['Air Programs']

['Air Emissions']

07/10/2024

...

§1065.301 Overview and general provisions.

(a) This subpart describes required and recommended calibrations and verifications of measurement systems. See subpart C of this part for specifications that apply to individual instruments.

(b) You must generally use complete measurement systems when performing calibrations or verifications in this subpart. For example, this would generally involve evaluating instruments based on values recorded with the complete system you use for recording test data, including analog-to-digital converters. For some calibrations and verifications, we may specify that you disconnect part of the measurement system to introduce a simulated signal.

(c) If we do not specify a calibration or verification for a portion of a measurement system, calibrate that portion of your system and verify its performance at a frequency consistent with any recommendations from the measurement-system manufacturer, consistent with good engineering judgment.

(d) Use NIST-traceable standards to the tolerances we specify for calibrations and verifications. Where we specify the need to use NIST-traceable standards, you may alternatively use international standards recognized by the CIPM Mutual Recognition Arrangement that are not NIST-traceable.

[88 FR 4673, Jan. 24, 2023]

§1065.303 Summary of required calibration and verifications.

The following table summarizes the required and recommended calibrations and verifications described in this subpart and indicates when these have to be performed:

| Type of calibration or verification | Minimum frequency |

| §1065.305: Accuracy, repeatability and noise | Accuracy: Not required, but recommended for initial installation. Repeatability: Not required, but recommended for initial installation. |

| Noise: Not required, but recommended for initial installation. | |

| §1065.307: Linearity verification | |

| Speed: Upon initial installation, within 370 days before testing and after major maintenance. | |

| Torque: Upon initial installation, within 370 days before testing and after major maintenance. | |

| Electrical power, current, and voltage: Upon initial installation, within 370 days before testing and after major maintenance. | |

| Fuel mass flow rate: Upon initial installation, within 370 days before testing, and after major maintenance. | |

| Fuel mass scale: Upon initial installation, within 370 days before testing, and after major maintenance. | |

| DEF mass flow rate: Upon initial installation, within 370 days before testing, and after major maintenance. | |

| DEF mass scale: Upon initial installation, within 370 days before testing, and after major maintenance. | |

| Intake-air, dilution air, diluted exhaust, and batch sampler flow rates: Upon initial installation, within 370 days before testing and after major maintenance.d | |

| Raw exhaust flow rate: Upon initial installation, within 185 days before testing and after major maintenance. | |

| Gas dividers: Upon initial installation, within 370 days before testing, and after major maintenance. | |

| Gas analyzers (unless otherwise noted): Upon initial installation, within 35 days before testing and after major maintenance. | |

| FTIR and photoacoustic analyzers: Upon initial installation, within 370 days before testing and after major maintenance. | |

| GC-ECD: Upon initial installation and after major maintenance. | |

| PM balance: Upon initial installation, within 370 days before testing and after major maintenance. | |

| Pressure, temperature, and dewpoint: Upon initial installation, within 370 days before testing and after major maintenance. | |

| §1065.308: Continuous gas analyzer system response and updating-recording verification—for gas analyzers not continuously compensated for other gas species | Upon initial installation or after system modification that would affect response. |

| §1065.309: Continuous gas analyzer system-response and updating-recording verification—for gas analyzers continuously compensated for other gas species | Upon initial installation or after system modification that would affect response. |

| §1065.310: Torque | Upon initial installation and after major maintenance. |

| §1065.315: Pressure, temperature, dewpoint | Upon initial installation and after major maintenance. |

| §1065.320: Fuel flow | Upon initial installation and after major maintenance. |

| §1065.325: Intake flow | Upon initial installation and after major maintenance. |

| §1065.330: Exhaust flow | Upon initial installation and after major maintenance. |

| §1065.340: Diluted exhaust flow (CVS) | Upon initial installation and after major maintenance. |

| §1065.341: CVS and PFD flow verification (propane check) | Upon initial installation, within 35 days before testing, and after major maintenance. |

| §1065.342 Sample dryer verification | For thermal chillers: Upon installation and after major maintenance. For osmotic membranes; upon installation, within 35 days of testing, and after major maintenance. |

| §1065.345: Vacuum leak | For laboratory testing: Upon initial installation of the sampling system, within 8 hours before the start of the first test interval of each duty-cycle sequence, and after maintenance such as pre-filter changes. |

| For field testing: After each installation of the sampling system on the vehicle, prior to the start of the field test, and after maintenance such as pre-filter changes. | |

| §1065.350: CO2 NDIR H2O interference | Upon initial installation and after major maintenance. |

| §1065.355: CO NDIR CO2 and H2O interference | Upon initial installation and after major maintenance. |

| §1065.360: FID calibration THC FID optimization, and THC FID verification | Calibrate all FID analyzers: upon initial installation and after major maintenance. |

| Optimize and determine CH4 response for THC FID analyzers: upon initial installation and after major maintenance. | |

| Verify CH4 response for THC FID analyzers: upon initial installation, within 185 days before testing, and after major maintenance. | |

| Verify C2H6 response for THC FID analyzers if used for NMNEHC determination: upon initial installation, within 185 days before testing, and after major maintenance. | |

| §1065.362: Raw exhaust FID O2 interference | For all FID analyzers: upon initial installation, and after major maintenance. |

| For THC FID analyzers: upon initial installation, after major maintenance, and after FID optimization according to §1065.360. | |

| §1065.365: Nonmethane cutter penetration | Upon initial installation, within 185 days before testing, and after major maintenance. |

| §1065.366: Interference verification for FTIR analyzers | Upon initial installation and after major maintenance. |

| §1065.369: H2O, CO, and CO2 interference verification for ethanol photoacoustic analyzers | Upon initial installation and after major maintenance. |

| §1065.370: CLD CO2 and H2O quench | Upon initial installation and after major maintenance. |

| §1065.372: NDUV HC and H2O interference | Upon initial installation and after major maintenance. |

| §1065.375: N2O analyzer interference | Upon initial installation and after major maintenance. |

| §1065.376: Chiller NO2 penetration | Upon initial installation and after major maintenance. |

| §1065.378: NO2-to-NO converter conversion | Upon initial installation, within 35 days before testing, and after major maintenance. |

| §1065.390: PM balance and weighing | Independent verification: Upon initial installation, within 370 days before testing, and after major maintenance. |

| Zero, span, and reference sample verifications: Within 12 hours of weighing, and after major maintenance. | |

| §1065.395: Inertial PM balance and weighing | Independent verification: Upon initial installation, within 370 days before testing, and after major maintenance. |

| Other verifications: Upon initial installation and after major maintenance. | |

| Perform calibrations and verifications more frequently than we specify, according to measurement system manufacturer instructions and good engineering judgment. | |

| Perform linearity verification either for electrical power or for current and voltage. | |

| Linearity verification is not required if DEF flow rate comes directly from the ECM signal as described in §1065.247(b). | |

| Linearity verification is not required if the flow signal's accuracy is verified by carbon balance error verification as described in §1065.307(e)(5) or a propane check as described in §1065.341. | |

| CVS and PFD flow verification (propane check) is not required for measurement systems verified by linearity verification as described in §1065.307 or carbon balance error verification as described in §1065.341(h). | |

[81 FR 74164, Oct. 25, 2016; 86 FR 34536, Jun. 29, 2021]

§1065.305 Verifications for accuracy, repeatability, and noise.

