62.14100 Scope and delegation of authority.

(a) This subpart contains emission requirements and compliance schedules for the control of pollutants from certain municipal waste combustors in accordance with section 111(d) and section 129 of the Clean Air Act and 40 CFR part 60, subparts B and Cb. This municipal waste combustor Federal plan applies to each affected facility as defined in §62.14102 that is not covered by an EPA approved and currently effective State or Tribal plan. This Federal plan, or portions thereof, also applies to each affected facility in any State whose approved State plan is subsequently vacated in whole or in part. This Federal plan, or portions thereof, also applies to each affected facility located in Indian country if the approved Tribal plan for that area is subsequently vacated in whole or in part.

(b) The following authorities shall be retained by the EPA Administrator and not transferred to the State upon delegation of authority to the State to implement and enforce the Federal plan:

(1) An alternative emission standard;

(2) Major alternatives to test methods;

(3) Major alternatives to monitoring;

(4) Waiver of recordkeeping; and

(5) Waiver of training requirement for chief facility operators, shift supervisors, and control room operators who have obtained provisional certification on or before the effective date of this subpart, as provided in §62.14105(d)(2) of this subpart.

§62.14101 Definitions.

Terms used but not defined in this subpart have the meaning given to them in the Clean Air Act and 40 CFR part 60, subparts A, B, and Eb.

Contract means a legally binding agreement or obligation that cannot be canceled or modified without substantial financial loss.

De-rate means to make a permanent physical change to the municipal waste combustor unit that reduces the maximum combustion capacity of the unit to less than or equal to 250 tons per day of municipal solid waste. A permit restriction or a change in the method of operation does not qualify as de-rating. (See the procedures specified in 40 CFR 60.58b(j) of subpart Eb for calculating municipal waste combustor unit capacity.)

EPA approved State plan means a State plan that EPA has reviewed and approved based on the requirements in 40 CFR part 60, subpart B to implement and enforce 40 CFR part 60, subpart Cb. An approved State plan becomes effective on the date specified in the notice published in the Federal Register announcing EPA's approval.

Municipal waste combustor plant means one or more affected facilities (as defined in §62.14102) at the same location.

Protectorate means American Samoa, the Commonwealth of Puerto Rico, the District of Columbia, Guam, the Northern Mariana Islands, and the Virgin Islands.

State means any of the 50 United States and the protectorates of the United States.

State plan means a plan submitted pursuant to section 111(d) and section 129(b)(2) of the Clean Air Act and 40 CFR part 60, subpart B that implements and enforces 40 CFR part 60, subpart Cb.

Tribal plan means a plan submitted by a Tribal Authority pursuant to 40 CFR parts 9, 35, 49, 50, and 81 that implements and enforces 40 CFR part 60, subpart Cb.

§62.14102 Affected facilities.

(a) The affected facility to which this subpart applies is each municipal waste combustor unit with a capacity to combust greater than 250 tons per day of municipal solid waste for which construction was commenced on or before September 20, 1994 that is not regulated by an EPA approved and currently effective State or Tribal plan. Table 1 of this subpart lists those units regulated by an EPA approved State plan. Notwithstanding the exclusions in table 1 of this subpart, this subpart applies to affected facilities not regulated by an EPA approved and currently effective State or Tribal plan.

(b) A municipal waste combustor unit regulated by an EPA approved and currently effective State or Tribal plan is not regulated by this subpart.

(c) Any municipal waste combustor unit that has the capacity to combust more than 250 tons per day of municipal solid waste and is subject to a Federally enforceable permit limiting the maximum amount of municipal solid waste that may be combusted in the unit to less than 11 tons per day is not subject to this subpart if the owner or operator:

(1) Notifies the EPA Administrator of an exemption claim;

(2) Provides a copy of the Federally enforceable permit that limits the firing of municipal solid waste to less than 11 tons per day; and

(3) Keeps records of the amount of municipal solid waste fired on a daily basis.

(d) Physical or operational changes made to an existing municipal waste combustor unit primarily for the purpose of complying with the emission requirements of this subpart are not considered in determining whether the unit is a modified or reconstructed facility under 40 CFR part 60, subpart Ea or subpart Eb.

(e) A qualifying small power production facility, as defined in section 3(17)(C) of the Federal Power Act (16 U.S.C. 796(17)(C)), that burns homogeneous waste (such as automotive tires orused oil, but not including refuse-derived fuel) for the production of electric energy is not subject to this subpart if the owner or operator of the facility notifies the EPA Administrator of this exemption and provides data documenting that the facility qualifies for this exemption.

(f) A qualifying cogeneration facility, as defined in section 3(18)(B) of the Federal Power Act (16 U.S.C. 796(18)(B)), that burns homogeneous waste (such as automotive tires or used oil, but not including refuse-derived fuel) for the production of electric energy and steam or forms of useful energy (such as heat) that are used for industrial, commercial, heating, or cooling purposes, is not subject to this subpart if the owner or operator of the facility notifies the EPA Administrator of this exemption and provides data documenting that the facility qualifies for this exemption.

(g) Any unit combusting a single-item waste stream of tires is not subject to this subpart if the owner or operator of the unit:

(1) Notifies the EPA Administrator of an exemption claim; and

(2) Provides data documenting that the unit qualifies for this exemption.

(h) Any unit required to have a permit under section 3005 of the Solid Waste Disposal Act is not subject to this subpart.

(i) Any materials recovery facility (including primary or secondary smelters) that combusts waste for the primary purpose of recovering metals is not subject to this subpart.

(j) Any cofired combustor, as defined under 40 CFR 60.51b of subpart Eb that meets the capacity specifications in paragraph (a) of this section is not subject to this subpart if the owner or operator of the cofired combustor:

(1) Notifies the EPA Administrator of an exemption claim;

(2) Provides a copy of the Federally enforceable permit (specified in the definition of cofired combustor in this section); and

(3) Keeps a record on a calendar quarter basis of the weight of municipal solid waste combusted at the cofired combustor and the weight of all other fuels combusted at the cofired combustor.

(k) Air curtain incinerators, as defined under 40 CFR 60.51b, that meet the capacity specifications in paragraph (a) of this section, and that combust a fuel stream composed of 100 percent yard waste are exempt from all provisions of this subpart except the opacity standard under §62.14107, and the testing procedures and the reporting and recordkeeping provisions under §62.14109.

(l) Air curtain incinerators that meet the capacity specifications in paragraph (a) of this section and that combust municipal solid waste other than yard waste are subject to all provisions of this subpart.

