Be Part of the Ultimate Safety & Compliance Community

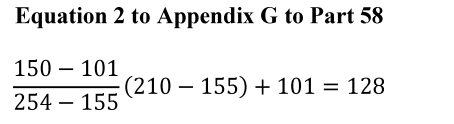

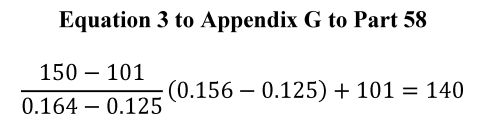

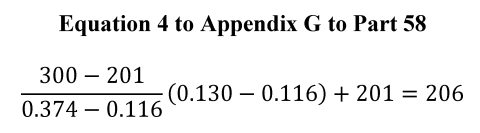

Trending news, knowledge-building content, and more – all personalized to you!

Based on the Environmental Protection Agency's (EPA's) reconsideration of the air quality criteria and the national ambient air quality standards (NAAQS) for particulate matter (PM), the EPA is revising the primary annual PM 2.5 standard by lowering the level from 12.0 µg/m 3 to 9.0 µg/m 3 . The Agency is retaining the current primary 24-hour PM 2.5 standard and the primary 24-hour PM 10 standard. The Agency also is not changing the secondary 24-hour PM 2.5 standard, secondary annual PM 2.5 standard, and secondary 24-hour PM 10 standard at this time. The EPA is also finalizing revisions to other key aspects related to the PM NAAQS, including revisions to the Air Quality Index (AQI) and monitoring requirements for the PM NAAQS.

DATES: This final rule is effective May 6, 2024, published in the Federal Register March 6, 2024, page 16202.

View final rule.

| §50.20 National primary ambient air quality standards for PM2.5. | ||

| Entire section | Added | View text |

| Appendix K to Part 50 - Interpretation of the National Ambient Air Quality Standards for Particulate Matter | ||

| Section 1.0 paragraph (b) | Revised | View text |

| Section 2.3 paragraph (d) | Added | View text |

| Section 3.0 paragraphs (a) and (b) | Added | View text |

| Appendix L to Part 50 - Reference Method for the Determination of Fine Particulate Matter as PM2.5 in the Atmosphere | ||

| Section 7.3.4 | Revised | View text |

| Section 7.3.4.5 | Added | View text |

| Appendix N to Part 50 - Interpretation of the National Ambient Air Quality Standards for PM2.5 | ||

| Section 1.0 paragraph (a) | Revised | View text |

| Section 3.0 paragraph (d)(3) | Added | View text |

| Section 4.1 paragraph (a) | Revised | View text |

| Section 4.2 paragraph (a) | Revised | View text |

| §53.4 Applications for reference or equivalent method determinations. | ||

| (a), (d) | Revised | View text |

| (b)(7) | Added | View text |

| §53.8 Designation of reference and equivalent methods. | ||

| (a) | Revised | View text |

| §53.14 Modification of a reference or equivalent method. | ||

| (c)(4)-(6) | Revised | View text |

| Table A–1 to Subpart A of Part 53—Summary of Applicable Requirements for Reference and Equivalent Methods for Air Monitoring of Criteria Pollutants | ||

| Entire table | Revised | View text |

| Table B-1 to Subpart B of Part 53- Performance Limit Specifications for Automated Methods | ||

| Footnote 4 | Revised | View text |

| Table B-3 to Subpart B of Part 53 - Interferent Test Concentration,1 Parts per Million | ||

| Entire table | Revised | View text |

| Appendix A to Subpart B of Part 53 - Optional Forms for Reporting Test Results | ||

| Figures B-3 and B-5 | Revised | View text |

| §53.35 Test procedure for Class II and Class III methods for PM2.5 and PM10−2.5. | ||

| (b)(1)(ii)(D) | Revised | View text |

| Table C-4 to Subpart C of Part 53—Test Specifications for PM10, PM2.5, and PM10–2.5 Candidate Equivalent Methods | ||

| Entire table | Revised | View text |

| §53.43 Test procedures. | ||

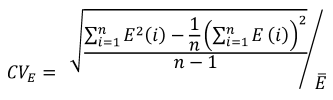

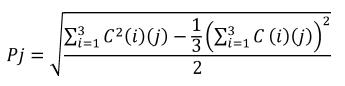

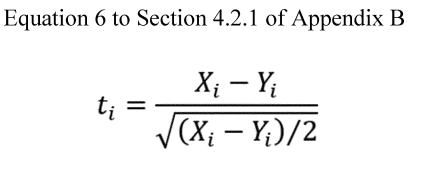

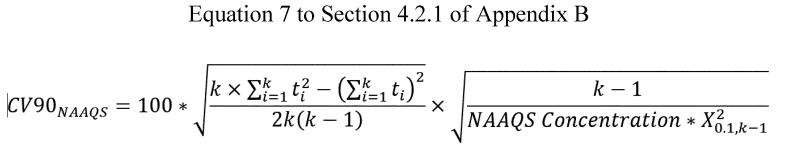

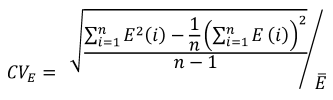

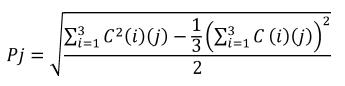

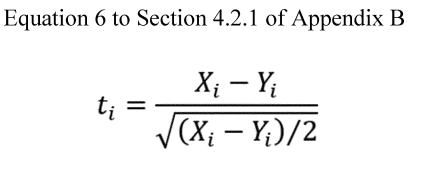

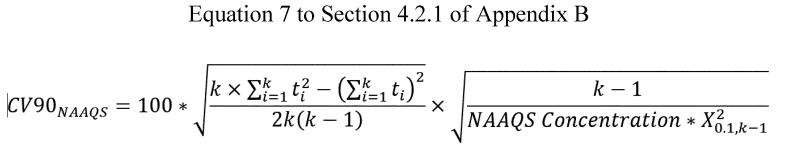

| Formulas in (a)(2)(xvi) and (c)(2)(iv) | Revised | View text |

| §53.51 Demonstration of compliance with design specifications and manufacturing and test requirements. | ||

| (d)(2) | Revised | View text |

| §53.61 Test conditions. | ||

| (g) | Revised | View text |

| §58.1 Definitions. | ||

| Definition for ”Approved regional method (ARM)” | Removed | View text |

| Definition for ”Traceable” | Removed | View text |

| §58.10 Annual monitoring network plan and periodic network assessment. | ||

| (a)(1), (b)(10), (b)(13), (d) | Revised | View text |

| (b)(14) | Added | View text |

| §58.11 Network technical requirements. | ||

| (a)(2), (e) | Revised | View text |

| §58.12 Operating schedules. | ||

| (d)(1) | Revised | View text |

| §58.15 Annual air monitoring data certification. | ||

| Entire section | Revised | View text |

| §58.20 Special purpose monitors (SPM). | ||

| (b)-(e) | Revised | View text |

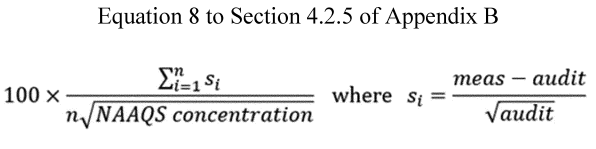

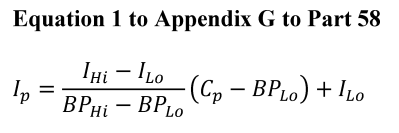

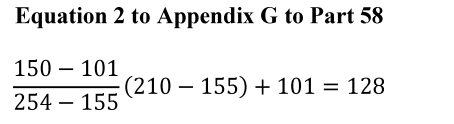

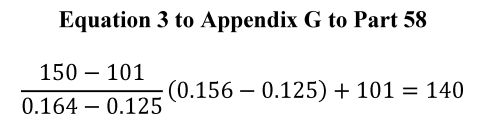

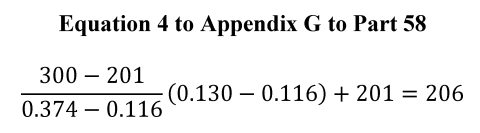

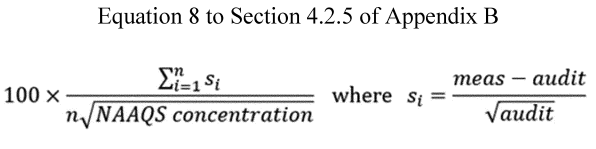

| Appendix A to Part 58 - Quality Assurance Requirements for Monitors used in Evaluations of National Ambient Air Quality Standards | ||

| Entire appendix | Revised | View text |

| Appendix B to Part 58 - Quality Assurance Requirements for Prevention of Significant Deterioration (PSD) Air Monitoring | ||

| Entire appendix | View text | |

| Appendix C to Part 58—Ambient Air Quality Monitoring Methodology | ||

| Section 2 | Revised | View text |

| Appendix D to Part 58—Network Design Criteria for Ambient Air Quality Monitoring | ||

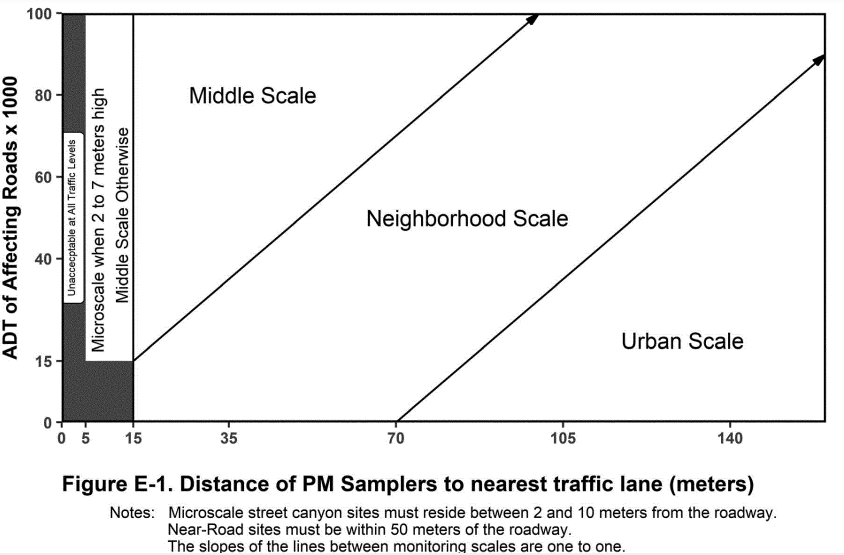

| Sections 1, 1.1(b), introductory text before table in 4.7.1(a), 4.7.1(b)(3), 4.7.2 | Revised | View text |