(a) This section describes how to determine the accuracy, repeatability, and noise of an instrument. Table 1 of §1065.205 specifies recommended values for individual instruments.

(b) We do not require you to verify instrument accuracy, repeatability, or noise.

However, it may be useful to consider these verifications to define a specification for a new instrument, to verify the performance of a new instrument upon delivery, or to troubleshoot an existing instrument.

(c) In this section we use the letter “y” to denote a generic measured quantity, the superscript over-bar to denote an arithmetic mean (such as y ͞), and the subscript “ref” to denote the reference quantity being measured.

(d) Conduct these verifications as follows:

(1) Prepare an instrument so it operates at its specified temperatures, pressures, and flows. Perform any instrument linearization or calibration procedures prescribed by the instrument manufacturer.

(2) Zero the instrument as you would before an emission test by introducing a zero signal. Depending on the instrument, this may be a zero-concentration gas, a reference signal, a set of reference thermodynamic conditions, or some combination of these. For gas analyzers, use a zero gas that meets the specifications of §1065.750.

(3) Span the instrument as you would before an emission test by introducing a span signal. Depending on the instrument, this may be a span-concentration gas, a reference signal, a set of reference thermodynamic conditions, or some combination of these. For gas analyzers, use a span gas that meets the specifications of §1065.750.

(4) Use the instrument to quantify a NIST-traceable reference quantity, yref. For gas analyzers the reference gas must meet the specifications of §1065.750. Select a reference quantity near the mean value expected during testing. For all gas analyzers, use a quantity near the flow-weighted mean concentration expected at the standard or expected during testing, whichever is greater. For noise verification, use the same zero gas from paragraph (d)(2) of this section as the reference quantity. In all cases, allow time for the instrument to stabilize while it measures the reference quantity. Stabilization time may include time to purge an instrument and time to account for its response.

(5) Sample and record values for 30 seconds (you may select a longer sampling period if the recording update frequency is less than 0.5 Hz), record the arithmetic mean, y ͞i and record the standard deviation, σi of the recorded values. Refer to §1065.602 for an example of calculating arithmetic mean and standard deviation.

(6) Also, if the reference quantity is not absolutely constant, which might be the case with a reference flow, sample and record values of yrefi for 30 seconds and record the arithmetic mean of the values, y ͞ref. Refer to §1065.602 for an example of calculating arithmetic mean.

(7) Subtract the reference value, yref (or y ͞refi), from the arithmetic mean, y ͞i. Record this value as the error, εi.

(8) Repeat the steps specified in paragraphs (d)(2) through (7) of this section until you have ten arithmetic means (y ͞1, y ͞2, y ͞i, ...y ͞10), ten standard deviations, (σ1, σ2, σi,...σ10), and ten errors (ε1, ε2, εi,...ε10).

(9) Use the following values to quantify your measurements:

(i) Accuracy. Instrument accuracy is the absolute difference between the reference quantity, yref (or y ͞ref), and the arithmetic mean of the ten y ͞i, y ͞ values. Refer to the example of an accuracy calculation in §1065.602. We recommend that instrument accuracy be within the specifications in Table 1 of §1065.205.

(ii) Repeatability. Repeatability is two times the standard deviation of the ten errors (that is, repeatability = 2 · sε). Refer to the example of a standard-deviation calculation in §1065.602. We recommend that instrument repeatability be within the specifications in Table 1 of §1065.205.

(iii) Noise. Noise is two times the root-mean-square of the ten standard deviations (that is, noise = 2 · rmsσ) when the reference signal is a zero-quantity signal. Refer to the example of a root-mean-square calculation in §1065.602. We recommend that instrument noise be within the specifications in Table 1 of §1065.205.

(10) You may use a measurement instrument that does not meet the accuracy, repeatability, or noise specifications in Table 1 of §1065.205, as long as you meet the following criteria:

(i) Your measurement systems meet all the other required calibration, verification, and validation specifications that apply as specified in the regulations.

(ii) The measurement deficiency does not adversely affect your ability to demonstrate compliance with the applicable standards in this chapter.

[70 FR 40516, July 13, 2005, as amended at 73 FR 37301, June 30, 2008; 75 FR 23037, Apr. 30, 2010; 79 FR 23763, Apr. 28, 2014; 88 FR 4673, Jan. 24, 2023]

§1065.307 Linearity verification.

(a) Scope and frequency. Perform linearity verification on each measurement system listed in Table 1 of this section at least as frequently as indicated in Table 1 of §1065.303, consistent with measurement system manufacturer's recommendations and good engineering judgment. The intent of linearity verification is to determine that a measurement system responds accurately and proportionally over the measurement range of interest. Linearity verification generally consists of introducing a series of at least 10 reference values to a measurement system. The measurement system quantifies each reference value. The measured values are then collectively compared to the reference values by using a least-squares linear regression and the linearity criteria specified in Table 1 of this section.

(b) Performance requirements. If a measurement system does not meet the applicable linearity criteria referenced in Table 1 of this section, correct the deficiency by re-calibrating, servicing, or replacing components as needed. Repeat the linearity verification after correcting the deficiency to ensure that the measurement system meets the linearity criteria. Before you may use a measurement system that does not meet linearity criteria, you must demonstrate to us that the deficiency does not adversely affect your ability to demonstrate compliance with the applicable standards in this chapter.

(c) Procedure. Use the following linearity verification protocol, or use good engineering judgment to develop a different protocol that satisfies the intent of this section, as described in paragraph (a) of this section:

(1) In this paragraph (c), the letter “y” denotes a generic measured quantity, the superscript over-bar denotes an arithmetic mean (such as y ͞), and the subscript “ref” denotes the known or reference quantity being measured.

(2) Use good engineering judgment to operate a measurement system at normal operating conditions. This may include any specified adjustment or periodic calibration of the measurement system.

(3) If applicable, zero the instrument as you would before an emission test by introducing a zero signal. Depending on the instrument, this may be a zero-concentration gas, a reference signal, a set of reference thermodynamic conditions, or some combination of these. For gas analyzers, use a zero gas that meets the specifications of §1065.750 and introduce it directly at the analyzer port.

(4) If applicable, span the instrument as you would before an emission test by introducing a span signal. Depending on the instrument, this may be a span-concentration gas, a reference signal, a set of reference thermodynamic conditions, or some combination of these. For gas analyzers, use a span gas that meets the specifications of §1065.750 and introduce it directly at the analyzer port.