(m) Pyrolysis/combustion units that are an integrated part of a plastics/rubber recycling unit (as defined in 40 CFR 60.51b) are not subject to this subpart if the owner or operator of the plastics/rubber recycling unit keeps records of the weight of plastics, rubber, and/or rubber tires processed on a calendar quarter basis; the weight of chemical plant feedstocks and petroleum refinery feedstocks produced and marketed on a calendar quarter basis; and the name and address of the purchaser of the feedstocks. The combustion of gasoline, diesel fuel, jet fuel, fuel oils, residual oil, refinery gas, petroleum coke, liquefied petroleum gas, propane, or butane produced by chemical plants or petroleum refineries that use feestocks produced by plastics/rubber recycling units are not subject to this subpart.

(n) Cement kilns firing municipal solid waste are not subject to this subpart.

[63 FR 63202, Nov. 12, 1998; 64 FR 17219, Apr. 8, 1999]

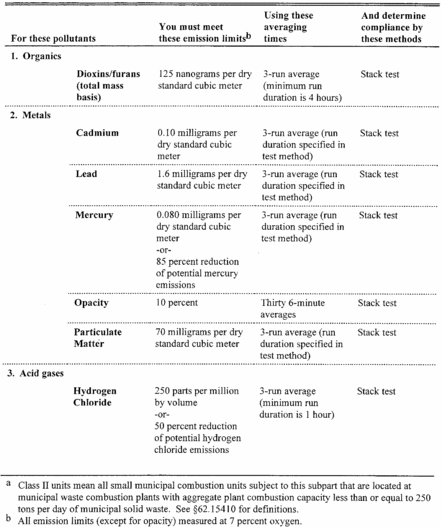

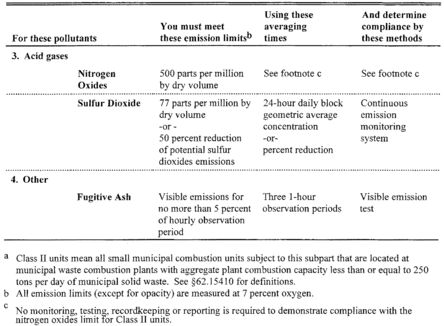

§62.14103 Emission limits for municipal waste combustor metals, acid gases, organics, and nitrogen oxides.

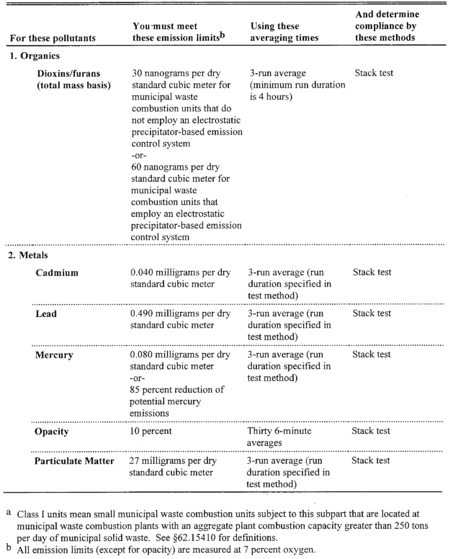

(a) The emission limits for municipal waste combustor metals are specified in paragraphs (a)(1) through (a)(3) of this section.

(1) The owner or operator of an affected facility must not cause to be discharged into the atmosphere from that affected facility any gases that contain: particulate matter in excess of 27 milligrams per dry standard cubic meter, corrected to 7 percent oxygen; and opacity in excess of 10 percent (6-minute average).

(2) The owner or operator of an affected facility must not cause to be discharged into the atmosphere from that affected facility any gases that contain: cadmium in excess of 0.040 milligrams per dry standard cubic meter, corrected to 7 percent oxygen; and lead in excess of 0.44 milligrams per dry standard cubic meter, corrected to 7 percent oxygen.

(3) The owner or operator of an affected facility must not cause to be discharged into the atmosphere from that affected facility any gases that contain mercury in excess of 0.080 milligrams per dry standard cubic meter or 15 percent of the potential mercury emission concentration (85-percent reduction by weight), corrected to 7 percent oxygen, whichever is less stringent.

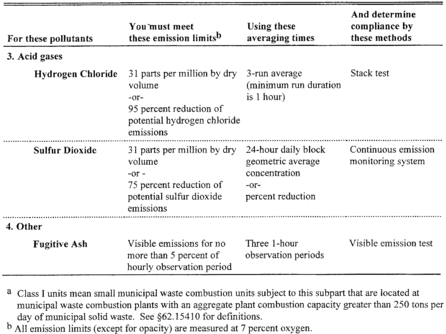

(b) The emission limits for municipal waste combustor acid gases, expressed as sulfur dioxide and hydrogen chloride, are specified in paragraphs (b)(1) and (b)(2) of this section.

(1) The owner or operator of an affected facility must not cause to be discharged into the atmosphere from that affected facility any gases that contain sulfur dioxide in excess of 29 parts per million by volume or 25 percent of the potential sulfur dioxide emission concentration (75-percent reduction by weight or volume), corrected to 7 percent oxygen (dry basis), whichever is less stringent. Compliance with this emission limit is based on a 24-hour daily geometric mean.

(2) The owner or operator of an affected facility must not cause to be discharged into the atmosphere from that affected facility any gases that contain hydrogen chloride in excess of 29 parts per million by volume or 5 percent of the potential hydrogen chloride emission concentration (95-percent reduction by weight or volume), corrected to 7 percent oxygen (dry basis), whichever is less stringent.

(c) The owner or operator of an affected facility must not cause to be discharged into the atmosphere from that affected facility any gases that contain municipal waste combustor organics, expressed as total mass dioxins/furans, in excess of the emission limits specified in either paragraph (c)(1) or (c)(2) of this section, as applicable.

(1) The emission limit for affected facilities that employ an electrostatic precipitator-based emission control system is 60 nanograms per dry standard cubic meter (total mass), corrected to 7 percent oxygen.

(2) The emission limit for affected facilities that do not employ an electrostatic precipitator-based emission control system is 30 nanograms per dry standard cubic meter (total mass), corrected to 7 percent oxygen.

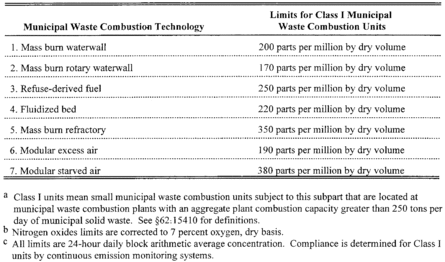

(d) The owner or operator of an affected facility must not cause to be discharged into the atmosphere from that affected facility any gases that contain nitrogen oxides in excess of the emission limits listed in table 2 of this subpart for affected facilities. Table 2 of this subpart provides emission limits for the nitrogen oxides concentration level for each type of affected facility.