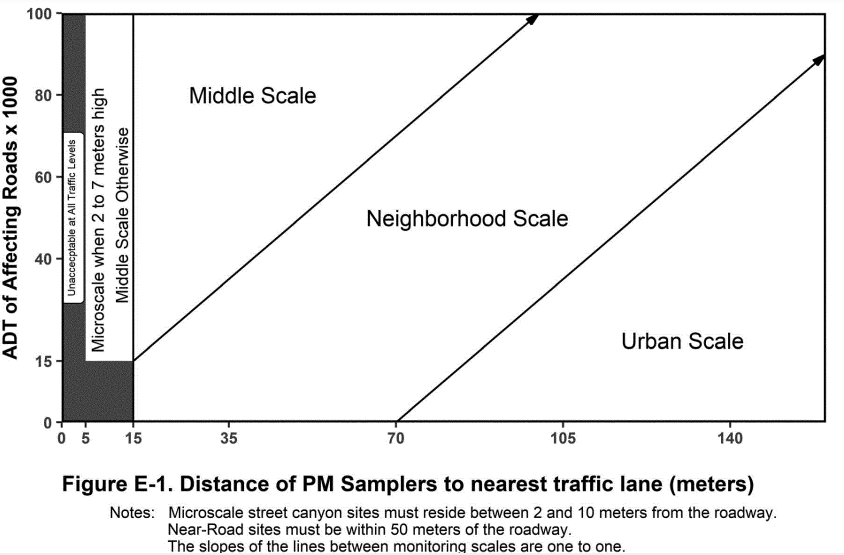

| Appendix E to Part 58—Probe and Monitoring Path Siting Criteria for Ambient Air Quality Monitoring | ||

| Entire appendix | Revised | View text |

| Appendix G to Part 58—Uniform Air Quality Index (AQI) and Daily Reporting | ||

| Entire appendix | Revised | View text |

New Text

Appendix K to Part 50 - Interpretation of the National Ambient Air Quality Standards for Particulate Matter

* * * *

(b) The terms used in this appendix are defined as follows:

Average refers to the arithmetic mean of the estimated number of exceedances per year, as per section 3.1 of this appendix.

Collocated monitors refer to two or more air measurement instruments for the same parameter (e.g., PM 10 mass) operated at the same site location, and whose placement is consistent with part 53 of this chapter. For purposes of considering a combined site record in this appendix, when two or more monitors are operated at the same site, one monitor is designated as the “primary” monitor with any additional monitors designated as “collocated.” It is implicit in these appendix procedures that the primary monitor and collocated monitor(s) are all reference or equivalent methods; however, it is not a requirement that the primary and collocated monitors utilize the same specific sampling and analysis method.

Combined site data record is the data set used for performing computations in this appendix and represents data for the primary monitors augmented with data from collocated monitors according to the procedure specified in section 3.0(a) of this appendix.

Daily value for PM10 refers to the 24-hour average concentration of PM 10 calculated or measured from midnight to midnight (local time).

Exceedance means a daily value that is above the level of the 24-hour standard after rounding to the nearest 10 µg/m 3i.e., values ending in 5 or greater are to be rounded up).

Expected annual value is the number approached when the annual values from an increasing number of years are averaged, in the absence of long-term trends in emissions or meteorological conditions.

Primary monitors are suitable monitors designated by a State or local agency in their annual network plan as the default data source for creating a combined site data record. If there is only one suitable monitor at a particular site location, then it is presumed to be a primary monitor.

Year refers to a calendar year.

Appendix L to Part 50 - Reference Method for the Determination of Fine Particulate Matter as PM2.5 in the Atmosphere

* * * *

7.3.4 Particle size separator. The sampler shall be configured with one of the three alternative particle size separators described in this section. One separator is an impactor-type separator (WINS impactor) described in sections 7.3.4.1, 7.3.4.2, and 7.3.4.3 of this appendix. One alternative separator is a cyclone-type separator (VSCC TM) described in section 7.3.4.4 of this appendix. The other alternative separator is also a cyclone-type separator (TE–PM 2.5 C) described in section 7.3.4.5 of this appendix.

Appendix N to Part 50 - Interpretation of the National Ambient Air Quality Standards for PM2.5

1.0 General

(a) This appendix explains the data handling conventions and computations necessary for determining when the national ambient air quality standards (NAAQS) for PM 2.5 are met, specifically the primary and secondary annual and 24-hour PM 2.5 NAAQS specified in §§50.7, 50.13, 50.18, and 50.20. PM 2.5 is defined, in general terms, as particles with an aerodynamic diameter less than or equal to a nominal 2.5 micrometers. PM 2.5 mass concentrations are measured in the ambient air by a Federal Reference Method (FRM) based on appendix L to this part, as applicable, and designated in accordance with part 53 of this chapter or by a Federal Equivalent Method (FEM) designated in accordance with part 53 of this chapter. Only those FRM and FEM measurements that are derived in accordance with part 58 of this chapter (i.e., that are deemed “suitable”) shall be used in comparisons with the PM 2.5 NAAQS. The data handling and computation procedures to be used to construct annual and 24-hour NAAQS metrics from reported PM 2.5 mass concentrations, and the associated instructions for comparing these calculated metrics to the levels of the PM 2.5 NAAQS, are specified in sections 2.0, 3.0, and 4.0 of this appendix.

* * * *

4.1 Annual PM2 . 5 NAAQS

(a) Levels of the primary and secondary annual PM 2.5 NAAQS are specified in §§50.7, 50.13, 50.18, and 50.20 as applicable.

* * * * *

4.2 Twenty-Four-Hour PM2 . 5 NAAQS

(a) Levels of the primary and secondary 24-hour PM 2.5 NAAQS are specified in §§50.7, 50.13, 50.18, and 50.20 as applicable.

§53.4 Applications for reference or equivalent method determinations.

(a) Applications for FRM or FEM determinations and modification requests of existing designated instruments shall be submitted to: U.S. Environmental Protection Agency, Director, Center for Environmental Measurement and Modeling, Reference and Equivalent Methods Designation Program (MD–D205–03), 109 T.W. Alexander Drive, P.O. Box 12055, Research Triangle Park, North Carolina 27711 (commercial delivery address: 4930 Old Page Road, Durham, North Carolina 27703).

* * * *

(d) For candidate reference or equivalent methods or for designated instruments that are the subject of a modification request, the applicant, if requested by EPA, shall provide to EPA a representative sampler or analyzer for test purposes. The sampler or analyzer shall be shipped free on board (FOB) destination to Director, Center for Environmental Measurements and Modeling, Reference and Equivalent Methods Designation Program (MD D205–03), U.S. Environmental Protection Agency, 4930 Old Page Road, Durham, North Carolina 27703, scheduled to arrive concurrently with or within 30 days of the arrival of the other application materials. This sampler or analyzer may be subjected to various tests that EPA determines to be necessary or appropriate under §53.5(f), and such tests may include special tests not described in this part. If the instrument submitted under this paragraph (d) malfunctions, becomes inoperative, or fails to perform as represented in the application before the necessary EPA testing is completed, the applicant shall be afforded the opportunity to repair or replace the device at no cost to the EPA. Upon completion of EPA testing, the sampler or analyzer submitted under this paragraph (d) shall be repacked by EPA for return shipment to the applicant, using the same packing materials used for shipping the instrument to EPA unless alternative packing is provided by the applicant. Arrangements for, and the cost of, return shipment shall be the responsibility of the applicant. The EPA does not warrant or assume any liability for the condition of the sampler or analyzer upon return to the applicant.

§53.8 Designation of reference and equivalent methods.

(a) A candidate method determined by the Administrator to satisfy the applicable requirements of this part shall be designated as an FRM or FEM (as applicable) by and upon publication of the designation in the Federal Register . Applicants shall not publicly announce, market, or sell the candidate sampler and analyzer as an approved FRM or FEM (as applicable) until the designation is published in the Federal Register .

§53.14 Modification of a reference or equivalent method.

* * * *

(c)(4) Send notice to the applicant that additional information must be submitted before a determination can be made and specify the additional information that is needed (in such cases, the 90-day period shall commence upon receipt of the additional information).

(c)(5) Send notice to the applicant that additional tests are necessary and specify which tests are necessary and how they shall be interpreted (in such cases, the 90-day period shall commence upon receipt of the additional test data).

(c)(6) Send notice to the applicant that additional tests will be conducted by the Administrator and specify the reasons for and the nature of the additional tests (in such cases, the 90-day period shall commence 1 calendar day after the additional tests are completed).

Table A–1 to Subpart A of Part 53—Summary of Applicable Requirements for Reference and Equivalent Methods for Air Monitoring of Criteria Pollutants

| 1 Some requirements may apply, based on the nature of each particular candidate method, as determined by the Administrator. | |||||||||

| 2 Alternative Class III requirements may be substituted. | |||||||||

| Pollutant | Reference or equivalent | Manual or automated | Applicable appendix of part 50 of this chapter | Applicable subparts of this part | |||||

| A | B | C | D | E | F | ||||

| SO 2 | Reference | Manual | A–2 | ||||||

| Automated | A–1 | ✓ | ✓ | ||||||

| Equivalent | Manual | A–1 | ✓ | ✓ | |||||

| Automated | A–1 | ✓ | ✓ | ✓ | |||||

| CO | Reference | Automated | C | ✓ | ✓ | ||||

| Equivalent | Manual | C | ✓ | ✓ | |||||

| Automated | C | ✓ | ✓ | ✓ | |||||

| O 3 | Reference | Automated | D | ✓ | ✓ | ||||

| Equivalent | Manual | D | ✓ | ✓ | |||||

| Automated | D | ✓ | ✓ | ✓ | |||||

| NO 2 | Reference | Automated | F | ✓ | ✓ | ||||

| Equivalent | Manual | F | ✓ | ✓ | |||||

| Automated | F | ✓ | ✓ | ✓ | |||||

| Pb | Reference | Manual | G | ||||||

| Equivalent | Manual | G | ✓ | ✓ | |||||

| Automated | G | ✓ | ✓ | ||||||

| PM 10 -Pb | Reference | Manual | Q | ||||||

| Equivalent | Manual | Q | ✓ | ✓ | |||||

| Automated | Q | ✓ | ✓ | ||||||

| PM 10 | Reference | Manual | J | ✓ | ✓ | ||||

| Equivalent | Manual | J | ✓ | ✓ | ✓ | ||||

| Automated | J | ✓ | ✓ | ✓ | |||||

| PM 2.5 | Reference | Manual | L | ✓ | ✓ | ||||

| Equivalent Class I | Manual | L | ✓ | ✓ | ✓ | ||||

| Equivalent Class II | Manual | L 1 | ✓ | 2 ✓ | ✓ | ✓ | |||

| Equivalent Class III | Automated | L 1 | ✓ | ✓ | ✓ | 1 ✓ | |||

| PM 10–2.5 | Reference | Manual | L, 2 O | ✓ | ✓ | ||||

| Equivalent Class I | Manual | L, 2 O | ✓ | ✓ | ✓ | ||||

| Equivalent Class II | Manual | L, 2 O | ✓ | 2 ✓ | ✓ | 1,2 ✓ | |||

| Equivalent Class III | Automated | 1 L, O | ✓ | ✓ | ✓ | 1 ✓ | |||

Table B-1 to Subpart B of Part 53- Performance Limit Specifications for Automated Methods

* * * *

4 For nitric oxide interference for the SO 2 ultraviolet fluorescence (UVF) method, interference equivalent is ±0.003 ppm for the lower range.