(5) If applicable, after spanning the instrument, check zero with the same signal you used in paragraph (c)(3) of this section. Based on the zero reading, use good engineering judgment to determine whether or not to rezero and or re-span the instrument before continuing.

(6) For all measured quantities, use the instrument manufacturer's recommendations and good engineering judgment to select reference values, yrefi, that cover a range of values that you expect would prevent extrapolation beyond these values during emission testing. We recommend selecting a zero reference signal as one of the reference values for the linearity verification. For pressure, temperature, dewpoint, power, current, voltage, photoacoustic analyzers, and GC-ECD linearity verifications, we recommend at least three reference values. For all other linearity verifications select at least ten reference values.

(7) Use the instrument manufacturer's recommendations and good engineering judgment to select the order in which you will introduce the series of reference values. For example, you may select the reference values randomly to avoid correlation with previous measurements and to avoid hysteresis; you may select reference values in ascending or descending order to avoid long settling times of reference signals; or you may select values to ascend and then descend to incorporate the effects of any instrument hysteresis into the linearity verification.

(8) Generate reference quantities as described in paragraph (d) of this section. For gas analyzers, use gas concentrations known to be within the specifications of §1065.750 and introduce them directly at the analyzer port.

(9) Introduce a reference signal to the measurement instrument.

(10) Allow time for the instrument to stabilize while it measures the value at the reference condition. Stabilization time may include time to purge an instrument and time to account for its response.

(11) At a recording frequency of at least f Hz, specified in Table 1 of §1065.205, measure the value at the reference condition for 30 seconds (you may select a longer sampling period if the recording update frequency is less than 0.5 Hz) and record the arithmetic mean of the recorded values, y ͞i. Refer to §1065.602 for an example of calculating an arithmetic mean.

(12) Repeat the steps in paragraphs (c)(9) though (11) of this section until measurements are complete at each of the reference conditions.

(13) Use the arithmetic means, ȳi, and reference values, yrefi, to calculate least-squares linear regression parameters and statistical values to compare to the minimum performance criteria specified in Table 1 of this section. Use the calculations for a floating intercept described in § 1065.602. Using good engineering judgment, you may weight the results of individual data pairs (i.e., (yrefi, ȳi)), in the linear regression calculations.

(d) Reference signals. This paragraph (d) describes recommended methods for generating reference values for the linearity-verification protocol in paragraph (c) of this section. Use reference values that simulate actual values, or introduce an actual value and measure it with a reference-measurement system. In the latter case, the reference value is the value reported by the reference-measurement system. Reference values and reference-measurement systems must be NIST-traceable. We recommend using calibration reference quantities that are NIST-traceable within ±0.5% uncertainty, if not specified elsewhere in this part 1065. Use the following recommended methods to generate reference values or use good engineering judgment to select a different reference:

(1) Speed. Run the engine or dynamometer at a series of steady-state speeds and use a strobe, photo tachometer, or laser tachometer to record reference speeds.

(2) Torque. Use a series of calibration weights and a calibration lever arm to simulate engine torque. You may instead use the engine or dynamometer itself to generate a nominal torque that is measured by a reference load cell or proving ring in series with the torque-measurement system. In this case, use the reference load cell measurement as the reference value. Refer to §1065.310 for a torque-calibration procedure similar to the linearity verification in this section.

(3) Electrical power, current, and voltage. You must perform linearity verification for either electrical power meters, or for current and voltage meters. Perform linearity verifications using a reference meter and controlled sources of current and voltage. We recommend using a complete calibration system that is suitable for the electrical power distribution industry.

(4) Fuel and DEF mass flow rate. Use a gravimetric reference measurement (such as a scale, balance, or mass comparator) and a container. Use a stopwatch or timer to measure the time intervals over which reference masses of fluid pass through the mass flow rate meter. Use good engineering judgment to correct the reference mass flowing through the mass flow rate meter for buoyancy effects from any tubes, temperature probes, or objects submerged in the fluid in the container that are not attached to the container. If the container has any tubes or wires connected to the container, recalibrate the gravimetric reference measurement device with them connected and at normal operating pressure using calibration weights that meet the requirements in §1065.790. The corrected reference mass that flowed through the mass flow rate meter during a time interval divided by the duration of the time interval is the average reference mass flow rate. For meters that report a different quantity (such as actual volume, standard volume, or moles), convert the reported quantity to mass. For meters that report a cumulative quantity calculate the average measured mass flow rate as the difference in the reported cumulative mass during the time interval divided by the duration of the time interval. For measuring flow rate of gaseous fuel prevent condensation on the fuel container and any attached tubes, fittings, or regulators.

(5) Flow rates - inlet air, dilution air, diluted exhaust, raw exhaust, or sample flow. Use a reference flow meter with a blower or pump to simulate flow rates. Use a restrictor, diverter valve, a variable-speed blower or a variable-speed pump to control the range of flow rates. Use the reference meter's response as the reference values.

(i) Reference flow meters. Because the flow range requirements for these various flows are large, we allow a variety of reference meters. For example, for diluted exhaust flow for a full-flow dilution system, we recommend a reference subsonic venturi flow meter with a restrictor valve and a blower to simulate flow rates. For inlet air, dilution air, diluted exhaust for partial-flow dilution, raw exhaust, or sample flow, we allow reference meters such as critical flow orifices, critical flow venturis, laminar flow elements, master mass flow standards, or Roots meters. Make sure the reference meter is calibrated and its calibration is NIST-traceable. If you use the difference of two flow measurements to determine a net flow rate, you may use one of the measurements as a reference for the other.

(ii) Reference flow values. Because the reference flow is not absolutely constant, sample and record values of n ̇refi for 30 seconds and use the arithmetic mean of the values, n ̇ref, as the reference value. Refer to §1065.602 for an example of calculating arithmetic mean.

(6) Gas division. Use one of the two reference signals:

(i) At the outlet of the gas-division system, connect a gas analyzer that meets the linearity verification described in this section and has not been linearized with the gas divider being verified. For example, verify the linearity of an analyzer using a series of reference analytical gases directly from compressed gas cylinders that meet the specifications of §1065.750. We recommend using a FID analyzer or a PMD or MPD O2 analyzer because of their inherent linearity. Operate this analyzer consistent with how you would operate it during an emission test. Connect a span gas containing only a single constituent of interest with balance of purified air or purified N2 to the gas-divider inlet. Use the gas-division system to divide the span gas with purified air or nitrogen. Select gas divisions that you typically use. Use a selected gas division as the measured value. Use the analyzer response divided by the span gas concentration as the reference gas-division value. Because the instrument response is not absolutely constant, sample and record values of x refi for 30 seconds and use the arithmetic mean of the values, x ref, as the reference value. Refer to §1065.602 for an example of calculating arithmetic mean.

(ii) Using good engineering judgment and the gas divider manufacturer's recommendations, use one or more reference flow meters to measure the flow rates of the gas divider and verify the gas-division value.