§62.14104 Requirements for municipal waste combustor operating practices.

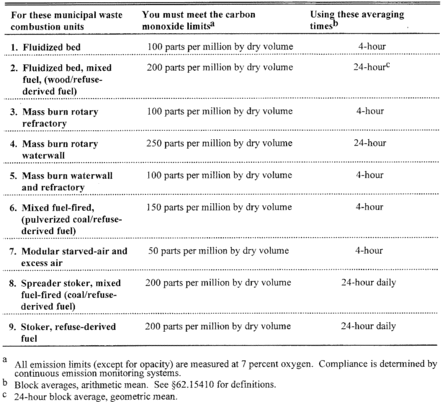

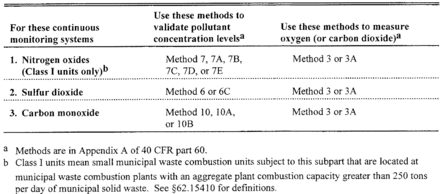

(a) The owner or operator of an affected facility must not cause to be discharged into the atmosphere from that affected facility any gases that contain carbon monoxide in excess of the emission limits listed in table 3 of this subpart. Table 3 provides emission limits for the carbon monoxide concentration level for each type of affected facility.

(b) The owner or operator of an affected facility must comply with the municipal waste combustor operating practice requirements listed in 40 CFR 60.53b(b) and (c) of subpart Eb. For calculating the steam (or feedwater) flow required under 40 CFR 60.58(i)(6)(i), proceed in accordance with ASME PTC 4.1-1964 (Reaffirmed 1991), Power Test Codes: Test Code for Steam Generating Units (with 1968 and 1969 Addenda). For design, construction, installation, calibration, and use of nozzles and orifices required in 40 CFR 60.58(i)(6)(ii), proceed in accordance with the recommendations in ASME Interim Supplement 19.5 on Instruments and Apparatus: Application, Part II of Fluid Meters, 6th Edition (1971). The Director of the Federal Register approves these incorporations by reference in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. You may obtain a copy from the American Society of Mechanical Engineers, Service Center, 22 Law Drive, Post Office Box 2900, Fairfield, NJ 07007. You may inspect a copy at the Office of Air Quality Planning and Standards Air Docket, EPA, Mutual Building, Room 540, 411 West Chapel Hill Street, Durham, NC 27701, or at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, call 202-741-6030, or go to: http://www.archives.gov/federal_register/code_of_federal_regulations/ibr_locations.html.

[63 FR 63202, Nov. 12, 1998, as amended at 69 FR 18803, Apr. 9, 2004]

§62.14105 Requirements for municipal waste combustor operator training and certification.

The owner or operator of an affected facility must comply with the municipal waste combustor operator training and certification requirements listed in paragraphs (a) through (g) of this section. For affected facilities, compliance with the municipal waste combustor operator training and certification requirements specified under paragraphs (a), (b), (d), and (g) of this section must be no later than 12 months after the effective date of this subpart.

(a) Each chief facility operator and shift supervisor must obtain and maintain a current provisional operator certification from either the American Society of Mechanical Engineers QRO-1-1994 or a State certification program in Connecticut and Maryland (if the affected facility is located in either of the respective States). If ASME certification is chosen, proceed in accordance with ASME QRO-1-1994, Standard for the Qualification and Certification of Resource Recovery Facility Operators. The Director of the Federal Register approves this incorporation by reference in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. You may obtain a copy from the American Society of Mechanical Engineers, Service Center, 22 Law Drive, Post Office Box 2900, Fairfield, NJ 07007. You may inspect a copy at the Office of Air Quality Planning and Standards Air Docket, EPA, Mutual Building, Room 540, 411 West Chapel Hill Street, Durham, NC 27701 or at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, call 202-741-6030, or go to: http://www.archives.gov/federal_register/code_of_federal_regulations/ibr_locations.html.

(b) Each chief facility operator and shift supervisor must have completed full certification or must have scheduled a full certification exam with either the American Society of Mechanical Engineers QRO-1-1994 or a State certification program in Connecticut and Maryland (if the affected facility is located in either of the respective States). If ASME certification is chosen, proceed in accordance with ASME QRO-1-1994, Standard for the Qualification and Certification of Resource Recovery Facility Operators. The Director of the Federal Register approves this incorporation by reference in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. You may obtain a copy from the American Society of Mechanical Engineers, Service Center, 22 Law Drive, Post Office Box 2900, Fairfield, NJ 07007. You may inspect a copy at the Office of Air Quality Planning and Standards Air Docket, EPA, Mutual Building, Room 540, 411 West Chapel Hill Street, Durham, NC 27701 or at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, call 202-741-6030, or go to: http://www.archives.gov/federal_register/code_of_federal_regulations/ibr_locations.html.

(c) The owner or operator of an affected facility must not allow the facility to be operated at any time unless one of the following persons is on duty at the affected facility: a fully certified chief facility operator; a provisionally certified chief facility operator who is scheduled to take the full certification exam no later than 12 months after the effective date of this subpart; a fully certified shift supervisor; or a provisionally certified shift supervisor who is scheduled to take the full certification exam no later than 12 months after the effective date of this subpart. If one of the persons listed in this paragraph must leave the affected facility during their operating shift, a provisionally certified control room operator who is onsite at the affected facility may fulfill the requirement in this paragraph.

(d)(1) Each chief facility operator, shift supervisor, and control room operator at an affected facility must complete the EPA municipal waste combustor operator training course or the State municipal waste combustor operator training course in Connecticut (if the affected facility is located in Connecticut).

(2) The requirement specified in this paragraph does not apply to chief facility operators, shift supervisors, and control room operators who have obtained full certification from the American Society of Mechanical Engineers on or before the effective date of this subpart. The owner or operator of an affected facility may request that the EPA Administrator waive the requirement specified in this paragraph for chief facility operators, shift supervisors, and control room operators who have obtained provisional certification from the American Society of Mechanical Engineers on or before the effective date of this subpart.

(e) The owner or operator of an affected facility must develop and update on a yearly basis a site-specific operating manual that must, at a minimum, address the elements of municipal waste combustor unit operation specified in paragraphs (e)(1) through (e)(11) of this section.

(1) A summary of the applicable standards under this subpart;

(2) A description of basic combustion theory applicable to a municipal waste combustor unit;

(3) Procedures for receiving, handling, and feeding municipal solid waste;

(4) Procedures for municipal waste combustor unit startup, shutdown, and malfunction;

(5) Procedures for maintaining proper combustion air supply levels;

(6) Procedures for operating the municipal waste combustor unit within the standards established under this subpart;

(7) Procedures for responding to periodic upset or off-specification conditions;

(8) Procedures for minimizing particulate matter carryover;

(9) Procedures for handling ash;

(10) Procedures for monitoring municipal waste combustor unit emissions; and

(11) Reporting and recordkeeping procedures.