Table B-3 to Subpart B of Part 53 - Interferent Test Concentration,1 Parts per Million

| Pollutant | Analyzer type 2 | Hydro-chloric acid | Ammonia | Hydrogen sulfide | Sulfur dioxide | Nitrogen dioxide | Nitric oxide | Carbon dioxide | Ethylene | Ozone | M-xylene | Water vapor | Carbon monoxide | Methane | Ethane | Naphthalene |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 Concentrations of interferent listed must be prepared and controlled to ±10 percent of the stated value. | ||||||||||||||||

| 2 Analyzer types not listed will be considered by the Administrator as special cases. | ||||||||||||||||

| 3 Do not mix interferent with the pollutant. | ||||||||||||||||

| 4 Concentration of pollutant used for test. These pollutant concentrations must be prepared to ±10 percent of the stated value. | ||||||||||||||||

| 5 If candidate method utilizes an elevated-temperature scrubber for removal of aromatic hydrocarbons, perform this interference test. | ||||||||||||||||

| 6 If naphthalene test concentration cannot be accurately quantified, remove the scrubber, use a test concentration that causes a full-scale response, reattach the scrubber, and evaluate response for interference. | ||||||||||||||||

| SO 2 | Ultraviolet fluorescence | 5 0.1 | 4 0.14 | 0.5 | 0.5 | 0.5 | 0.2 | 20,000 | 6 0.05 | |||||||

| SO 2 | Flame photometric | 0.01 | 4 0.14 | 750 | 3 20,000 | 50 | ||||||||||

| SO 2 | Gas chromatography | 0.1 | 4 0.14 | 750 | 3 20,000 | 50 | ||||||||||

| SO 2 | Spectrophotometric-wet chemical (pararosanaline) | 0.2 | 0.1 | 0.1 | 4 0.14 | 0.5 | 750 | 0.5 | ||||||||

| SO 2 | Electrochemical | 0.2 | 0.1 | 0.1 | 4 0.14 | 0.5 | 0.5 | 0.2 | 0.5 | 3 20,000 | ||||||

| SO 2 | Conductivity | 0.2 | 0.1 | 4 0.14 | 0.5 | 750 | ||||||||||

| SO 2 | Spectrophotometric-gas phase, including DOAS | 4 0.14 | 0.5 | 0.5 | 0.5 | 0.2 | ||||||||||

| O 3 | Ethylene Chemiluminescence | 3 0.1 | 750 | 4 0.08 | 3 20,000 | |||||||||||

| O 3 | NO-chemiluminescence | 3 0.1 | 0.5 | 750 | 4 0.08 | 3 20,000 | ||||||||||

| O 3 | Electrochemical | 3 0.1 | 0.5 | 0.5 | 4 0.08 | 3 20,000 | ||||||||||

| O 3 | Spectrophotometric-wet chemical (potassium iodide) | 3 0.1 | 0.5 | 0.5 | 3 0.5 | 4 0.08 | ||||||||||

| O 3 | Spectrophotometric-gas phase, including ultraviolet absorption and DOAS | 0.5 | 0.5 | 3 0.5 | 4 0.08 | 0.02 | 20,000 | |||||||||

| CO | Non-dispersive Infrared | 750 | 20,000 | 4 10 | ||||||||||||

| CO | Gas chromatography with flame ionization detector | 20,000 | 4 10 | 0.5 | ||||||||||||

| CO | Electrochemical | 0.5 | 0.2 | 20,000 | 4 10 | |||||||||||

| CO | Catalytic combustion-thermal detection | 0.1 | 750 | 0.2 | 20,000 | 4 10 | 5.0 | 0.5 | ||||||||

| CO | IR fluorescence | 750 | 20,000 | 4 10 | 0.5 | |||||||||||

| CO | Mercury replacement-UV photometric | 0.2 | 4 10 | 0.5 | ||||||||||||

| NO 2 | Chemiluminescent | 3 0.1 | 0.5 | 4 0.1 | 0.5 | 20,000 | ||||||||||

| NO 2 | Spectrophotometric-wet chemical (azo-dye reaction) | 0.5 | 4 0.1 | 0.5 | 750 | 0.5 | ||||||||||

| NO 2 | Electrochemical | 0.2 | 3 0.1 | 0.5 | 4 0.1 | 0.5 | 750 | 0.5 | 20,000 | 50 | ||||||

| NO 2 | Spectrophotometric-gas phase | 3 0.1 | 0.5 | 4 0.1 | 0.5 | 0.5 | 20,000 | 50 | ||||||||

Appendix A to Subpart B of Part 53 - Optional Forms for Reporting Test Results

* * * * *

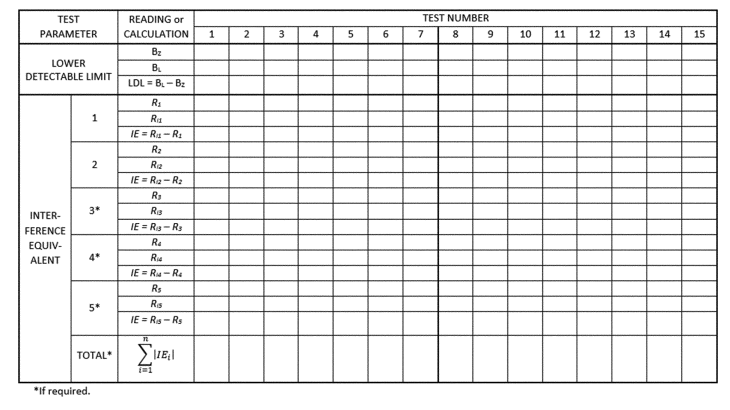

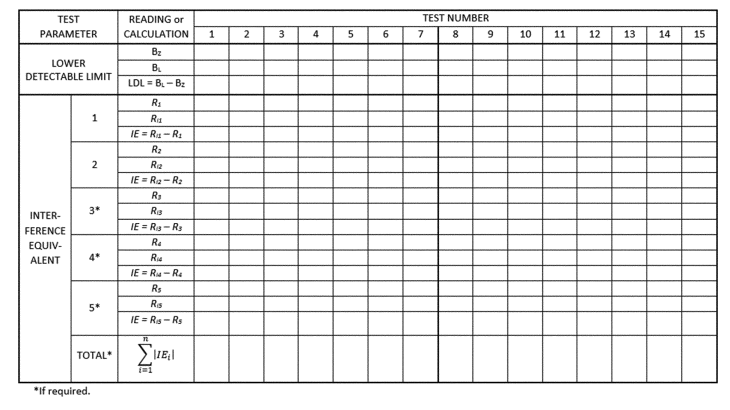

Figure B–3 to Appendix A to Subpart B of Part 53—Form for Test Data and Calculations for Lower Detectable Limit (LDL) and Interference Equivalent (IE) (see §53.23(c) and (d))

LDL Interference Test Data

Applicant _________________

Analyzer _________________

Date _________________

Pollutant _________________

* * * * *

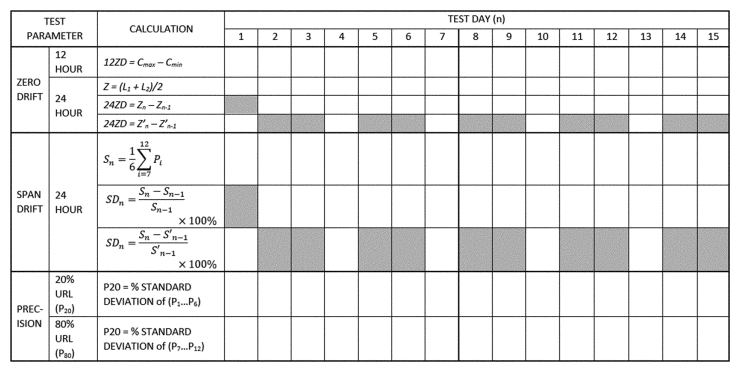

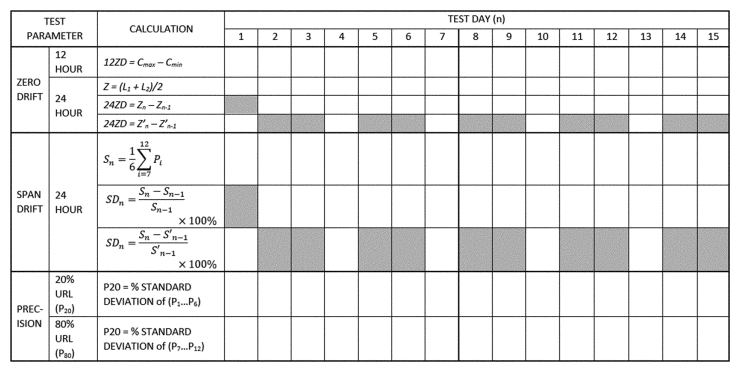

Figure B–5 to Appendix A to Subpart B of Part 53—Form for Calculating Zero Drift, Span Drift and Precision (see §53.23(e))

Calculation of Zero Drift, Span Drift, and Precision

Applicant _________________

Analyzer _________________

Date _________________

Pollutant _________________

§53.35 Test procedure for Class II and Class III methods for PM2.5 and PM10−2.5.

* * * *

(b)(1)(ii)(D) Site D shall be in a large city east of the Mississippi River, having characteristically high humidity levels.