(7) Continuous constituent concentration. For reference values, use a series of gas cylinders of known gas concentration containing only a single constituent of interest with balance of purified air or purified N2 or use a gas-division system that is known to be linear with a span gas. Gas cylinders, gas-division systems, and span gases that you use for reference values must meet the specifications of §1065.750.

(8) Temperature. You may perform the linearity verification for temperature measurement systems with thermocouples, RTDs, and thermistors by removing the sensor from the system and using a simulator in its place. Use a NIST-traceable simulator that is independently calibrated and, as appropriate, cold-junction-compensated. The simulator uncertainty scaled to absolute temperature must be less than 0.5% of Tmax. If you use this option, you must use sensors that the supplier states are accurate to better than 0.5% of Tmax compared with their standard calibration curve.

(9) Mass. For linearity verification for gravimetric PM balances, fuel mass scales, and DEF mass scales, use external calibration weights that meet the requirements in §1065.790. Perform the linearity verification for fuel mass scales and DEF mass scales with the in-use container, installing all objects that interface with the container. For example, this includes all tubes, temperature probes, and objects submerged in the fluid in the container; it also includes tubes, fittings, regulators, and wires, and any other objects attached to the container. We recommend that you develop and apply appropriate buoyancy corrections for the configuration of your mass scale during normal testing, consistent with good engineering judgment. Account for the scale weighing a calibration weight instead of fluid if you calculate buoyancy corrections. You may also correct for the effect of natural convection currents from temperature differences between the container and ambient air. Prepare for linearity verification by taking the following steps for vented and unvented containers:

(i) If the container is vented to ambient, fill the container and tubes with fluid above the minimum level used to trigger a fill operation; drain the fluid down to the minimum level; tare the scale; and perform the linearity verification.

(ii) If the container is rigid and not vented, drain the fluid down to the minimum level; fill all tubes attached to the container to normal operating pressure; tare the scale; and perform the linearity verification.

(e) Measurement systems that require linearity verification. Table 1 of this section indicates measurement systems that require linearity verification, subject to the following provisions:

(1) Perform linearity verification more frequently based on the instrument manufacturer's recommendation or good engineering judgment.

(2) The expression “xmin” refers to the reference value used during linearity verification that is closest to zero. This is the value used to calculate the first tolerance in Table 1 of this section using the intercept, a0. Note that this value may be zero, positive, or negative depending on the reference values. For example, if the reference values chosen to validate a pressure transducer vary from −10 to −1 kPa, xmin is −1 kPa. If the reference values used to validate a temperature device vary from 290 to 390 K, xmin is 290 K.

The expression “max” generally refers to the absolute value of the reference value used during linearity verification that is furthest from zero. This is the value used to scale the first and third tolerances in Table 1 of this section using a0 and SEE. For example, if the reference values chosen to validate a pressure transducer vary from −10 to −1 kPa, then pmax is +10 kPa. If the reference values used to validate a temperature device vary from 290 to 390 K, then Tmax is 390 K. For gas dividers where “max” is expressed as, xmax/xspan; xmax is the maximum gas concentration used during the verification, xspan is the undivided, undiluted, span gas concentration, and the resulting ratio is the maximum divider point reference value used during the verification (typically 1). The following are special cases where “max” refers to a different value:

(i) For linearity verification of a PM balance, m max is the typical mass of a PM filter.

(ii) For linearity verification of a torque measurement system used with the engine's primary output shaft, T max is the manufacturer's specified peak torque of the lowest torque engine expected during testing.

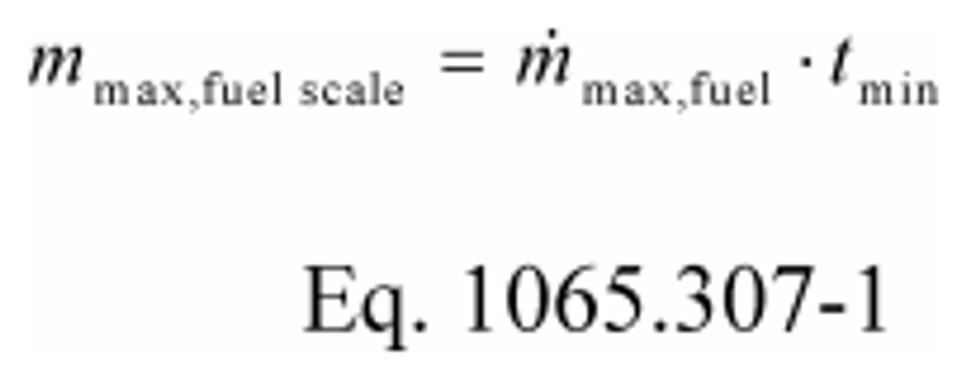

(iii) For linearity verification of a fuel mass scale, m max is determined based on the range of engines and test interval durations expected during testing. It is the minimum, over all engines expected during testing, of the fuel consumption expected over the minimum test interval duration at the engine's maximum fuel rate. If the minimum test interval duration used during testing does not change with engine power or if the minimum test interval duration used during testing increases with engine power, m max is given by Eq. 1065.307-1. Calculate m max using the following equation:

Where:

m max,fuel = the manufacturer's specified maximum fuel rate on the lowest-power engine expected during testing.

t min = the minimum test interval duration expected during testing. If the minimum test interval duration decreases with engine power, evaluate Eq. 1065.307-1 for the range of engines expected during testing and use the minimum calculated value of m max,fuel scale.

(iv) For linearity verification of a DEF mass scale, m max is 10% of the value determined for a fuel mass scale in paragraph (e)(3)(iii) of this section. You may determine m max for a DEF mass scale by evaluating m max for a fuel mass scale based only on the DEF-using engines expected during testing.

(v) For linearity verification of a fuel flow rate meter, ṁmax is the manufacturer's specified maximum fuel rate of the lowest-power engine expected during testing.

(vi)For linearity verification of a DEF flow rate meter, ṁmax is 10% of the manufacturer's specified maximum fuel rate of the lowest-power DEF-using engine expected during testing.

(vii) For linearity verification of an intake-air flow rate meter, n max is the manufacturer's specified maximum intake-air flow rate (converted to molar flow rate) of the lowest-power engine expected during testing.

(viii) For linearity verification of a raw exhaust flow rate meter, n max is the manufacturer's specified maximum exhaust flow rate (converted to molar flow rate) of the lowest-power engine expected during testing.

(ix) For linearity verification of an electrical-power measurement system used to determine the engine's primary output shaft torque, P max is the manufacturer's specified maximum power of the lowest-power engine expected during testing.

(x) For linearity verification of an electrical-current measurement system used to determine the engine's primary output shaft torque, I max is the maximum current expected on the lowest-power engine expected during testing.

(xi) For linearity verification of an electrical-voltage measurement system used to determine the engine's primary output shaft torque, V max is the minimum peak voltage expected on the range of engines expected during testing.

(4) The specified ranges are inclusive. For example, a specified range of 0.98-1.02 for a1 means 0.98≤a1≤1.02.