(f) The owner or operator of an affected facility must establish a training program to review the operating manual according to the schedule specified in paragraphs (f)(1) and (f)(2) of this section with each person who has responsibilities affecting the operation of an affected facility including, but not limited to, chief facility operators, shift supervisors, control room operators, ash handlers, maintenance personnel, and crane/load handlers.

(1) Each person specified in paragraph (f) of this section must undergo initial training no later than the date specified in paragraph (f)(1)(i) or (f)(1)(ii) of this section, whichever is later.

(i) The date prior to the day the person assumes responsibilities affecting municipal waste combustor unit operation; or

(ii) The date 12 months after the effective date of this subpart.

(2) Annually, following the initial review required by paragraph (f)(1) of this section.

(g) The operating manual required by paragraph (e) of this section must be kept in a location readily accessible to each person required to undergo training under paragraph (f) of this section. The operating manual and records of training must be available for inspection by the EPA or its delegated enforcement agency upon request.

[63 FR 63202, Nov. 12, 1998, as amended at 69 FR 18803, Apr. 9, 2004]

§62.14106 Emission limits for municipal waste combustor fugitive ash emissions.

(a) The owner or operator of an affected facility must not cause to be discharged to the atmosphere from that affected facility visible emissions of combustion ash from an ash conveying system (including conveyor transfer points) in excess of 5 percent of the observation period (i.e., 9 minutes per 3-hour period), as determined by EPA Reference Method 22 observations as specified in 40 CFR 60.58b(k) of subpart Eb, except as provided in paragraphs (b) and (c) of this section.

(b) The emission limit specified in paragraph (a) of this section does not cover visible emissions discharged inside buildings or enclosures of ash conveying systems; however, the emission limit specified in paragraph (a) of this section does cover visible emissions discharged to the atmosphere from buildings or enclosures of ash conveying systems.

(c) The provisions specified in paragraph (a) of this section do not apply during maintenance and repair of ash conveying systems.

§62.14107 Emission limits for air curtain incinerators.

The owner or operator of an air curtain incinerator with the capacity to combust greater than 250 tons per day of municipal solid waste and that combusts a fuel feed stream composed of 100 percent yard waste and no other municipal solid waste materials must not (at any time) cause to be discharged into the atmosphere from that incinerator any gases that exhibit greater than 10-percent opacity (6-minute average), except that an opacity level of up to 35 percent (6-minute average) is permitted during startup periods during the first 30 minutes of operation of the unit.

§62.14108 Compliance schedules.

(a) The owner or operator of an affected facility must achieve the increments of progress specified in paragraphs (a)(1) through (a)(5) to retrofit air pollution control devices to meet the emission limits of this subpart. As specified in 40 CFR part 60, subpart B, the compliance schedules and increments of progress apply to each owner or operator of an affected facility who is taking longer than 1 year after the date of publication of this subpart FFF final rule to comply with the emission limits specified in this subpart.

(1) Submit a final control plan according to the requirements of §62.14109(g).

(2) Award contract(s): Award contract(s) to initiate on-site construction, initiate on-site installation of emission control equipment, or incorporate process changes. The owner or operator must submit a signed copy of the contract(s) awarded according to the requirements of §62.14109(h).

(3) Initiate on-site construction: Initiate on-site construction, initiate on-site installation of emission control equipment, or initiate process changes needed to meet the emission limits as outlined in the final control plan.

(4) Complete on-site construction: Complete on-site construction and installation of emission control equipment or complete process changes.

(5) Achieve final compliance: Incorporate all process changes or complete retrofit construction as designed in the final control plan and connect the air pollution control equipment or process changes with the affected facility identified in the final control plan such that if the affected facility is brought on line, all necessary process changes or air pollution control equipment are operating fully. Within 180 days after the date the affected facility is required to achieve final compliance, the initial performance test must be conducted.

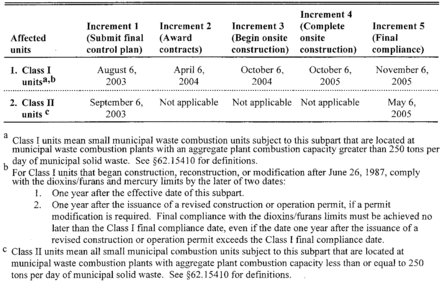

(b) The owner or operator of an affected facility must achieve the increments of progress specified in paragraphs (a)(1) through (a)(5) of this section according to the schedule specified in paragraphs (b)(1) through (b)(4) of this section, except as provided in paragraphs (c), (d), and (e) of this section.

(1) The owner or operator of an affected facility that commenced construction, modification, or reconstruction on or before June 26, 1987 and will take longer than 1 year after the date of publication of this subpart FFF (or 1 year after a revised construction permit or a revised operating permit is issued, if a permit modification is required) to comply with the emission limits of this subpart must achieve the increments of progress according to the schedule in table 4 of this subpart, except for those affected facilities specified in paragraphs (b)(3) and (b)(4) of this section.

(2) The owner or operator of an affected facility that began construction, modification, or reconstruction after June 26, 1987 must achieve the increments of progress according to the schedule in table 5 of this subpart to comply with the emission limits of this subpart, except for those affected facilities specified in paragraphs (b)(3) and (b)(4) of this section.

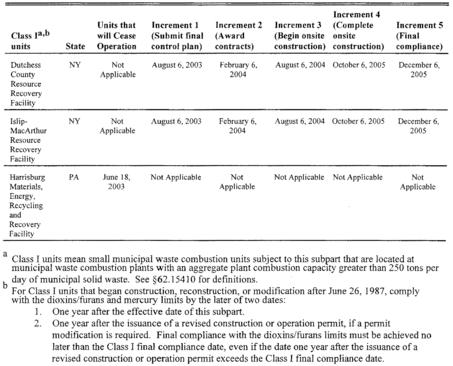

(3) The owner or operator of each specified affected facility in table 6 of this subpart must achieve the increments of progress according to the schedule in table 6 of this subpart.

(4) For affected facilities that are subject to the schedule requirements of paragraph (b)(1) or (b)(2) of this section, the owner or operator (or the State air pollution control authority) may submit for approval alternative dates for achieving increments 2, 3, and 4. The owner or operator (or the State air pollution control authority) that is submitting these alternative dates must meet the reporting requirements of §62.14109(m).

(c) The owner or operator of an affected facility that has ceased operation but will reopen prior to the applicable final compliance date specified in paragraphs (b)(1) through (b)(4) of this section must meet the same compliance dates and increments of progress specified in paragraphs (b)(1) through (b)(4) of this section.