Table C-4 to Subpart C of Part 53—Test Specifications for PM10, PM2.5, and PM10–2.5 Candidate Equivalent Methodss

| Specification | PM 10 | PM 2.5 | PM 10–2.5 | |||

|---|---|---|---|---|---|---|

| Class I | Class II | Class III | Class II | Class III | ||

| 1 Some missing daily measurement values may be permitted; see test procedure. | ||||||

| 2 Calculated as the root mean square over all measurement sets. | ||||||

| Acceptable concentration range (R j), µg/m 3 | 5–300 | 3–200 | 3–200 | 3–200 | 3–200 | 3–200. |

| Minimum number of test sites | 2 | 1 | 2 | 4 | 2 | 4. |

| Minimum number of candidate method samplers or analyzers per site | 3 | 3 | 3 1 | 3 1 | 3 1 | 3. 1 |

| Number of reference method samplers per site | 3 | 3 | 3 1 | 3 1 | 3 1 | 3. 1 |

| Minimum number of acceptable sample sets per site for PM 10 methods: | ||||||

| R j < 20 µg/m 3 | 3 | |||||

| R j > 20 µg/m 3 | 3 | |||||

| Total | 10 | |||||

| Minimum number of acceptable sample sets per site for PM 2.5 and PM 10–2.5 candidate equivalent methods: | ||||||

| R j < 15 µg/m 3 for 24-hr or R j < 8 µg/m 3 for 48-hr samples. | 3 | 3 | 3 | 3 | 3. | |

| Rj > 15 µg/m 3 for 24-hr or R j > 8 µg/m 3 for 48-hr samples | 3 | 3 | 3 | 3 | 3. | |

| Each season | 10 | 23 | 23 | 23 | 23. | |

| Total, each site | 10 | 23 | 23 (46 for two-season sites) | 23 | 23 (46 for two-season sites). | |

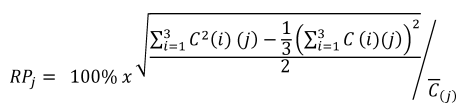

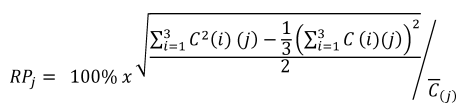

| Precision of replicate reference method measurements, P Rj or RP Rj , respectively; RP for Class II or III PM 2.5 or PM 10–2.5 , maximum | 5 μg/m 3 or 7%. | 2 μg/m 3 or 5%. | 10% 2 | 10% 2 | 10% 2 | 10%. 2 |

| Precision of PM 2.5 or PM 10–2.5 candidate method, CP, each site | 10% 2 | 15% 2 | 15% 2 | 15%. 2 | ||

| Slope of regression relationship | 1 ±0.10 | 1 ±0.05 | 1 ±0.10 | 1 ±0.10 | 1 ±0.10 | 1 ±0.12. |

| Intercept of regression relationship, µg/m 3 | 0 ±5 | 0 ±1 | Between: 13.55—(15.05 × slope), but not less than—1.5; and 16.56—(15.05 × slope), but not more than +1.5 | Between: 15.05—(17.32 × slope), but not less than—2.0; and 15.05—(13.20 × slope), but not more than +2.0 | Between: 62.05—(70.5 × slope), but not less than—3.5; and 78.95—(70.5 × slope), but not more than +3.5 | Between: 70.50—(82.93 × slope), but not less than—7.0; and 70.50—(61.16 × slope), but not more than +7.0. |

| Correlation of reference method and candidate method measurements | ≥ 0.97 | ≥ 0.97 | ≥ 0.93—for CCV ≤ 0.4; ≥ 0.85 + 0.2 × CCV—for 0.4 ≤ CCV ≤ 0.5; ≥ 0.95—for CCV ≥ 0.5 | |||

§53.43 Test procedures.

(a)(2)(xvi)

(c)(2)(iv) * * *

if C j is below 80 µg/m 3 , or

if C j is above 80 µg/m 3 .

§53.51 Demonstration of compliance with design specifications and manufacturing and test requirements.

* * * *

(d)(2) VSCC and TE–PM2.5C separators. For samplers and monitors utilizing the BGI VSCC or Tisch TE–PM 2.5 C particle size separators specified in sections 7.3.4.4 and 7.3.4.5 of appendix L to part 50 of this chapter, respectively, the respective manufacturers shall identify the critical dimensions and manufacturing tolerances for the separator, devise appropriate test procedures to verify that the critical dimensions and tolerances are maintained during the manufacturing process, and carry out those procedures on each separator manufactured to verify conformance of the manufactured products. The manufacturer shall also maintain records of these tests and their test results and submit evidence that this procedure is incorporated into the manufacturing procedure, that the test is or will be routinely implemented, and that an appropriate procedure is in place for the disposition of units that fail this tolerance tests.

§53.61 Test conditions.

(g) Vibrating Orifice Aerosol Generator (VOAG) and Flow-Focusing Monodisperse Aerosol Generator (FMAG) conventions. This section prescribes conventions regarding the use of the vibrating orifice aerosol generator (VOAG) and the flow-focusing monodisperse aerosol generator (FMAG) for the size-selective performance tests outlined in §§53.62, 53.63, 53.64, and 53.65.

(1) Particle aerodynamic diameter. The VOAG and FMAG produce near-monodisperse droplets through the controlled breakup of a liquid jet. When the liquid solution consists of a non-volatile solute dissolved in a volatile solvent, the droplets dry to form particles of near-monodisperse size.

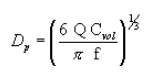

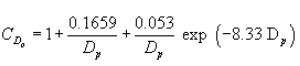

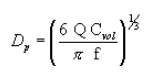

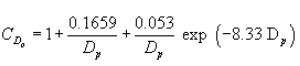

(i) The physical diameter of a generated spherical particle can be calculated from the operational parameters of the VOAG and FMAG as:

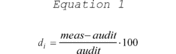

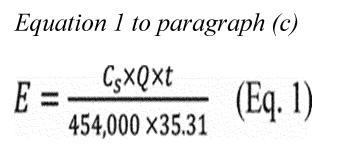

Equation 1

where:

Dp = particle physical diameter, µm;

Q = liquid volumetric flow rate, µm 3/sec;

Cvol = volume concentration (particle volume produced per drop volume), dimensionless; and

f = frequency of applied vibrational signal, 1/sec.

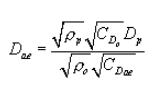

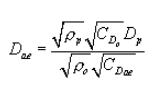

(ii) A given particle's aerodynamic behavior is a function of its physical particle size, particle shape, and density. Aerodynamic diameter is defined as the diameter of a unit density (ρo = 1g/cm 3) sphere having the same settling velocity as the particle under consideration. For converting a spherical particle of known density to aerodynamic diameter, the governing relationship is:

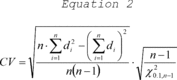

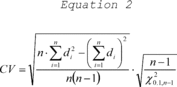

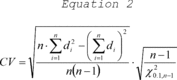

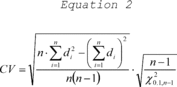

Equation 2

where:

Dae = particle aerodynamic diameter, µm;

ρp = particle density, g/cm 3;

ρo = aerodynamic particle density = 1 g/cm 3;

CDp = Cunningham's slip correction factor for physical particle diameter, dimensionless; and

CDae = Cunningham's slip correction factor for aerodynamic particle diameter, dimensionless.

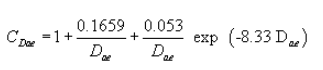

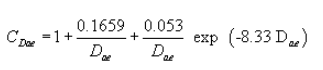

(iii) At room temperature and standard pressure, the Cunningham's slip correction factor is solely a function of particle diameter:

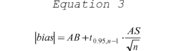

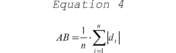

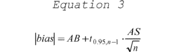

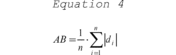

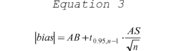

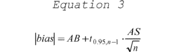

Equation 3

or

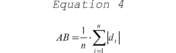

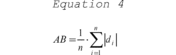

Equation 4

(iv) Since the slip correction factor is itself a function of particle diameter, the aerodynamic diameter in equation 2 of paragraph (g)(1)(ii) of this section cannot be solved directly but must be determined by iteration.

(2) Solid particle generation. (i) Solid particle tests performed in this subpart shall be conducted using particles composed of ammonium fluorescein. For use in the VOAG or FMAG, liquid solutions of known volumetric concentration can be prepared by diluting fluorescein powder (C 2 OH 12 O 5 , FW = 332.31, CAS 2321–07–5) with aqueous ammonia. Guidelines for preparation of fluorescein solutions of the desired volume concentration (C vol) are presented in Vanderpool and Rubow (1988) (Reference 2 in appendix A to this subpart). For purposes of converting particle physical diameter to aerodynamic diameter, an ammonium fluorescein particle density of 1.35 g/cm 3 shall be used.

(ii) Mass deposits of ammonium fluorescein shall be extracted and analyzed using solutions of 0.01 N ammonium hydroxide.

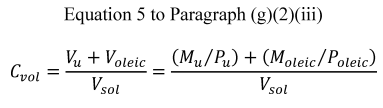

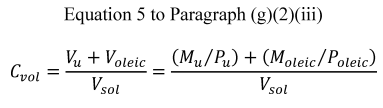

(iii) Calculation of the physical diameter of the particles produced by the VOAG and FMAG requires knowledge of the liquid solution's volume concentration (C vol). Because uranine is essentially insoluble in oleic acid, the total particle volume is the sum of the oleic acid volume and the uranine volume. The volume concentration of the liquid solution shall be calculated as:

Where:

V u = uranine volume, ml;

V oleic = oleic acid volume, ml;

V sol = total solution volume, ml;

M u = uranine mass, g;

P u = uranine density, g/cm 3 ;

M oleic = oleic acid mass, g; and

P oleic = oleic acid density, g/cm 3 .

(3) Liquid particle generation. (i) Tests prescribed in §53.63 for inlet aspiration require the use of liquid particle tests composed of oleic acid tagged with uranine to enable subsequent fluorometric quantitation of collected aerosol mass deposits. Oleic acid (C18H34O2, FW = 282.47, CAS 112-80-1) has a density of 0.8935 g/cm 3. Because the viscosity of oleic acid is relatively high, significant errors can occur when dispensing oleic acid using volumetric pipettes. For this reason, it is recommended that oleic acid solutions be prepared by quantifying dispensed oleic acid gravimetrically. The volume of oleic acid dispensed can then be calculated simply by dividing the dispensed mass by the oleic acid density.