(5) Table 2 of this section describes optional verification procedures you may perform instead of linearity verification for certain systems. The following provisions apply for the alternative verification procedures:

(i) Perform the propane check verification described in §1065.341 at the frequency specified in Table 1 of §1065.303.

(ii) Perform the carbon balance error verification described in §1065.543 on all test sequences that use the corresponding system. It must also meet the restrictions listed in Table 2 of this section. You may evaluate the carbon balance error verification multiple ways with different inputs to validate multiple flow-measurement systems.

(6) You must meet the a1 criteria for these quantities only if the absolute value of the quantity is required, as opposed to a signal that is only linearly proportional to the actual value.

(7) Linearity verification is required for the following temperature measurements:

(i) The following temperature measurements always require linearity verification:

(A) Air intake.

(B) Aftertreatment bed(s), for engines tested with aftertreatment devices subject to cold-start testing.

(C) Dilution air for gaseous and PM sampling, including CVS, double-dilution, and partial-flow systems.

(D) PM sample.

(E) Chiller sample, for gaseous sampling systems that use thermal chillers to dry samples and use chiller temperature to calculate the dewpoint at the outlet of the chiller. For your testing, if you choose to use a high alarm temperature setpoint for the chiller temperature as a constant value in determining the amount of water removed from the emission sample, you may use good engineering judgment to verify the accuracy of the high alarm temperature setpoint instead of linearity verification on the chiller temperature. To verify that the alarm trip point value is no less than 2.0°C below the reference value at the trip point, we recommend that you input a reference simulated temperature signal below the alarm trip point and increase this signal until the high alarm trips.

(F) Transmission oil.

(G) Axle gear oil.

(ii) Linearity verification is required for the following temperature measurements if these temperature measurements are specified by the engine manufacturer:

(A) Fuel inlet.

(B) Air outlet to the test cell's charge air cooler air outlet, for engines tested with a laboratory heat exchanger that simulates an installed charge air cooler.

(C) Coolant inlet to the test cell's charge air cooler, for engines tested with a laboratory heat exchanger that simulates an installed charge air cooler.

(D) Oil in the sump/pan.

(E) Coolant before the thermostat, for liquid-cooled engines.

(8) Linearity verification is required for the following pressure measurements:

(i) The following pressure measurements always require linearity verification:

(A) Air intake restriction.

(B) Exhaust back pressure as required in §1065.130(h).

(C) Barometer.

(D) CVS inlet gage pressure where the raw exhaust enters the tunnel.

(E) Sample dryer, for gaseous sampling systems that use either osmotic-membrane or thermal chillers to dry samples. For your testing, if you choose to use a low alarm pressure setpoint for the sample dryer pressure as a constant value in determining the amount of water removed from the emission sample, you may use good engineering judgment to verify the accuracy of the low alarm pressure setpoint instead of linearity verification on the sample dryer pressure. To verify that the trip point value is no more than 4.0 kPa above the reference value at the trip point, we recommend that you input a reference pressure signal above the alarm trip point and decrease this signal until the low alarm trips.

(ii) Linearity verification is required for the following pressure measurements if these pressure measurements are specified by the engine manufacturer:

(A) The test cell's charge air cooler and interconnecting pipe pressure drop, for turbo-charged engines tested with a laboratory heat exchanger that simulates an installed charge air cooler.

(B) Fuel outlet.

(f) Performance criteria for measurement systems. Table 1 follows:

| a For flow meters that determine volumetric flow rate, V std , you may substitute V std for n as the quantity and substitute V stdmax for n max . | |||||

| Measurement system | Quantity | Linearity criteria | |||

| | x min (a 1 -1)+ a 0 | | a 1 | SEE | r 2 | ||

| Speed | f n | ≤0.05% · f nmax | 0.98-1.02 | ≤2% · f nmax | ≥0.990 |

| Torque | T | ≤1% · T max | 0.98-1.02 | ≤2% · T max | ≥0.990 |

| Electrical power | P | ≤1% · P max | 0.98-1.02 | ≤2% · P max | ≥0.990 |

| Current | I | ≤1% · I max | 0.98-1.02 | ≤2% · I max | ≥0.990 |

| Voltage | U | ≤1% · U max | 0.98-1.02 | ≤2% · U max | ≥0.990 |

| Fuel flow rate | m | ≤1% · m max | 0.98-1.02 | ≤2% · m max | ≥0.990 |

| Fuel mass scale | m | ≤0.3% · m max | 0.996-1.004 | ≤0.4% · m max | ≥0.999 |

| DEF flow rate | m | ≤1% · m max | 0.98-1.02 | ≤2% · m max | ≥0.990 |

| DEF mass scale | m | ≤0.3% · m max | 0.996-1.004 | ≤0.4% · m max | ≥0.999 |

| Intake-air flow rate a | n | ≤1% · n max | 0.98-1.02 | ≤2% · n max | ≥0.990 |

| Dilution air flow rate a | n | ≤1% · n max | 0.98-1.02 | ≤2% · n max | ≥0.990 |

| Diluted exhaust flow rate a | n | ≤1% · n max | 0.98-1.02 | ≤2% · n max | ≥0.990 |

| Raw exhaust flow rate a | n | ≤1% · n max | 0.98-1.02 | ≤2% · n max | ≥0.990 |

| Batch sampler flow rates a | n | ≤1% · n max | 0.98-1.02 | ≤2% · n max | ≥0.990 |

| Gas dividers | x/x span | ≤0.5% · x max/x span | 0.98-1.02 | ≤2% · x max/x span | ≥0.990 |

| Gas analyzers for laboratory testing | x | ≤0.5% · x max | 0.99-1.01 | ≤1% · x max | ≥0.998 |

| Gas analyzers for field testing | x | ≤1% · x max | 0.99-1.01 | ≤1% · x max | ≥0.998 |

| Electrical aerosol analyzer for field testing | x | ≤5% · x max | 0.85-1.15 | ≤10% · x max | ≥0.950 |

| Photoacoustic analyzer for field testing | x | ≤5% · x max | 0.90-1.10 | ≤10% · x max | ≥0.980 |

| PM balance | m | ≤1% · m max | 0.99-1.01 | ≤1% · m max | ≥0.998 |

| Pressures | p | ≤1% · p max | 0.99-1.01 | ≤1% · p max | ≥0.998 |

| Dewpoint for intake air, PM-stabilization and balance environments | T dew | ≤0.5% · T dewmax | 0.99-1.01 | ≤0.5% · T dewmax | ≥0.998 |

| Other dewpoint measurements | T dew | ≤1% · T dewmax | 0.99-1.01 | ≤1% · T dewmax | ≥0.998 |

| Analog-to-digital conversion of temperature signals | T | ≤1% · T max | 0.99-1.01 | ≤1% · T max | ≥0.998 |