(d) The owner or operator of an affected facility that has ceased or ceases operation of an affected facility and restarts the affected facility after the compliance dates specified in paragraphs (b)(1) through (b)(4) of this section must comply with the emission limits, requirements for combustor operating practices, and operator training and certification requirements of this subpart upon the date the affected facility restarts. The initial performance tests required by §62.14109(c) must be conducted within 180 days after the date the unit restarts.

(e) The owner or operator of an affected facility that will be de-rated prior to the applicable final compliance date instead of complying with the emission limits of this subpart must meet the same increments of progress and achieve the de-rating by the final compliance date (specified in paragraphs (b)(1) through (b)(4) of this section) that would be applicable to the affected facility if it did not de-rate. The owner or operator of an affected facility that will be de-rated must meet the reporting requirements of §62.14109k. After de-rating is accomplished, the municipal waste combustor affected facility is no longer subject to this subpart.

§62.14109 Reporting and recordkeeping and compliance and performance testing.

(a) The owner or operator of an affected facility must comply with the reporting and recordkeeping provisions listed in 40 CFR 60.59b of subpart Eb, except as provided in paragraphs (a)(1) through (a)(3) of this section.

(1) The siting requirements under 40 CFR 60.59b(a), (b)(5), and (d)(11) of subpart Eb and the notification of construction requirements under 40 CFR 60.59b(b) and (c) of subpart Eb do not apply.

(2) 40 CFR 60.54b, 60.56b, and 60.58b(g)(5)(iii) of subpart Eb do not apply to this subpart (see §§62.14105 and 62.14107 of this subpart).

(b) The owner or operator of an affected facility must comply with the compliance and performance testing methods and procedures listed in 40 CFR 60.58b of subpart Eb, except as provided in paragraphs (c) and (d) of this section.

(c) The initial performance test must be completed within 180 days after the date of final compliance specified in §62.14108, rather than the date for the initial performance test specified in 40 CFR 60.58b of subpart Eb.

(d) The owner or operator of an affected facility may follow the alternative performance testing schedule for dioxin/furan emissions specified in paragraph (d)(1) of this section.

(1) If all performance tests for all affected facilities at the MWC plant over a 2-year period indicate that dioxin/furan emissions are less than or equal to 15 nanograms per dry standard cubic meter total mass, corrected to 7 percent oxygen for all affected facilities located within a municipal waste combustor plant, the owner or operator of the municipal waste combustor plant may elect to conduct annual performance tests for one affected facility (i.e., unit) per year at the municipal waste combustor plant. At a minimum, a performance test for dioxin/furan emissions shall be conducted annually (no more than 12 months following the previous performance test) for one affected facility at the municipal waste combustor plant. Each year a different affected facility at the municipal waste combustor plant shall be tested, and the affected facilities at the plant shall be tested in sequence (e.g., unit 1, unit 2, unit 3, as applicable). If each annual performance test continues to indicate a dioxin/furan emission level less than or equal to 15 nanograms per dry standard cubic meter (total mass), the owner or operator may continue conducting a performance test on only one affected facility per year. If any annual performance test indicates a dioxin/furan emission level greater than 15 nanograms per dry standrd cubic meter (total mass), performance tests thereafter shall be conducted annually on all affected facilities at the plant until and unless all annual performance tests for all affected facilities at the plant over a 2-year period indicate a dioxin/furan emission level less than or equal to 15 nanograms per dry standard cubic meter (total mass).

(2) The owner or operator who is following the alternative performance testing schedule for dioxin/furan emissions specified in paragraph (d)(1) of this section may choose an alternative testing sequence (e.g., unit 1, 3, 2, 4) for affected facilities at the municipal waste combustor plant. The owner or operator must submit a request to EPA for approval of the alternative testing sequence. After approval, the alternative testing sequence is effective until a different testing sequence is received and approved by EPA.

(e) The owner or operator of an affected facility that is taking longer than 1 year after the date of publication of this subpart FFF final rule to comply with the emission limits of this subpart must submit notification to the EPA Regional Office within 10 business days of completing each increment. Each notification must indicate which increment of progress specified in §62.14108(a)(1) through (a)(5) has been achieved. The notification must be signed by the owner or operator of the affected facility.

(f) The owner or operator of an affected facility that is taking longer than 1 year after the date of publication of this subpart FFF to comply with the emission limits of this subpart who fails to meet any increment of progress specified in §62.14108(a)(1) through (a)(5) according to the applicable schedule in §62.14108 must submit notification to the EPA Regional Office within 10 business days of the applicable date in §62.14108 that the owner or operator failed to meet the increment.

(g) The owner or operator of an affected facility that is taking longer than 1 year after the date of publication of this subpart FFF to comply with the emission limits of this subpart must submit a final control plan by the date specified in §62.14108(b) with the notification required by §62.14109(e). The final control plan must, at a minimum, include a description of the air pollution control devices or process changes that will be employed for each unit to comply with the emission limits and other requirements of this subpart.

(h) The owner or operator of an affected facility that is taking longer than 1 year after the date of publication of this subpart FFF to comply with the emission limits of this subpart must submit a signed copy of the contract or contracts awarded according to the requirements of §62.14108(a)(2) with the notification required by §62.14109(e).

(i) The owner or operator of an affected facility that is taking longer than 1 year after the date of publication of this subpart FFF to comply with the emission limits of this subpart must keep on site a copy of the final control plan required by §62.14109(g).

(j) The owner or operator of an affected facility that plans to cease operation of the affected facility on or before December 19, 2000 rather than comply with the emission limits of this subpart by the applicable compliance date specified in §62.14108 must submit a notification by the date specified for the final control plan according to the schedule specified in paragraphs §62.14108(b)(1) through (b)(4), as applicable. (Affected facilities that cease operation on or before December 19, 2000 rather than comply with the emission limits of this subpart by the compliance date specified in §62.14108 are not required to submit a final control plan.) The notification must state the date by which the affected facility will cease operation. If the cease operation date is later than 1 year after the date of publication of this subpart FFF, the owner or operator must enter into a legally binding closure agreement with EPA by the date the final control plan is due. The agreement must specify the date by which operation will cease.

(k) The owner or operator of an affected facility that plans to de-rate the affected facility on or before December 19, 2000 rather than comply with the emission limits of this subpart by the compliance date specified in §62.14108 must submit a final control plan as required by paragraph (g) of this section and submit notification of increments of progress as required by paragraphs (e) and (f) of this section and §62.14108(e) of this subpart.

(1) The final control plan must, at a minimum, include the information in paragraphs (k)(1)(i) and (k)(1)(ii) of this section rather than the information in paragraph (g) of this section.