(ii) Oleic acid solutions tagged with uranine shall be prepared as follows. A known mass of oleic acid shall first be diluted using absolute ethanol. The desired mass of the uranine tag should then be diluted in a separate container using absolute ethanol. Uranine (C20H10O5Na2, FW = 376.3, CAS 518-47-8) is the disodium salt of fluorescein and has a density of 1.53 g/cm 3. In preparing uranine tagged oleic acid particles, the uranine content shall not exceed 20 percent on a mass basis. Once both oleic acid and uranine solutions are properly prepared, they can then be combined and diluted to final volume using absolute ethanol.

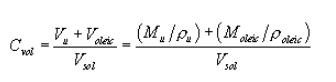

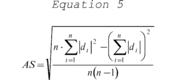

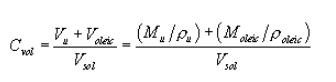

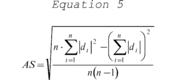

(iii) Calculation of the physical diameter of the particles produced by the VOAG requires knowledge of the liquid solution's volume concentration (Cvol). Because uranine is essentially insoluble in oleic acid, the total particle volume is the sum of the oleic acid volume and the uranine volume. The volume concentration of the liquid solution shall be calculated as:

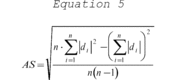

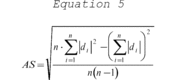

Equation 5

where:

Vu = uranine volume, ml;

Voleic = oleic acid volume, ml;

Vsol = total solution volume, ml;

Mu = uranine mass, g;

ρu = uranine density, g/cm 3;

Moleic = oleic acid mass, g; and

ρoleic = oleic acid density, g/cm. 3

(iv) For purposes of converting the particles' physical diameter to aerodynamic diameter, the density of the generated particles shall be calculated as:

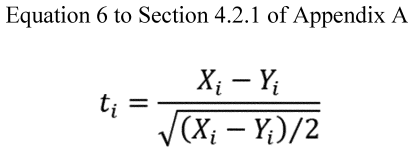

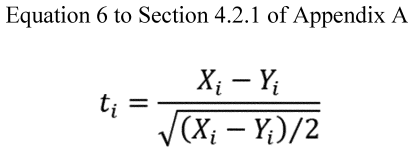

Equation 6

(v) Mass deposits of oleic acid shall be extracted and analyzed using solutions of 0.01 N sodium hydroxide.

§58.1 Definitions.

* * * *

Traceable means a measurement result from a local standard whereby the result can be related to the International System of Units (SI) through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty. Traceable measurement results must be compared and certified, either directly or via not more than one intermediate standard, to a National Institute of Standards and Technology (NIST)-certified reference standard. Examples include but are not limited to NIST Standard Reference Material (SRM), NIST-traceable Reference Material (NTRM), or a NIST-certified Research Gas Mixture (RGM). Traceability to the SI through other National Metrology Institutes (NMIs) in addition to NIST is allowed if a Declaration of Equivalence (DoE) exists between NIST and that NMI.

§58.10 Annual monitoring network plan and periodic network assessment.

* * * *

(a)(1) Beginning July 1, 2007, the State, or where applicable local, agency shall submit to the Regional Administrator an annual monitoring network plan which shall provide for the documentation of the establishment and maintenance of an air quality surveillance system that consists of a network of SLAMS monitoring stations that can include FRM and FEM monitors that are part of SLAMS, NCore, CSN, PAMS, and SPM stations. The plan shall include a statement of whether the operation of each monitor meets the requirements of appendices A, B, C, D, and E to this part, where applicable. The Regional Administrator may require additional information in support of this statement. The annual monitoring network plan must be made available for public inspection and comment for at least 30 days prior to submission to the EPA and the submitted plan shall include and address, as appropriate, any received comments.

* * * * *

(b)(10) Any monitors for which a waiver has been requested or granted by the EPA Regional Administrator as allowed for under appendix D or appendix E to this part. For those monitors where a waiver has been approved, the annual monitoring network plan shall include the date the waiver was approved.

* * * * *

(b)(13) The identification of any PM 2.5 FEMs used in the monitoring agency's network where the data are not of sufficient quality such that data are not to be compared to the national ambient air quality standards (NAAQS). For required SLAMS where the agency identifies that the PM 2.5 Class III FEM does not produce data of sufficient quality for comparison to the NAAQS, the monitoring agency must ensure that an operating FRM or filter-based FEM meeting the sample frequency requirements described in §58.12 or other Class III PM 2.5 FEM with data of sufficient quality is operating and reporting data to meet the network design criteria described in appendix D to this part.

* * * * *

(d) The State, or where applicable local, agency shall perform and submit to the EPA Regional Administrator an assessment of the air quality surveillance system every 5 years to determine, at a minimum, if the network meets the monitoring objectives defined in appendix D to this part, whether new sites are needed, whether existing sites are no longer needed and can be terminated, and whether new technologies are appropriate for incorporation into the ambient air monitoring network. The network assessment must consider the ability of existing and proposed sites to support air quality characterization for areas with relatively high populations of susceptible individuals (e.g., children with asthma) and other at-risk populations, and, for any sites that are being proposed for discontinuance, the effect on data users other than the agency itself, such as nearby States and Tribes or health effects studies. The State, or where applicable local, agency must submit a copy of this 5-year assessment, along with a revised annual network plan, to the Regional Administrator. The assessments are due every 5 years beginning July 1, 2010.

§58.11 Network technical requirements.

* * * *

(a)(2) Beginning January 1, 2009, State and local governments shall follow the quality assurance criteria contained in appendix A to this part that apply to SPM sites when operating any SPM site which uses an FRM or an FEM and meets the requirements of appendix E to this part, unless the Regional Administrator approves an alternative to the requirements of appendix A with respect to such SPM sites because meeting those requirements would be physically and/or financially impractical due to physical conditions at the monitoring site and the requirements are not essential to achieving the intended data objectives of the SPM site. Alternatives to the requirements of appendix A may be approved for an SPM site as part of the approval of the annual monitoring plan, or separately.

* * * *

(e) State and local governments must assess data from Class III PM 2.5 FEM monitors operated within their network using the performance criteria described in table C–4 to subpart C of part 53 of this chapter, for cases where the data are identified as not of sufficient comparability to a collocated FRM, and the monitoring agency requests that the FEM data should not be used in comparison to the NAAQS. These assessments are required in the monitoring agency's annual monitoring network plan described in §58.10(b) for cases where the FEM is identified as not of sufficient comparability to a collocated FRM. For these collocated PM 2.5 monitors, the performance criteria apply with the following additional provisions:

(1) The acceptable concentration range (Rj), µg/m 3 may include values down to 0 µg/m 3 .

(2) The minimum number of test sites shall be at least one; however, the number of test sites will generally include all locations within an agency's network with collocated FRMs and FEMs.

(3) The minimum number of methods shall include at least one FRM and at least one FEM.

(4) Since multiple FRMs and FEMs may not be present at each site, the precision statistic requirement does not apply, even if precision data are available.

(5) All seasons must be covered with no more than 36 consecutive months of data in total aggregated together.

(6) The key statistical metric to include in an assessment is the bias (both additive and multiplicative) of the PM 2.5 continuous FEM(s) compared to a collocated FRM(s). Correlation is required to be reported in the assessment, but failure to meet the correlation criteria, by itself, is not cause to exclude data from a continuous FEM monitor.

§58.12 Operating schedules.

* * * *

(1)(i) Manual PM 2.5 samplers at required SLAMS stations without a collocated continuously operating PM 2.5 monitor must operate on at least a 1-in-3 day schedule unless a waiver for an alternative schedule has been approved per paragraph (d)(1)(ii) of this section.

(ii) For SLAMS PM 2.5 sites with both manual and continuous PM 2.5 monitors operating, the monitoring agency may request approval for a reduction to 1-in-6 day PM 2.5 sampling or for seasonal sampling from the EPA Regional Administrator. Other requests for a reduction to 1-in-6 day PM 2.5 sampling or for seasonal sampling may be approved on a case-by-case basis. The EPA Regional Administrator may grant sampling frequency reductions after consideration of factors (including but not limited to the historical PM 2.5 data quality assessments, the location of current PM 2.5 design value sites, and their regulatory data needs) if the Regional Administrator determines that the reduction in sampling frequency will not compromise data needed for implementation of the NAAQS. Required SLAMS stations whose measurements determine the design value for their area and that are within plus or minus 10 percent of the annual NAAQS, and all required sites where one or more 24-hour values have exceeded the 24-hour NAAQS each year for a consecutive period of at least 3 years are required to maintain at least a 1-in-3 day sampling frequency until the design value no longer meets the criteria in this paragraph (d)(1)(ii) for 3 consecutive years. A continuously operating FEM PM 2.5 monitor satisfies the requirement in this paragraph (d)(1)(ii) unless it is identified in the monitoring agency's annual monitoring network plan as not appropriate for comparison to the NAAQS and the EPA Regional Administrator has approved that the data from that monitor may be excluded from comparison to the NAAQS.

(iii) Required SLAMS stations whose measurements determine the 24-hour design value for their area and whose data are within plus or minus 5 percent of the level of the 24-hour PM 2.5 NAAQS must have an FRM or FEM operate on a daily schedule if that area's design value for the annual NAAQS is less than the level of the annual PM 2.5 standard. A continuously operating FEM or PM 2.5 monitor satisfies the requirement in this paragraph (d)(1)(iii) unless it is identified in the monitoring agency's annual monitoring network plan as not appropriate for comparison to the NAAQS and the EPA Regional Administrator has approved that the data from that monitor may be excluded from comparison to the NAAQS. The daily schedule must be maintained until the referenced design values no longer meets the criteria in this paragraph (d)(1)(iii) for 3 consecutive years.

(iv) Changes in sampling frequency attributable to changes in design values shall be implemented no later than January 1 of the calendar year following the certification of such data as described in §58.15.

§58.15 Annual air monitoring data certification.

(a) The State, or where appropriate local, agency shall submit to the EPA Regional Administrator an annual air monitoring data certification letter to certify data collected by FRM and FEM monitors at SLAMS and SPM sites that meet criteria in appendix A to this part from January 1 to December 31 of the previous year. The head official in each monitoring agency, or his or her designee, shall certify that the previous year of ambient concentration and quality assurance data are completely submitted to AQS and that the ambient concentration data are accurate to the best of her or his knowledge, taking into consideration the quality assurance findings. The annual data certification letter is due by May 1 of each year.

(b) Along with each certification letter, the State shall submit to the Regional Administrator an annual summary report of all the ambient air quality data collected by FRM and FEM monitors at SLAMS and SPM sites. The annual report(s) shall be submitted for data collected from January 1 to December 31 of the previous year. The annual summary serves as the record of the specific data that is the object of the certification letter.