(g) Alternative verification procedures. Table 2 follows:

| Measurement system | §1065.341 | §1065.543 | Restrictions for §1065.543 |

| Intake-air flow rate | Yes | Yes | Determine raw exhaust flow rate using the intake-air flow rate signal as an input into Eq. 1065.655-24 and determine mass of CO2 over each test interval input into Eq. 1065.643-6 using samples taken from the raw exhaust (continuous or bag, and with or without a PFD). |

| Dilution air flow rate for CVS | Yes | No | Not allowed. |

| Diluted exhaust flow rate for CVS | Yes | Yes | Determine mass of CO2 over each test interval input into Eq. 1065.643-6 using samples taken from the CVS (continuous or bag, and with or without a PFD). |

| Raw exhaust flow rate for exhaust stack | Yes | Yes | Determine mass of CO2 over each test interval input into Eq. 1065.643-6 using samples taken from the raw exhaust (continuous or bag, and with or without a PFD). |

| Flow measurements in a PFD (usually dilution air and diluted exhaust streams) used to determine the dilution ratio in the PFD | Yes | Yes | Determine mass of CO2 over each test interval input into Eq. 1065.643-6 using samples taken from the PFD (continuous or bag). |

| Batch sampler flow rates | Yes | No | Not allowed. |

| Fuel mass flow rate | No | Yes | Determine mass of a carbon-carrying fluid stream used as an input into Eq. 1065.643-1 using the fuel mass flow rate meter. |

| Fuel mass scale | No | Yes | Determine mass of a carbon-carrying fluid stream used as an input into Eq. 1065.643-1 using the fuel mass scale. |

[79 FR 23763, Apr. 28, 2014; 86 FR 34538, Jun. 29, 2021; 87 FR 64865, Oct. 26, 2022; 88 FR 4673, Jan. 24, 2023]

§1065.308 Continuous gas analyzer system-response and updating-recording verification - for gas analyzers not continuously compensated for other gas species.

(a) Scope and frequency. This section describes a verification procedure for system response and updating-recording frequency for continuous gas analyzers that output a gas species mole fraction (i.e., concentration) using a single gas detector, i.e., gas analyzers not continuously compensated for other gas species measured with multiple gas detectors. See §1065.309 for verification procedures that apply to continuous gas analyzers that are continuously compensated for other gas species measured with multiple gas detectors. Perform this verification to determine the system response of the continuous gas analyzer and its sampling system. This verification is required for continuous gas analyzers used for transient or ramped-modal testing. You need not perform this verification for batch gas analyzer systems or for continuous gas analyzer systems that are used only for discrete-mode testing. Perform this verification after initial installation (i.e., test cell commissioning) and after any modifications to the system that would change system response. For example, perform this verification if you add a significant volume to the transfer lines by increasing their length or adding a filter; or if you reduce the frequency at which the gas analyzer updates its output or the frequency at which you sample and record gas-analyzer concentrations.

(b) Measurement principles. This test verifies that the updating and recording frequencies match the overall system response to a rapid change in the value of concentrations at the sample probe. Gas analyzers and their sampling systems must be optimized such that their overall response to a rapid change in concentration is updated and recorded at an appropriate frequency to prevent loss of information. This test also verifies that the measurement system meets a minimum response time. You may use the results of this test to determine transformation time, t50, for the purposes of time alignment of continuous data in accordance with §1065.650(c)(2)(i). You may also use an alternate procedure to determine t50 in accordance with good engineering judgment. Note that any such procedure for determining t50 must account for both transport delay and analyzer response time.

(c) System requirements. Demonstrate that each continuous analyzer has adequate update and recording frequencies and has a minimum rise time and a minimum fall time during a rapid change in gas concentration. You must meet one of the following criteria:

(1) The product of the mean rise time, t10-90, and the frequency at which the system records an updated concentration must be at least 5, and the product of the mean fall time, t90-10, and the frequency at which the system records an updated concentration must be at least 5. If the recording frequency is different than the analyzer's output update frequency, you must use the lower of these two frequencies for this verification, which is referred to as the updating-recording frequency. This verification applies to the nominal updating and recording frequencies. This criterion makes no assumption regarding the frequency content of changes in emission concentrations during emission testing; therefore, it is valid for any testing. Also, the mean rise time must be at or below 10 seconds and the mean fall time must be at or below 10 seconds.

(2) The frequency at which the system records an updated concentration must be at least 5 Hz. This criterion assumes that the frequency content of significant changes in emission concentrations during emission testing do not exceed 1 Hz. Also, the mean rise time must be at or below 10 seconds and the mean fall time must be at or below 10 seconds.

(3) You may use other criteria if we approve the criteria in advance.

(4) You may meet the overall PEMS verification in §1065.920 instead of the verification in this section for field testing with PEMS.

(d) Procedure. Use the following procedure to verify the response of each continuous gas analyzer:

(1) Instrument setup. Follow the analyzer manufacturer's start-up and operating instructions. Adjust the measurement system as needed to optimize performance. Run this verification with the analyzer operating in the same manner you will use for emission testing. If the analyzer shares its sampling system with other analyzers, and if gas flow to the other analyzers will affect the system response time, then start up and operate the other analyzers while running this verification test. You may run this verification test on multiple analyzers sharing the same sampling system at the same time. If you use any analog or real-time digital filters during emission testing, you must operate those filters in the same manner during this verification.

(2) Equipment setup. We recommend using minimal lengths of gas transfer lines between all connections and fast-acting three-way valves (2 inlets, 1 outlet) to control the flow of zero and blended span gases to the sample system's probe inlet or a tee near the outlet of the probe. If you inject the gas at a tee near the outlet of the probe, you may correct the transformation time, t50, for an estimate of the transport time from the probe inlet to the tee. Normally the gas flow rate is higher than the sample flow rate and the excess is overflowed out the inlet of the probe. If the gas flow rate is lower than the sample flow rate, the gas concentrations must be adjusted to account for the dilution from ambient air drawn into the probe. We recommend you use the final, stabilized analyzer reading as the final gas concentration. Select span gases for the species being measured. You may use binary or multi-gas span gases. You may use a gas blending or mixing device to blend span gases. A gas blending or mixing device is recommended when blending span gases diluted in N2 with span gases diluted in air. You may use a multi-gas span gas, such as NO-CO-CO2-C3H8-CH4, to verify multiple analyzers at the same time. If you use standard binary span gases, you must run separate response tests for each analyzer. In designing your experimental setup, avoid pressure pulsations due to stopping the flow through the gas-blending device. The change in gas concentration must be at least 20% of the analyzer's range.

(3) Data collection. (i) Start the flow of zero gas.

(ii) Allow for stabilization, accounting for transport delays and the slowest analyzer's full response.

(iii) Start recording data. For this verification you must record data at a frequency greater than or equal to that of the updating-recording frequency used during emission testing. You may not use interpolation or filtering to alter the recorded values.

(iv) Switch the flow to allow the blended span gases to flow to the analyzer. If you intend to use the data from this test to determine t50 for time alignment, record this time as t0.