(i) A description of the physical changes that will be made to accomplish the de-rating.

(ii) Calculations of the current maximum combustion capacity and the planned maximum combustion capacity after the de-rating. (See the procedures specified in 40 CFR 60.58b(j) of subpart Eb for calculating municipal waste combustor unit capacity.)

(2) The owner or operator must submit a signed copy of the contract or contracts awarded to initiate the de-rating with the notification required by paragraph (e) of this section.

(l) The owner or operator of an affected facility that is ceasing operation more than 1 year following the date of publication of this subpart FFF must submit performance test results for dioxin/furan emissions conducted during or after 1990 for each affected facility by the date 1 year after the date of publication of this subpart FFF. The performance test shall be conducted according to the procedure in paragraph (b) of this section.

(m) The owner or operator (or the State air pollution control authority) that is submitting alternative dates for increments 2, 3, and 4 according to §62.14108(b)(4) must submit the alternative dates by the date specified for the final control plan according to the schedule specified in paragraphs §62.14108 (b)(1) and (b)(2), as applicable. The owner or operator (or the State air pollution control authority) must submit a justification if any of the alternative dates are later than the increment dates in tables 4 or 5 of this subpart. The owner or operator must also submit the alternative dates and justification to the State.

[63 FR 63202, Nov. 12, 1998; 64 FR 17219, Apr. 8, 1999]

Table 1 to Subpart FFF of Part 62 - Municipal Waste Combustor Units (MWC Units) Excluded From Subpart FFF 1

| State | MWC units |

|---|---|

| 1 Notwithstanding the exclusions in table 1 of this subpart, this subpart applies to affected facilities not regulated by an EPA approved and currently effective State or Tribal plan. | |

| Alabama |

Existing facilities with an MWC unit capacity greater than 250 tons per day of municipal solid waste at the following MWC sites:

(a) Solid Waste Disposal Authority of the City of Huntsville, Alabama. |

| Florida | Existing MWC units with capacity to combust more than 250 tons per day of municipal solid waste. |

| Georgia | Existing facilities with a MWC unit capacity greater than 250 tons per day of municipal solid waste at the following MWC sites: |

| (a) Savannah Energy Systems Company, Savannah, Georgia. | |

| Illinois | Existing MWC units located at Robbins Resource Recovery Center, Robbins, Illinois. |

| Maine |

Existing facilities with an MWC unit capacity greater than 250 tons per day of municipal solid waste at the following MWC sites:

(a) Penobscot Energy Recovery Company, Orrington, Maine. (b) Maine Energy Recovery Company, Biddeford, Maine. (c) Regional Waste Systems, Inc., Portland, Maine. |

| Maryland | Existing MWC facilities with an MWC unit capacity greater than 250 tons per day of municipal solid waste. |

| Minnesota | All MWC units with unit capacities greater than 93.75 million British thermal units per hour on a heat input basis (250 tons per day) located in Minnesota. |

| New York | Existing MWC units with capacity to combust more than 250 tons per day of municipal solid waste. |

| Oklahoma |

Existing MWC facilities with an MWC unit capacity greater than 250 tons per day of municipal solid waste at the following MWC site:

Ogden-Martin Systems of Tulsa, Incorporated, 2122 South Yukon Avenue, Tulsa, Oklahoma. |

| Oregon | Existing facilities at the following MWC sites: |

| (a) Ogden Martin Systems, Marion County, Oregon. | |

| (b) Coos County, Coos Bay, Oregon. | |

| Pennsylvania |

Existing MWC facilities with an MWC unit capacity greater than 250 tons per day of municipal solid waste at the following MWC site:

(a) American Ref-fuel of Delaware Valley, LP (formerly Delaware County Resource Recovery facility), City of Chester, PA. (b) Harrisburg Materials, Energy, Recycling and Recovery Facility, City of Harrisburg, PA. (c) Lancaster County Solid Waste Management Authority, Conoy Township, Lancaster County, PA. (d) Montenay Montgomery Limited Partnership, Plymouth Township, Montgomery County, PA. (e) Wheelabrator Falls, Inc., Falls Township, Bucks County, PA. (f) York County Solid Waste and Refuse Authority, York, PA. |

| South Carolina | Existing facilities with a MWC unit capacity greater than 250 tons per day of municipal solid waste at the following MWC sites: |

| (a) Foster Wheeler Charleston Resource Recovery Facility, Charleston, South Carolina. | |

| Tennessee | Existing MWC units with capacity to combust more than 250 tons per day of municipal solid waste. |

[63 FR 63202, Nov. 12, 1998, as amended at 65 FR 33468, May 24, 2000]

Table 2 to Subpart FFF of Part 62 - Nitrogen Oxides Requirements for Affected Facilities

| Municipal waste combustor technology | Nitrogen oxides emission limit (parts per million by volume) a |

|---|---|

| a Corrected to 7 percent oxygen, dry basis. | |

| Mass burn waterwall | 205. |

| Mass burn rotary waterwall | 250. |

| Refuse-derived fuel combustor | 250. |

| Fluidized bed combustor | 180. |

| Mass burn refractory combustors | No limit. |

Table 3 to Subpart FFF of Part 62 - Municipal Waste Combustor Operating Requirements

| Municipal waste combustor technology | Carbon monoxide emissions level (parts per million by volume) a | Averaging time (hrs) b |

|---|---|---|

| a Measured at the combustor outlet in conjunction with a measurement of oxygen concentration, corrected to 7 percent oxygen, dry basis. Calculated as an arithmetic average.

b Averaging times are 4-hour or 24-hour block averages. c 24-hour block average, geometric mean. | ||

| Mass burn waterwall | 100 | 4 |

| Mass burn refractory | 100 | 4 |

| Mass burn rotary refractory | 100 | 24 |

| Mass burn rotary waterwall | 250 | 24 |

| Modular starved air | 50 | 4 |

| Modular excess air | 50 | 4 |

| Refuse-derived fuel stoker | 200 | 24 |

| Fluidized bed, mixed fuel (wood/refuse-derived fuel) | 200 | c 24 |

| Bubbling fluidized bed combustor | 100 | 4 |

| Circulating fluidized bed combustor | 100 | 4 |

| Pulverized coal/refuse-derived fuel mixed fuel-fired combustor | 150 | 4 |

| Spreader stoker coal/refuse-derived fuel mixed fuel-fired combustor | 200 | 24 |

[69 FR 42121, July 14, 2004]