(c) Along with each certification letter, the State shall submit to the Regional Administrator a summary of the precision and accuracy data for all ambient air quality data collected by FRM and FEM monitors at SLAMS and SPM sites. The summary of precision and accuracy shall be submitted for data collected from January 1 to December 31 of the previous year.

§58.20 Special purpose monitors (SPM).

* * * *

(b) Any SPM data collected by an air monitoring agency using a Federal reference method (FRM) or Federal equivalent method (FEM) must meet the requirements of §§58.11 and 58.12 and appendix A to this part or an approved alternative to appendix A. Compliance with appendix E to this part is optional but encouraged except when the monitoring agency's data objectives are inconsistent with the requirements in appendix E. Data collected at an SPM using a FRM or FEM meeting the requirements of appendix A must be submitted to AQS according to the requirements of §58.16. Data collected by other SPMs may be submitted. The monitoring agency must also submit to AQS an indication of whether each SPM reporting data to AQS monitor meets the requirements of appendices A and E.

(c) All data from an SPM using an FRM or FEM which has operated for more than 24 months are eligible for comparison to the relevant NAAQS, subject to the conditions of §§58.11(e) and 58.30, unless the air monitoring agency demonstrates that the data came from a particular period during which the requirements of appendix A, appendix C, or appendix E to this part were not met, subject to review and EPA Regional Office approval as part of the annual monitoring network plan described in §58.10.

(d) If an SPM using an FRM or FEM is discontinued within 24 months of start-up, the Administrator will not base a NAAQS violation determination for the PM 2.5 or ozone NAAQS solely on data from the SPM.

(e) If an SPM using an FRM or FEM is discontinued within 24 months of start-up, the Administrator will not designate an area as nonattainment for the CO, SO 2 , NO 2 , or 24-hour PM 10 NAAQS solely on the basis of data from the SPM. Such data are eligible for use in determinations of whether a nonattainment area has attained one of these NAAQS.

Appendix A to Part 58 - Quality Assurance Requirements for Monitors used in Evaluations of National Ambient Air Quality Standards

1. General Information

2. Quality System Requirements

3. Measurement Quality Check Requirements

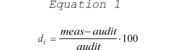

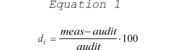

4. Calculations for Data Quality Assessments

5. Reporting Requirements

6. References

1. General Information

1.1 Applicability. (a) This appendix specifies the minimum quality system requirements applicable to SLAMS and other monitor types whose data are intended to be used to determine compliance with the NAAQS (e.g., SPMs, tribal, CASTNET, NCore, industrial, etc.), unless the EPA Regional Administrator has reviewed and approved the monitor for exclusion from NAAQS use and these quality assurance requirements.

(b) Primary quality assurance organizations are encouraged to develop and maintain quality systems more extensive than the required minimums. Additional guidance for the requirements reflected in this appendix can be found in the “Quality Assurance Handbook for Air Pollution Measurement Systems,” Volume II (see reference 10 of this appendix) and at a national level in references 1, 2, and 3 of this appendix.

1.2 Primary Quality Assurance Organization (PQAO). A PQAO is defined as a monitoring organization or a group of monitoring organizations or other organization that is responsible for a set of stations that monitors the same pollutant and for which data quality assessments will be pooled. Each criteria pollutant sampler/monitor must be associated with only one PQAO. In some cases, data quality is assessed at the PQAO level.

1.2.1 Each PQAO shall be defined such that measurement uncertainty among all stations in the organization can be expected to be reasonably homogeneous as a result of common factors. Common factors that should be considered in defining PQAOs include:

(a) Operation by a common team of field operators according to a common set of procedures;

(b) Use of a common quality assurance project plan (QAPP) or standard operating procedures;

(c) Common calibration facilities and standards;

(d) Oversight by a common quality assurance organization; and

(e) Support by a common management organization (i.e., state agency) or laboratory.

Since data quality assessments are made and data certified at the PQAO level, the monitoring organization identified as the PQAO will be responsible for the oversight of the quality of data of all monitoring organizations within the PQAO.

1.2.2 Monitoring organizations having difficulty describing its PQAO or in assigning specific monitors to primary quality assurance organizations should consult with the appropriate EPA Regional Office. Any consolidation of monitoring organizations to PQAOs shall be subject to final approval by the appropriate EPA Regional Office.

1.2.3 Each PQAO is required to implement a quality system that provides sufficient information to assess the quality of the monitoring data. The quality system must, at a minimum, include the specific requirements described in this appendix. Failure to conduct or pass a required check or procedure, or a series of required checks or procedures, does not by itself invalidate data for regulatory decision making. Rather, PQAOs and the EPA shall use the checks and procedures required in this appendix in combination with other data quality information, reports, and similar documentation that demonstrate overall compliance with Part 58. Accordingly, the EPA and PQAOs shall use a “weight of evidence” approach when determining the suitability of data for regulatory decisions. The EPA reserves the authority to use or not use monitoring data submitted by a monitoring organization when making regulatory decisions based on the EPA's assessment of the quality of the data. Consensus built validation templates or validation criteria already approved in QAPPs should be used as the basis for the weight of evidence approach.

1.3 Definitions.

(a) Measurement Uncertainty. A term used to describe deviations from a true concentration or estimate that are related to the measurement process and not to spatial or temporal population attributes of the air being measured.

(b) Precision. A measurement of mutual agreement among individual measurements of the same property usually under prescribed similar conditions, expressed generally in terms of the standard deviation.

(c) Bias. The systematic or persistent distortion of a measurement process which causes errors in one direction.

(d) Accuracy. The degree of agreement between an observed value and an accepted reference value. Accuracy includes a combination of random error (imprecision) and systematic error (bias) components which are due to sampling and analytical operations.

(e) Completeness. A measure of the amount of valid data obtained from a measurement system compared to the amount that was expected to be obtained under correct, normal conditions.

(f) Detection Limit. The lowest concentration or amount of target analyte that can be determined to be different from zero by a single measurement at a stated level of probability.

1.4 Measurement Quality Checks. The measurement quality checks described in section 3 of this appendix shall be reported to AQS and are included in the data required for certification.

1.5 Assessments and Reports. Periodic assessments and documentation of data quality are required to be reported to the EPA. To provide national uniformity in this assessment and reporting of data quality for all networks, specific assessment and reporting procedures are prescribed in detail in sections 3, 4, and 5 of this appendix. On the other hand, the selection and extent of the quality assurance and quality control activities used by a monitoring organization depend on a number of local factors such as field and laboratory conditions, the objectives for monitoring, the level of data quality needed, the expertise of assigned personnel, the cost of control procedures, pollutant concentration levels, etc. Therefore, quality system requirements in section 2 of this appendix are specified in general terms to allow each monitoring organization to develop a quality system that is most efficient and effective for its own circumstances while achieving the data quality objectives described in this appendix.

2. Quality System Requirements

A quality system (reference 1 of this appendix) is the means by which an organization manages the quality of the monitoring information it produces in a systematic, organized manner. It provides a framework for planning, implementing, assessing and reporting work performed by an organization and for carrying out required quality assurance and quality control activities.

2.1 Quality Management Plans and Quality Assurance Project Plans. All PQAOs must develop a quality system that is described and approved in quality management plans (QMP) and QAPPs to ensure that the monitoring results:

(a) Meet a well-defined need, use, or purpose (reference 5 of this appendix);

(b) Provide data of adequate quality for the intended monitoring objectives;

(c) Satisfy stakeholder expectations;

(d) Comply with applicable standards specifications;

(e) Comply with statutory (and other legal) requirements; and

(f) Reflect consideration of cost and economics.

2.1.1 The QMP describes the quality system in terms of the organizational structure, functional responsibilities of management and staff, lines of authority, and required interfaces for those planning, implementing, assessing and reporting activities involving environmental data operations (EDO). The QMP must be suitably documented in accordance with EPA requirements (reference 2 of this appendix), and approved by the appropriate Regional Administrator, or his or her representative. The quality system described in the QMP will be reviewed during the systems audits described in section 2.5 of this appendix. Organizations that implement long-term monitoring programs with EPA funds should have a separate QMP document. Smaller organizations, organizations that do infrequent work with the EPA or have monitoring programs of limited size or scope may combine the QMP with the QAPP if approved by, and subject to any conditions of the EPA. Additional guidance on this process can be found in reference 10 of this appendix. Approval of the recipient's QMP by the appropriate Regional Administrator or his or her representative may allow delegation of authority to the PQAOs independent quality assurance function to review and approve environmental data collection activities adequately described and covered under the scope of the QMP and documented in appropriate planning documents (QAPP). Where a PQAO or monitoring organization has been delegated authority to review and approve their QAPP, an electronic copy must be submitted to the EPA region at the time it is submitted to the PQAO/monitoring organization's QAPP approving authority. The QAPP will be reviewed by the EPA during systems audits or circumstances related to data quality. The QMP submission and approval dates for PQAOs/monitoring organizations must be reported to AQS either by the monitoring organization or the EPA Region.

2.1.2 The QAPP is a formal document describing, in sufficient detail, the quality system that must be implemented to ensure that the results of work performed will satisfy the stated objectives. PQAOs must develop QAPPs that describe how the organization intends to control measurement uncertainty to an appropriate level in order to achieve the data quality objectives for the EDO. The quality assurance policy of the EPA requires every EDO to have a written and approved QAPP prior to the start of the EDO. It is the responsibility of the PQAO/monitoring organization to adhere to this policy. The QAPP must be suitably documented in accordance with EPA requirements (reference 3 of this appendix) and include standard operating procedures for all EDOs either within the document or by appropriate reference. The QAPP must identify each PQAO operating monitors under the QAPP as well as generally identify the sites and monitors to which it is applicable either within the document or by appropriate reference. The QAPP submission and approval dates must be reported to AQS either by the monitoring organization or the EPA Region.

2.1.3 The PQAO/monitoring organization's quality system must have adequate resources both in personnel and funding to plan, implement, assess and report on the achievement of the requirements of this appendix and it's approved QAPP.

2.2 Independence of Quality Assurance. The PQAO must provide for a quality assurance management function, that aspect of the overall management system of the organization that determines and implements the quality policy defined in a PQAO's QMP. Quality management includes strategic planning, allocation of resources and other systematic planning activities (e.g., planning, implementation, assessing and reporting) pertaining to the quality system. The quality assurance management function must have sufficient technical expertise and management authority to conduct independent oversight and assure the implementation of the organization's quality system relative to the ambient air quality monitoring program and should be organizationally independent of environmental data generation activities.