(v) Allow for transport delays and the slowest analyzer's full response.

(vi) Switch the flow to allow zero gas to flow to the analyzer. If you intend to use the data from this test to determine t50 for time alignment, record this time as t100.

(vii) Allow for transport delays and the slowest analyzer's full response.

(viii) Repeat the steps in paragraphs (d)(3)(iv) through (vii) of this section to record seven full cycles, ending with zero gas flowing to the analyzers.

(ix) Stop recording.

(e) Performance evaluation. (1) If you choose to demonstrate compliance with paragraph (c)(1) of this section, use the data from paragraph (d)(3) of this section to calculate the mean rise time, t10-90, and mean fall time, t90-10, for each of the analyzers being verified. You may use interpolation between recorded values to determine rise and fall times. If the recording frequency used during emission testing is different from the analyzer's output update frequency, you must use the lower of these two frequencies for this verification. Multiply these times (in seconds) by their respective updating-recording frequencies in Hertz (1/second). The resulting product must be at least 5 for both rise time and fall time. If either value is less than 5, increase the updating-recording frequency, or adjust the flows or design of the sampling system to increase the rise time and fall time as needed. You may also configure analog or digital filters before recording to increase rise and fall times. In no case may the mean rise time or mean fall time be greater than 10 seconds.

(2) If a measurement system fails the criterion in paragraph (e)(1) of this section, ensure that signals from the system are updated and recorded at a frequency of at least 5 Hz. In no case may the mean rise time or mean fall time be greater than 10 seconds.

(3) If a measurement system fails the criteria in paragraphs (e)(1) and (2) of this section, you may use the measurement system only if the deficiency does not adversely affect your ability to show compliance with the applicable standards in this chapter.

(f) Transformation time, t50, determination. If you choose to determine t50 for purposes of time alignment using data generated in paragraph (d)(3) of this section, calculate the mean t0-50 and the mean t100-50 from the recorded data. Average these two values to determine the final t50 for the purposes of time alignment in accordance with §1065.650(c)(2)(i).

(g) Optional procedure. Instead of using a three-way valve to switch between zero and span gases, you may use a fast-acting two-way valve to switch sampling between ambient air and span gas at the probe inlet. For this alternate procedure, the following provisions apply:

(1) If your probe is sampling from a continuously flowing gas stream (e.g., a CVS tunnel), you may adjust the span gas flow rate to be different than the sample flow rate.

(2) If your probe is sampling from a gas stream that is not continuously flowing (e.g., a raw exhaust stack), you must adjust the span gas flow rate to be less than the sample flow rate so ambient air is always being drawn into the probe inlet. This avoids errors associated with overflowing span gas out of the probe inlet and drawing it back in when sampling ambient air.

(3) When sampling ambient air or ambient air mixed with span gas, all the analyzer readings must be stable within ±0.5% of the target gas concentration step size. If any analyzer reading is outside the specified range, you must resolve the problem and verify that all the analyzer readings meet this specification.

(4) For oxygen analyzers, you may use purified N2 as the zero gas and ambient air (plus purified N2 if needed) as the reference gas. Perform the verification with seven repeat measurements that each consist of stabilizing with purified N2, switching to ambient air and observing the analyzer's rise and stabilized reading, followed by switching back to purified N2 and observing the analyzer's fall and stabilized reading.

[73 FR 59325, Oct. 8, 2008, as amended at 79 FR 23766, Apr. 28, 2014; 88 FR 4674, Jan. 24, 2023]

§1065.309 Continuous gas analyzer system-response and updating-recording verification - for gas analyzers continuously compensated for other gas species.

(a) Scope and frequency. This section describes a verification procedure for system response and updating-recording frequency for continuous gas analyzers that output a single gas species mole fraction (i.e., concentration) based on a continuous combination of multiple gas species measured with multiple detectors (i.e., gas analyzers continuously compensated for other gas species). See §1065.308 for verification procedures that apply to continuous gas analyzers that are not continuously compensated for other gas species or that use only one detector for gaseous species. Perform this verification to determine the system response of the continuous gas analyzer and its sampling system. This verification is required for continuous gas analyzers used for transient or ramped-modal testing. You need not perform this verification for batch gas analyzers or for continuous gas analyzers that are used only for discrete-mode testing. For this check we consider water vapor a gaseous constituent. This verification does not apply to any processing of individual analyzer signals that are time-aligned to their t50 times and were verified according to §1065.308. For example, this verification does not apply to correction for water removed from the sample done in post-processing according to §1065.659 (40 CFR 1066.620 for vehicle testing) and it does not apply to NMHC determination from THC and CH4 according to §1065.660. Perform this verification after initial installation (i.e., test cell commissioning) and after any modifications to the system that would change the system response.

(b) Measurement principles. This procedure verifies that the updating and recording frequencies match the overall system response to a rapid change in the value of concentrations at the sample probe. It indirectly verifies the time-alignment and uniform response of all the continuous gas detectors used to generate a continuously combined/compensated concentration measurement signal. Gas analyzer systems must be optimized such that their overall response to rapid change in concentration is updated and recorded at an appropriate frequency to prevent loss of information. This test also verifies that the measurement system meets a minimum response time. For this procedure, ensure that all compensation algorithms and humidity corrections are turned on. You may use the results of this test to determine transformation time, t50, for the purposes of time alignment of continuous data in accordance with §1065.650(c)(2)(i). You may also use an alternate procedure to determine t50 consistent with good engineering judgment. Note that any such procedure for determining t50 must account for both transport delay and analyzer response time.

(c) System requirements. Demonstrate that each continuously combined/compensated concentration measurement has adequate updating and recording frequencies and has a minimum rise time and a minimum fall time during a system response to a rapid change in multiple gas concentrations, including H2O concentration if H2O compensation is applied. You must meet one of the following criteria:

(1) The product of the mean rise time, t10-90, and the frequency at which the system records an updated concentration must be at least 5, and the product of the mean fall time, t90-10, and the frequency at which the system records an updated concentration must be at least 5. If the recording frequency is different than the update frequency of the continuously combined/compensated signal, you must use the lower of these two frequencies for this verification. This criterion makes no assumption regarding the frequency content of changes in emission concentrations during emission testing; therefore, it is valid for any testing. Also, the mean rise time must be at or below 10 seconds and the mean fall time must be at or below 10 seconds.

(2) The frequency at which the system records an updated concentration must be at least 5 Hz. This criterion assumes that the frequency content of significant changes in emission concentrations during emission testing do not exceed 1 Hz. Also, the mean rise time must be at or below 10 seconds and the mean fall time must be at or below 10 seconds.

(3) You may use other criteria if we approve them in advance.

(4) You may meet the overall PEMS verification in §1065.920 instead of the verification in this section for field testing with PEMS.