Table 4 to Subpart FFF of Part 62 - Generic Compliance Schedule and Increments of Progress (Pre-1987 MWCs) a b

| Affected facilities |

Increment 1

Submit final control plan |

Increment 2

Award contracts |

Increment 3

Begin on-site construction |

Increment 4

Complete on-site construction |

Increment 5

Final compliance |

|---|---|---|---|---|---|

| a Table 4 or 5 of this subpart applies to MWC units subject to the Federal plan except those with site-specific compliance schedules shown in Table 6 of this subpart.

b As an alternative to this schedule, the owner or operator may close the affected facility by December 19, 2000, complete the retrofit while the affected facility is closed, and achieve final compliance upon restarting. See §§62.14108(c), 62.14108(d), and 62.14109(i) of this subpart. | |||||

| Affected facilities that commenced construction, modification, or reconstruction on or before June 26, 1987 (All pollutants) | January 11, 1999 | 05/18/99 | 11/16/99 | 11/19/00 | 12/19/00 |

Table 5 to Subpart FFF of Part 62 - Generic Compliance Schedules and Increments of Progress

| Affected facilities |

Increment 1

Submit final control plan |

Increment 2

Award contracts |

Increment 3

Begin on-site construction |

Increment 4

Complete on-site construction |

Increment 5

Final compliance |

|---|---|---|---|---|---|

| a Table 4 or 5 of this subpart applies to MWC units subject to the Federal plan except those with site-specific compliance schedules shown in table 6 of this subpart.

b As an alternative to this schedule, the unit may close by December 19, 2000, complete retrofit while closed, and achieve final compliance upon restarting. See §§62.14108(c), 62.14108(d), and 62.14109(i) of this subpart. c Because final compliance is achieved in 1 year, no increments of progress are required. d Permit issuance is issuance of a revised construction permit or revised operating permit, if a permit modification is required to retrofit controls. e Final compliance must be achieved no later than December 19, 2000, even if the date “1 year after permit issuance” exceeds December 19, 2000. | |||||

| Affected facilities that commenced construction modification, or reconstruction after June 26, 1987: | |||||

| 1. Emission limits for Hg, dioxin/furan | NA c | NA c | NA c | NA c | 11/12/99 or 1 year after permit issuance d e |

| 2. Emission limits for SO2, HCl, PM, Pb, Cd, opacity CO, NOX | January 11, 1999 | 05/18/99 | 11/16/99 | 11/19/00 | 12/19/00. |

[63 FR 63202, Nov. 12, 1998, as amended at 65 FR 33468, May 24, 2000]

Table 6 to Subpart FFF of Part 62 - Site-Specific Compliance Schedules and Increments of Progress a

| Affected facilities at the following MWC sites | City, State |

Increment 1

Submit final control plan |

Increment 2

Award contracts |

Increment 3

Begin on-site construction |

Increment 4

Complete on-site construction |

Increment 5

Final compliance c |

|---|---|---|---|---|---|---|

| a These schedules have been reviewed and determined to be acceptable by EPA.

b This schedule applies to HC1 SO2, PM, Pb, Cd, CO, and NOX. However, owners and operators of large MWC units in New Jersey have the option of reserving the portion of their control plan that addresses NOX. Owners and operators must submit the reserved portion to EPA by December 15, 1999. c The owner or operator of an affected facility that began construction, modification, or reconstruction after June 26, 1987 must achieve final compliance with the mercury and dioxins/furans limits within 1 year after promulgation of subpart FFF (i.e., by 11/12/99) or 1 year after permit issuance. Permit issuance is issuance of a revised construction permit or revised operating permit if a permit modification is required to retrofit controls. Final compliance must be achieved no later than December 19, 2000, even if the date “1 year after permit issuance” exceeds December 19, 2000. | ||||||

| Stanislaus Resource Recovery Facility | Crows Landing, California | January 11, 1999 | 01/19/00 | 05/19/00 | 11/19/00 | 12/19/00 |

| Southeast Resource Recovery Facility | Long Beach, California | January 11, 1999 | 04/30/99 | 10/31/99 | 04/30/00 | 12/19/00 |

| All large MWC units | Maine | January 11, 1999 | 01/01/99 | 07/01/99 | 09/01/00 | 12/19/00 |

| Baltimore Resco | Baltimore, Maryland | January 11, 1999 | January 11, 1999 | January 11, 1999 | 09/01/00 | 12/19/00 |

| All large MWC units | New Jersey b | January 11, 1999 | 05/18/99 | 11/14/99 | 11/19/00 | 12/19/00 |

| American Ref-Fuel | Delaware County, Pennsylvania | 11/01/98 | 05/18/99 | 11/14/99 | 11/19/00 | 12/19/00 |

| Montenay Energy Resource | Montgomery County, Pennsylvania | 11/01/98 | 05/18/99 | 11/14/99 | 11/19/00 | 12/19/00 |

| I-95 Energy/Resource Recovery Facility | Lorton, Virginia | January 11, 1999 | 10/15/99 | 03/01/00 | 11/19/00 | 12/19/00 |

| New Hanover County, Unit 3A | Wilmington, North Carolina | 09/15/99 | 03/01/00 | 07/01/00 | 11/19/00 | 12/19/00 |

[63 FR 63202, Nov. 12, 1998; 64 FR 17219, Apr. 8, 1999, as amended at 65 FR 33469, May 24, 2000]

Subpart GGG - Federal Plan Requirements for Municipal Solid Waste Landfills That Commenced Construction Prior to May 30, 1991 and Have Not Been Modified or Reconstructed Since May 30, 1991

§62.14350 Scope and delegation of authority.

(a) This subpart contains emission requirements and compliance schedules for the control of designated pollutants from certain municipal solid waste landfills in accordance with section 111(d) of the Clean Air Act and 40 CFR part 60, subpart B. This municipal solid waste landfills Federal plan applies to each designated facility as defined in §62.14352 of this subpart that is not covered by an EPA approved and currently effective State or Tribal plan.

(b) The following authorities shall be retained by the Administrator and not transferred to the State or Tribe upon delegation of authority to the State or Tribe to implement and enforce the Federal plan pursuant to sections 101(a)(3) and 111 of the Clean Air Act:

(1) Approval of alternative methods to determine site-specific NMOC concentration (C NMOC) or site-specific methane generation rate constant (k) used in calculating the annual NMOC emission rate (as provided in 40 CFR 60.754(a)(5) of subpart WWW),

(2) Alternative emission standards,

(3) Major alternatives 1 to test methods,

1 Major changes to test methods or to monitoring are modifications made to a federally enforceable test method or to a federal monitoring requirement. These changes would involve the use of unproven technology or procedures or an entirely new method (which is sometimes necessary when the required test method or monitoring requirement is unsuitable).

(4) Major alternatives to monitoring, or

(5) Waivers of recordkeeping.

§62.14351 Definitions.

Terms used but not defined in this subpart have the meaning given them in the Clean Air Act and 40 CFR part 60, subparts A, B, and WWW.