2.3. Data Quality Performance Requirements.

2.3.1 Data Quality Objectives. The DQOs, or the results of other systematic planning processes, are statements that define the appropriate type of data to collect and specify the tolerable levels of potential decision errors that will be used as a basis for establishing the quality and quantity of data needed to support the monitoring objectives (reference 5 of this appendix). The DQOs will be developed by the EPA to support the primary regulatory objectives for each criteria pollutant. As they are developed, they will be added to the regulation. The quality of the conclusions derived from data interpretation can be affected by population uncertainty (spatial or temporal uncertainty) and measurement uncertainty (uncertainty associated with collecting, analyzing, reducing and reporting concentration data). This appendix focuses on assessing and controlling measurement uncertainty.

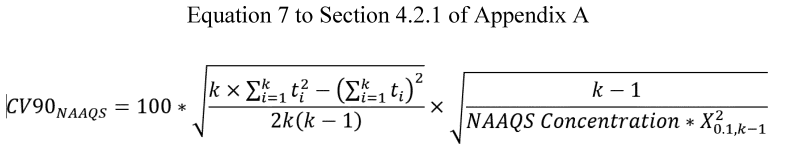

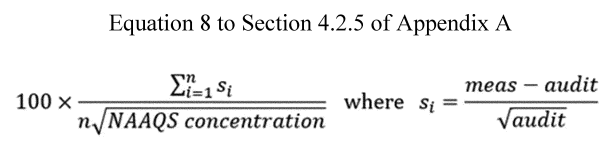

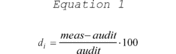

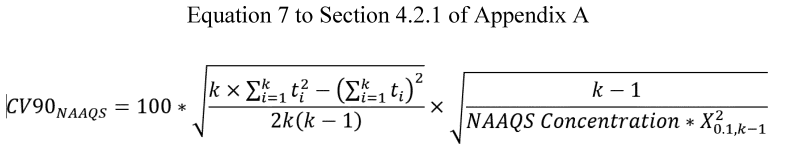

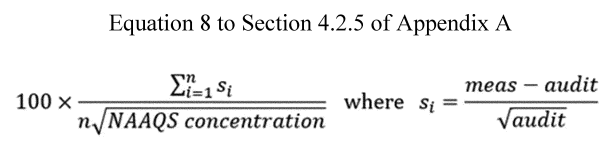

2.3.1.1 Measurement Uncertainty for Automated and Manual PM2.5Methods. The goal for acceptable measurement uncertainty is defined for precision as an upper 90 percent confidence limit for the coefficient of variation (CV) of 10 percent and ±10 percent for total bias.

2.3.1.2 Measurement Uncertainty for Automated O3Methods. The goal for acceptable measurement uncertainty is defined for precision as an upper 90 percent confidence limit for the CV of 7 percent and for bias as an upper 95 percent confidence limit for the absolute bias of 7 percent.

2.3.1.3 Measurement Uncertainty for Pb Methods. The goal for acceptable measurement uncertainty is defined for precision as an upper 90 percent confidence limit for the CV of 20 percent and for bias as an upper 95 percent confidence limit for the absolute bias of 15 percent.

2.3.1.4 Measurement Uncertainty for NO2. The goal for acceptable measurement uncertainty is defined for precision as an upper 90 percent confidence limit for the CV of 15 percent and for bias as an upper 95 percent confidence limit for the absolute bias of 15 percent.

2.3.1.5 Measurement Uncertainty for SO2. The goal for acceptable measurement uncertainty for precision is defined as an upper 90 percent confidence limit for the CV of 10 percent and for bias as an upper 95 percent confidence limit for the absolute bias of 10 percent.

2.4 National Performance Evaluation Programs. The PQAO shall provide for the implementation of a program of independent and adequate audits of all monitors providing data for NAAQS compliance purposes including the provision of adequate resources for such audit programs. A monitoring plan (or QAPP) which provides for PQAO participation in the EPA's National Performance Audit Program (NPAP), the PM2.5 Performance Evaluation Program (PM2.5-PEP) program and the Pb Performance Evaluation Program (Pb-PEP) and indicates the consent of the PQAO for the EPA to apply an appropriate portion of the grant funds, which the EPA would otherwise award to the PQAO for these QA activities, will be deemed by the EPA to meet this requirement. For clarification and to participate, PQAOs should contact either the appropriate EPA regional quality assurance (QA) coordinator at the appropriate EPA Regional Office location, or the NPAP coordinator at the EPA Air Quality Assessment Division, Office of Air Quality Planning and Standards, in Research Triangle Park, North Carolina. The PQAOs that plan to implement these programs (self-implement) rather than use the federal programs must meet the adequacy requirements found in the appropriate sections that follow, as well as meet the definition of independent assessment that follows.

2.4.1 Independent assessment. An assessment performed by a qualified individual, group, or organization that is not part of the organization directly performing and accountable for the work being assessed. This auditing organization must not be involved with the generation of the ambient air monitoring data. An organization can conduct the performance evaluation (PE) if it can meet this definition and has a management structure that, at a minimum, will allow for the separation of its routine sampling personnel from its auditing personnel by two levels of management. In addition, the sample analysis of audit filters must be performed by a laboratory facility and laboratory equipment separate from the facilities used for routine sample analysis. Field and laboratory personnel will be required to meet PE field and laboratory training and certification requirements to establish comparability to federally implemented programs.

2.5 Technical Systems Audit Program. Technical systems audits of each PQAO shall be conducted at least every 3 years by the appropriate EPA Regional Office and reported to the AQS. If a PQAO is made up of more than one monitoring organization, all monitoring organizations in the PQAO should be audited within 6 years (two TSA cycles of the PQAO). As an example, if a state has five local monitoring organizations that are consolidated under one PQAO, all five local monitoring organizations should receive a technical systems audit within a 6-year period. Systems audit programs are described in reference 10 of this appendix.

2.6 Gaseous and Flow Rate Audit Standards.

2.6.1 Gaseous pollutant concentration standards (permeation devices or cylinders of compressed gas) used to obtain test concentrations for CO, SO 2 , NO, and NO 2 must be EPA Protocol Gases certified in accordance with one of the procedures given in Reference 4 of this appendix.

2.6.1.1 The concentrations of EPA Protocol Gas standards used for ambient air monitoring must be certified with a 95-percent confidence interval to have an analytical uncertainty of no more than ±2.0 percent (inclusive) of the certified concentration (tag value) of the gas mixture. The uncertainty must be calculated in accordance with the statistical procedures defined in Reference 4 of this appendix.

2.6.1.2 Specialty gas producers advertising certification with the procedures provided in Reference 4 of this appendix and distributing gases as “EPA Protocol Gas” for ambient air monitoring purposes must adhere to the regulatory requirements specified in 40 CFR 75.21(g) or not use “EPA” in any form of advertising. Monitoring organizations must provide information to the EPA on the specialty gas producers they use on an annual basis. PQAOs, when requested by the EPA, must participate in the EPA Ambient Air Protocol Gas Verification Program at least once every 5 years by sending a new unused standard to a designated verification laboratory.

2.6.2 Test concentrations for O3 must be obtained in accordance with the ultraviolet photometric calibration procedure specified in appendix D to Part 50 of this chapter and by means of a certified NIST-traceable O3 transfer standard. Consult references 7 and 8 of this appendix for guidance on transfer standards for O3.

2.6.3 Flow rate measurements must be made by a flow measuring instrument that is NIST-traceable to an authoritative volume or other applicable standard. Guidance for certifying some types of flowmeters is provided in reference 10 of this appendix.

2.7 Primary Requirements and Guidance. Requirements and guidance documents for developing the quality system are contained in references 1 through 11 of this appendix, which also contain many suggested procedures, checks, and control specifications. Reference 10 describes specific guidance for the development of a quality system for data collected for comparison to the NAAQS. Many specific quality control checks and specifications for methods are included in the respective reference methods described in Part 50 of this chapter or in the respective equivalent method descriptions available from the EPA (reference 6 of this appendix). Similarly, quality control procedures related to specifically designated reference and equivalent method monitors are contained in the respective operation or instruction manuals associated with those monitors.

3. Measurement Quality Check Requirements

This section provides the requirements for PQAOs to perform the measurement quality checks that can be used to assess data quality. Data from these checks are required to be submitted to the AQS within the same time frame as routinely-collected ambient concentration data as described in 40 CFR 58.16. Table A-1 of this appendix provides a summary of the types and frequency of the measurement quality checks that will be described in this section.

3.1. Gaseous Monitors of SO2, NO2, O3, and CO.

3.1.1 One-Point Quality Control (QC) Check for SO2, NO2, O3, and CO. (a) A one-point QC check must be performed at least once every 2 weeks on each automated monitor used to measure SO2, NO2, O3 and CO. With the advent of automated calibration systems, more frequent checking is strongly encouraged. See Reference 10 of this appendix for guidance on the review procedure. The QC check is made by challenging the monitor with a QC check gas of known concentration (effective concentration for open path monitors) between the prescribed range of 0.005 and 0.08 parts per million (ppm) for SO2, NO2, and O3, and between the prescribed range of 0.5 and 5 ppm for CO monitors. The QC check gas concentration selected within the prescribed range should be related to the monitoring objectives for the monitor. If monitoring at an NCore site or for trace level monitoring, the QC check concentration should be selected to represent the mean or median concentrations at the site. If the mean or median concentrations at trace gas sites are below the MDL of the instrument the agency can select the lowest concentration in the prescribed range that can be practically achieved. If the mean or median concentrations at trace gas sites are above the prescribed range the agency can select the highest concentration in the prescribed range. An additional QC check point is encouraged for those organizations that may have occasional high values or would like to confirm the monitors' linearity at the higher end of the operational range or around NAAQS concentrations. If monitoring for NAAQS decisions, the QC concentration can be selected at a higher concentration within the prescribed range but should also consider precision points around mean or median monitor concentrations.

(b) Point analyzers must operate in their normal sampling mode during the QC check and the test atmosphere must pass through all filters, scrubbers, conditioners and other components used during normal ambient sampling and as much of the ambient air inlet system as is practicable. The QC check must be conducted before any calibration or adjustment to the monitor.