(d) Procedure. Use the following procedure to verify the response of each continuously compensated analyzer (verify the combined signal, not each individual continuously combined concentration signal):

(1) Instrument setup. Follow the analyzer manufacturer's start-up and operating instructions. Adjust the measurement system as needed to optimize performance. Run this verification with the analyzer operating in the same manner you will use for emission testing. If the analyzer shares its sampling system with other analyzers, and if gas flow to the other analyzers will affect the system response time, then start up and operate the other analyzers while running this verification test. You may run this verification test on multiple analyzers sharing the same sampling system at the same time. If you use any analog or real-time digital filters during emission testing, you must operate those filters in the same manner during this verification.

(2) Equipment setup. We recommend using minimal lengths of gas transfer lines between all connections and fast-acting three-way valves (2 inlets, 1 outlet) to control the flow of zero and blended span gases to the sample system's probe inlet or a tee near the outlet of the probe. If you inject the gas at a tee near the outlet of the probe, you may correct the transformation time, t50, for an estimate of the transport time from the probe inlet to the tee. Normally the gas flow rate is higher than the sample flow rate and the excess is overflowed out the inlet of the probe. If the gas flow rate is lower than the sample flow rate, the gas concentrations must be adjusted to account for the dilution from ambient air drawn into the probe. We recommend you use the final, stabilized analyzer reading as the final gas concentration. Select span gases for the species being continuously combined, other than H2O. Select concentrations of compensating species that will yield concentrations of these species at the analyzer inlet that covers the range of concentrations expected during testing. You may use binary or multi-gas span gases. You may use a gas blending or mixing device to blend span gases. A gas blending or mixing device is recommended when blending span gases diluted in N2 with span gases diluted in air. You may use a multi-gas span gas, such as NO-CO-CO2-C3H8-CH4, to verify multiple analyzers at the same time. In designing your experimental setup, avoid pressure pulsations due to stopping the flow through the gas blending device. The change in gas concentration must be at least 20% of the analyzer's range. If H2O correction is applicable, then span gases must be humidified before entering the analyzer; however, you may not humidify NO2 span gas by passing it through a sealed humidification vessel that contains H2O. You must humidify NO2 span gas with another moist gas stream. We recommend humidifying your NO-CO-CO2-C3H8-CH4, balance N2, blended gas by bubbling the gas mixture that meets the specifications in §1065.750 through distilled H2O in a sealed vessel and then mixing the gas with dry NO2 gas, balance purified air, or by using a device that introduces distilled H2O as vapor into a controlled span gas flow. If the sample does not pass through a dryer during emission testing, humidify your span gas to an H2O level at or above the maximum expected during emission testing. If the sample passes through a dryer during emission testing, it must pass the sample dryer verification check in §1065.342, and you must humidify your span gas to an H2O level at or above the level determined in §1065.145(e)(2) for that dryer. If you are humidifying span gases without NO2, use good engineering judgment to ensure that the wall temperatures in the transfer lines, fittings, and valves from the humidifying system to the probe are above the dewpoint required for the target H2O content. If you are humidifying span gases with NO2, use good engineering judgment to ensure that there is no condensation in the transfer lines, fittings, or valves from the point where humidified gas is mixed with NO2 span gas to the probe. We recommend that you design your setup so that the wall temperatures in the transfer lines, fittings, and valves from the humidifying system to the probe are at least 5 °C above the local sample gas dewpoint. Operate the measurement and sample handling system as you do for emission testing. Make no modifications to the sample handling system to reduce the risk of condensation. Flow humidified gas through the sampling system before this check to allow stabilization of the measurement system's sampling handling system to occur, as it would for an emission test.

(3) Data collection. (i) Start the flow of zero gas.

(ii) Allow for stabilization, accounting for transport delays and the slowest analyzer's full response.

(iii) Start recording data. For this verification you must record data at a frequency greater than or equal to that of the updating-recording frequency used during emission testing. You may not use interpolation or filtering to alter the recorded values.

(iv) Switch the flow to allow the blended span gases to flow to the analyzer. If you intend to use the data from this test to determine t50 for time alignment, record this time as t0.

(v) Allow for transport delays and the slowest analyzer's full response.

(vi) Switch the flow to allow zero gas to flow to the analyzer. If you intend to use the data from this test to determine t50 for time alignment, record this time as t100.

(vii) Allow for transport delays and the slowest analyzer's full response.

(viii) Repeat the steps in paragraphs (d)(3)(iv) through (vii) of this section to record seven full cycles, ending with zero gas flowing to the analyzers.

(ix) Stop recording.

(e) Performance evaluations. (1) If you choose to demonstrate compliance with paragraph (c)(1) of this section, use the data from paragraph (d)(3) of this section to calculate the mean rise time, t10-90, and mean fall time, t90-10, for the continuously combined signal from each analyzer being verified. You may use interpolation between recorded values to determine rise and fall times. If the recording frequency used during emission testing is different from the analyzer's output update frequency, you must use the lower of these two frequencies for this verification. Multiply these times (in seconds) by their respective updating-recording frequencies in Hz (1/second). The resulting product must be at least 5 for both rise time and fall time. If either value is less than 5, increase the updating-recording frequency or adjust the flows or design of the sampling system to increase the rise time and fall time as needed. You may also configure analog or digital filters before recording to increase rise and fall times. In no case may the mean rise time or mean fall time be greater than 10 seconds.

(2) If a measurement system fails the criterion in paragraph (e)(1) of this section, ensure that signals from the system are updated and recorded at a frequency of at least 5 Hz. In no case may the mean rise time or mean fall time be greater than 10 seconds.

(3) If a measurement system fails the criteria in paragraphs (e)(1) and (2) of this section, you may use the measurement system only if the deficiency does not adversely affect your ability to show compliance with the applicable standards in this chapter.

(f) Transformation time, t50, determination. If you choose to determine t50 for purposes of time alignment using data generated in paragraph (d)(3) of this section, calculate the mean t0-50 and the mean t100-50 from the recorded data. Average these two values to determine the final t50 for the purposes of time alignment in accordance with §1065.650(c)(2)(i).

(g) Optional procedure. Follow the optional procedures in §1065.308(g), noting that you may use compensating gases mixed with ambient air for oxygen analyzers.

(h) Analyzers with H2O compensation sampling downstream of a sample dryer. You may omit humidifying the span gas as described in this paragraph (h). If an analyzer compensates only for H2O, you may apply the requirements of §1065.308 instead of the requirements of this section. You may omit humidifying the span gas if you meet the following conditions:

(1) The analyzer is located downstream of a sample dryer.

(2) The maximum value for H2O mole fraction downstream of the dryer must be less than or equal to 0.010. Verify this during each sample dryer verification according to §1065.342.

[73 FR 59326, Oct. 8, 2008, as amended at 75 FR 23039, Apr. 30, 2010; 79 FR 23767, Apr. 28, 2014; 86 FR 34538, Jun. 29, 2021; 88 FR 4674, Jan. 24, 2023]

['Air Programs']

['Air Emissions']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.