Achieve final compliance means to connect and operate the collection and control system as specified in the final control plan. Within 180 days after the date the landfill is required to achieve final compliance, the initial performance test must be conducted.

Award contract means the MSW landfill owner or operator enters into legally binding agreements or contractual obligations that cannot be canceled or modified without substantial financial loss to the MSW landfill owner or operator. The MSW landfill owner or operator may award a number of contracts to install the collection and control system. To meet this increment of progress, the MSW landfill owner or operator must award a contract or contracts to initiate on-site construction or installation of the collection and control system.

Complete on-site construction means that all necessary collection system components and air pollution control devices identified in the final control plan are on site, in place, and ready for operation.

Design capacity means the maximum amount of solid waste a landfill can accept, as indicated in terms of volume or mass in the most recent permit issued by the State, local, or Tribal agency responsible for regulating the landfill, plus any in-place waste not accounted for in the most recent permit. If the owner or operator chooses to convert the design capacity from volume to mass or from mass to volume to demonstrate its design capacity is less than 2.5 million megagrams or 2.5 million cubic meters, the calculation must include a site-specific density, which must be recalculated annually.

EPA approved State plan means a State plan that EPA has approved based on the requirements in 40 CFR part 60, subpart B to implement and enforce 40 CFR part 60, subpart Cc. An approved State plan becomes effective on the date specified in the notice published in the Federal Register announcing EPA's approval.

Federal Indian Reservation means for purposes of the Clean Air Act, all land within the limits of any Indian reservation under the jurisdiction of the United States government, notwithstanding the issuance of any patent, and including rights-of-way running through the reservation.

Final control plan (Collection and control system design plan) means a plan that describes the collection and control system that will capture the gas generated within an MSW landfill. The collection and control system design plan must be prepared by a professional engineer and must describe a collection and control system that meets the requirements of 40 CFR 60.752(b)(2)(ii). The final control plan must contain engineering specifications and drawings of the collection and control system. The final control plan must include any alternatives to the operational standards, test methods, procedures, compliance measures, monitoring, recordkeeping or reporting provisions of 40 CFR 60.753 through 60.758 proposed by the owner or operator. The final control plan must either conform with the specifications for active collection systems in 40 CFR 60.759 or include a demonstration that shows that based on the size of the landfill and the amount of waste expected to be accepted, the system is sized properly to collect the gas, control emissions of NMOC to the required level and meet the operational standards for a landfill.

Indian Country means all land within the limits of any Indian reservation under the jurisdiction of the United States government, notwithstanding the issuance of any patent, and including rights-of-way running through the reservation; all dependent Indian communities within the borders of the United States whether within the original or subsequently acquired territory thereof, and whether within or without the limits of a State; and all Indian allotments, the Indian titles to which have not been extinguished, including rights-of-way running through the same.

Initiate on-site construction means to begin any of the following: installation of the collection and control system to be used to comply with the emission limits as outlined in the final control plan; physical preparation necessary for the installation of the collection and control system to be used to comply with the final emission limits as outlined in the final control plan; or, alteration of an existing collection and control system to be used to comply with the final emission limits as outlined in the final control plan.

Modification means an increase in the permitted volume design capacity of the landfill by either horizontal or vertical expansion based on its permitted design capacity as of May 30, 1991. Modification does not occur until the owner or operator commences construction on the horizontal or vertical expansion.

Municipal solid waste landfill or MSW landfill means an entire disposal facility in a contiguous geographical space where household waste is placed in or on land. A municipal solid waste landfill may also receive other types of RCRA Subtitle D wastes such as commercial solid waste, nonhazardous sludge, conditionally exempt small quantity generator waste, and industrial solid waste. Portions of a municipal solid waste landfill may be separated by access roads. A municipal solid waste landfill may be publicly or privately owned.

Negative declaration letter means a letter to EPA declaring that there are no existing MSW landfills in the State or that there are no existing MSW landfills in the State that must install collection and control systems according to the requirements of 40 CFR part 60, subpart Cc. The negative declaration letter must include the design capacities of any existing MSW landfills with a design capacity less than 2.5 million megagrams or 2.5 million cubic meters.

Protectorate means American Samoa, the Commonwealth of Puerto Rico, the District of Columbia, Guam, the Northern Mariana Islands, and the Virgin Islands.

State means any of the 50 United States and the protectorates of the United States.

State plan means a plan submitted pursuant to section 111(d) of the Clean Air Act and 40 CFR part 60, subpart B that implements and enforces 40 CFR part 60, subpart Cc. State plans include plans developed by States, local agencies, and protectorates.

Tribal plan means a plan submitted by a Tribal Authority pursuant to 40 CFR parts 9, 35, 49, 50, and 81 that implements and enforces 40 CFR part 60, subpart Cc.

§62.14352 Designated facilities.

(a) The designated facility to which this subpart applies is each municipal solid waste landfill in all States, protectorates, and Indian Country that meets the conditions of paragraphs (a)(1) and (a)(2) of this section, except for landfills exempted by paragraphs (b) and (c) of this section.

(1) The municipal solid waste landfill commenced construction, reconstruction, or modification before May 30, 1991 (landfills that commence construction, modification, or reconstruction on or after May 30, 1991 are subject to 40 CFR part 60, subpart WWW), and

(2) The municipal solid waste landfill has accepted waste at any time since November 8, 1987 or the landfill has additional capacity for future waste deposition.

(b) A municipal solid waste landfill regulated by an EPA approved and currently effective State or Tribal plan is not subject to the requirements of this subpart. States that have an approved and effective State plan are listed in table 1 of this subpart. Notwithstanding the exclusions in table 1 of this subpart, any MSW landfill located in a State or portion of Indian country that does not have an EPA approved and currently effective State or Tribal plan is subject to the requirements of this subpart.

(c) A municipal solid waste landfill located in a State, locality, or portion of Indian country that submitted a negative declaration letter is not subject to the requirements of this subpart other than the requirements in the definition of design capacity to recalculate the site-specific density annually and in §62.14355 to submit an amended design capacity report in the event that the recalculated design capacity is equal to or greater than 2.5 million megagrams and 2.5 million cubic meters. However, if the existing municipal solid waste landfill already has a design capacity equal to or greater than 2.5 million megagrams and 2.5 million cubic meters, then it is subject to the requirements of the Federal plan. States, localities, or portions of Indian country that submitted negative declaration letters are listed in table 2 of this subpart.

(d) Physical or operational changes made to an existing municipal solid waste landfill solely to comply with an emission guideline are not considered a modification or reconstruction and would not subject an existing municipal solid waste landfill to the requirements of 40 CFR part 60, subpart WWW.