(c) Open path monitors are tested by inserting a test cell containing a QC check gas concentration into the optical measurement beam of the instrument. If possible, the normally used transmitter, receiver, and as appropriate, reflecting devices should be used during the test, and the normal monitoring configuration of the instrument should be altered as little as possible to accommodate the test cell for the test. However, if permitted by the associated operation or instruction manual, an alternate local light source or an alternate optical path that does not include the normal atmospheric monitoring path may be used. The actual concentration of the QC check gas in the test cell must be selected to produce an effective concentration in the range specified earlier in this section. Generally, the QC test concentration measurement will be the sum of the atmospheric pollutant concentration and the QC test concentration. As such, the result must be corrected to remove the atmospheric concentration contribution. The corrected concentration is obtained by subtracting the average of the atmospheric concentrations measured by the open path instrument under test immediately before and immediately after the QC test from the QC check gas concentration measurement. If the difference between these before and after measurements is greater than 20 percent of the effective concentration of the test gas, discard the test result and repeat the test. If possible, open path monitors should be tested during periods when the atmospheric pollutant concentrations are relatively low and steady.

(d) Report the audit concentration of the QC gas and the corresponding measured concentration indicated by the monitor to AQS. The percent differences between these concentrations are used to assess the precision and bias of the monitoring data as described in sections 4.1.2 (precision) and 4.1.3 (bias) of this appendix.

3.1.2 Annual performance evaluation for SO2, NO2, O3, or CO. A performance evaluation must be conducted on each primary monitor once a year. This can be accomplished by evaluating 25 percent of the primary monitors each quarter. The evaluation should be conducted by a trained experienced technician other than the routine site operator.

3.1.2.1 The evaluation is made by challenging the monitor with audit gas standards of known concentration from at least three audit levels. One point must be within two to three times the method detection limit of the instruments within the PQAOs network, the second point will be less than or equal to the 99th percentile of the data at the site or the network of sites in the PQAO or the next highest audit concentration level. The third point can be around the primary NAAQS or the highest 3-year concentration at the site or the network of sites in the PQAO. An additional 4th level is encouraged for those agencies that would like to confirm the monitors' linearity at the higher end of the operational range. In rare circumstances, there may be sites measuring concentrations above audit level 10. Notify the appropriate EPA region and the AQS program in order to make accommodations for auditing at levels above level 10.

| Audit level | Concentration Range, ppm | |||

|---|---|---|---|---|

| O3 | SO2 | NO2 | CO | |

| 1 | 0.004-0.0059 | 0.0003-0.0029 | 0.0003-0.0029 | 0.020-0.059 |

| 2 | 0.006-0.019 | 0.0030-0.0049 | 0.0030-0.0049 | 0.060-0.199 |

| 3 | 0.020-0.039 | 0.0050-0.0079 | 0.0050-0.0079 | 0.200-0.899 |

| 4 | 0.040-0.069 | 0.0080-0.0199 | 0.0080-0.0199 | 0.900-2.999 |

| 5 | 0.070-0.089 | 0.0200-0.0499 | 0.0200-0.0499 | 3.000-7.999 |

| 6 | 0.090-0.119 | 0.0500-0.0999 | 0.0500-0.0999 | 8.000-15.999 |

| 7 | 0.120-0.139 | 0.1000-0.1499 | 0.1000-0.2999 | 16.000-30.999 |

| 8 | 0.140-0.169 | 0.1500-0.2599 | 0.3000-0.4999 | 31.000-39.999 |

| 9 | 0.170-0.189 | 0.2600-0.7999 | 0.5000-0.7999 | 40.000-49.999 |

| 10 | 0.190-0.259 | 0.8000-1.000 | 0.8000-1.000 | 50.000-60.000 |

3.1.2.2 The standards from which audit gas test concentrations are obtained must meet the specifications of section 2.6.1 of this appendix. The gas standards and equipment used for the performance evaluation must not be the same as the standards and equipment used for one-point QC, calibrations, span evaluations or NPAP.

3.1.2.3 For point analyzers, the evaluation shall be carried out by allowing the monitor to analyze the audit gas test atmosphere in its normal sampling mode such that the test atmosphere passes through all filters, scrubbers, conditioners, and other sample inlet components used during normal ambient sampling and as much of the ambient air inlet system as is practicable.

3.1.2.4 Open-path monitors are evaluated by inserting a test cell containing the various audit gas concentrations into the optical measurement beam of the instrument. If possible, the normally used transmitter, receiver, and, as appropriate, reflecting devices should be used during the evaluation, and the normal monitoring configuration of the instrument should be modified as little as possible to accommodate the test cell for the evaluation. However, if permitted by the associated operation or instruction manual, an alternate local light source or an alternate optical path that does not include the normal atmospheric monitoring path may be used. The actual concentrations of the audit gas in the test cell must be selected to produce effective concentrations in the evaluation level ranges specified in this section of this appendix. Generally, each evaluation concentration measurement result will be the sum of the atmospheric pollutant concentration and the evaluation test concentration. As such, the result must be corrected to remove the atmospheric concentration contribution. The corrected concentration is obtained by subtracting the average of the atmospheric concentrations measured by the open path instrument under test immediately before and immediately after the evaluation test (or preferably before and after each evaluation concentration level) from the evaluation concentration measurement. If the difference between the before and after measurements is greater than 20 percent of the effective concentration of the test gas standard, discard the test result for that concentration level and repeat the test for that level. If possible, open path monitors should be evaluated during periods when the atmospheric pollutant concentrations are relatively low and steady. Also, if the open-path instrument is not installed in a permanent manner, the monitoring path length must be reverified to be within ±3 percent to validate the evaluation since the monitoring path length is critical to the determination of the effective concentration.

3.1.2.5 Report both the evaluation concentrations (effective concentrations for open-path monitors) of the audit gases and the corresponding measured concentration (corrected concentrations, if applicable, for open path monitors) indicated or produced by the monitor being tested to AQS. The percent differences between these concentrations are used to assess the quality of the monitoring data as described in section 4.1.1 of this appendix.

3.1.3 National Performance Audit Program (NPAP).

The NPAP is a performance evaluation which is a type of audit where quantitative data are collected independently in order to evaluate the proficiency of an analyst, monitoring instrument or laboratory. Due to the implementation approach used in the program, NPAP provides a national independent assessment of performance while maintaining a consistent level of data quality. Details of the program can be found in reference 11 of this appendix. The program requirements include:

3.1.3.1 Performing audits of the primary monitors at 20 percent of monitoring sites per year, and 100 percent of the sites every 6 years. High-priority sites may be audited more frequently. Since not all gaseous criteria pollutants are monitored at every site within a PQAO, it is not required that 20 percent of the primary monitors for each pollutant receive an NPAP audit each year only that 20 percent of the PQAOs monitoring sites receive an NPAP audit. It is expected that over the 6-year period all primary monitors for all gaseous pollutants will receive an NPAP audit.

3.1.3.2 Developing a delivery system that will allow for the audit concentration gasses to be introduced to the probe inlet where logistically feasible.

3.1.3.3 Using audit gases that are verified against the NIST standard reference methods or special review procedures and validated per the certification periods specified in Reference 4 of this appendix (EPA Traceability Protocol for Assay and Certification of Gaseous Calibration Standards) for CO, SO 2 , and NO 2 and using O 3 analyzers that are verified quarterly against a standard reference photometer.

3.1.3.4 As described in section 2.4 of this appendix, the PQAO may elect, on an annual basis, to utilize the federally implemented NPAP program. If the PQAO plans to self-implement NPAP, the EPA will establish training and other technical requirements for PQAOs to establish comparability to federally implemented programs. In addition to meeting the requirements in sections 3.1.3.1 through 3.1.3.3 of this appendix, the PQAO must:

(a) Utilize an audit system equivalent to the federally implemented NPAP audit system and is separate from equipment used in annual performance evaluations.

(b) Perform a whole system check by having the NPAP system tested against an independent and qualified EPA lab, or equivalent.

(c) Evaluate the system with the EPA NPAP program through collocated auditing at an acceptable number of sites each year (at least one for an agency network of five or less sites; at least two for a network with more than five sites).

(d) Incorporate the NPAP in the PQAO's quality assurance project plan.

(e) Be subject to review by independent, EPA-trained personnel.

(f) Participate in initial and update training/certification sessions.

3.1.3.5 OAQPS, in consultation with the relevant EPA Regional Office, may approve the PQAO's plan to self-implement NPAP if the OAQPS determines that the PQAO's self-implementation plan is equivalent to the federal programs and adequate to meet the objectives of national consistency and data quality.

3.2 PM2.5.

3.2.1 Flow Rate Verification for PM2.5. A one-point flow rate verification check must be performed at least once every month (each verification minimally separated by 14 days) on each monitor used to measure PM2.5. The verification is made by checking the operational flow rate of the monitor. If the verification is made in conjunction with a flow rate adjustment, it must be made prior to such flow rate adjustment. For the standard procedure, use a flow rate transfer standard certified in accordance with section 2.6 of this appendix to check the monitor's normal flow rate. Care should be used in selecting and using the flow rate measurement device such that it does not alter the normal operating flow rate of the monitor. Report the flow rate of the transfer standard and the corresponding flow rate measured by the monitor to AQS. The percent differences between the audit and measured flow rates are used to assess the bias of the monitoring data as described in section 4.2.2 of this appendix (using flow rates in lieu of concentrations).

3.2.2 Semi-Annual Flow Rate Audit for PM2.5. Audit the flow rate of the particulate monitor twice a year. The two audits should ideally be spaced between 5 and 7 months apart. The EPA strongly encourages more frequent auditing. The audit should (preferably) be conducted by a trained experienced technician other than the routine site operator. The audit is made by measuring the monitor's normal operating flow rate(s) using a flow rate transfer standard certified in accordance with section 2.6 of this appendix. The flow rate standard used for auditing must not be the same flow rate standard used for verifications or to calibrate the monitor. However, both the calibration standard and the audit standard may be referenced to the same primary flow rate or volume standard. Care must be taken in auditing the flow rate to be certain that the flow measurement device does not alter the normal operating flow rate of the monitor. Report the audit flow rate of the transfer standard and the corresponding flow rate measured by the monitor to AQS. The percent differences between these flow rates are used to evaluate monitor performance.

3.2.3 Collocated Quality Control Sampling Procedures for PM2.5. For each pair of collocated monitors, designate one sampler as the primary monitor whose concentrations will be used to report air quality for the site, and designate the other as the quality control monitor. There can be only one primary monitor at a monitoring site for a given time period.

3.2.3.1 For each distinct monitoring method designation (FRM or FEM) that a PQAO is using for a primary monitor, the PQAO must have 15 percent of the primary monitors of each method designation collocated (values of 0.5 and greater round up); and have at least one collocated quality control monitor (if the total number of monitors is less than three). The first collocated monitor must be a designated FRM monitor.

3.2.3.2 In addition, monitors selected for collocation must also meet the following requirements:

(a) A primary monitor designated as an EPA FRM shall be collocated with a quality control monitor having the same EPA FRM method designation.